Patents

Literature

38results about How to "Improve alignment stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

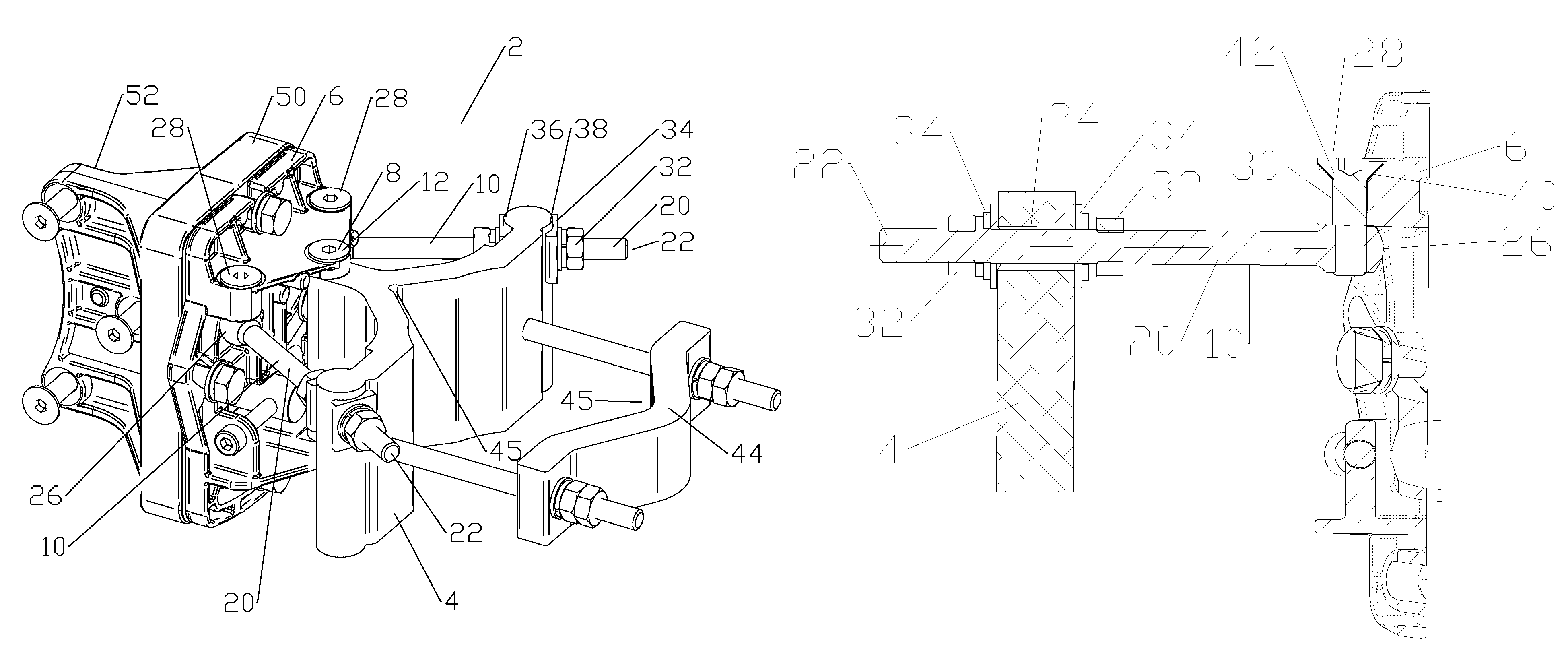

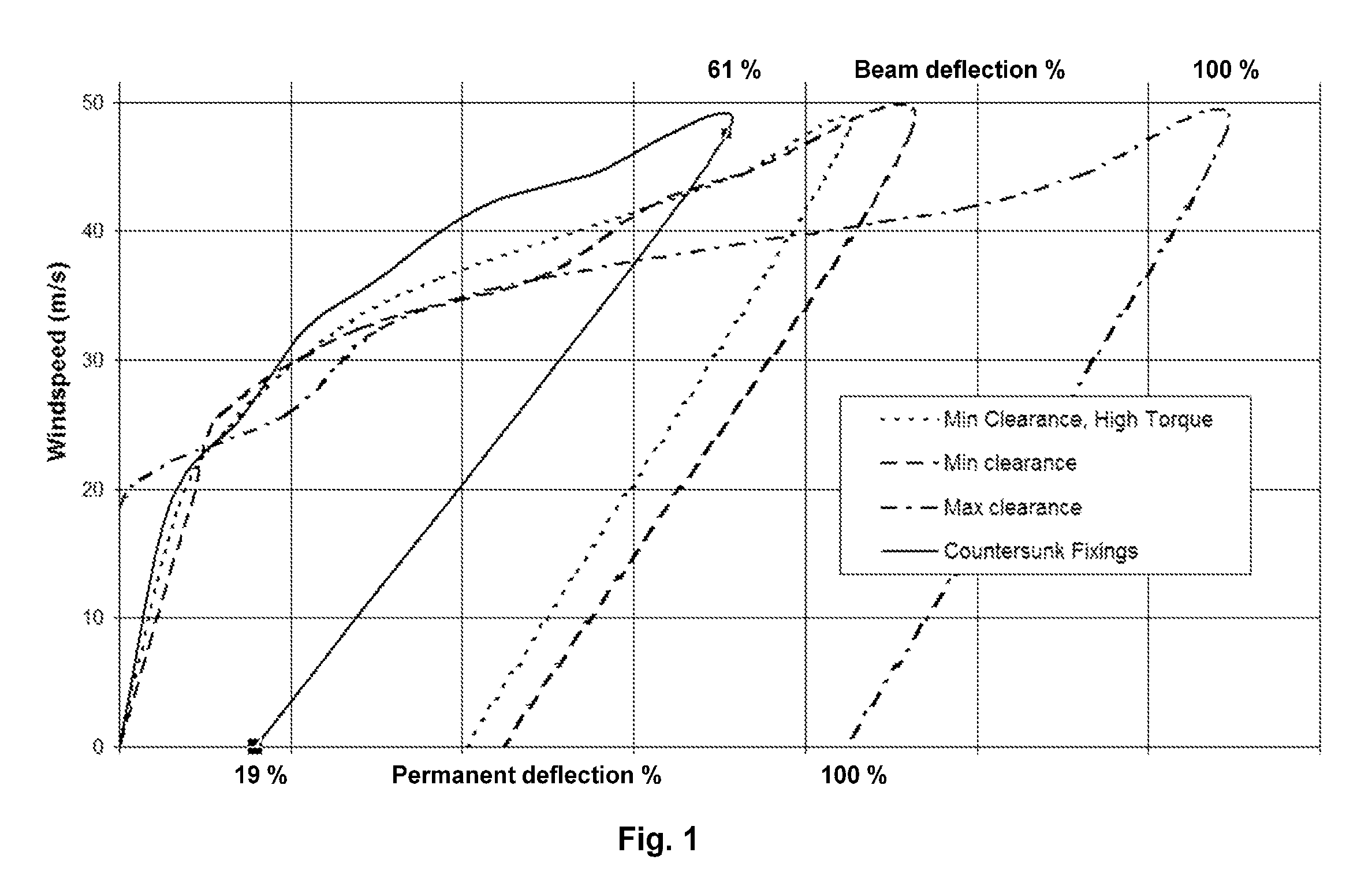

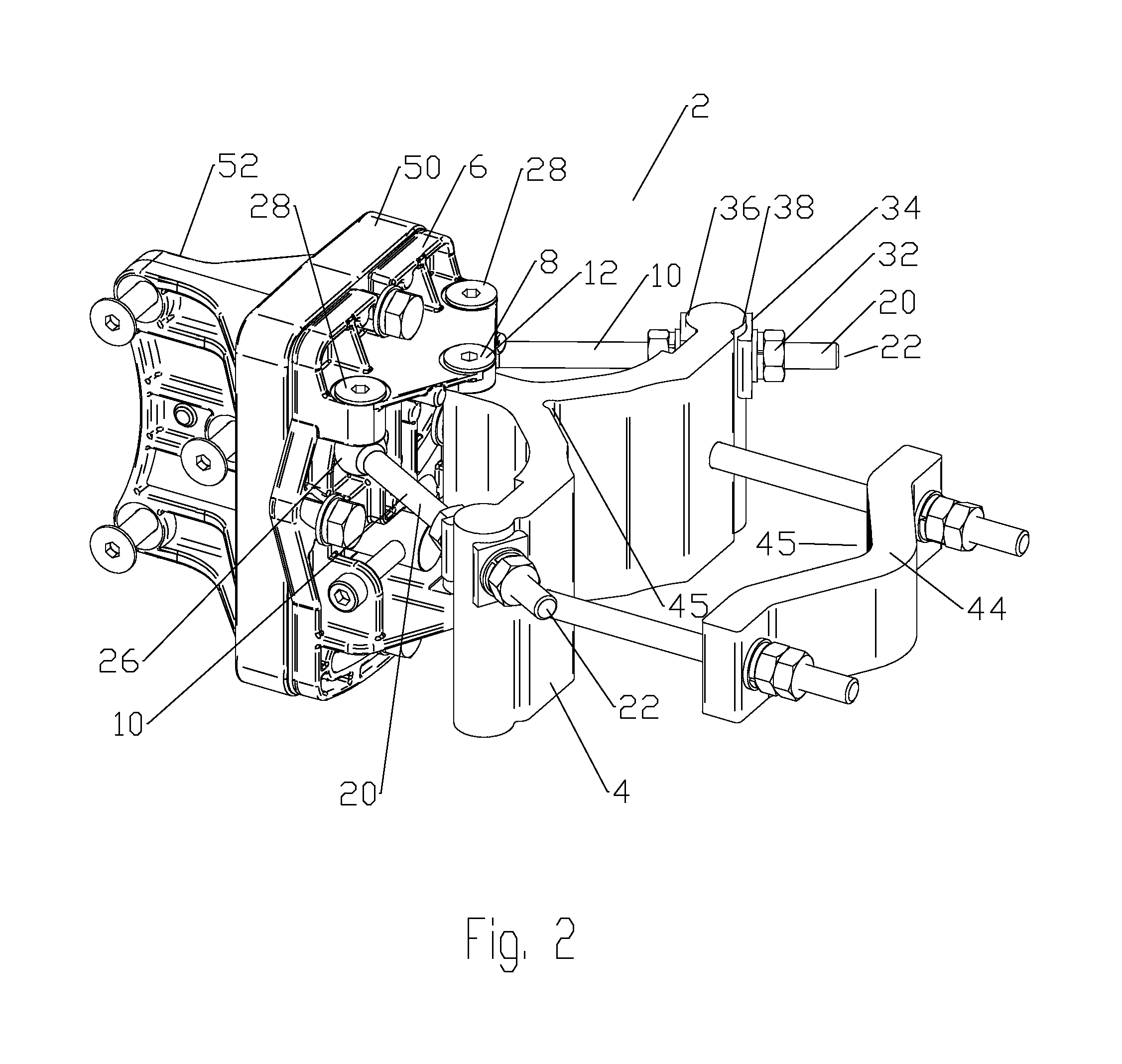

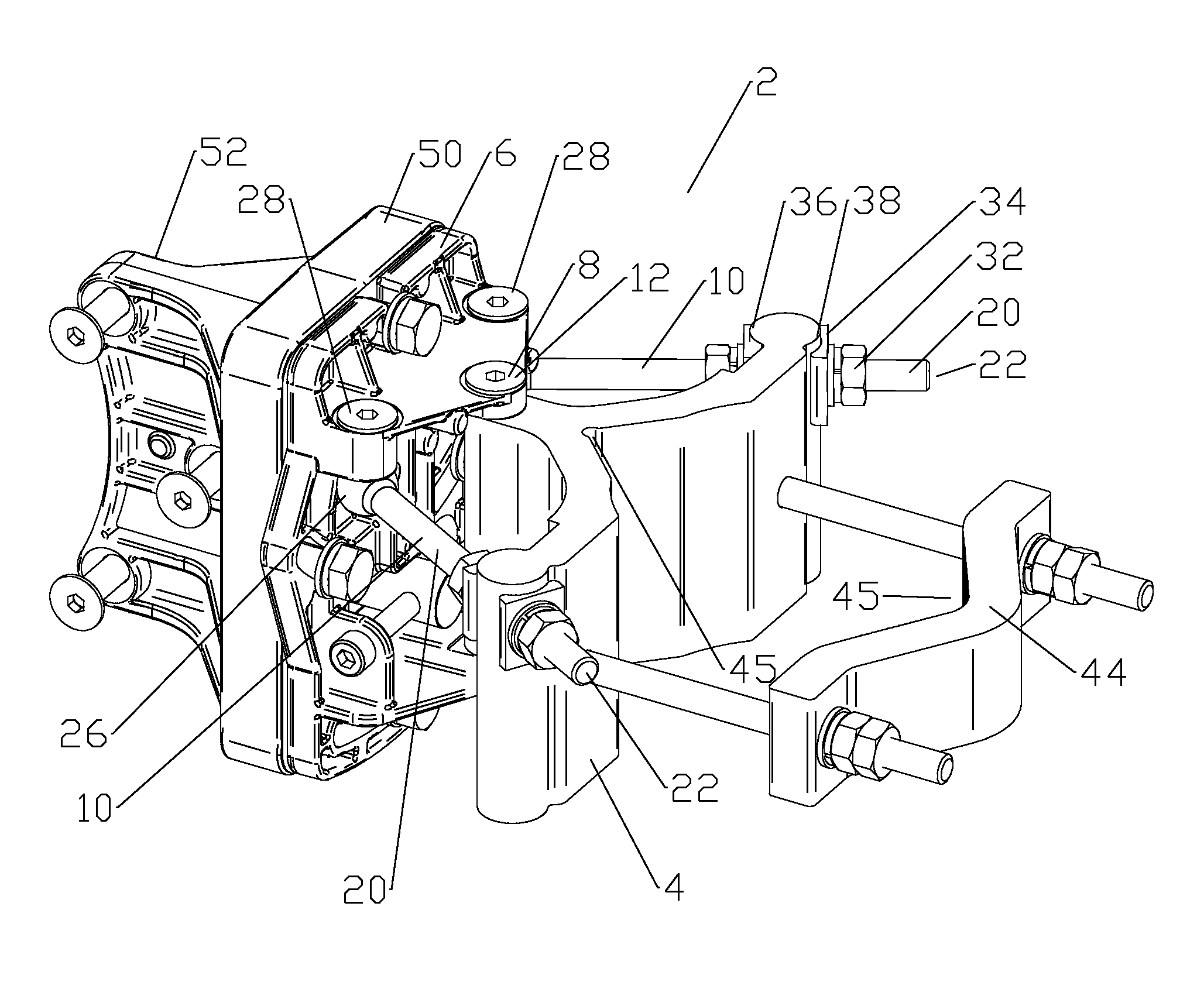

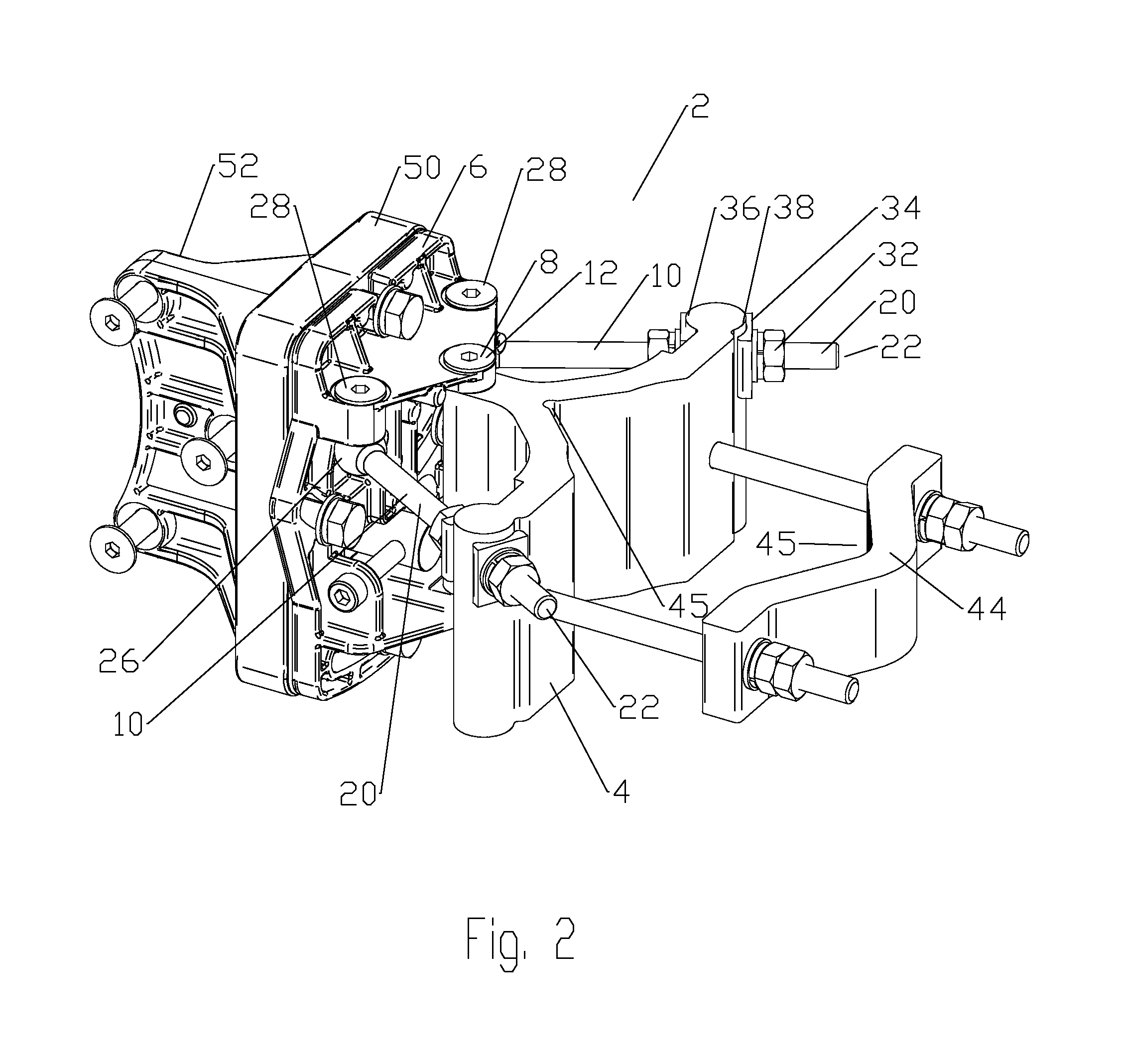

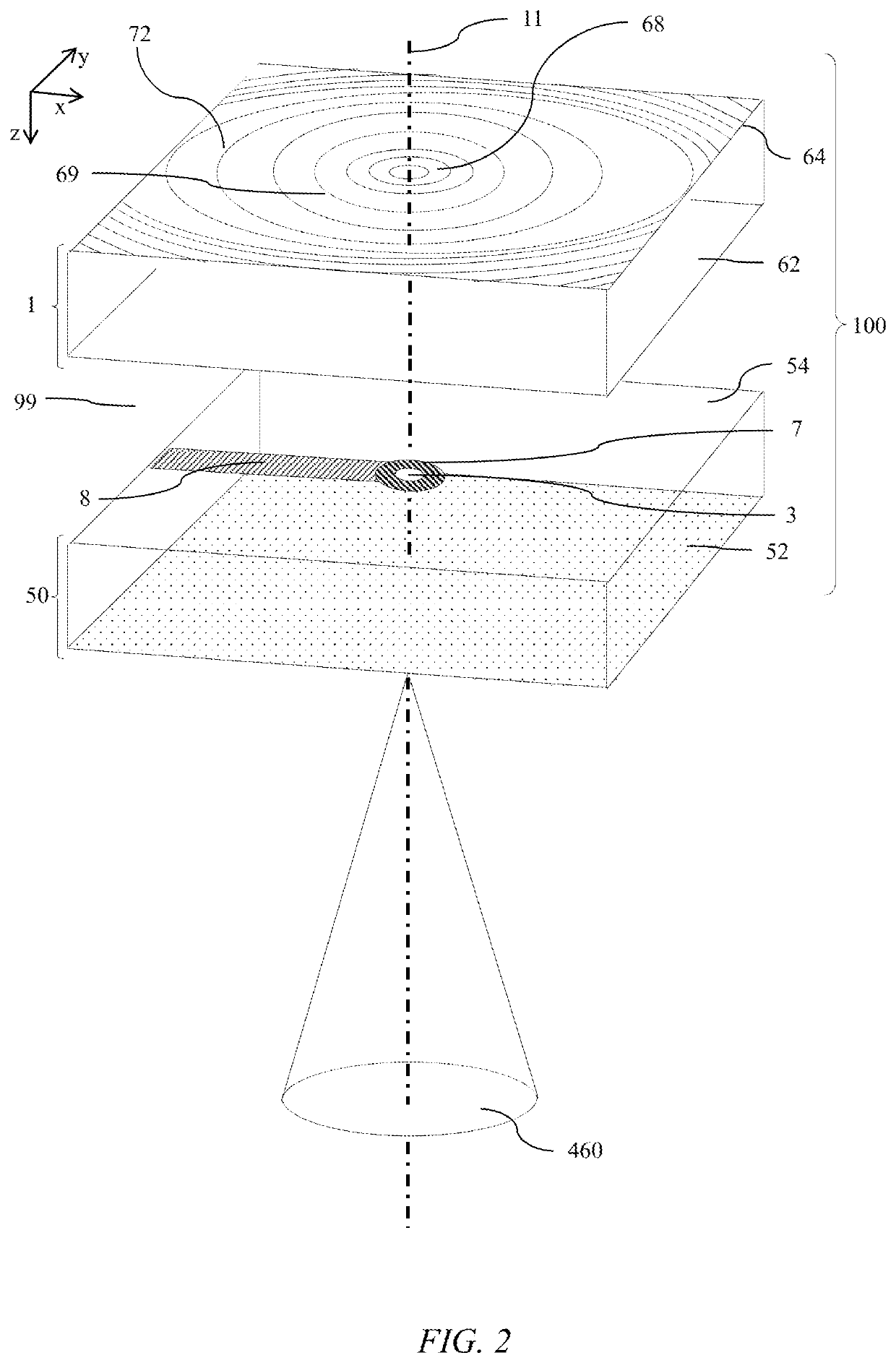

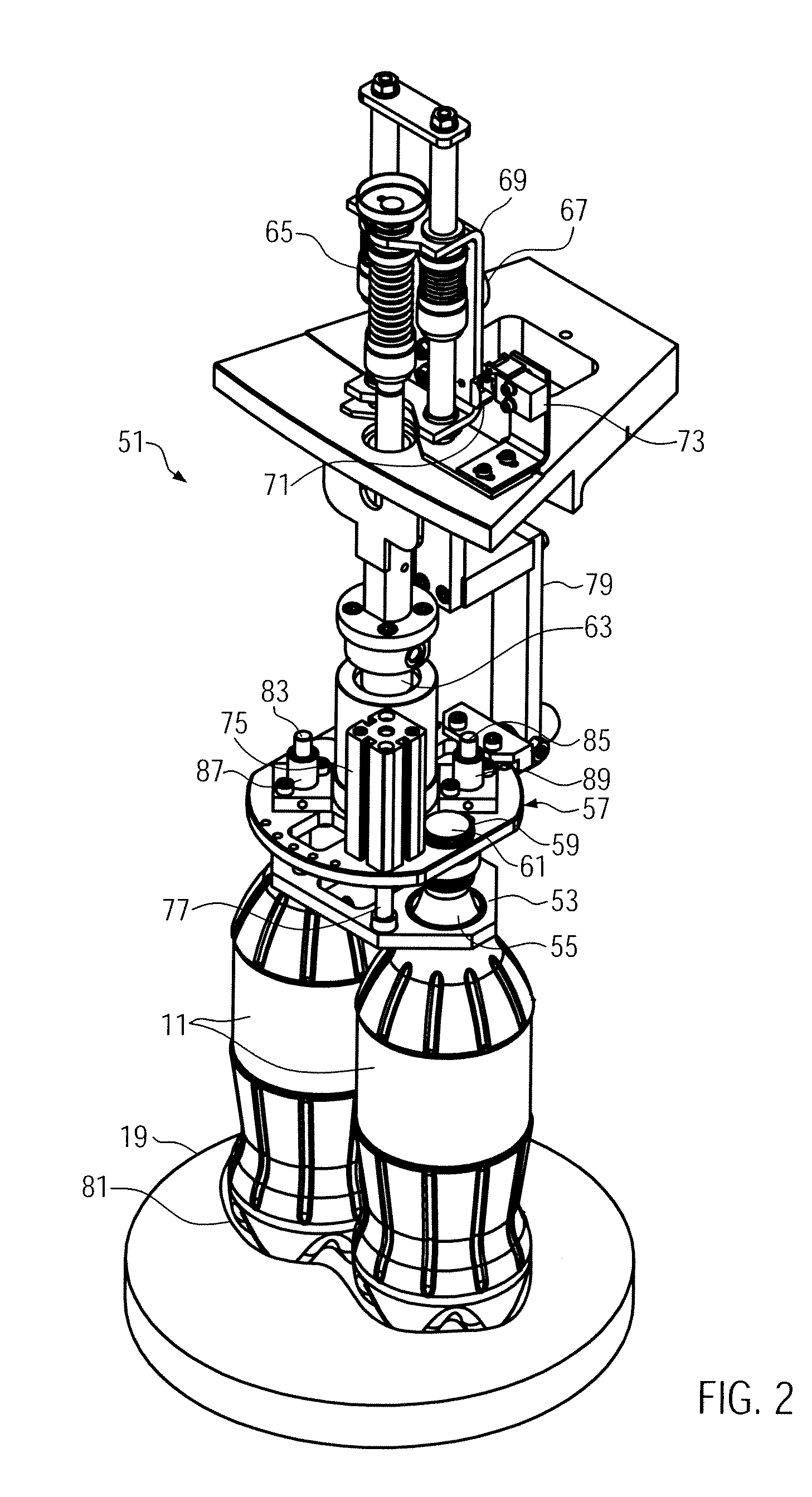

Alignment stable adjustable antenna mount

ActiveUS8866695B2Speed up preparationImprove alignment stabilityCandle holdersLighting support devicesEngineeringMechanical engineering

Owner:COMMSCOPE TECH LLC

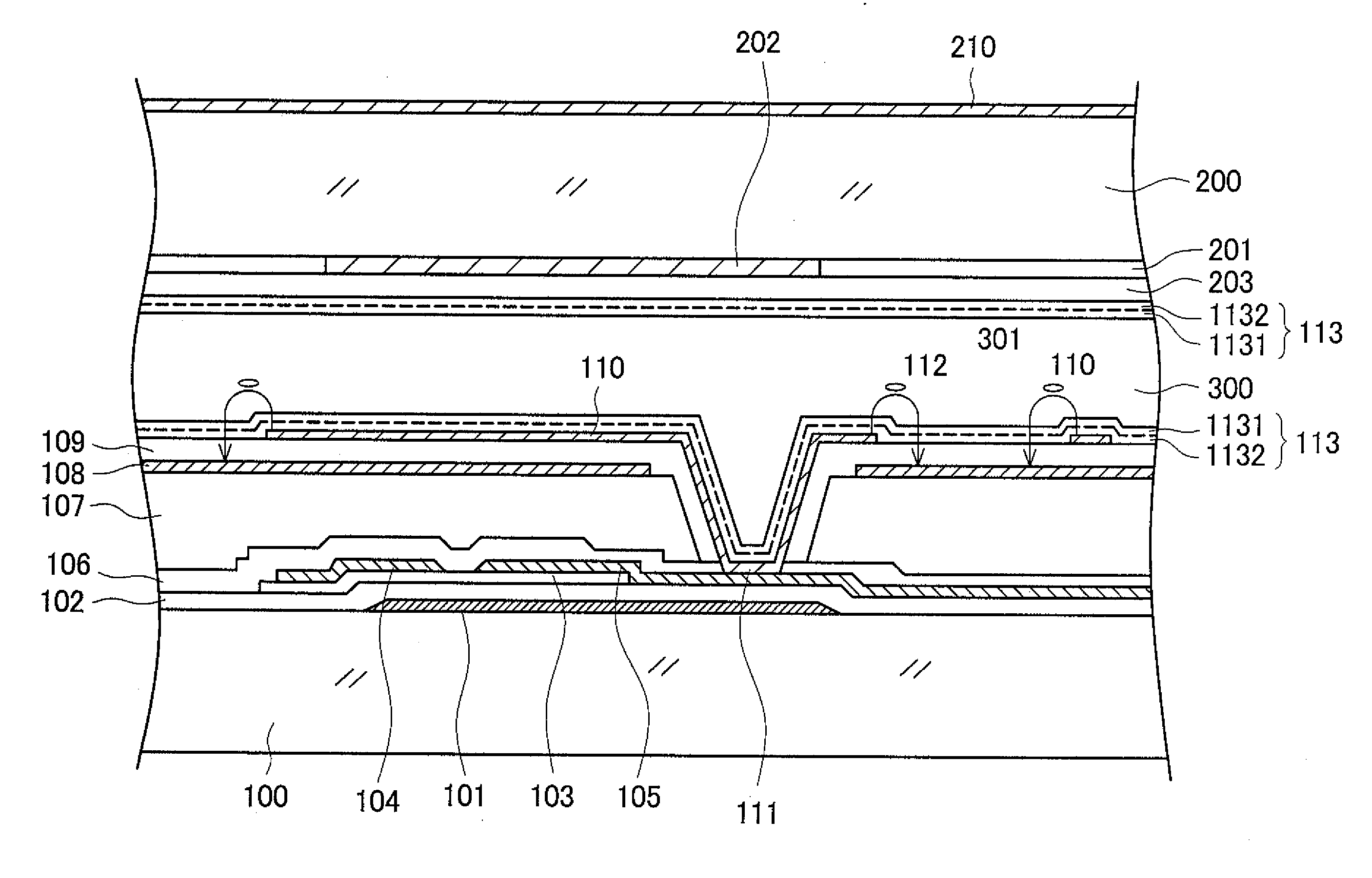

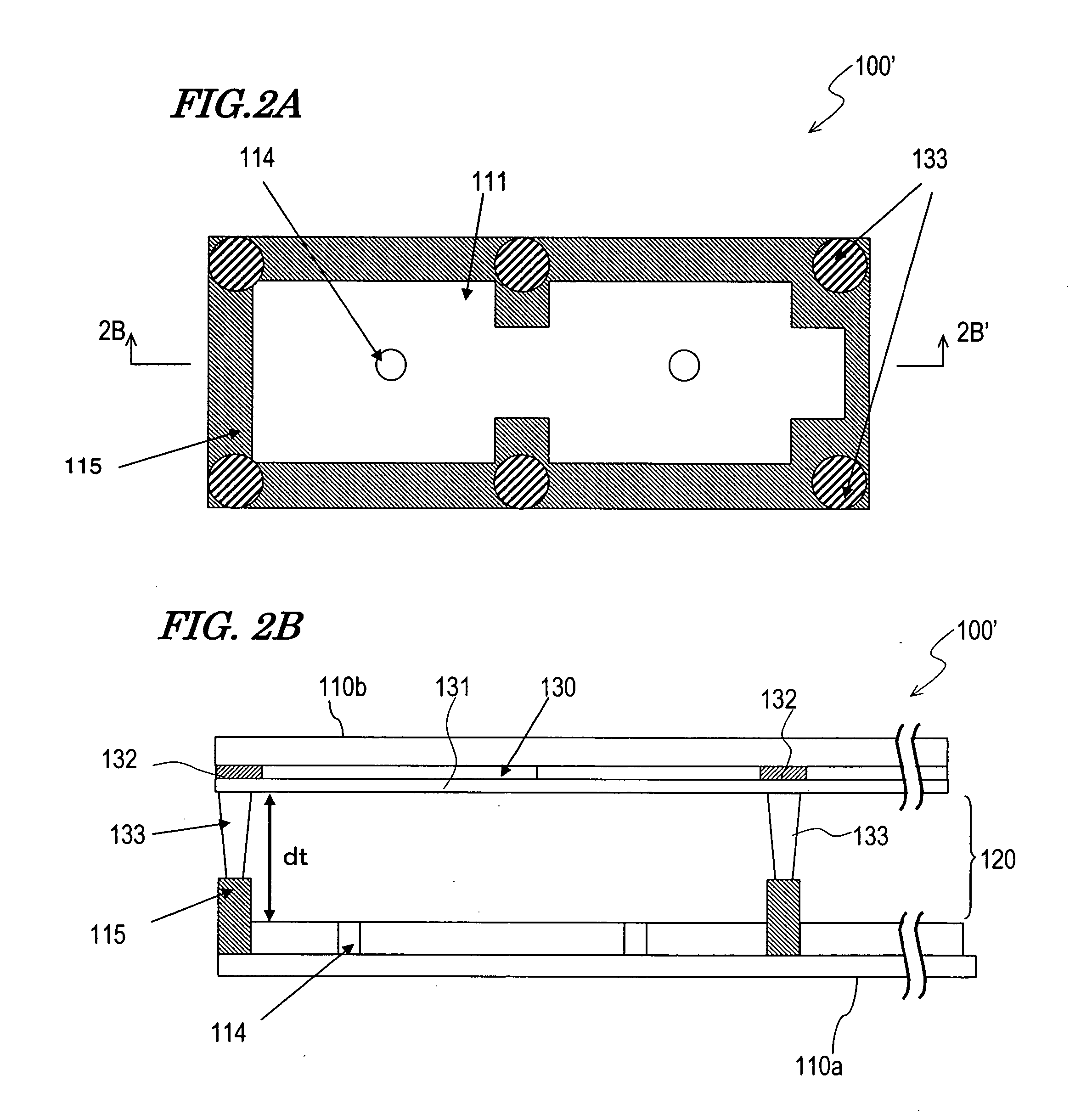

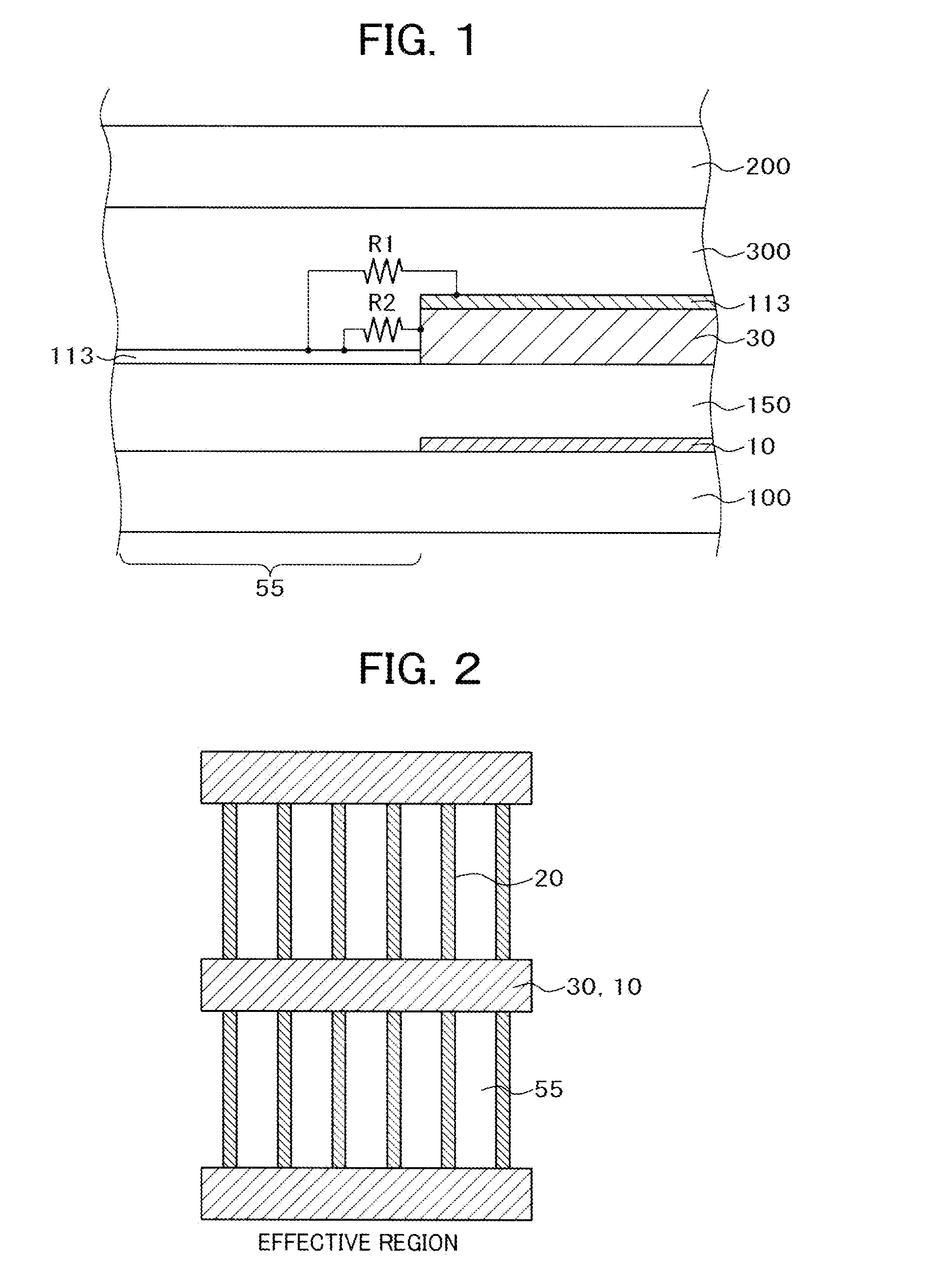

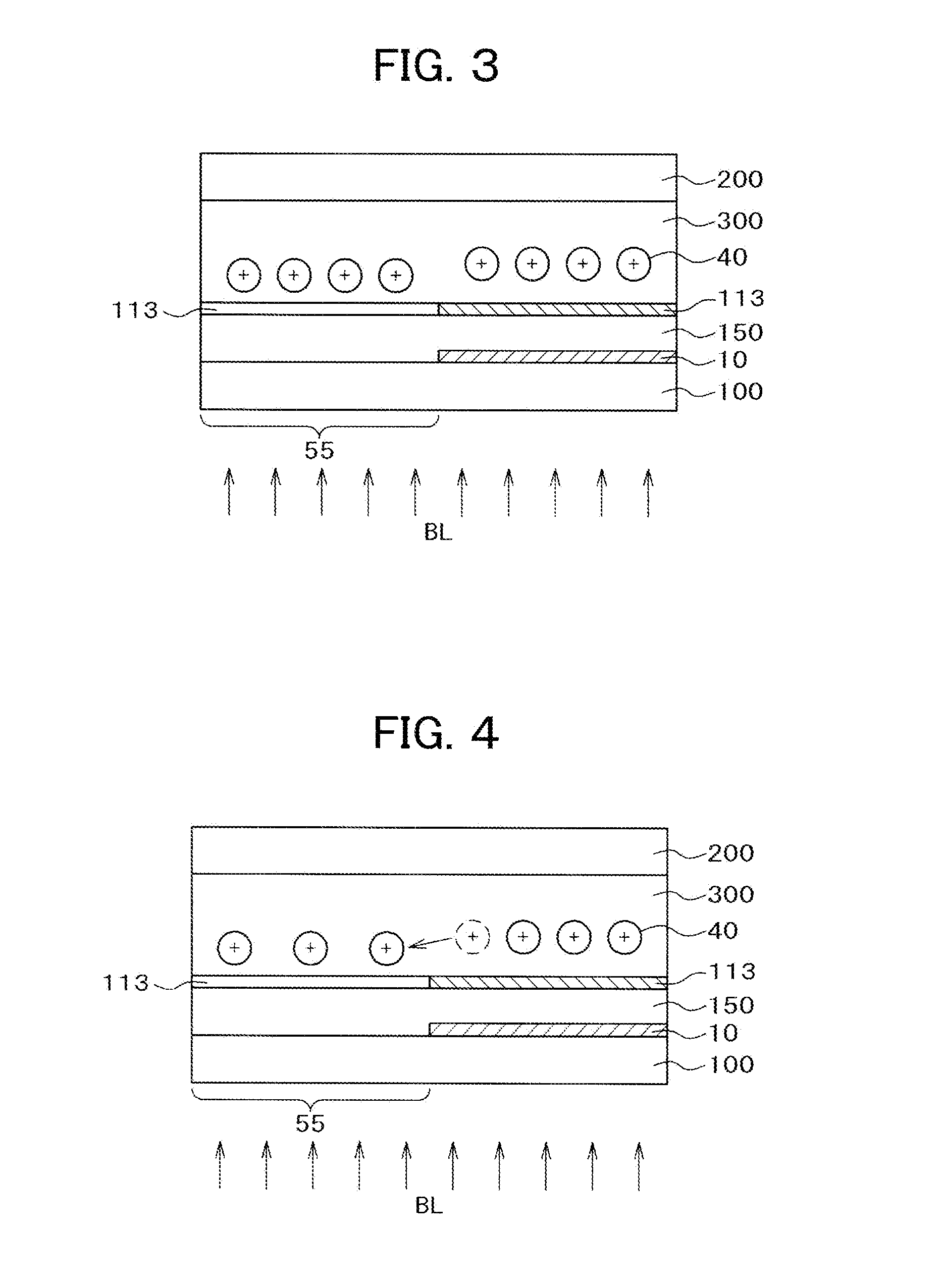

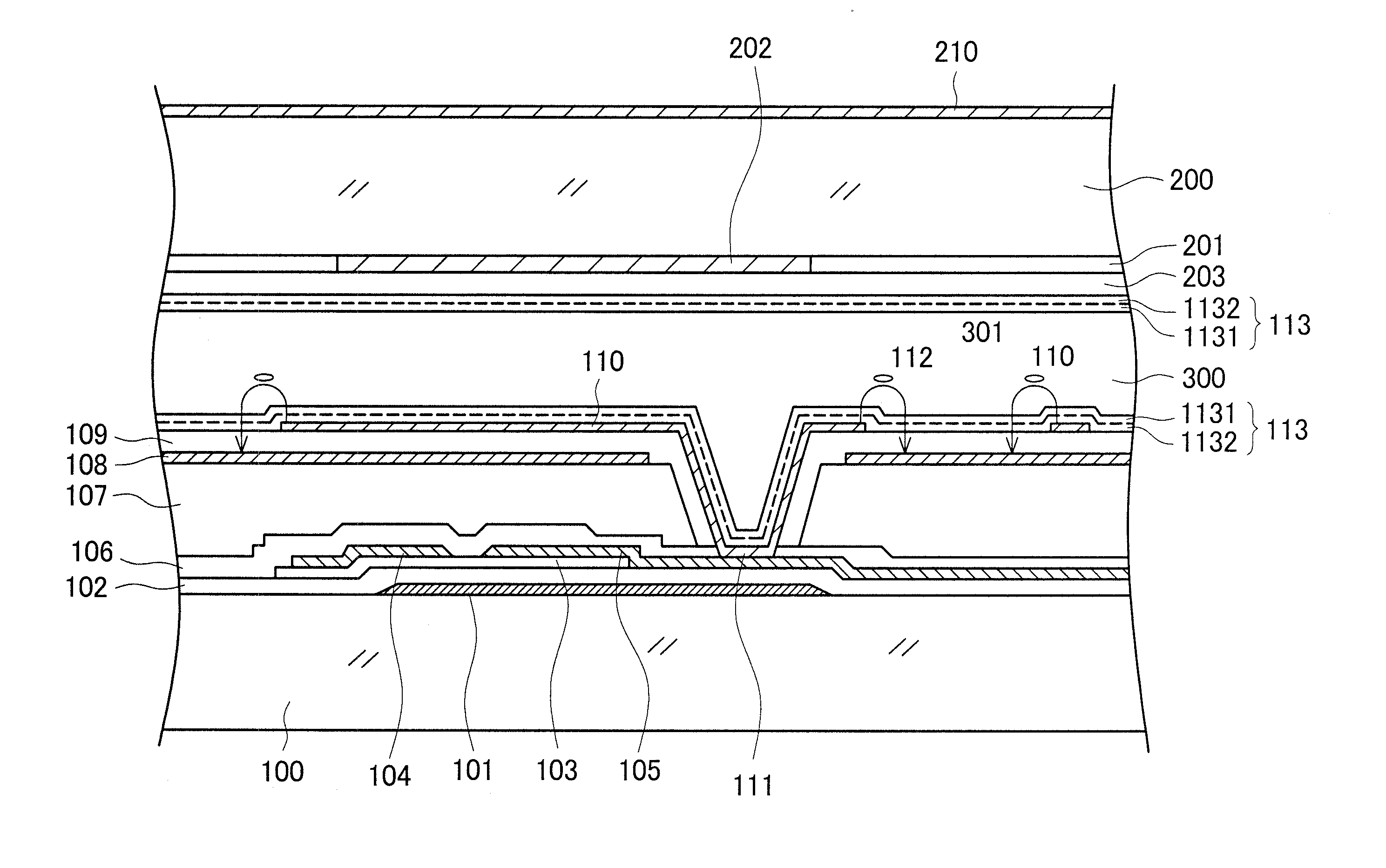

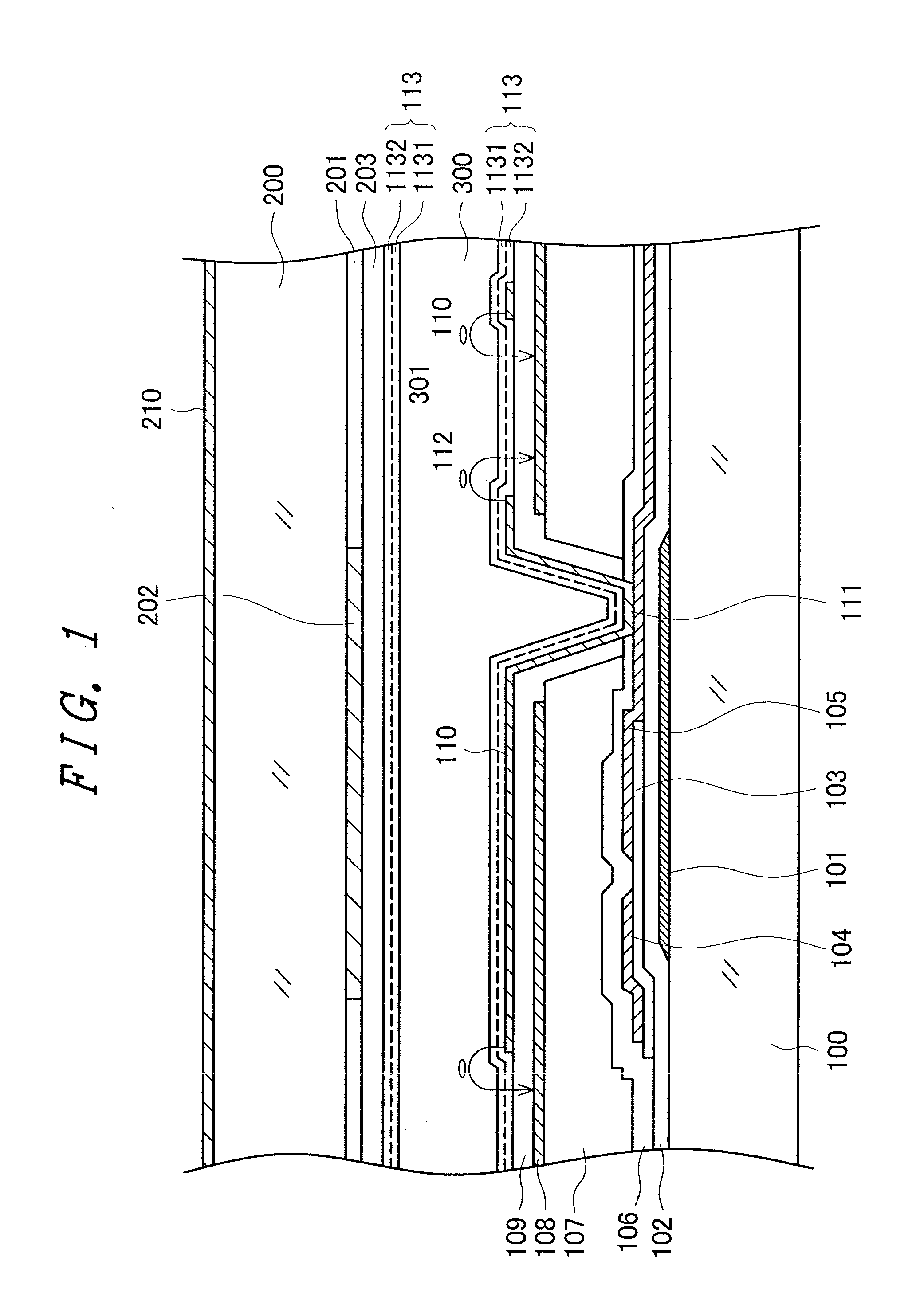

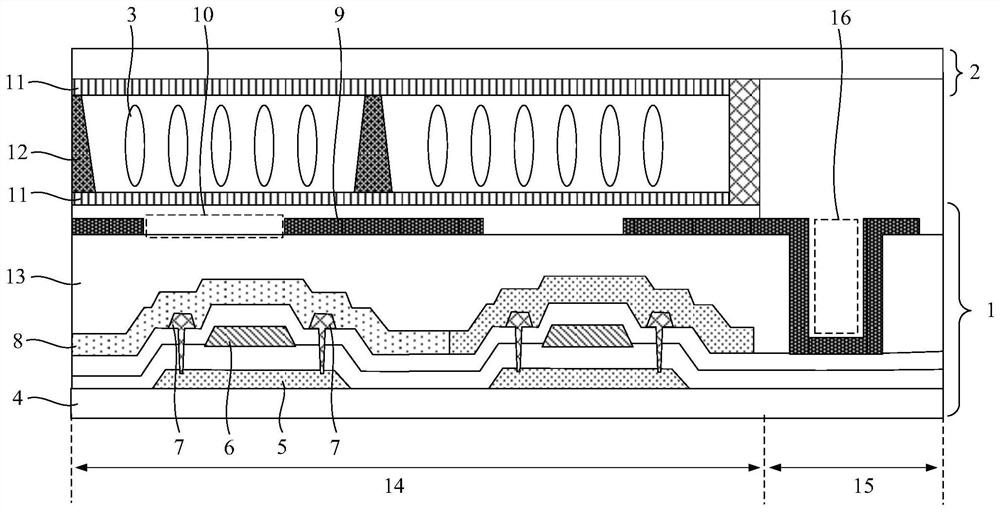

Liquid crystal display device

ActiveUS20100066961A1Shorten the disappearance timeLong stabilityLiquid crystal compositionsLayered productsLiquid-crystal displayPolyamide

An alignment film is given a 2-layer structure comprising a photoalignment film that is photoalignable and a low-resistivity alignment film whose resistivity is smaller than that of the photoalignment film. The photoalignment film is formed by a polyimide whose precursor is polyamide acid alkyl ester, the number molecular weight of the photoalignment film is large, and the stability of alignment of the photoalignment film by photoalignment is excellent. The low-resistivity alignment film is formed by a polyimide whose precursor is polyamide acid, the number molecular weight of the low-resistivity alignment film is small, and the resistivity of the low-resistivity alignment film is small. The 2-layer structure alignment film can be maintaining an excellent photoalignment characteristic, so DC afterimages can be controlled.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

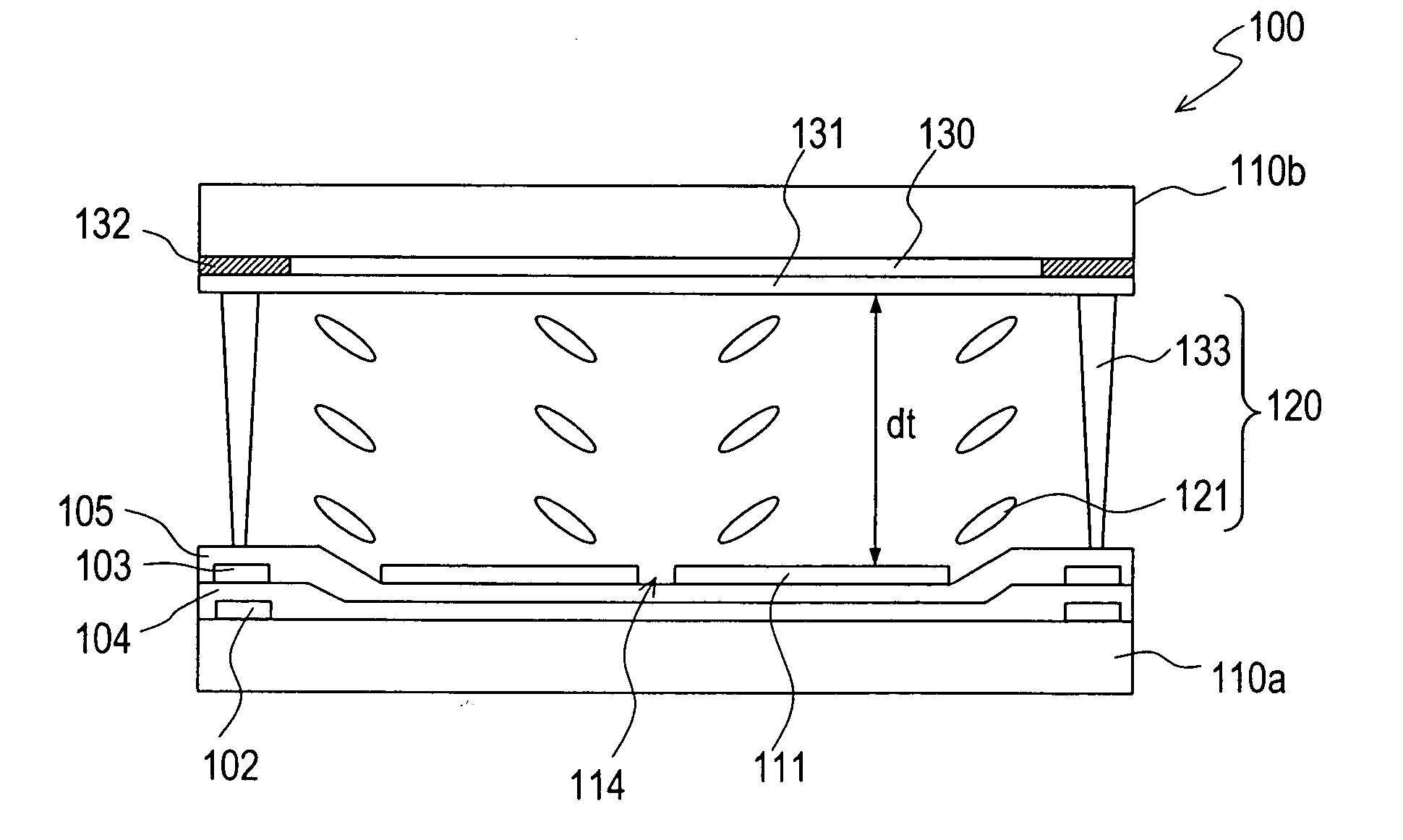

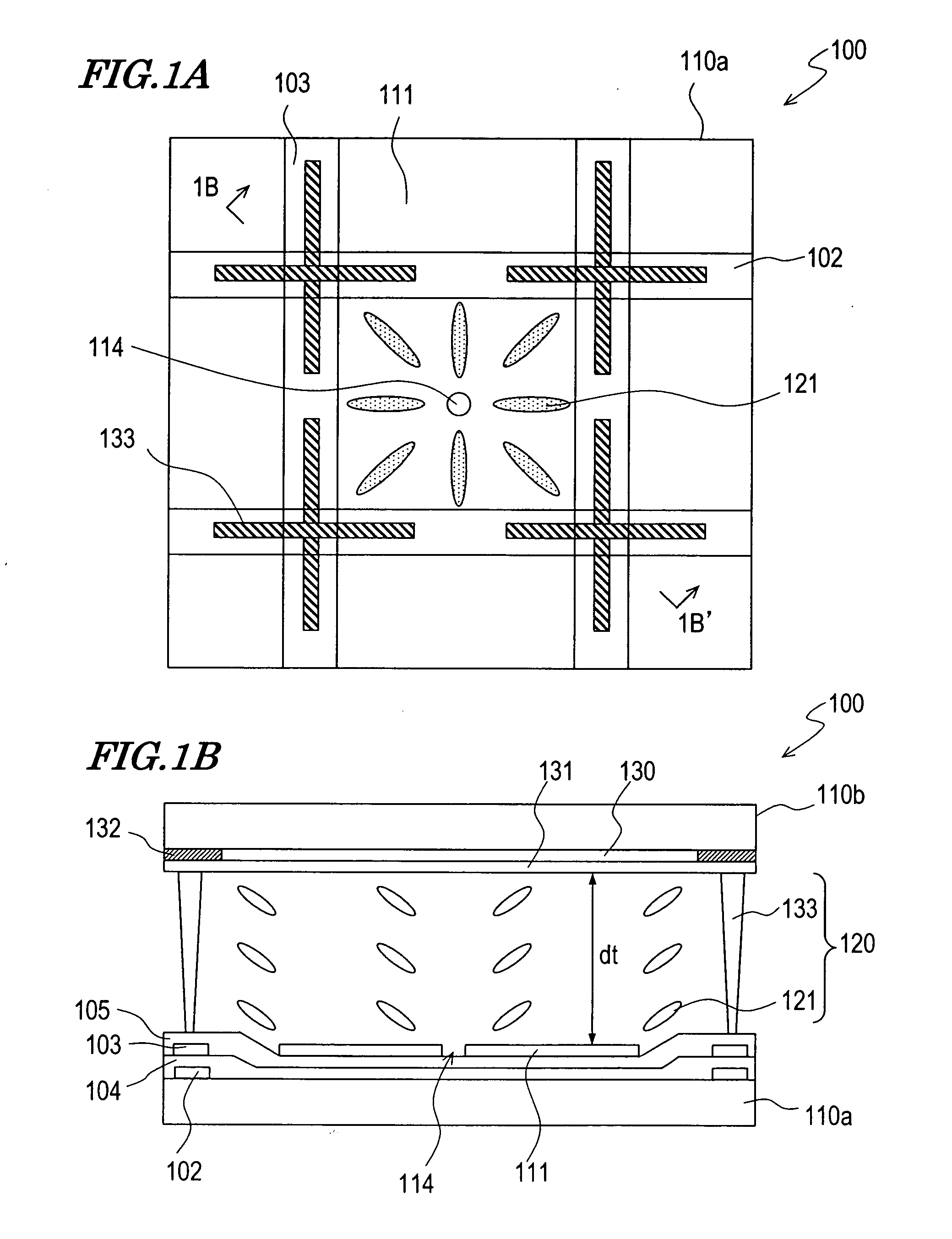

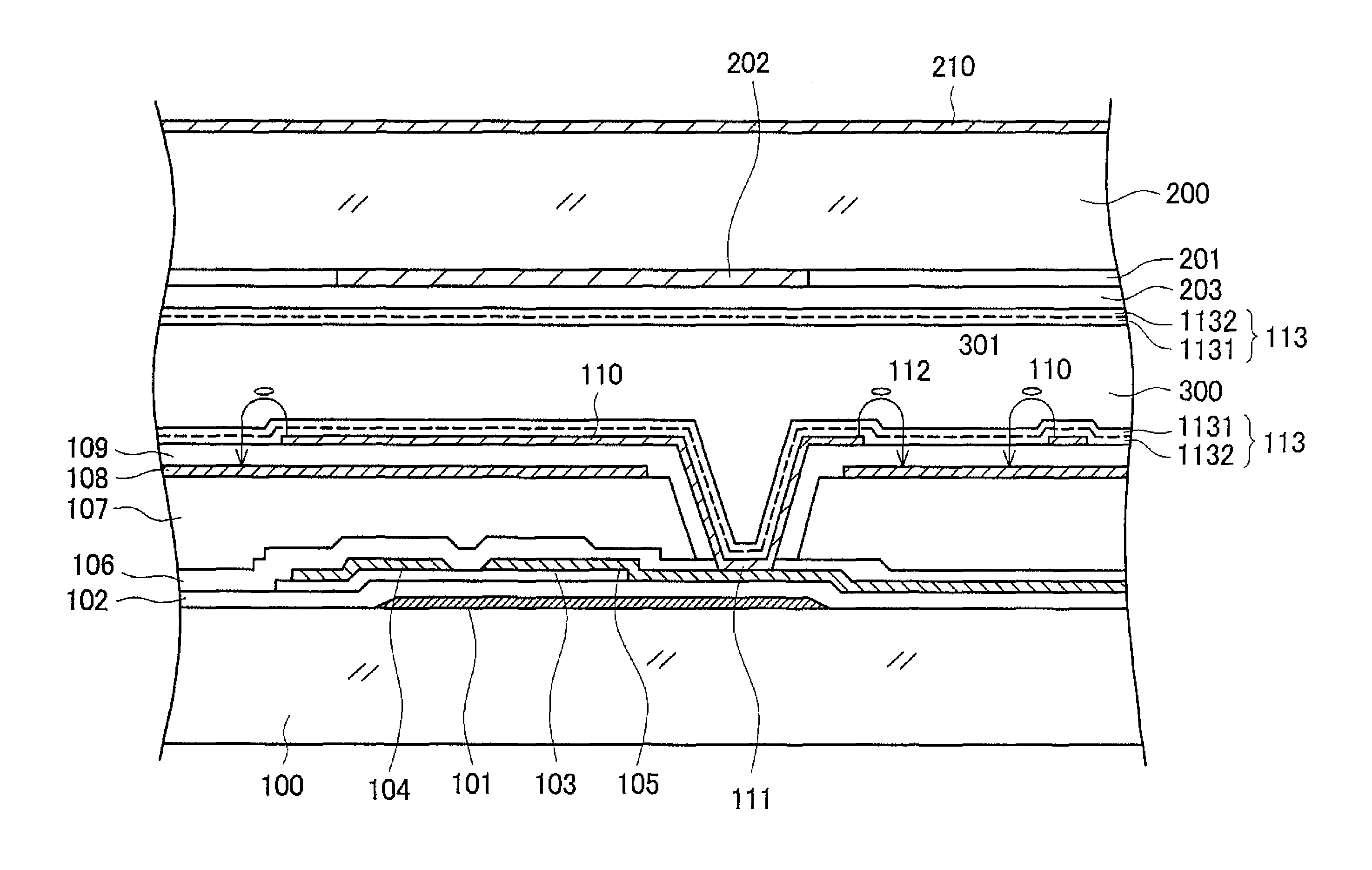

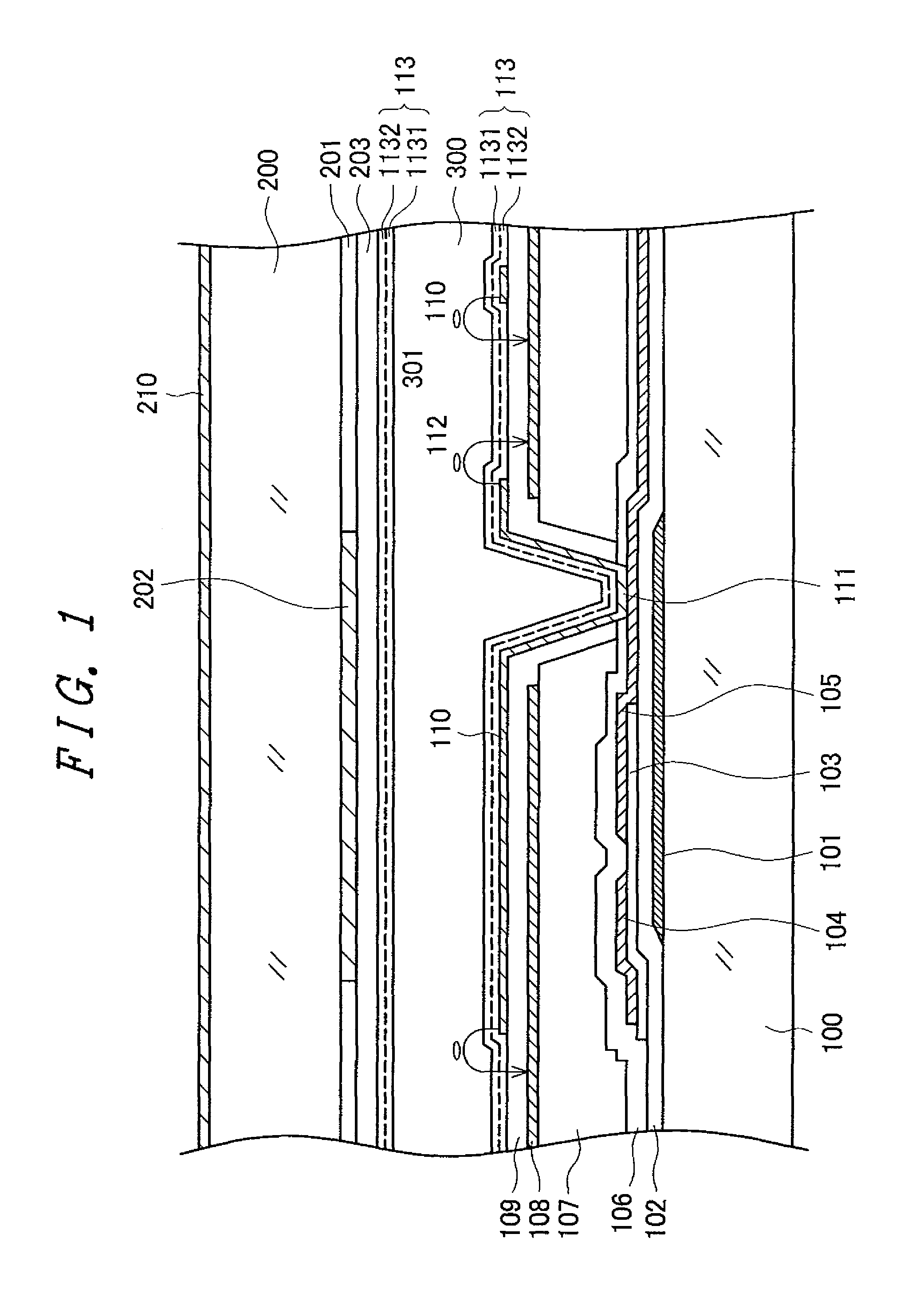

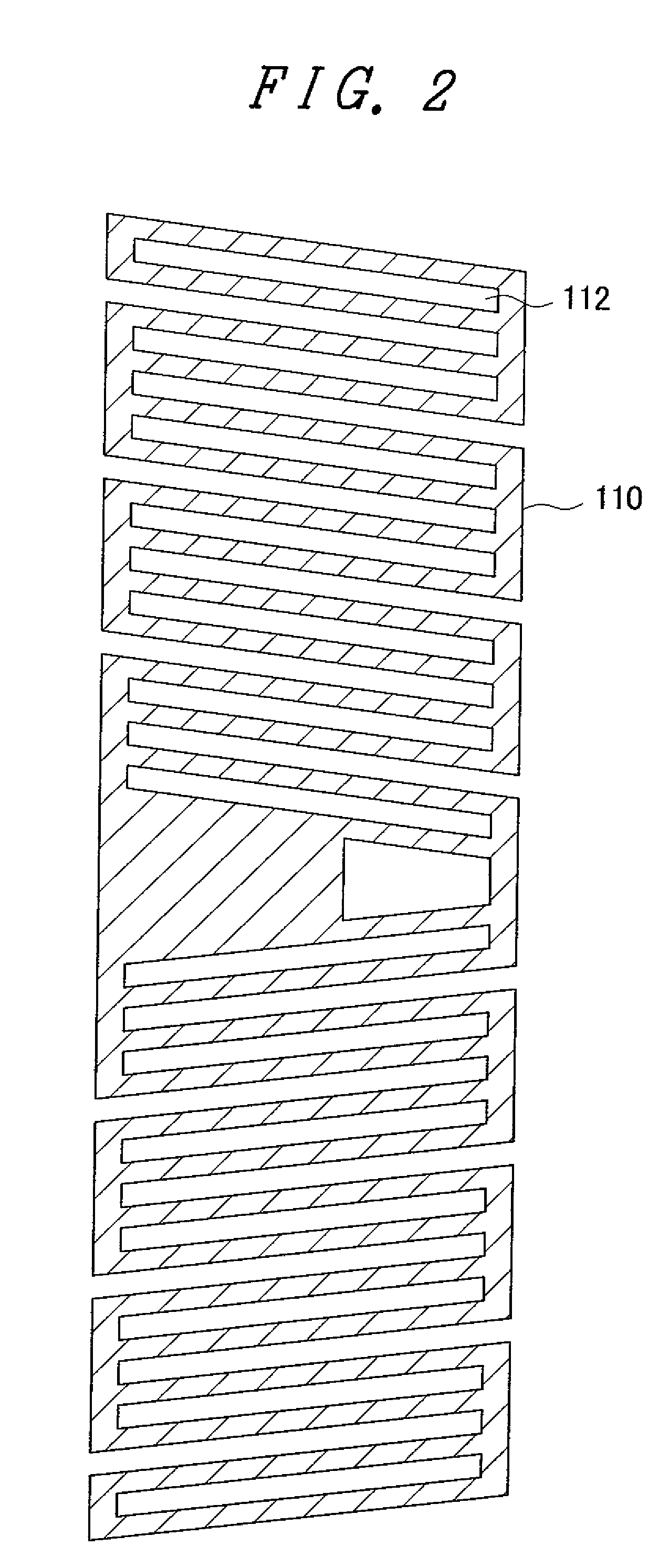

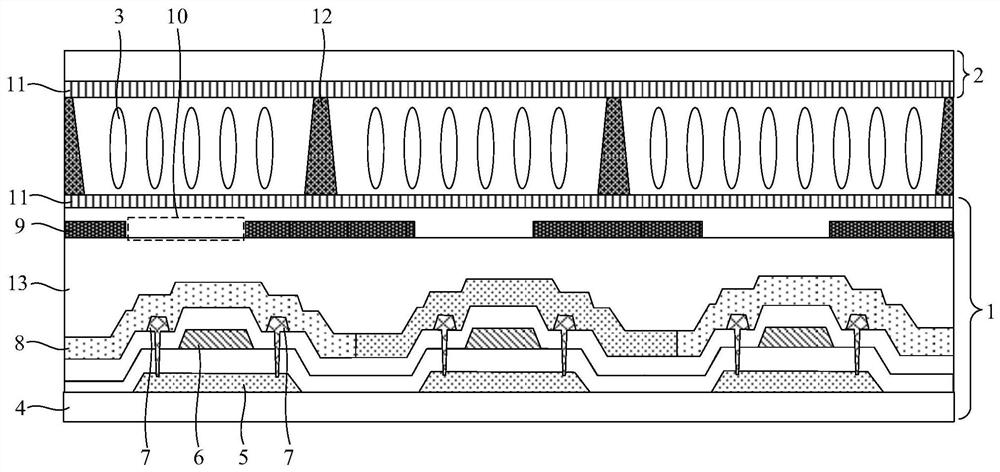

Liquid crystal display device

InactiveUS20050200784A1Effective aperture ratioImprove contrast ratioPolarising elementsNon-linear opticsEngineeringVoltage

The liquid crystal display device of the present invention includes a first substrate, a second substrate and a vertically aligned liquid crystal layer interposed between the first and second substrate. The device has a plurality of pixels each including a first electrode formed on the first substrate, a second electrode formed on the second substrate, and the liquid crystal layer interposed between the first and second electrode, and a shading region provided around the pixels. A plurality of supports for defining the thickness of the liquid crystal layer are placed regularly on the surface of the first or second substrate facing the liquid crystal layer in the shading region. The liquid crystal layer forms at least one liquid crystal domain exhibiting axisymmetric alignment when at least a predetermined voltage is applied, and the tilt direction of liquid crystal molecules in the at least one liquid crystal domain is defined with inclined sides of the plurality of supports.

Owner:SHARP KK

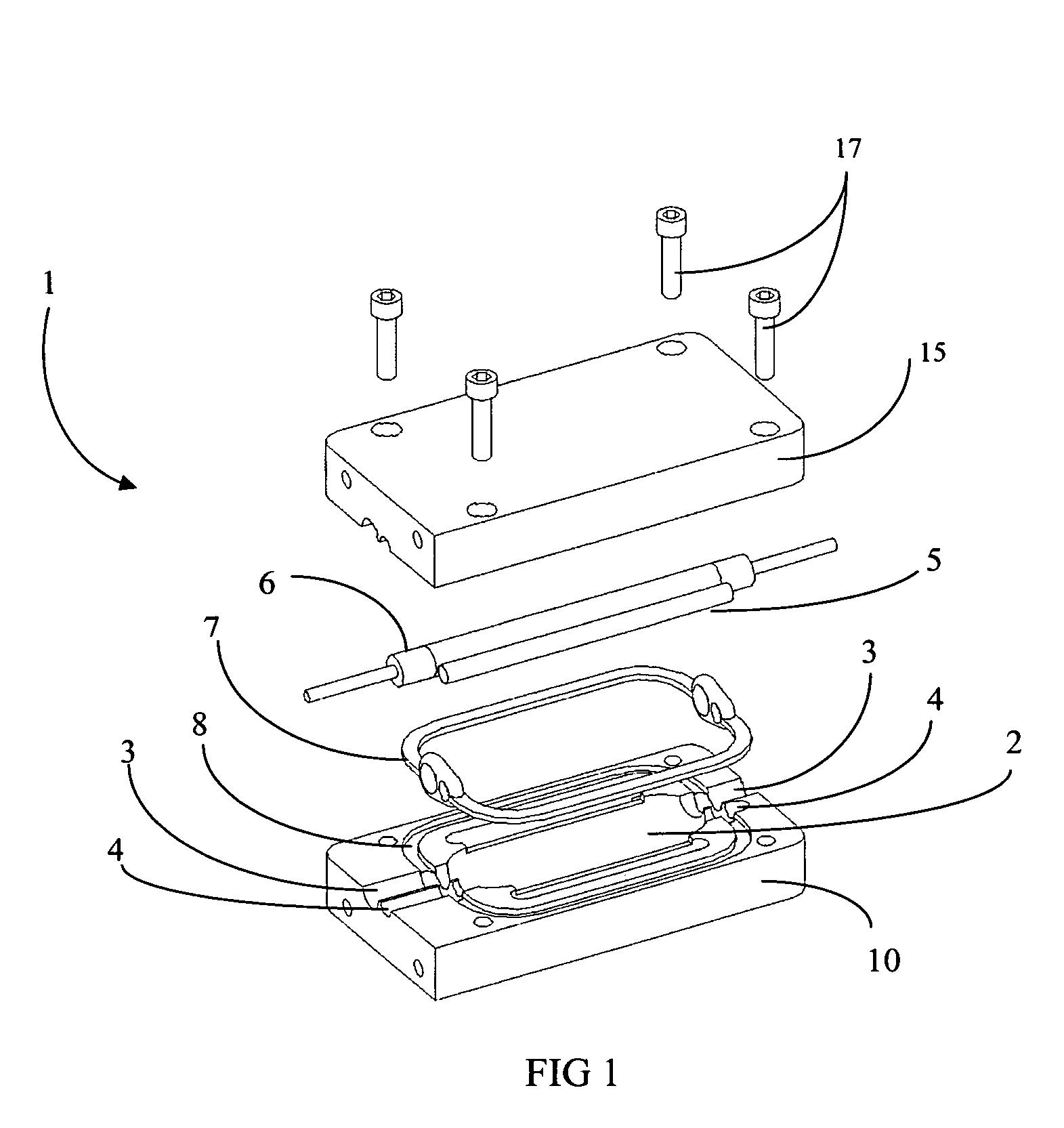

Alignment Stable Adjustable Antenna Mount

ActiveUS20130221182A1Speed up preparationImprove alignment stabilityWalking sticksApparel holdersMechanical engineering

An antenna mount is provided with a pivot base and a pivot saddle rotatably coupled to the pivot base by a pivot connection and at least one pivot arm connection. The pivot connection is provided with dual opposing conical countersunk head pivot connection bolts seated within conical countersunk pivot connection bolt holes of the pivot saddle, the conical countersunk head pivot connection bolts extending through the conical countersunk pivot connection bolt holes of the pivot saddle to couple with the pivot base about a pivot axis.

Owner:COMMSCOPE TECH LLC

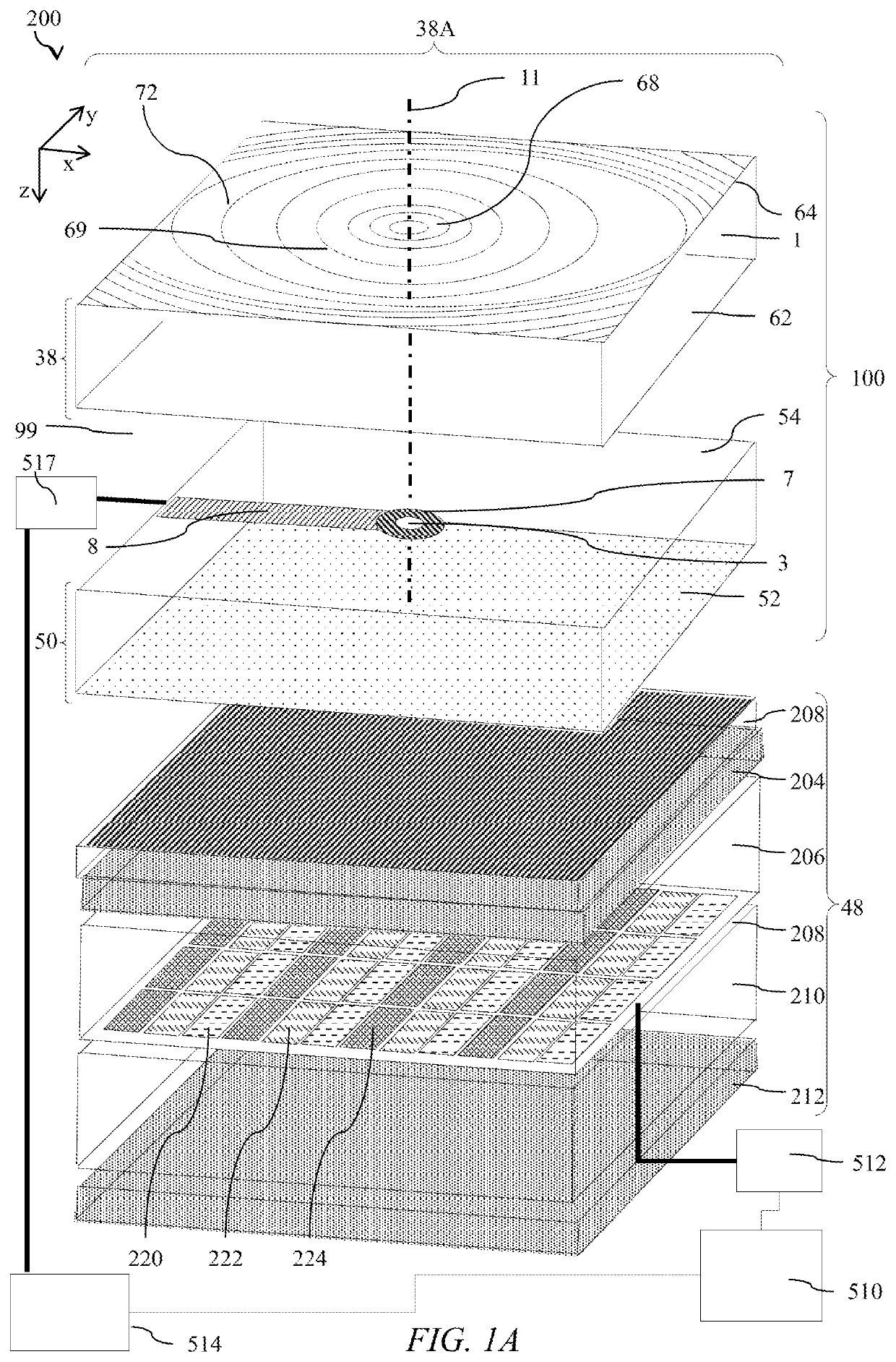

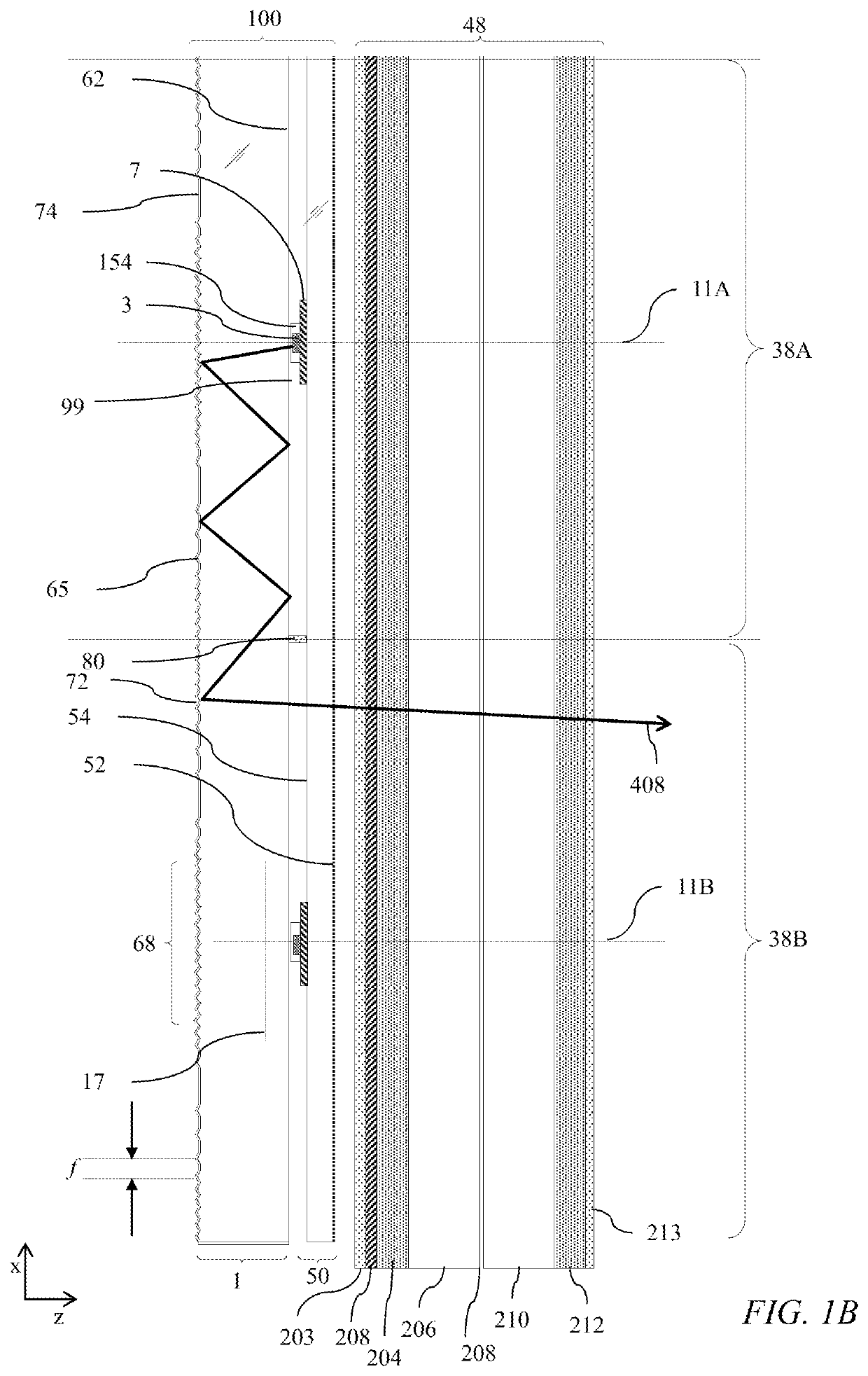

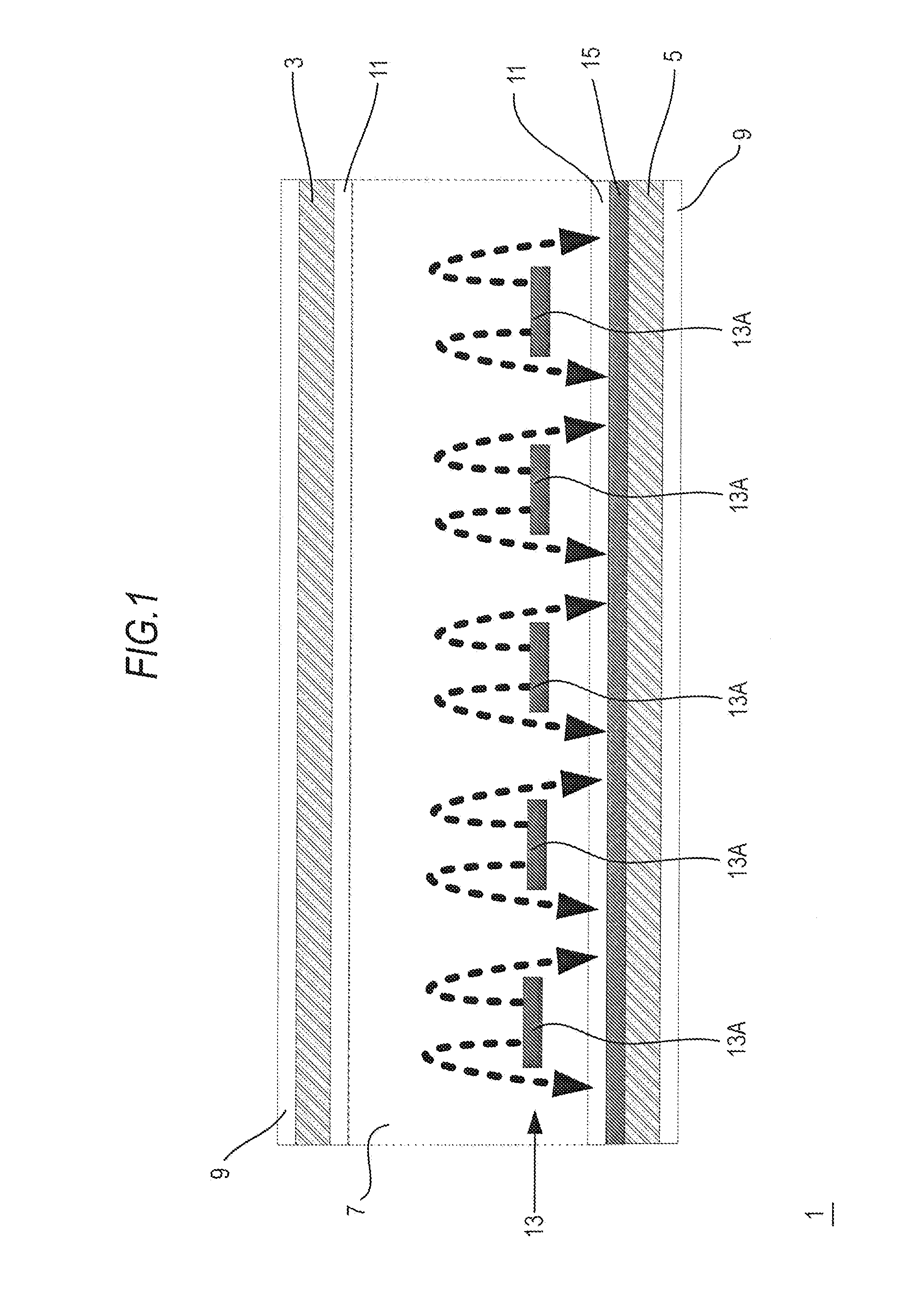

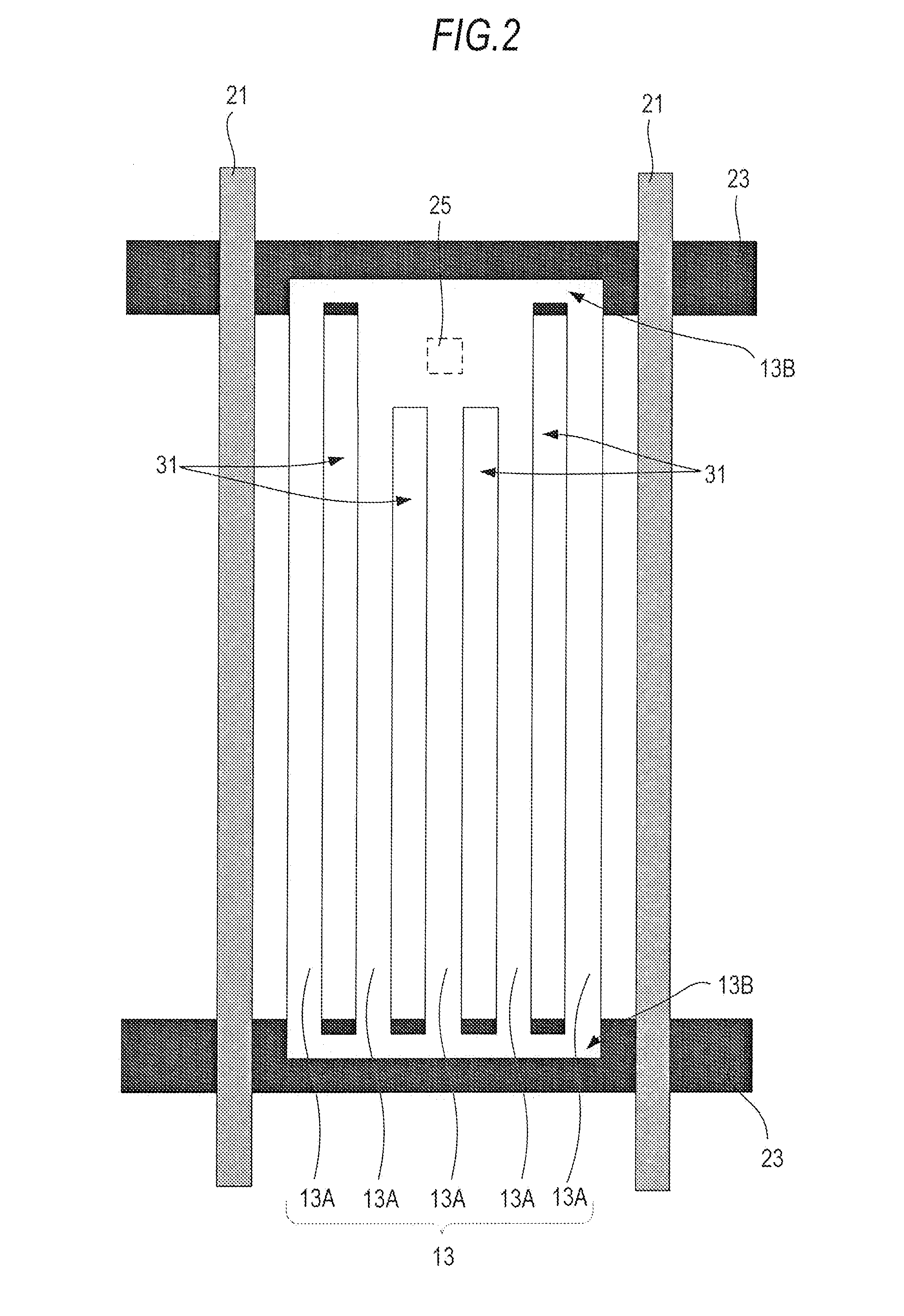

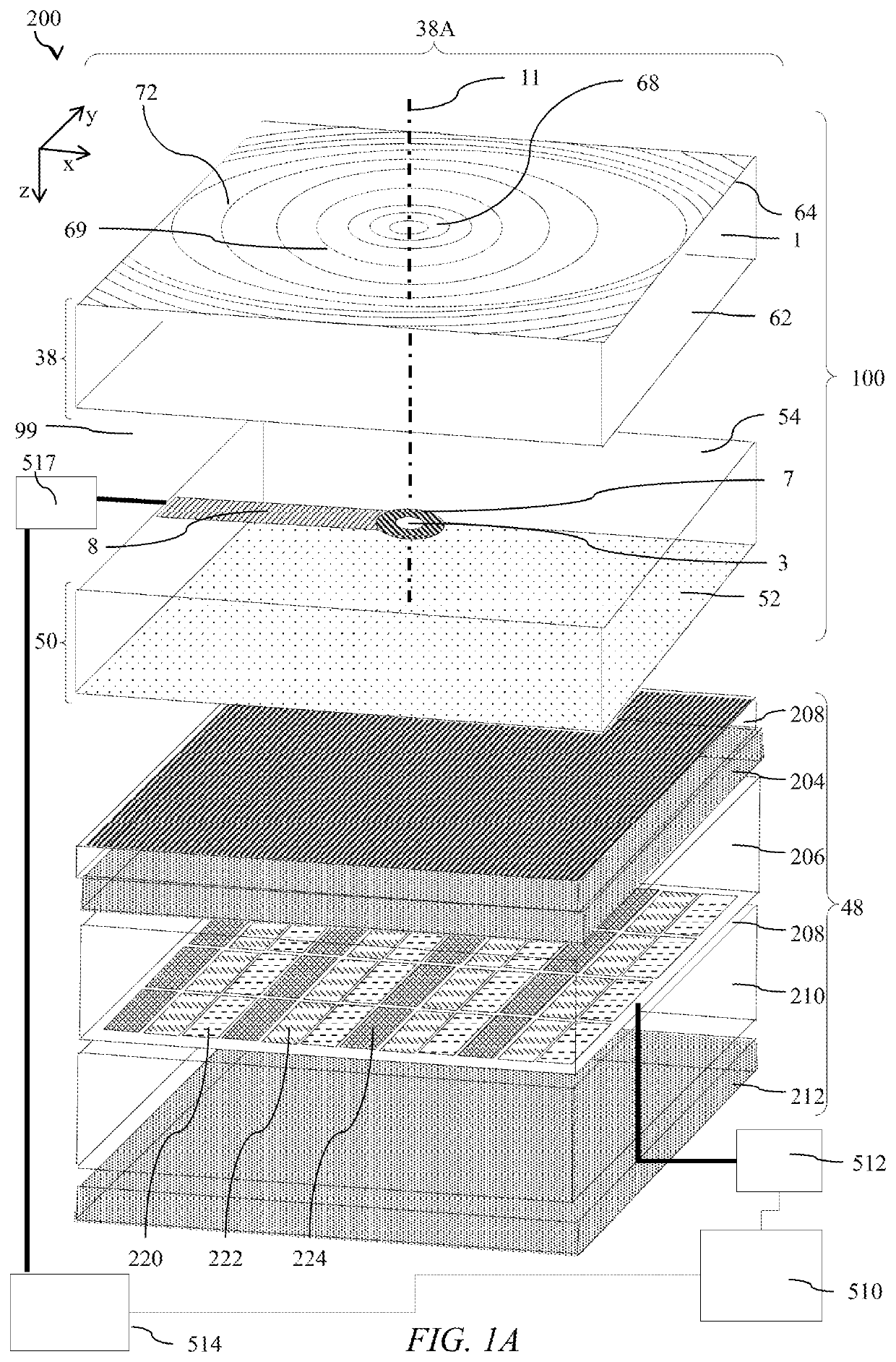

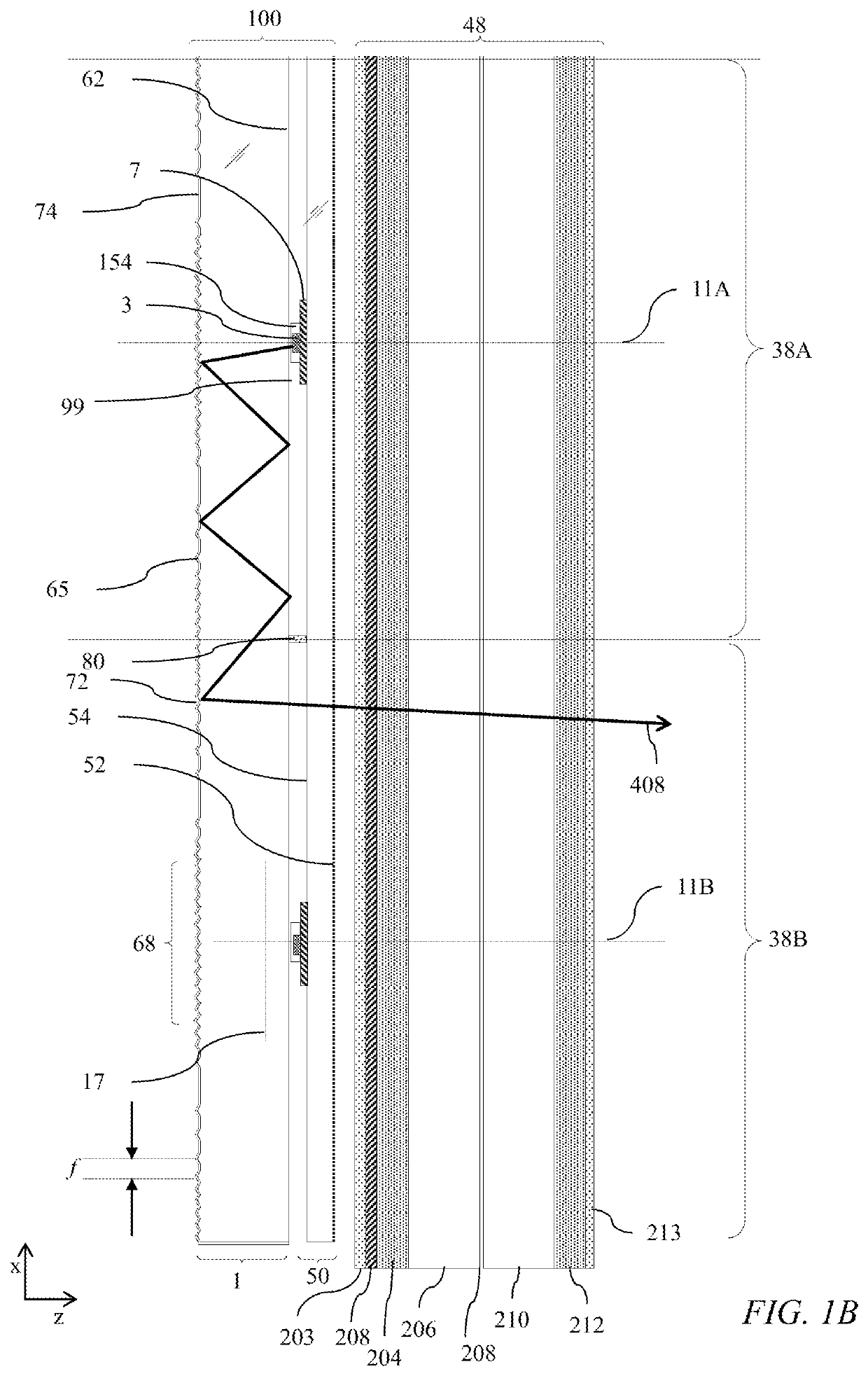

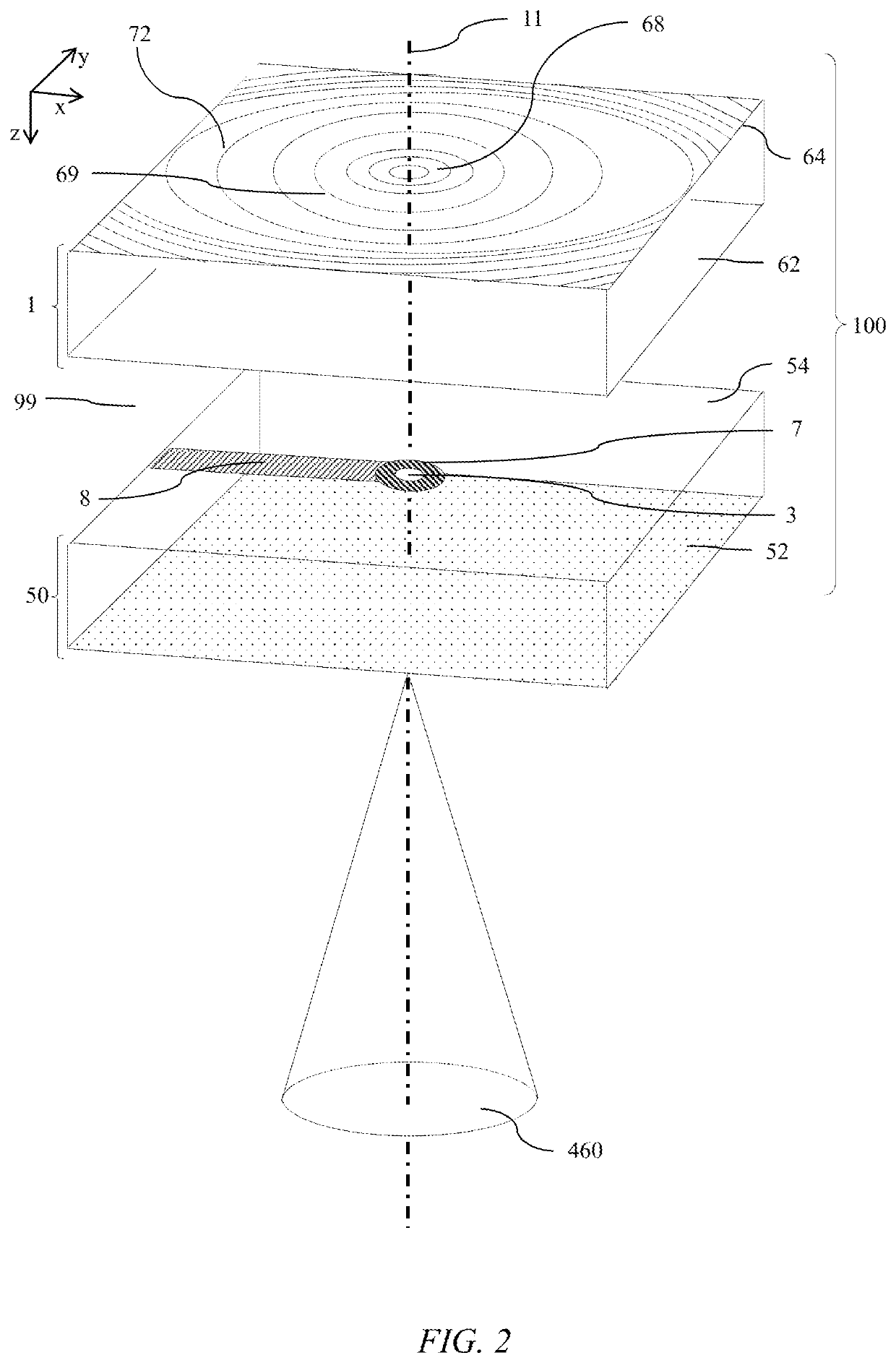

Directional illumination apparatus and privacy display

ActiveUS11016341B2Low surface profile variationThin directional illumination apparatusSolid-state devicesPlanar/plate-like light guidesLight equipmentDisplay device

A directional illumination apparatus comprises a waveguide with a reflective surface comprising reflective pairs of light input facets, reflective light extraction facets and an output transmissive surface. An array of micro-LEDs is arranged to illuminate the reflective surface in a rearwards direction. The pairs of light input facets direct light within the waveguide and reflective light extraction facets cooperate to provide a uniform output illumination across the output aperture of the waveguide with collimated light. A thin and efficient illumination apparatus may be used for high dynamic range display backlighting, privacy display or environmental illumination applications.

Owner:REALD SPARK LLC

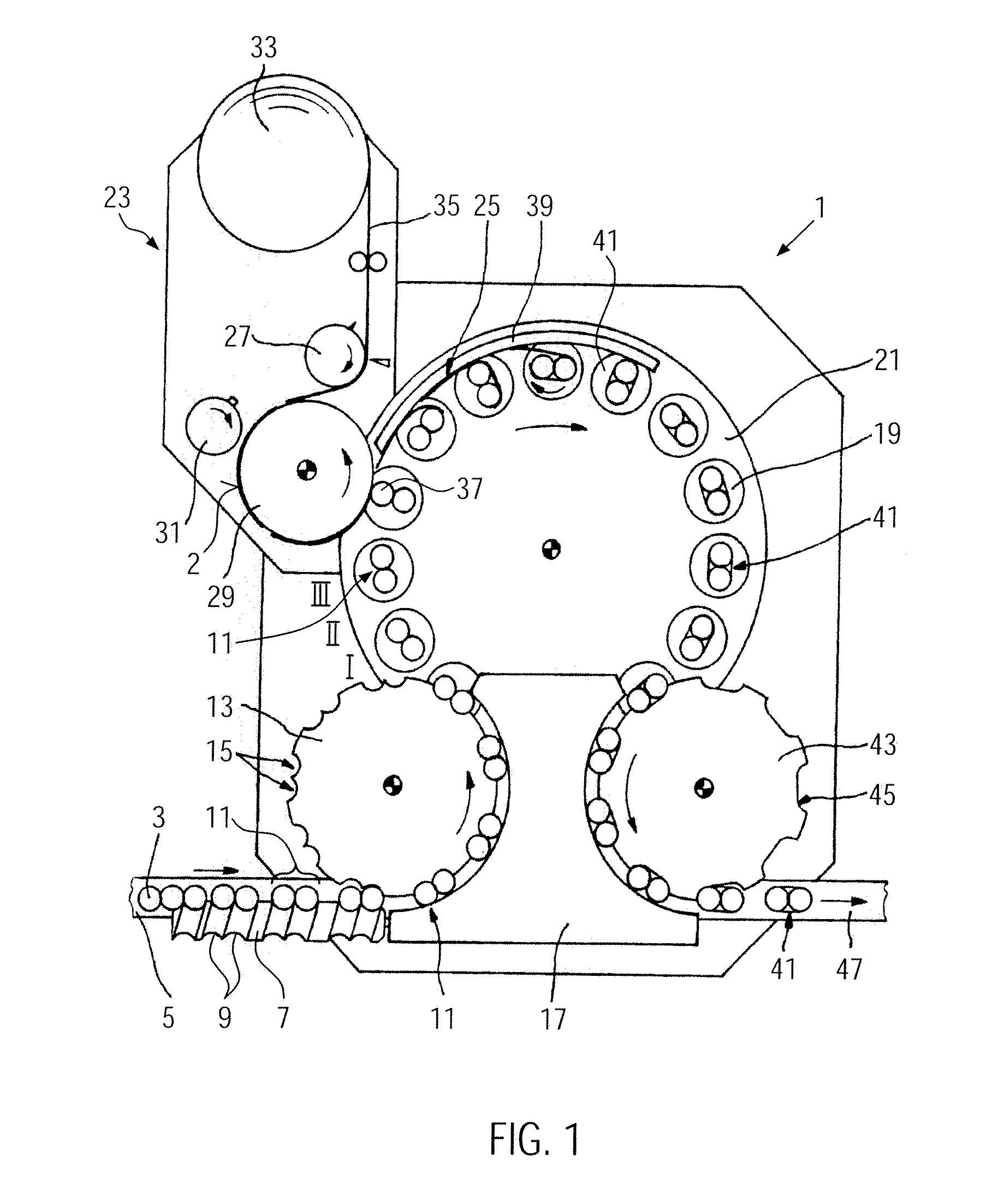

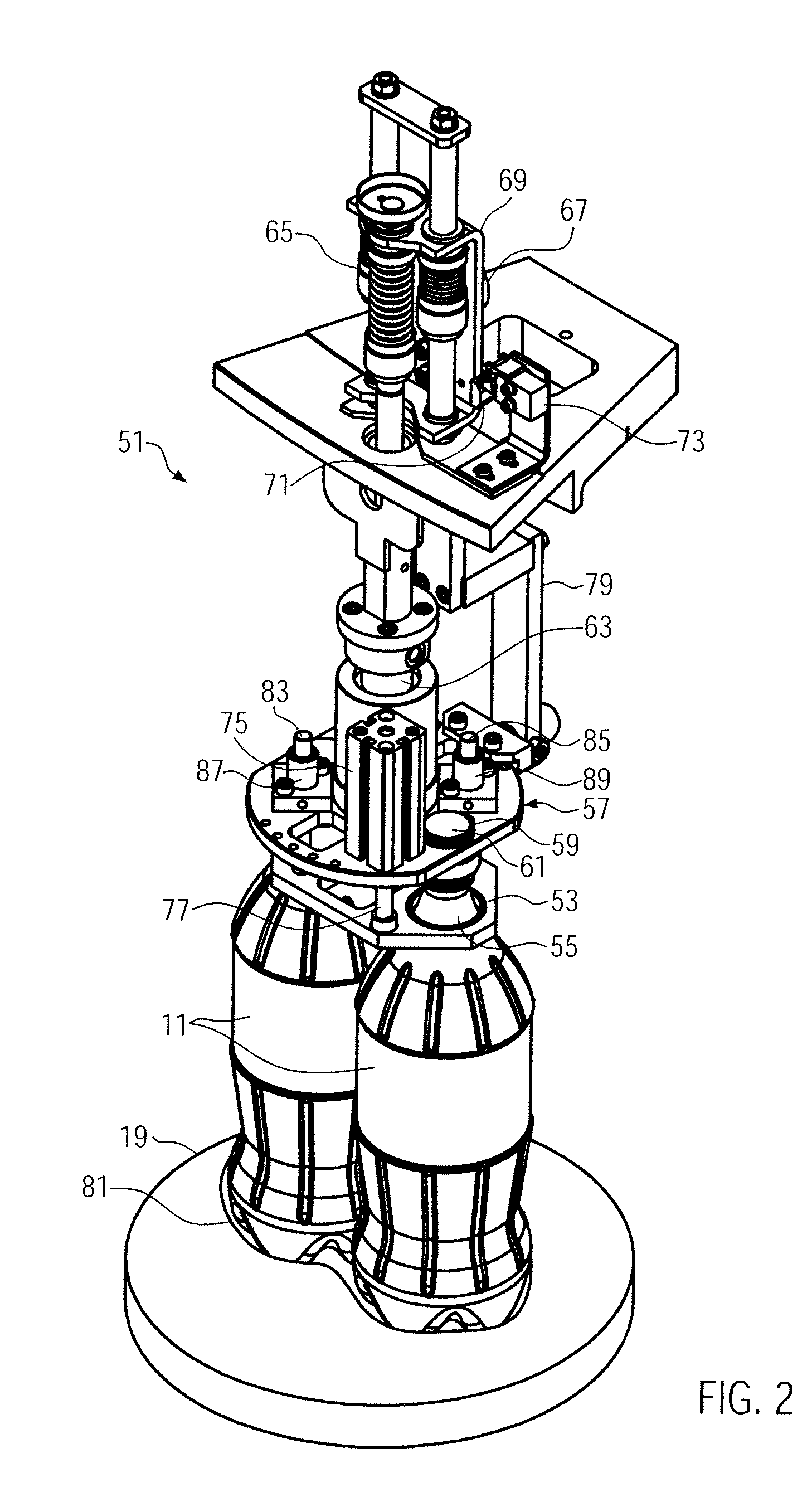

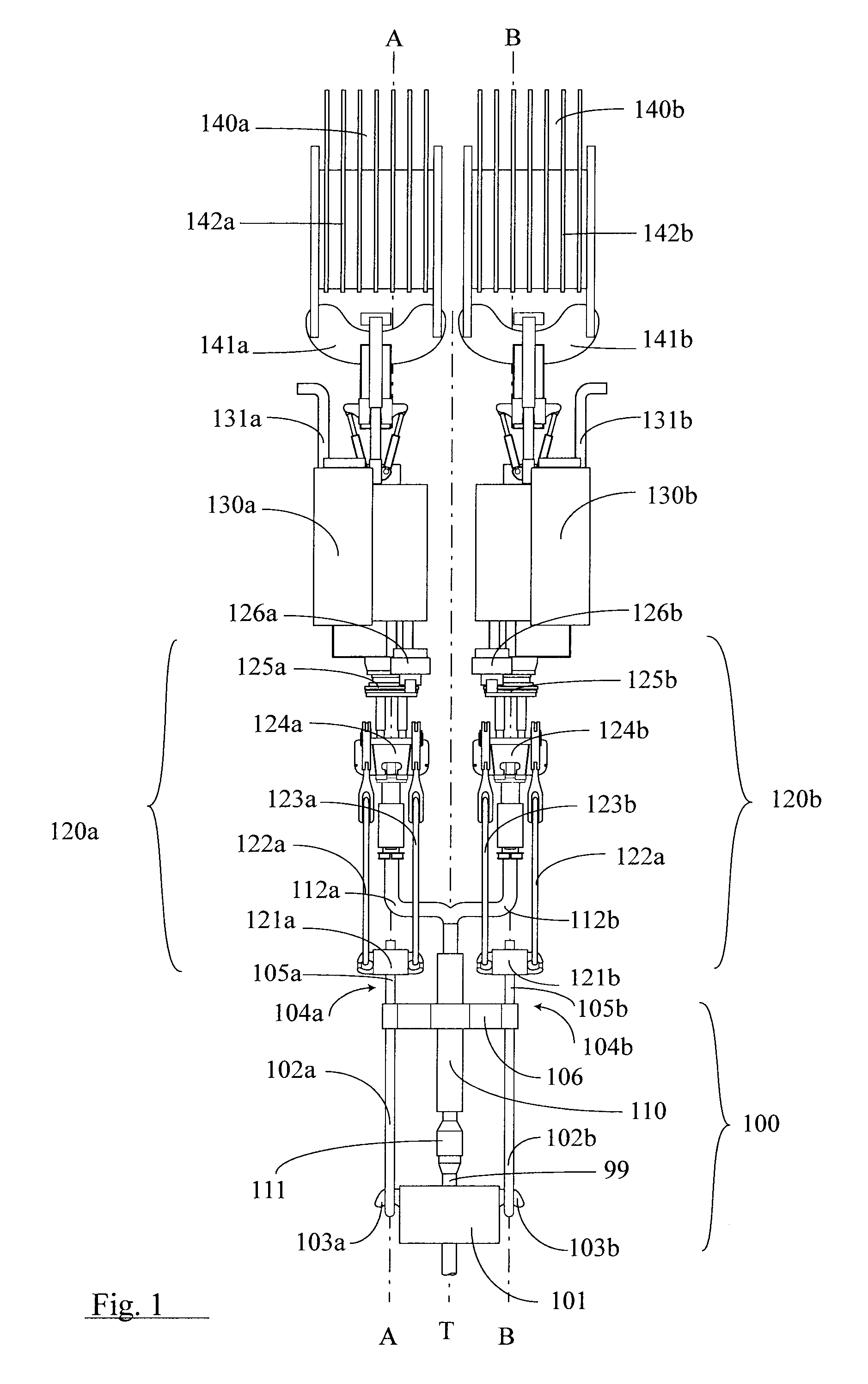

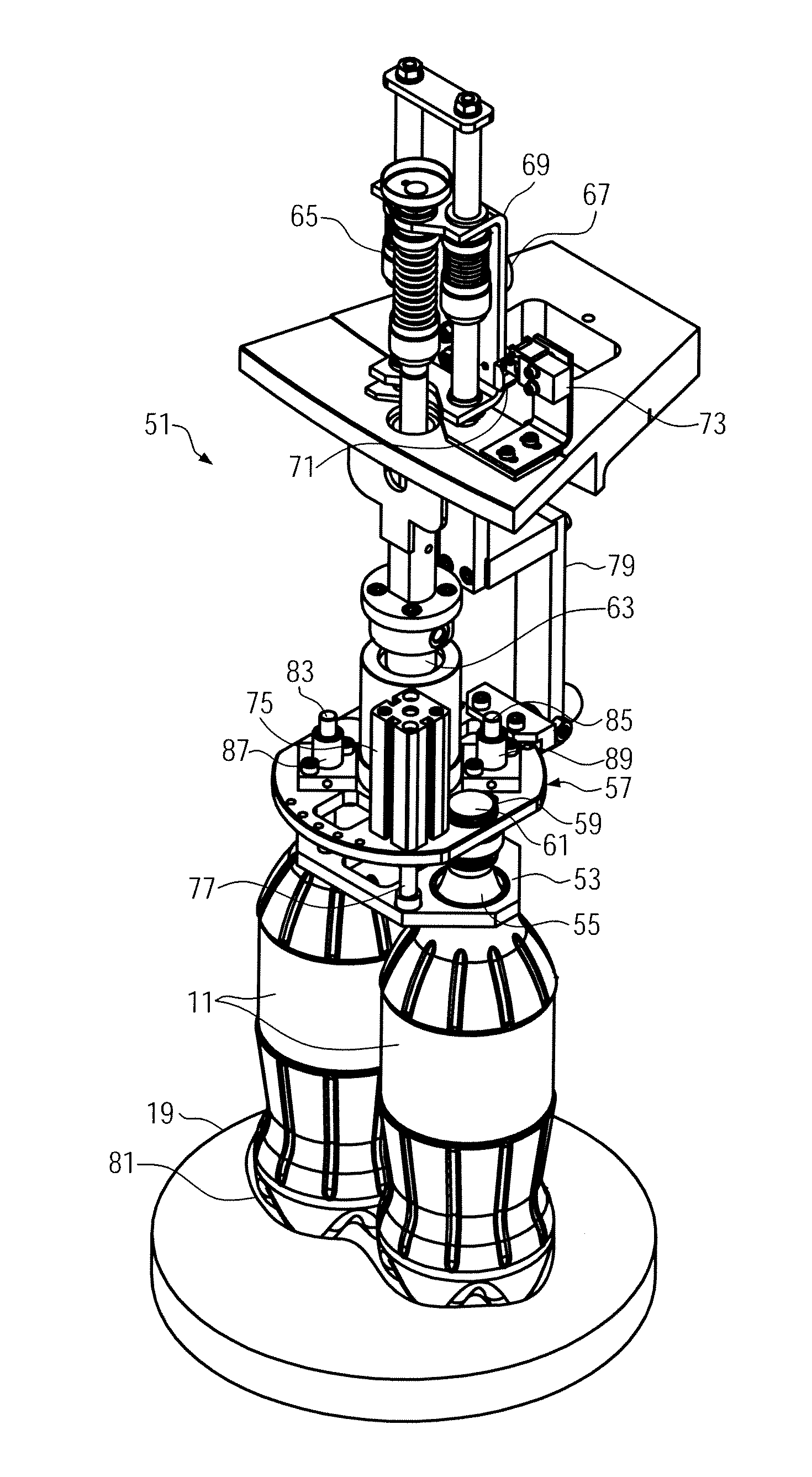

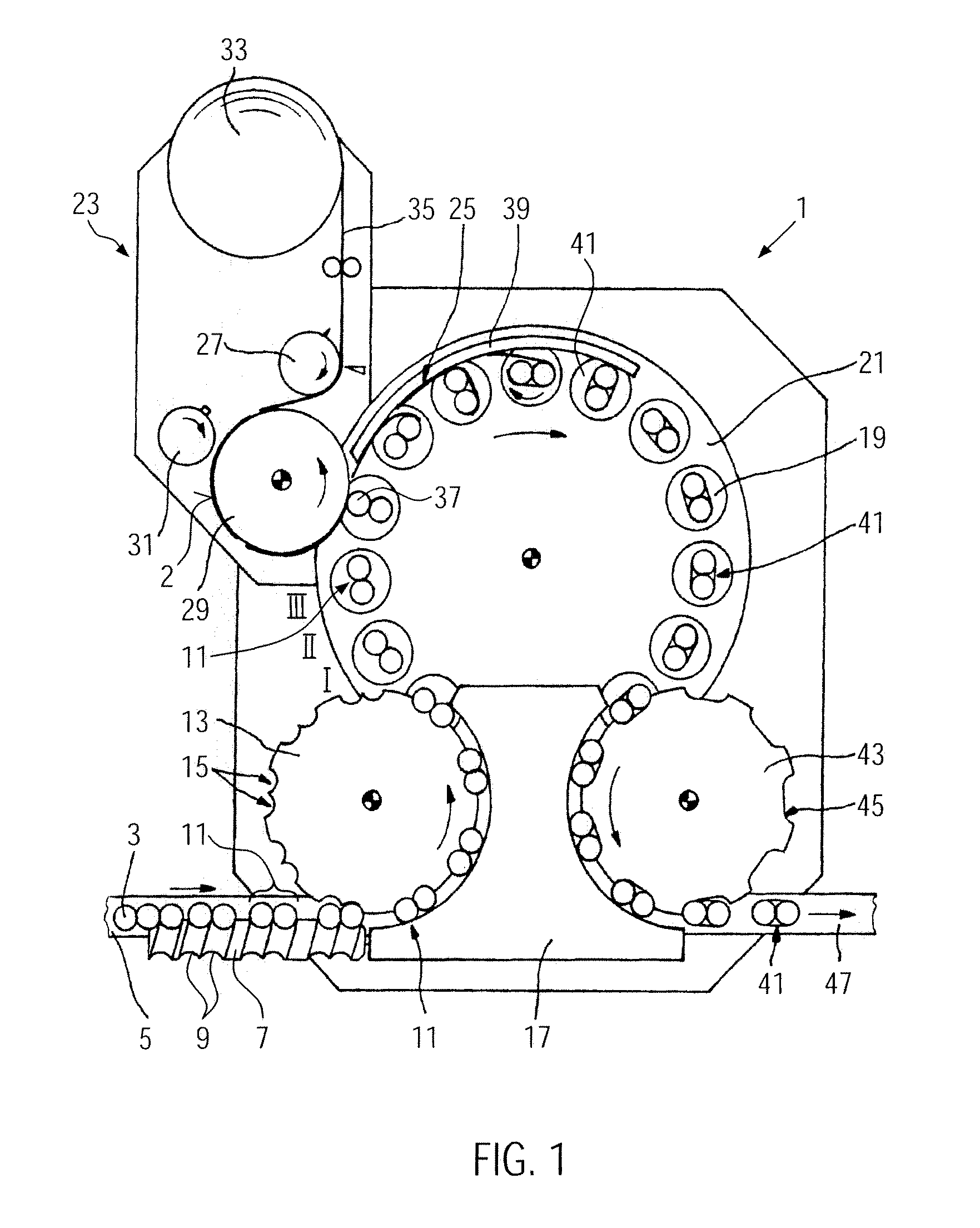

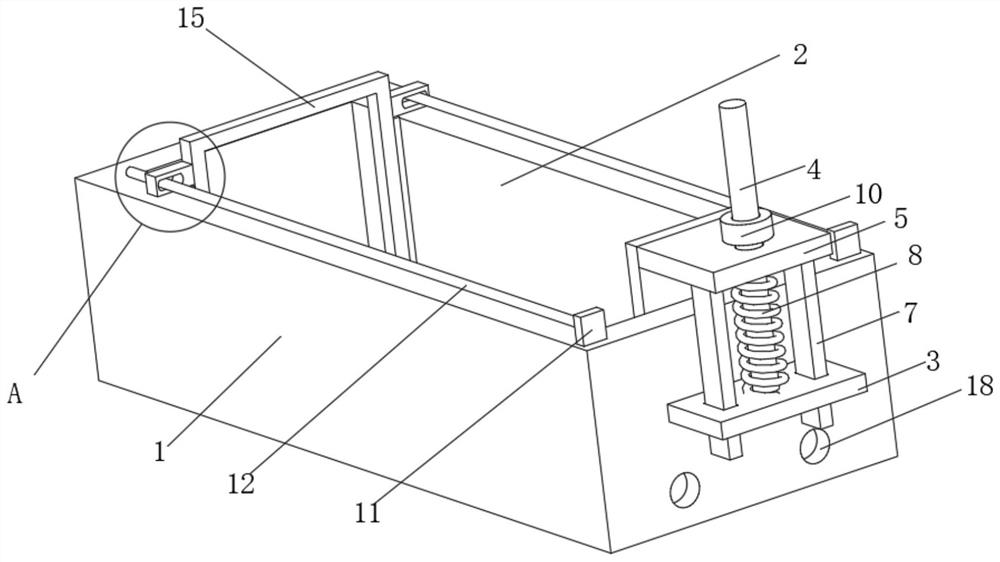

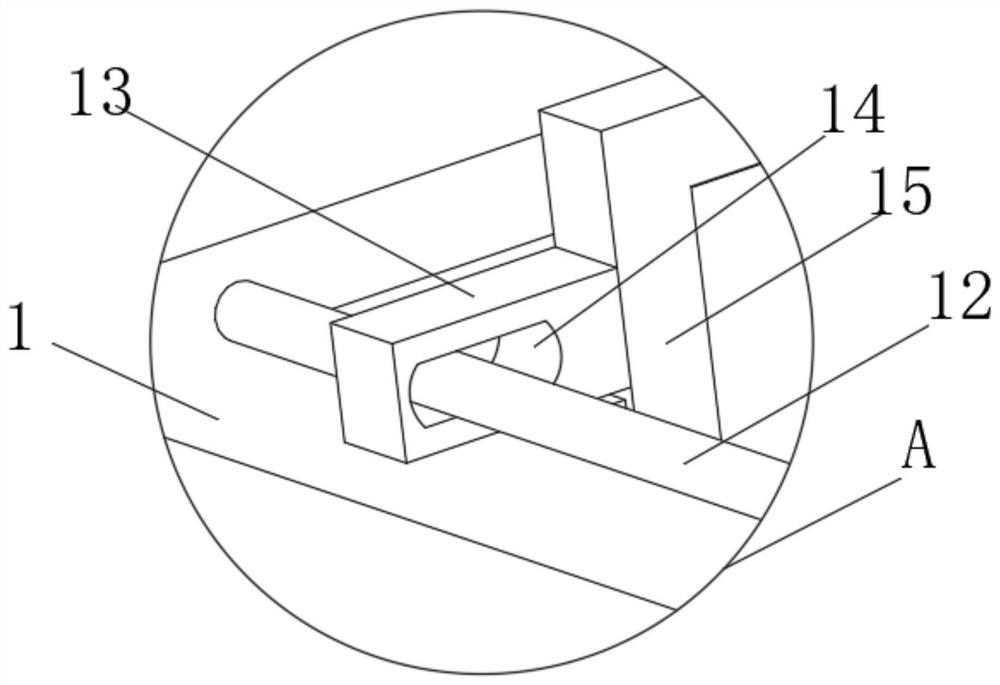

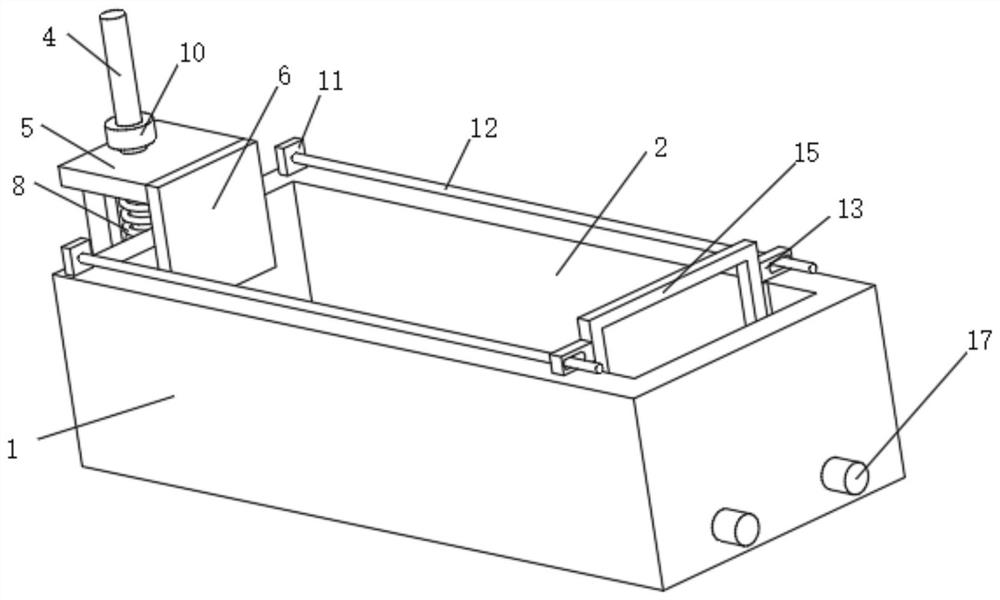

Centering Unit for Aligning at Least Two Grouped Vessels and Method for Aligning Two Grouped Vessels

InactiveUS20100058716A1Effective positioningImprove convenienceRotary pressesButter manufactureMechanical engineeringEngineering

Owner:KRONES AG

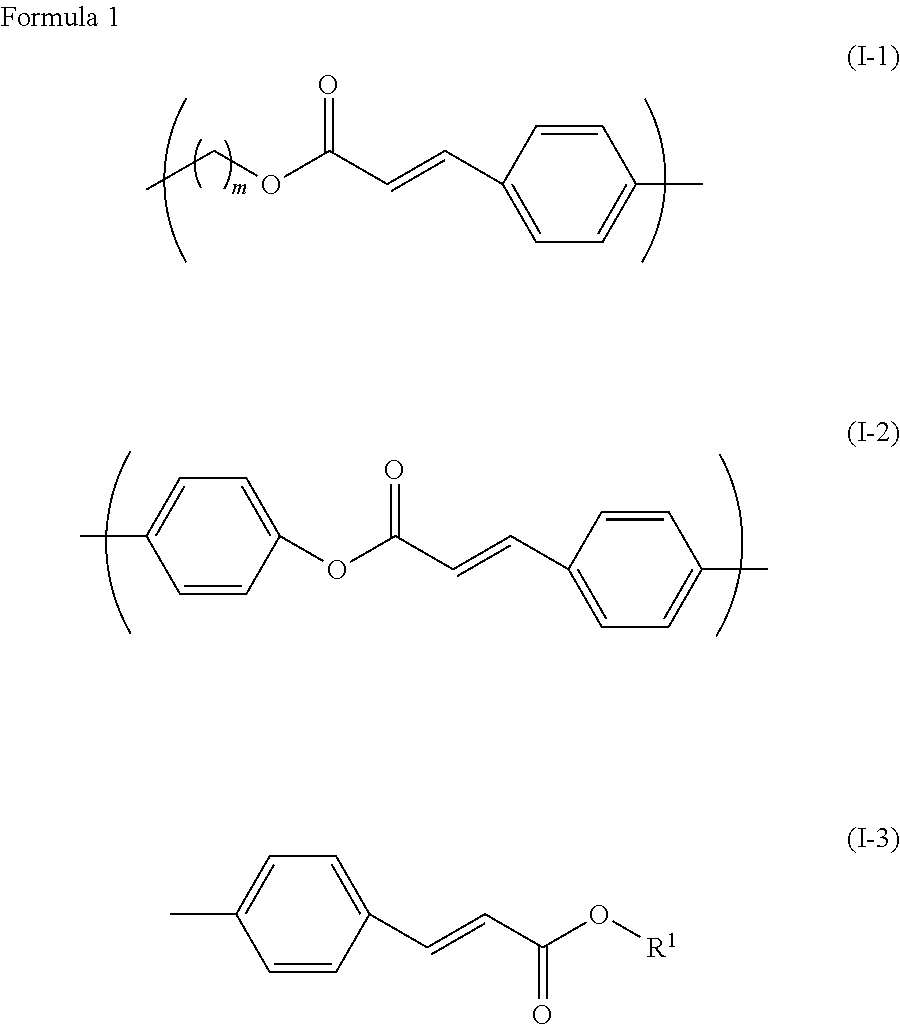

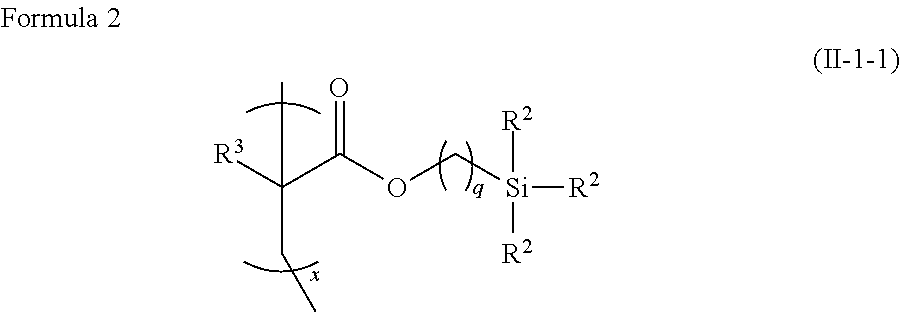

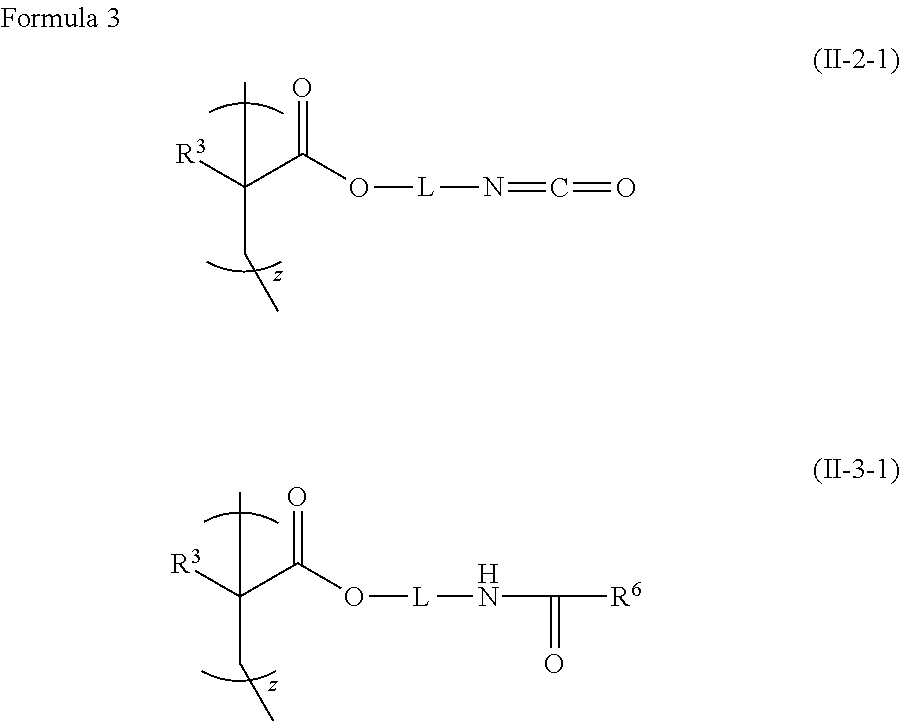

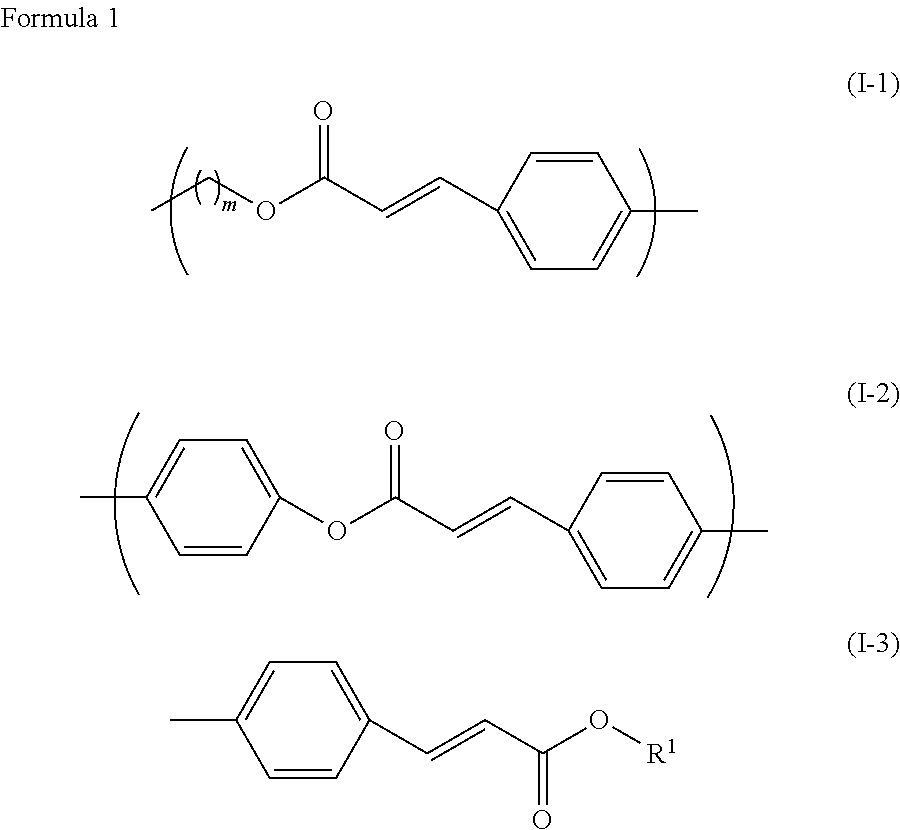

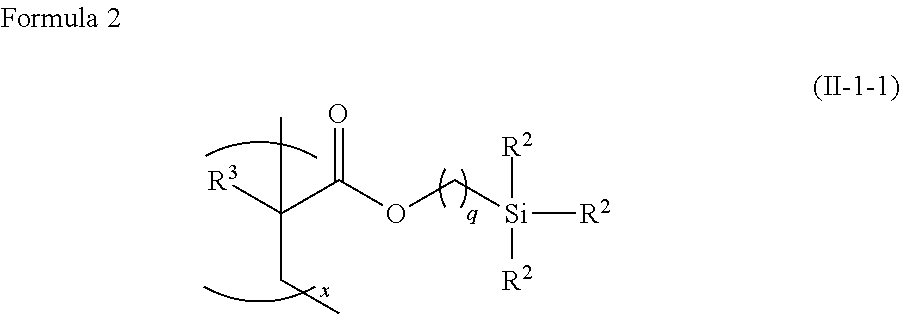

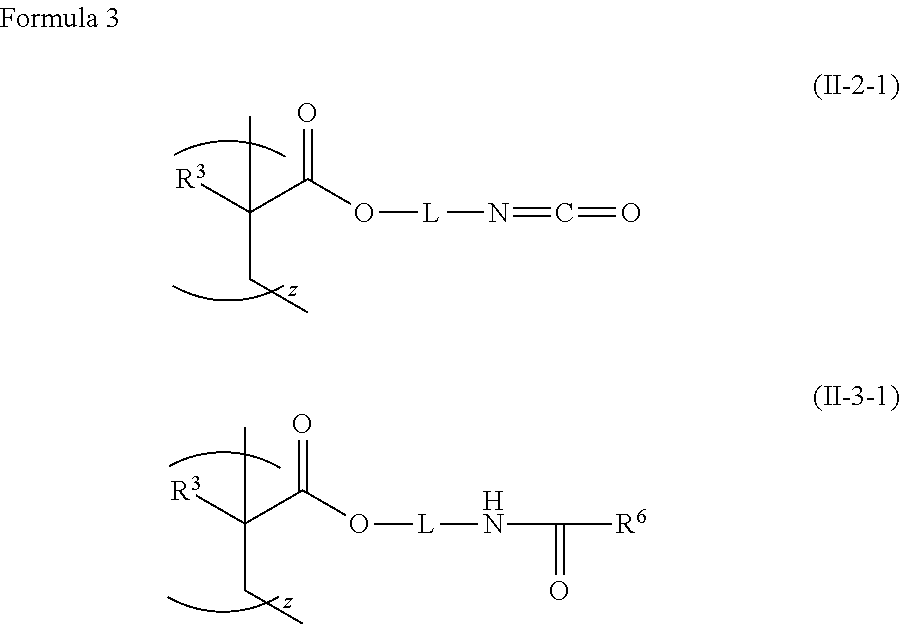

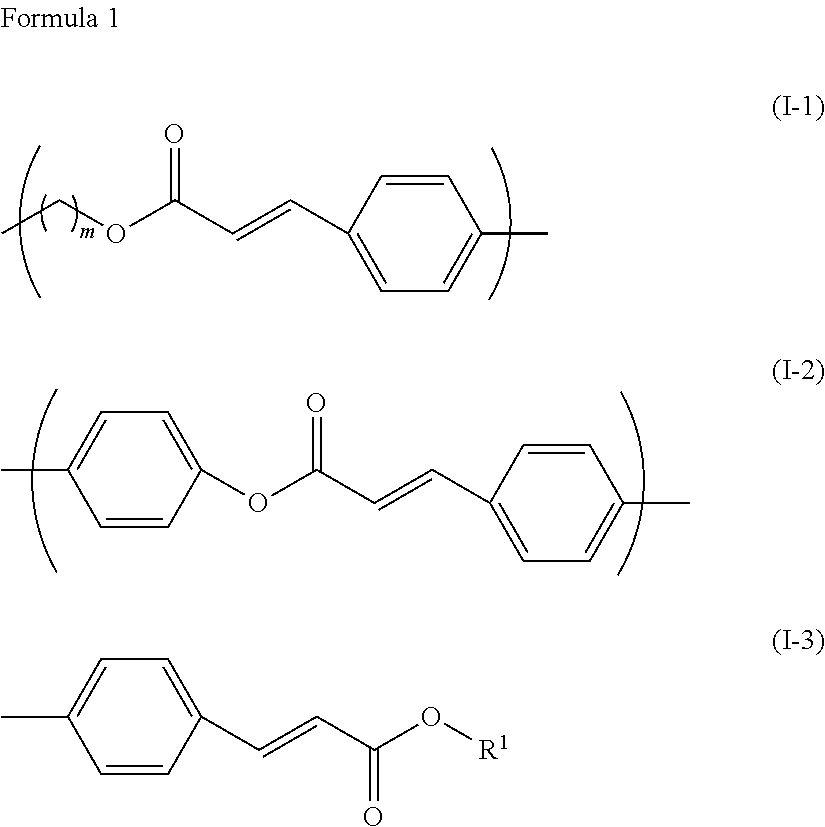

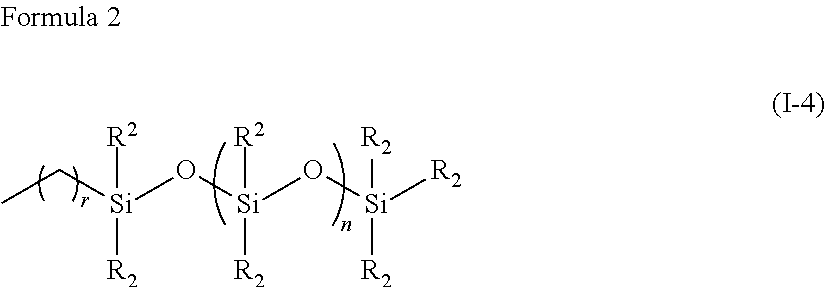

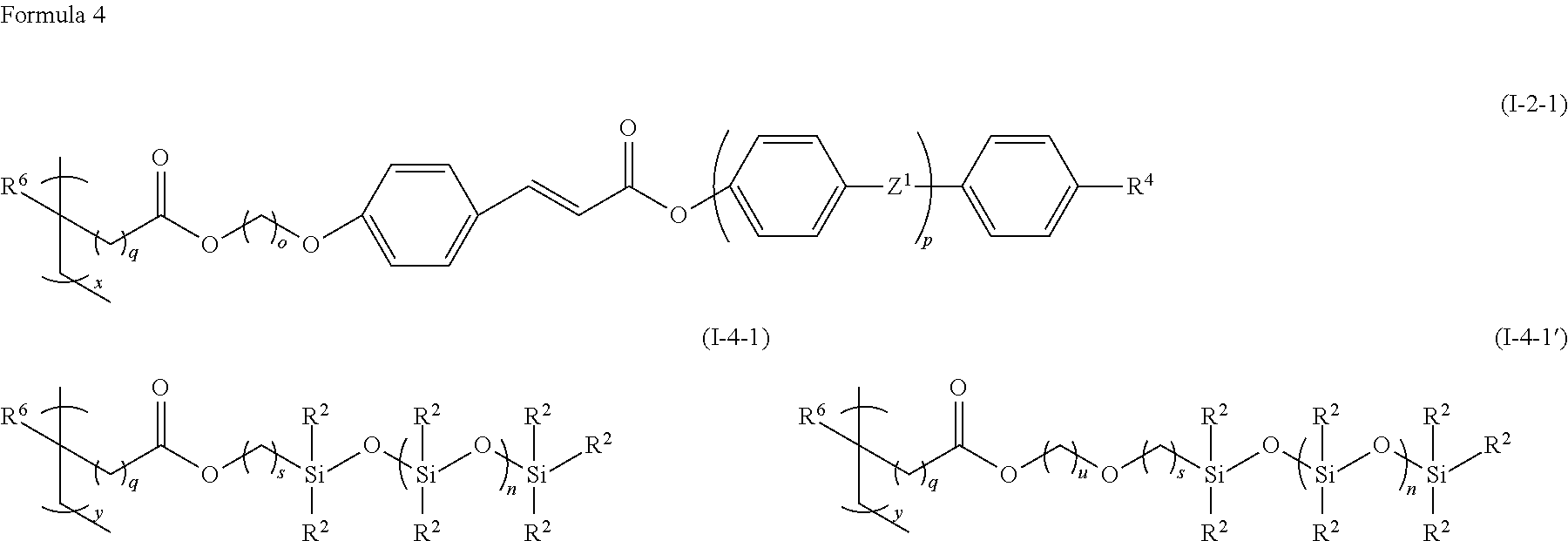

Polymer composition having photoalignable group, liquid crystal alignment film formed of the polymer composition, and optical device having phase difference plate formed of the liquid crystal alignment film

InactiveUS20130331482A1High sensitivityImprove Optical UniformityLiquid crystal compositionsPolarising elementsPhase differencePolymer chemistry

To provide a photoalignable material that can yield a photoalignable film having a high optical uniformity and no alignment defect, and is excellent in sensitivity to allow photoalignment even with exposure in a short period of time, and a liquid crystal alignment film having a high alignment stability of a liquid crystal compound from the photoalignable material. A photoalignable polymer composition containing a specific photoalignable polymer and a specific polymer that is reactive with the photoalignable polymer is manufactured, and the photoalignable film is manufactured by applying the polymer composition onto a base material or the like, drying the applied composition thereon, and irradiating the dried composition with light. Furthermore, the liquid crystal alignment film is manufactured by allowing alignment of molecules of the liquid crystal compound in the photoalignment film.

Owner:JNC CORP +1

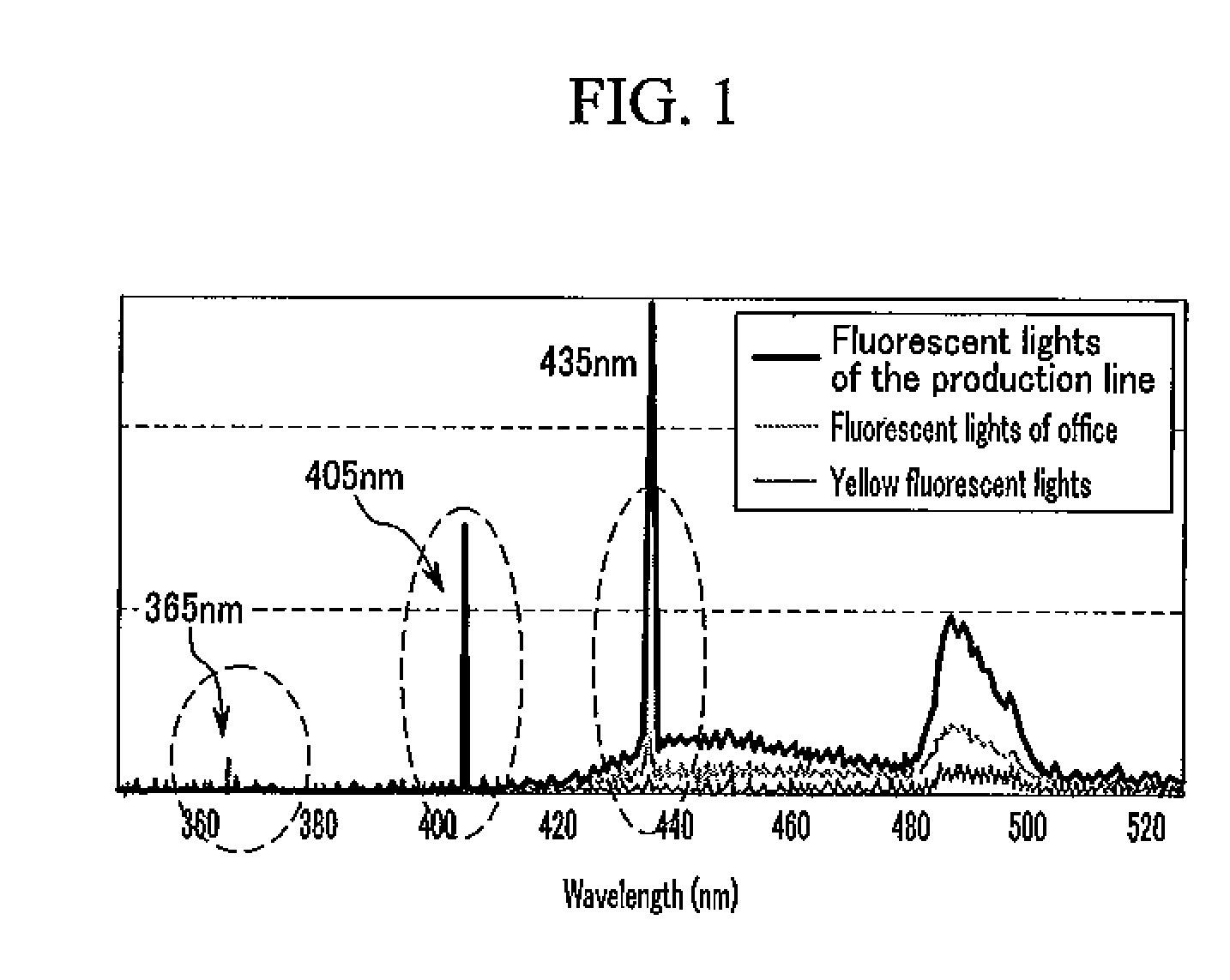

Light absorption layer for a display device

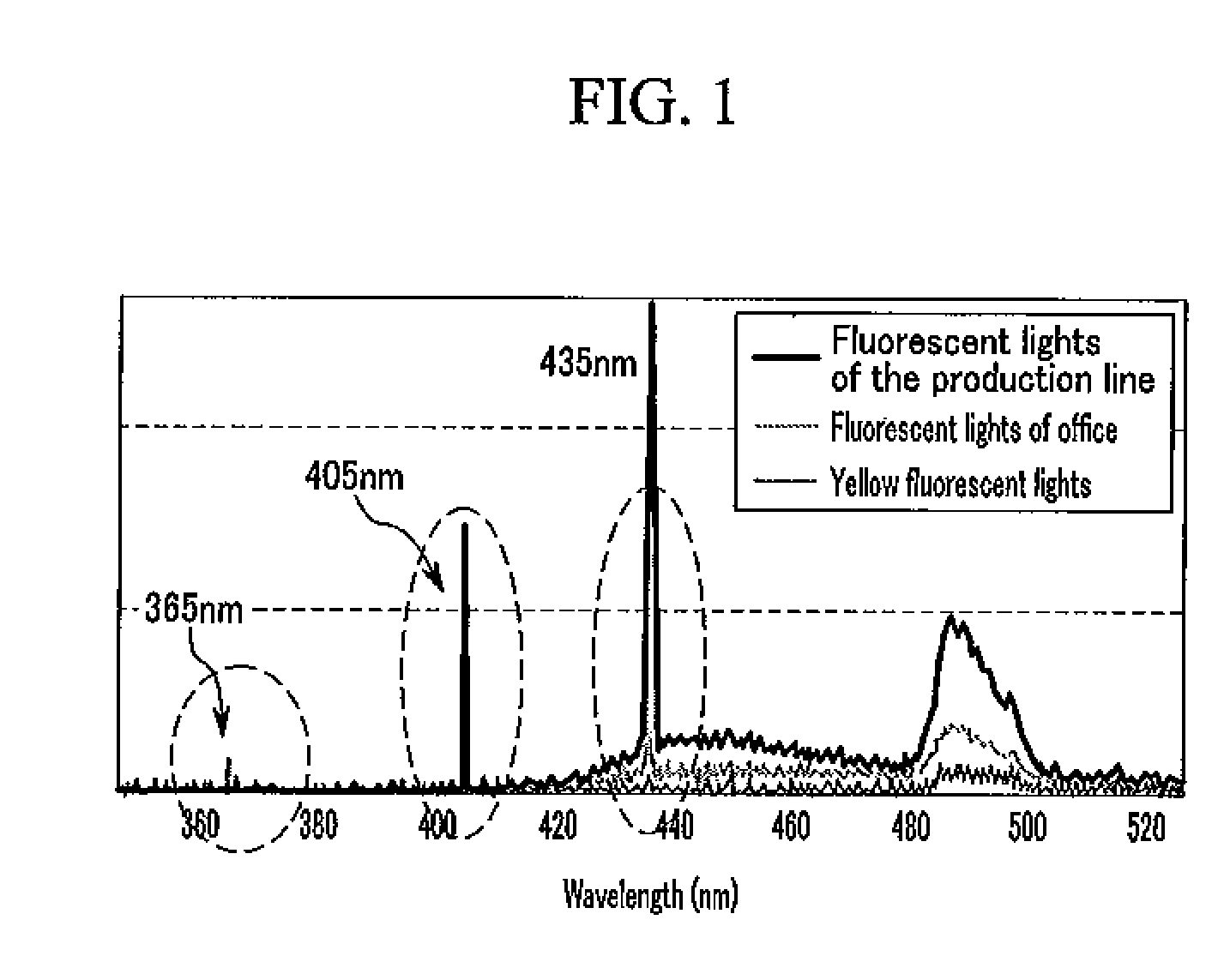

ActiveUS20100033657A1Preventing alignment spotImprove alignment stabilityLiquid crystal compositionsNon-linear opticsLiquid-crystal displayDisplay device

A liquid crystal display is presented. The liquid crystal display includes: a first substrate; a pixel electrode formed on the first substrate; a first alignment layer formed on the pixel electrode; a second substrate facing the first substrate; a common electrode formed on the second substrate; a second alignment layer formed on the common electrode; a liquid crystal layer formed between the first alignment layer and the second alignment layer; and a light absorption layer formed between the first substrate and the first alignment layer, or the second substrate and the second alignment layer, wherein the light absorption layer absorbs light having a UV wavelength between about 280 nm and about 450 nm.

Owner:SAMSUNG DISPLAY CO LTD

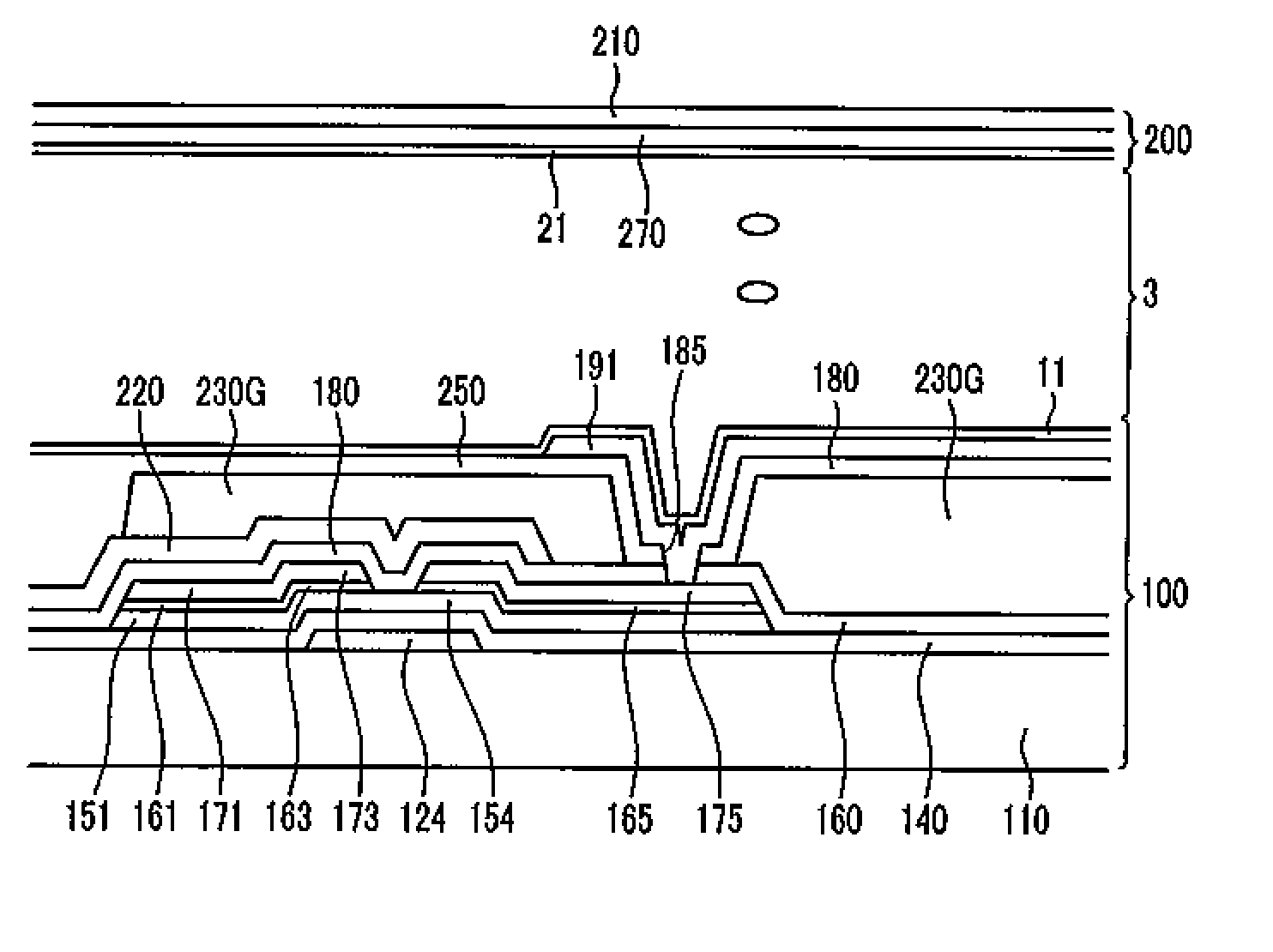

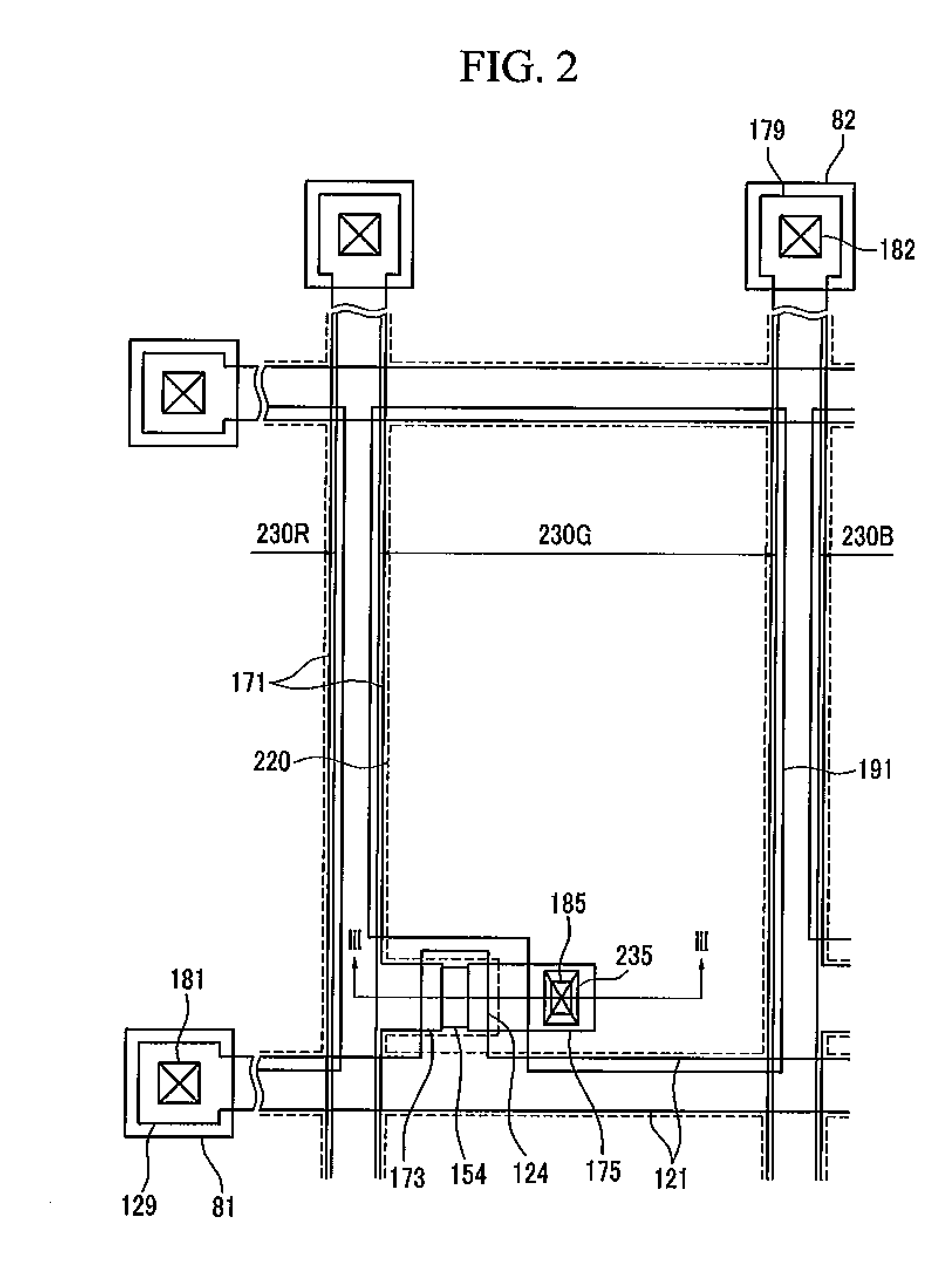

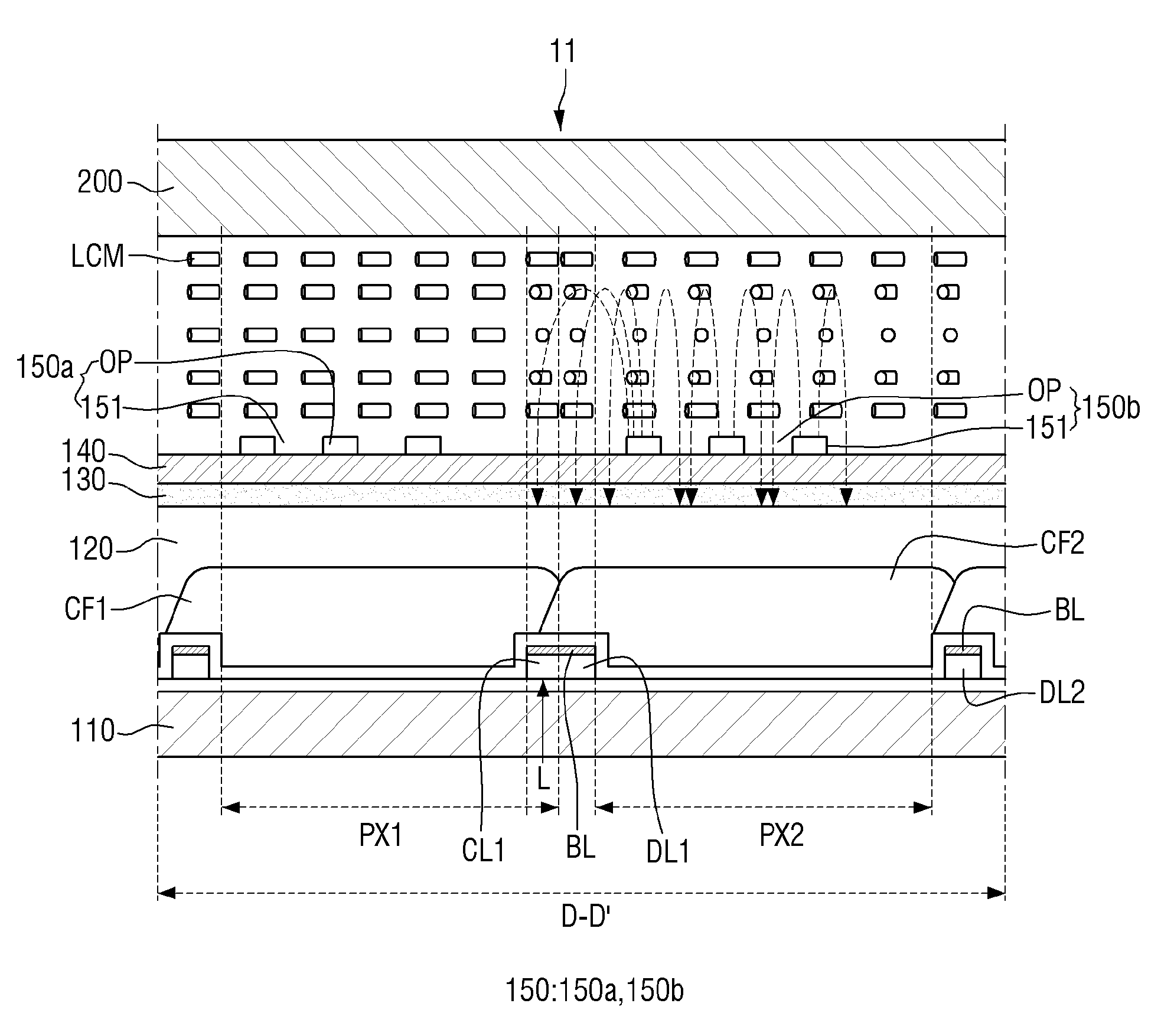

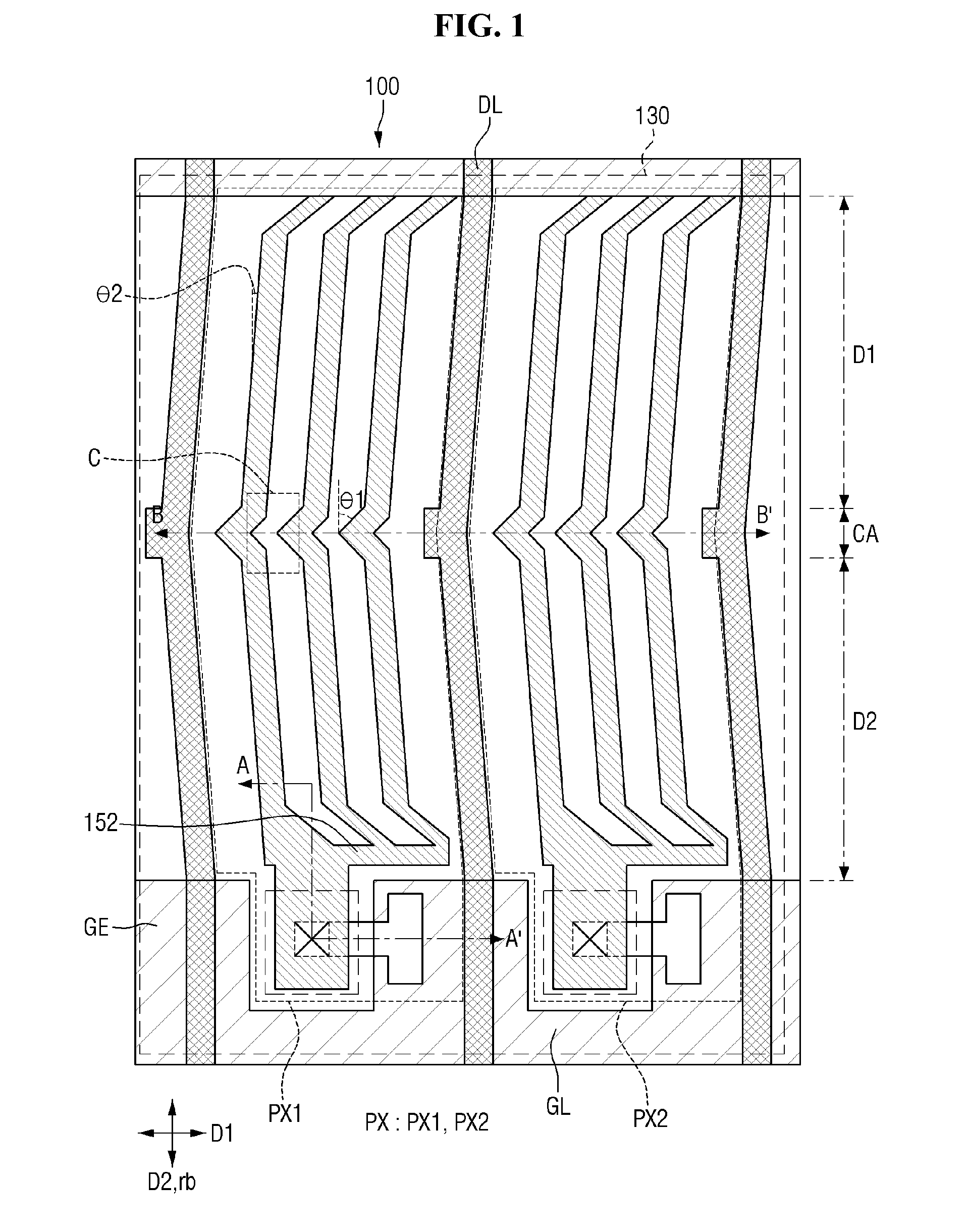

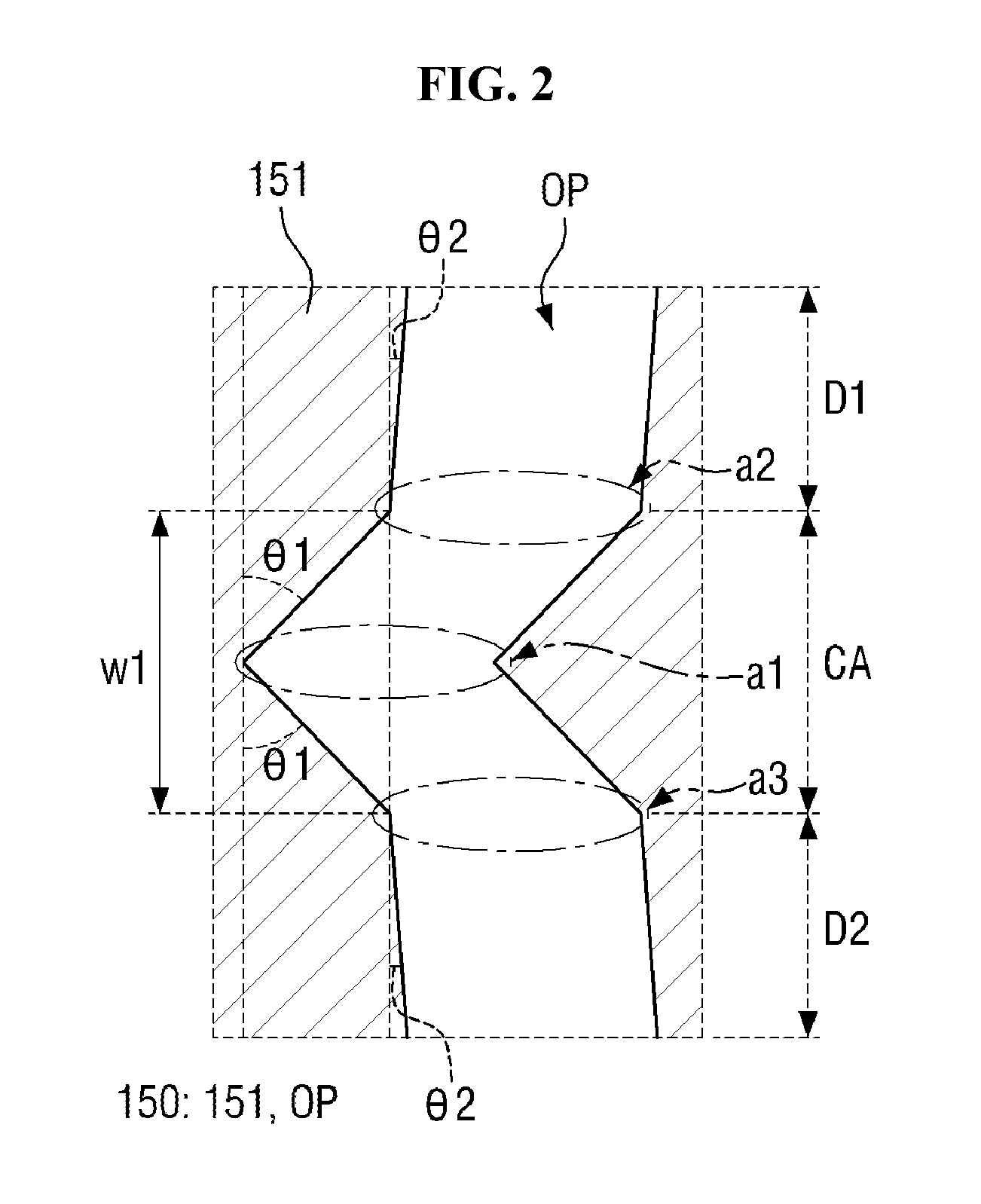

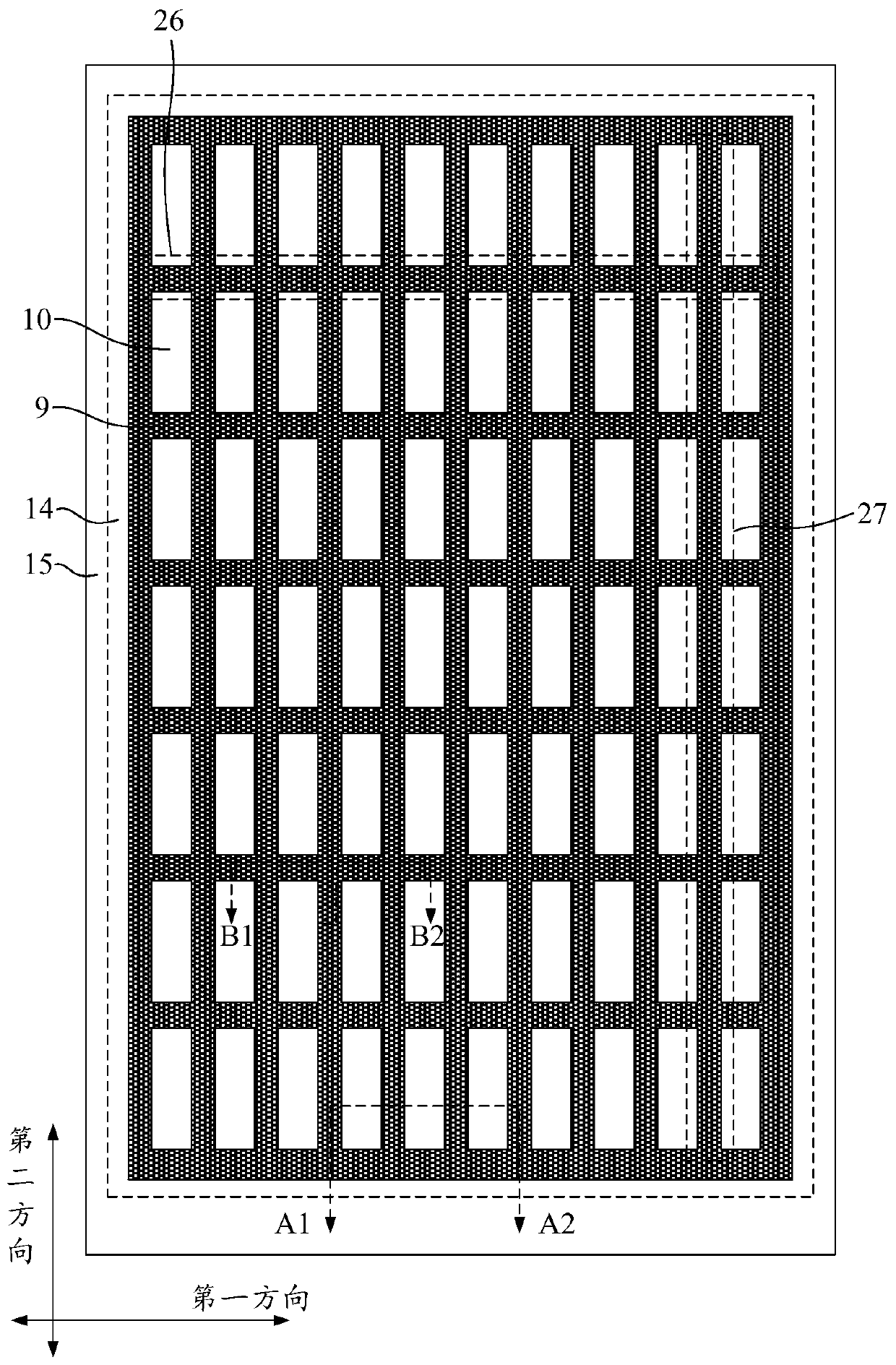

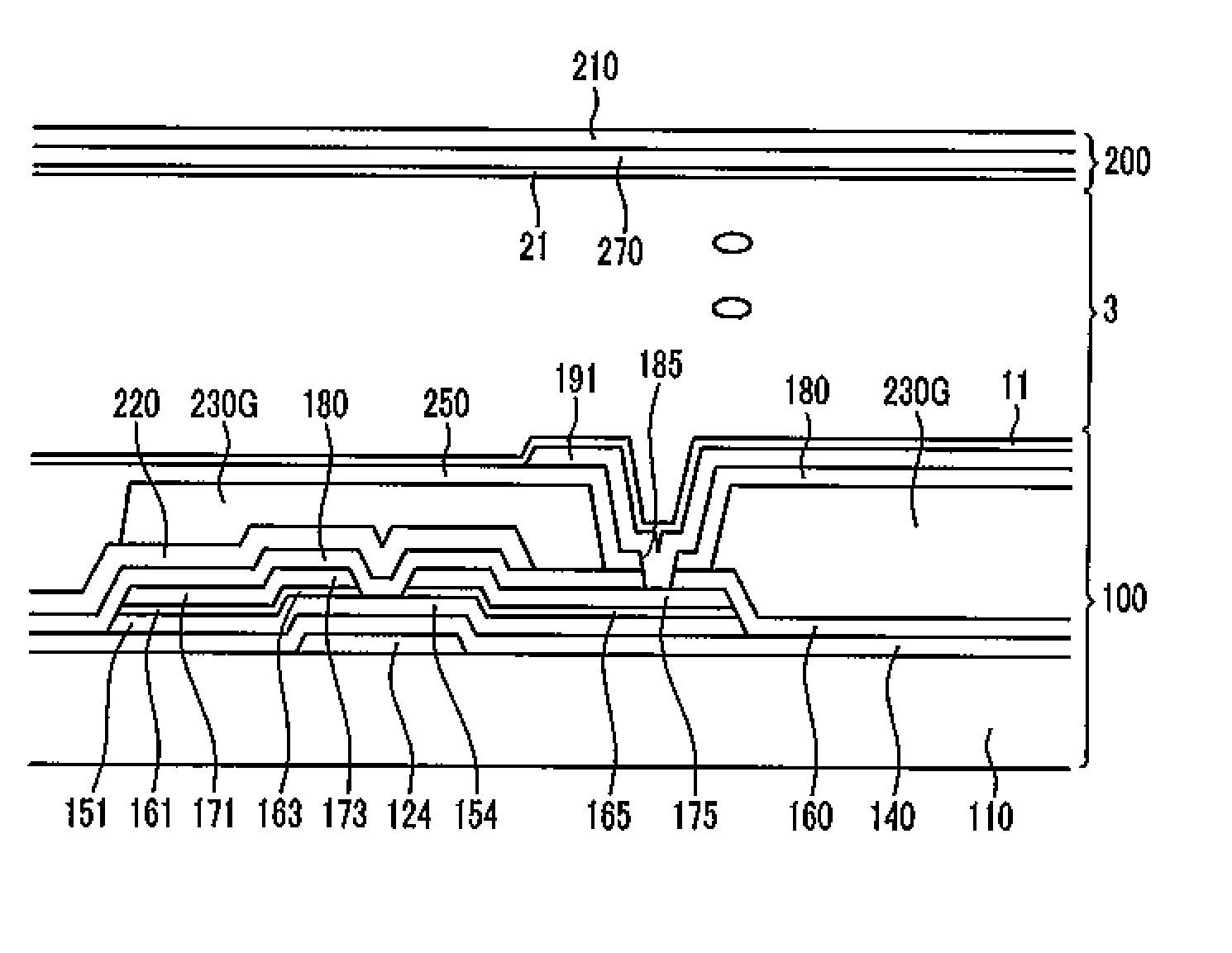

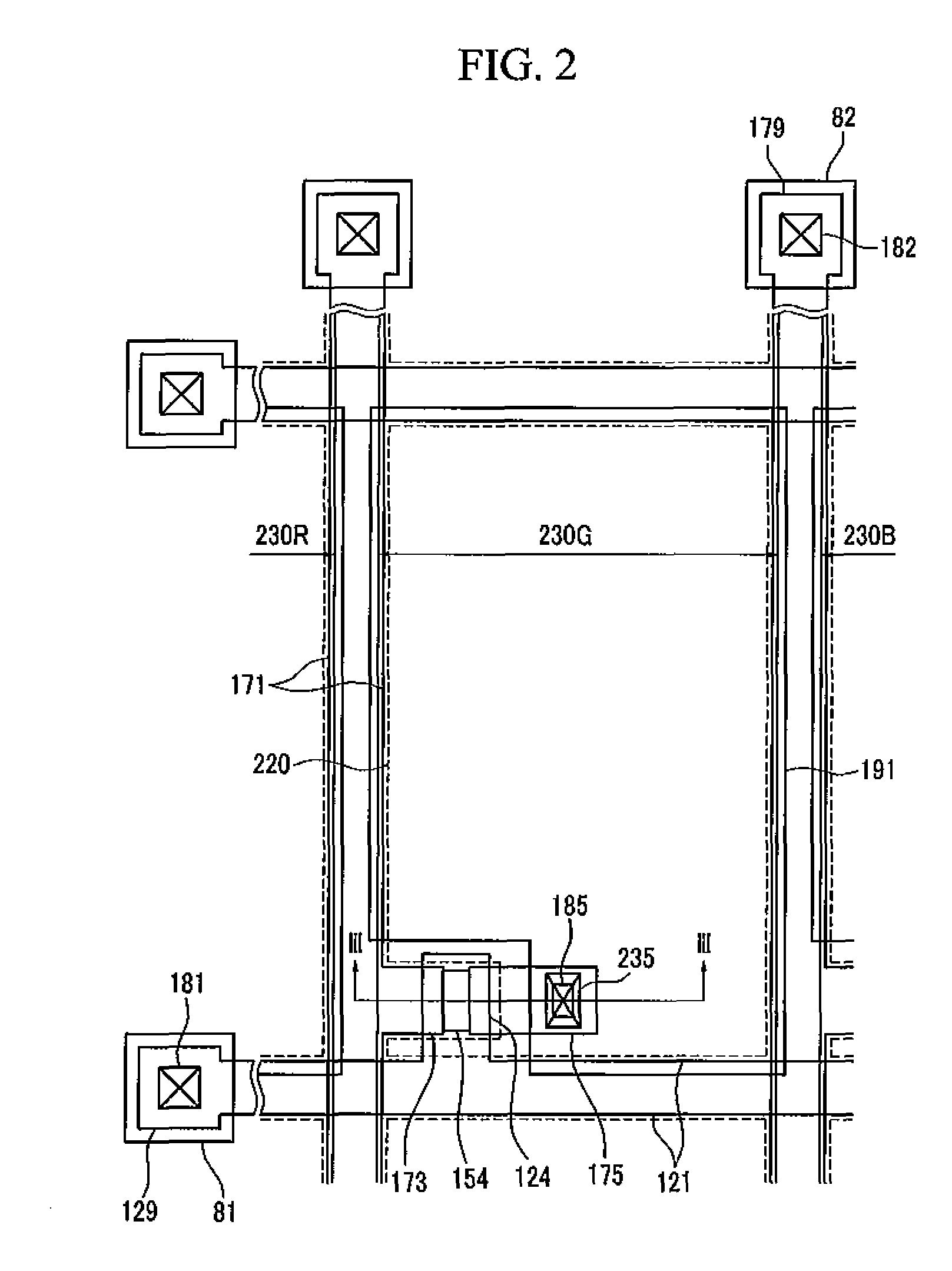

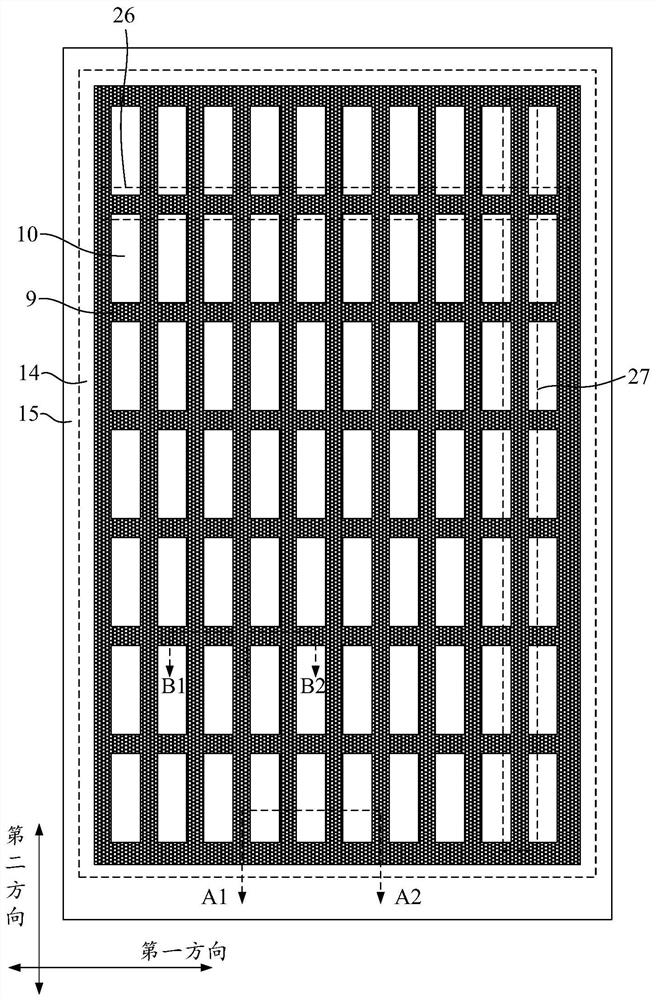

Array substrate and liquid crystal display including the same

ActiveUS20160349587A1Improve alignment stabilityGapSolid-state devicesNon-linear opticsLiquid-crystal displayEngineering

Array substrate includes a gate line which extends along a first direction, a gate insulating layer which covers the gate line, a data line located on the gate insulating layer and intersects the gate line, a thin-film transistor (“TFT”) which has a control electrode connected to the gate line and an electrode connected to the data line, a pixel electrode connected to the other electrode of the TFT, where the pixel electrode includes branch electrodes, openings are defined between the branch electrodes, each of the openings includes a first bent portion which corresponds to a middle part of the pixel area and a second bent portion and a third bent portion located symmetrically to each other with respect to the first bent portion, and the data line includes a cover region which protrudes toward the pixel area and covers at least part of the pixel area.

Owner:SAMSUNG DISPLAY CO LTD

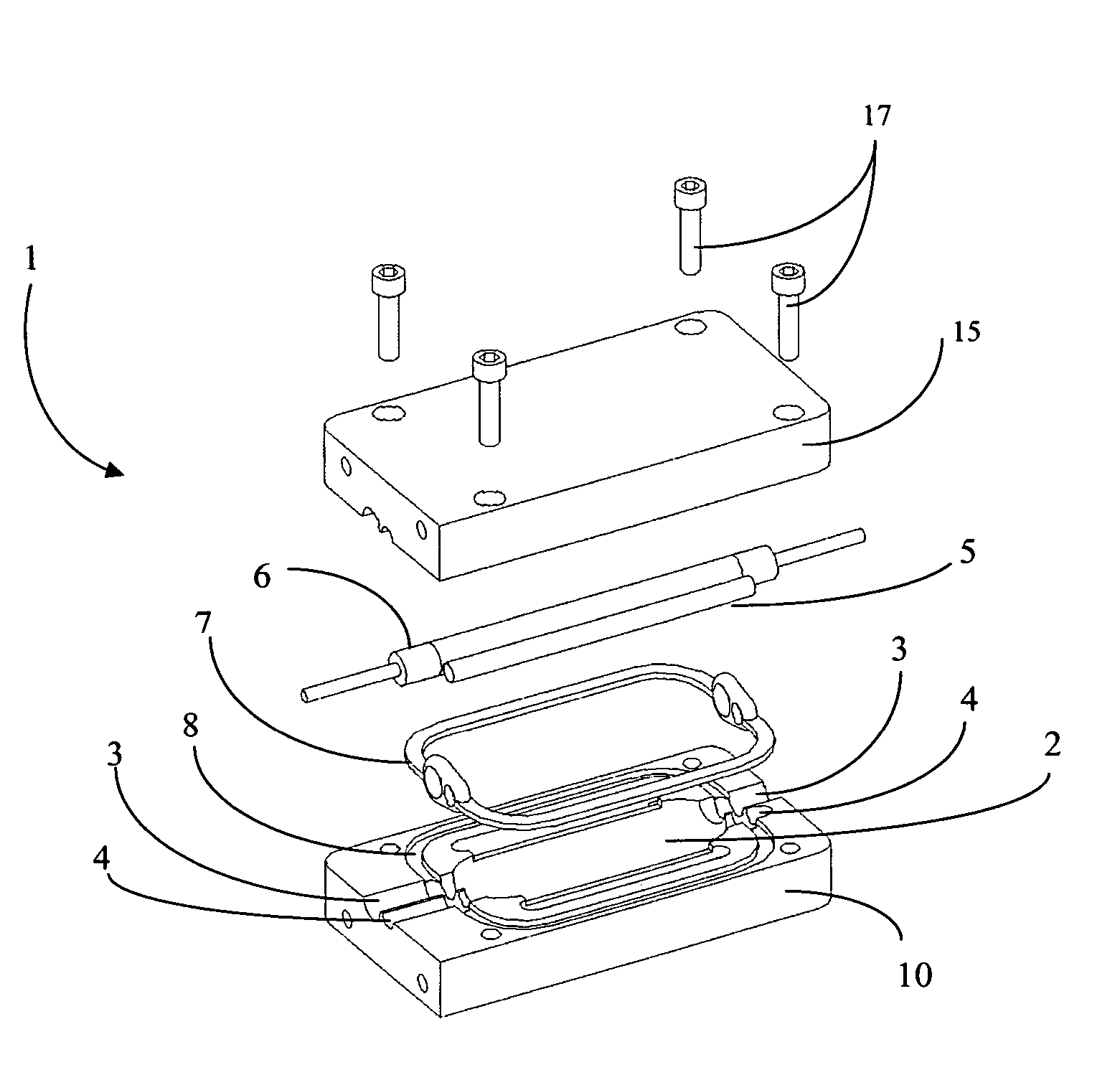

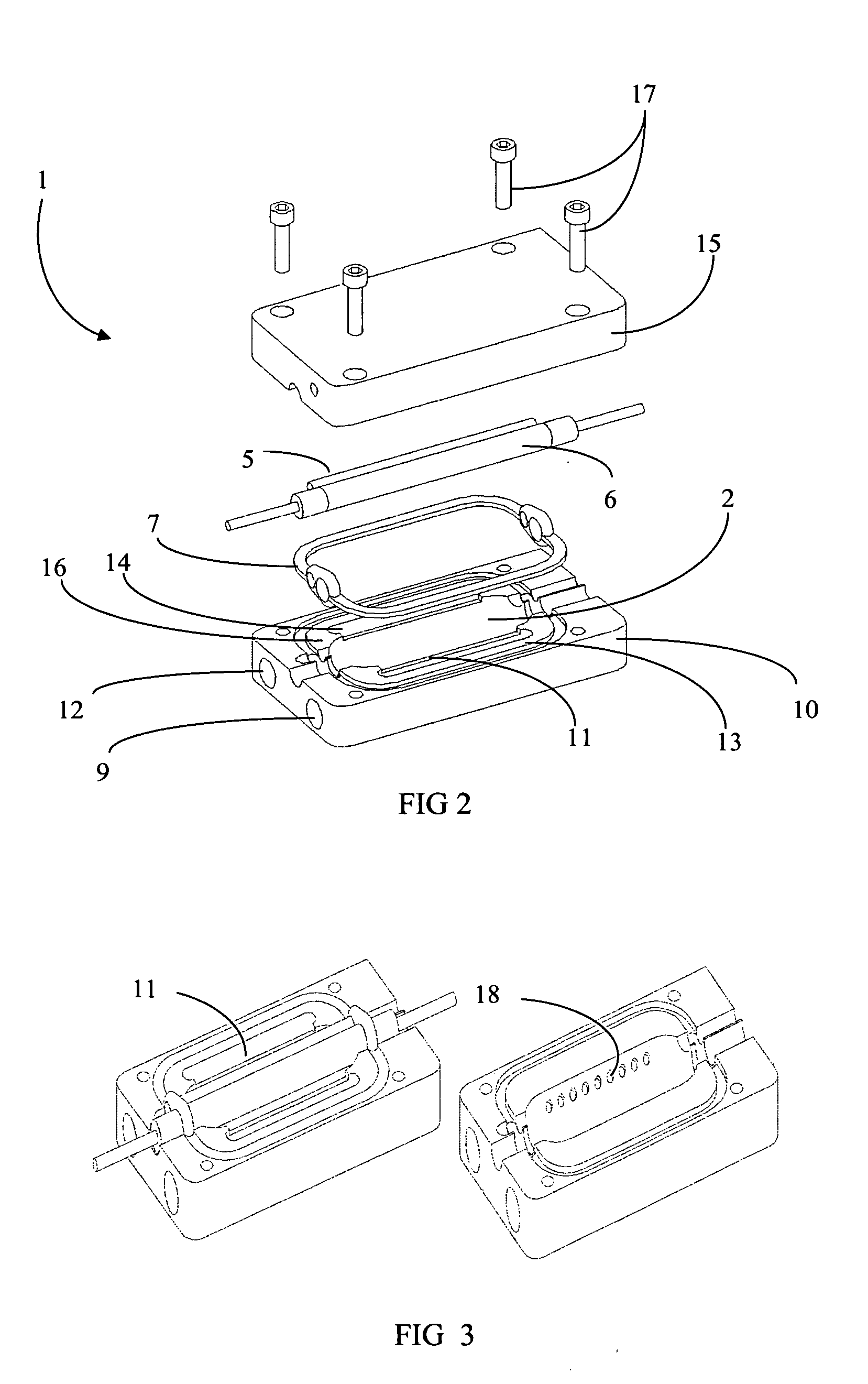

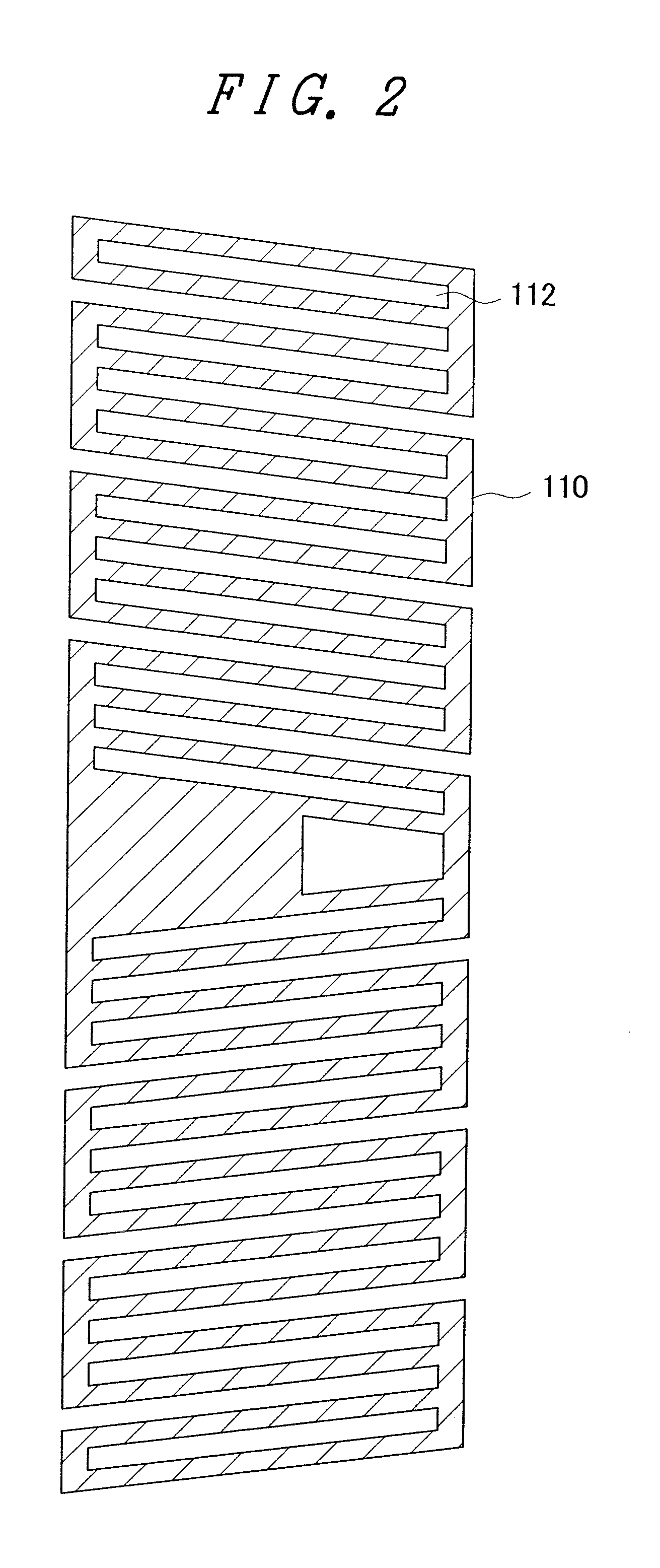

Integrated laser cavity with transverse flow cooling

InactiveUS20050147140A1Improve alignment stabilityIncrease coolant flowLaser cooling arrangementsOptoelectronicsLaser

A laser cavity includes two half shells adapted to be held together forming a sealed, integrated laser structure. The laser cavity is adapted for retaining an excitation source and a lasing medium. At least one coolant passage formed in at least one of the half shells causes liquid to flow transversely over the excitation source and lasing medium. At least one coolant passage formed in at least one of the half shells removes liquid from the laser cavity after the liquid is caused to flow transversely over the excitation source and lasing medium. An inlet formed in at least one of the two half shells can transport liquid into the laser cavity and through the coolant passages. An outlet formed in at least one of the two half shells can remove coolant from the laser cavity after the liquid is caused to flow transversely over the excitation source and lasing medium.

Owner:AIKEN STEPHEN R

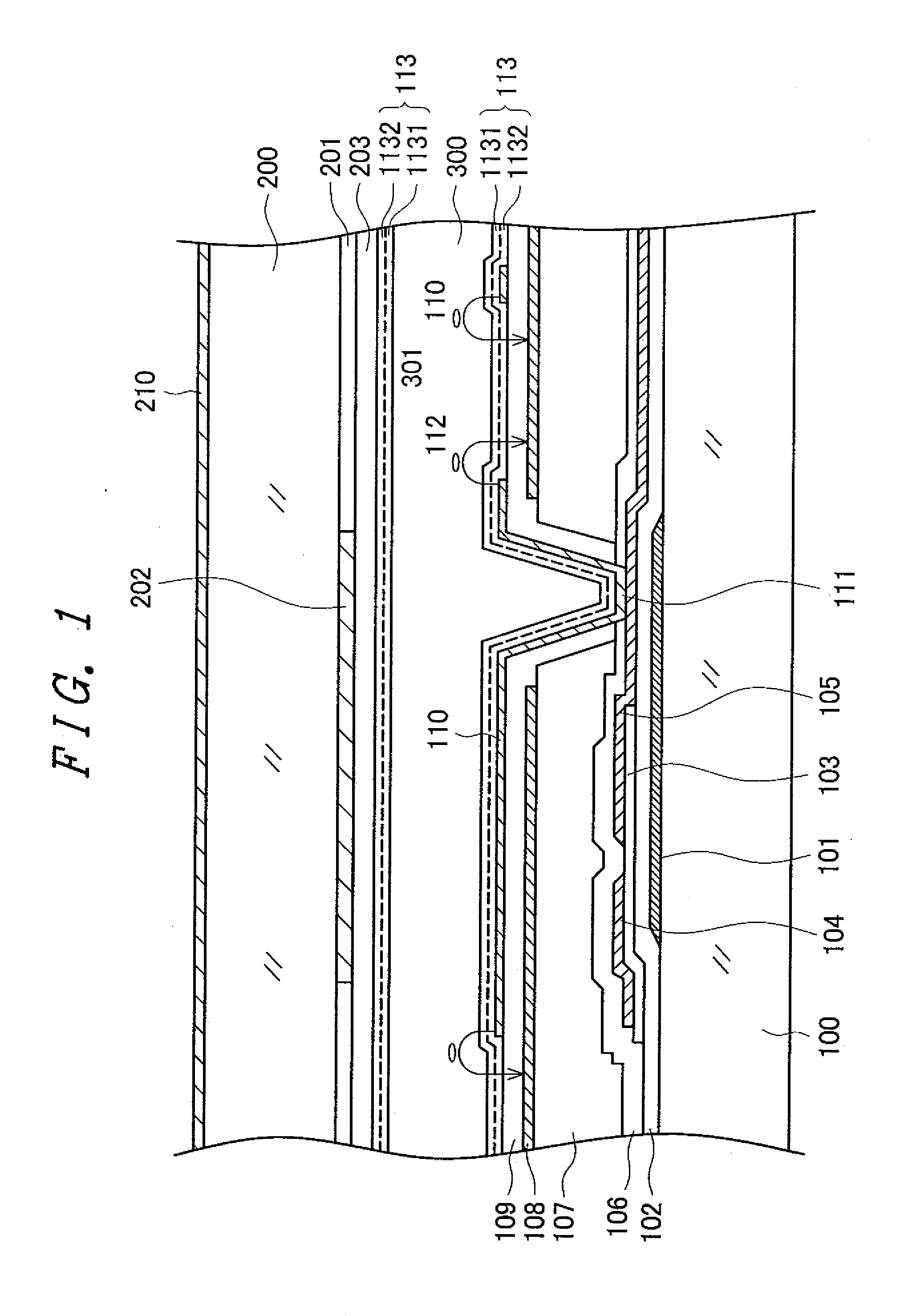

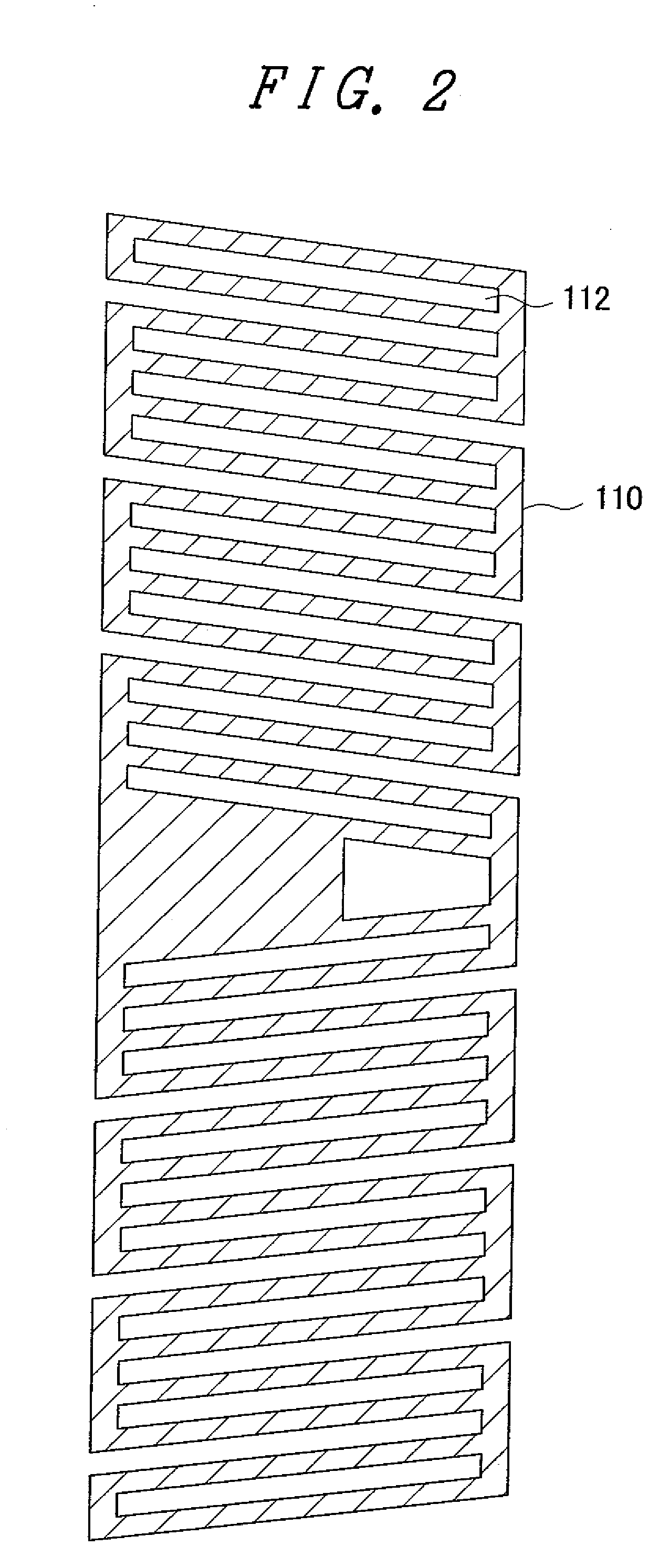

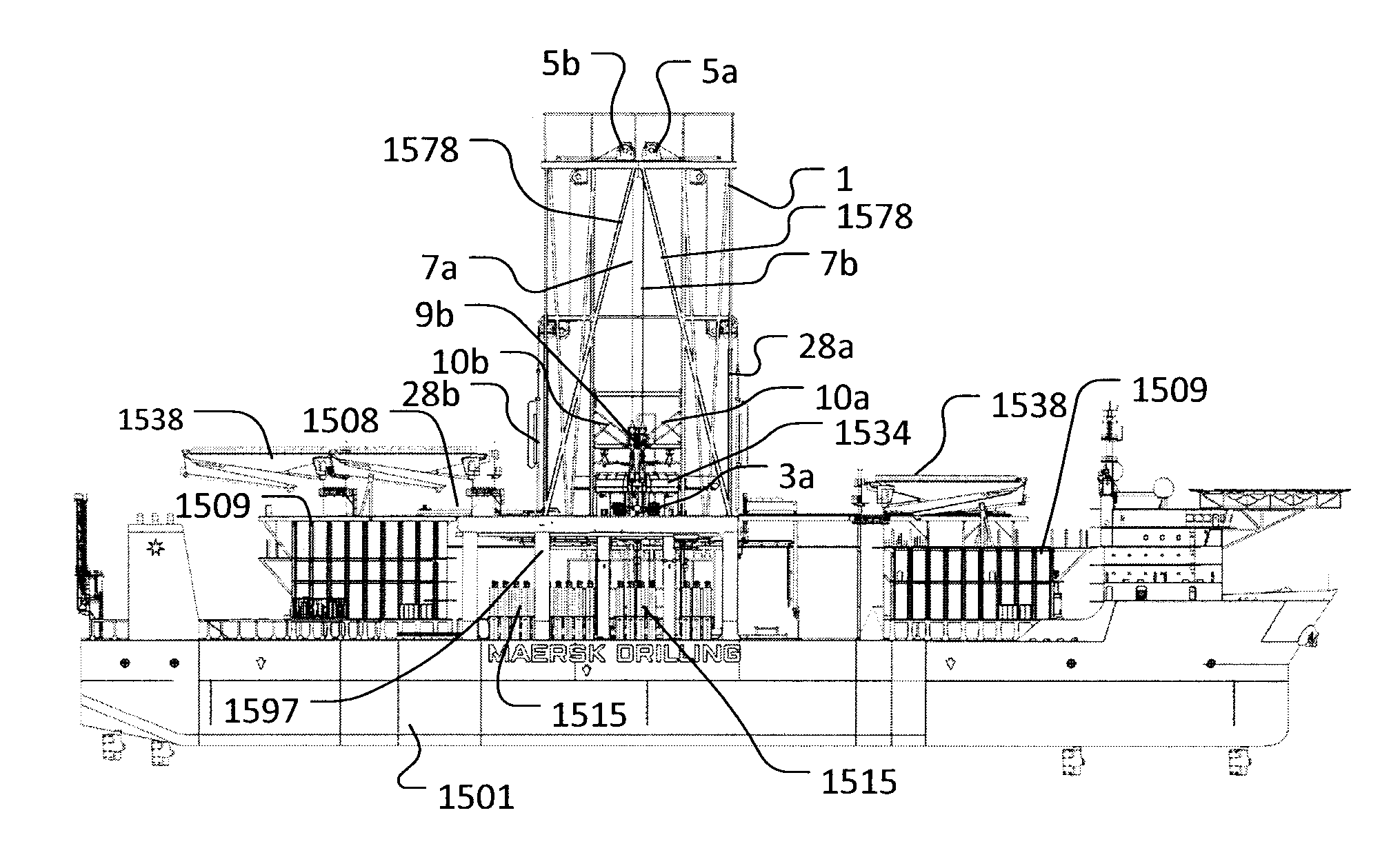

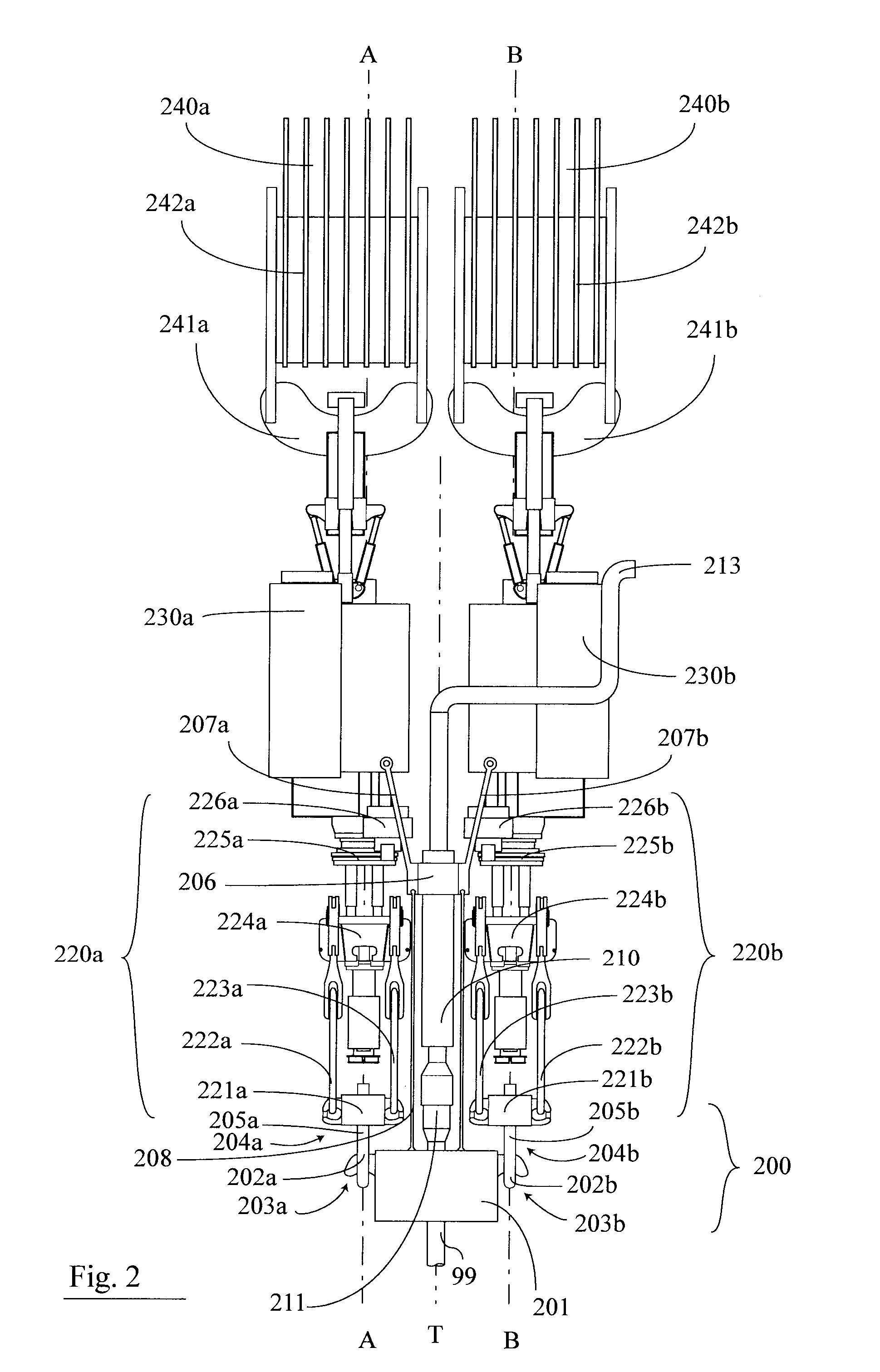

Dual activity off-shore drilling rig

ActiveUS20160090794A1Increase flexibilityImprove alignment stabilityDrilling rodsDerricks/mastsMarine engineeringShore

An offshore drilling rig configured for lowering and / or raising a string of tubular equipment into a subsea borehole. The drilling rig includes a drill deck; a first hoisting system being adapted for raising or lowering a first load carrier along a vertical first hoisting axis, wherein the first hoisting system is supported by a first support structure extending upwardly relative to the drill deck; a second hoisting system being adapted for raising or lowering a second load carrier along a vertical second hoisting axis located apart from the first hoisting axis, wherein the second hoisting system is supported by a second support structure extending upwardly relative to the drill deck; and a joint operations well centre on the drill deck. During joint operations, the first and second hoisting axes are preferably located apart from the joint operations well centre.

Owner:NOBLE DRILLING AS

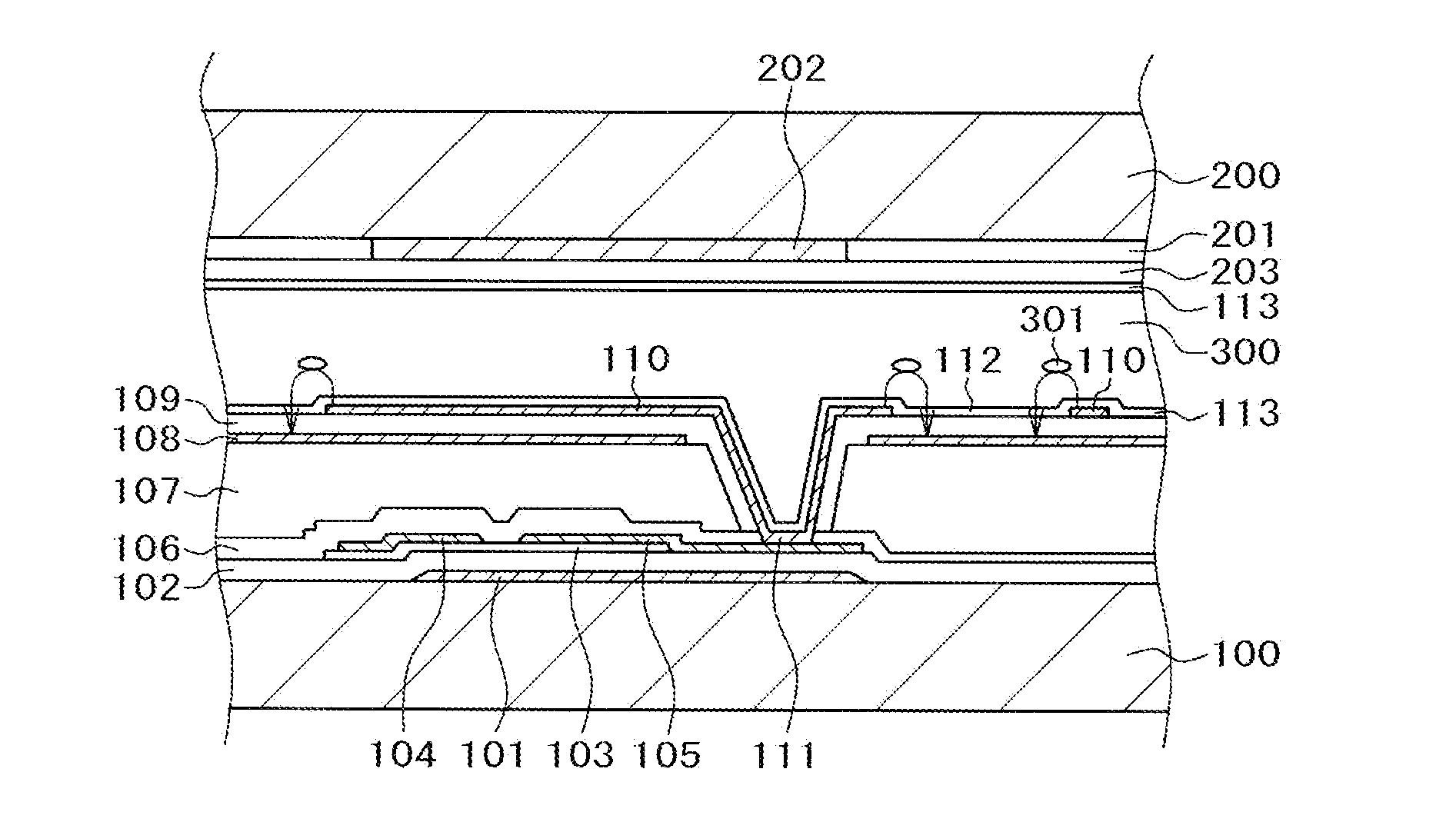

Liquid crystal display device and manufacturing method thereof

ActiveUS20130128187A1Improve image qualityResidual image can be improvedVessels or leading-in conductors manufactureNon-linear opticsLiquid-crystal displayEngineering

A high quality liquid crystal display device has an alignment film with a photoconductive characteristic. Since a region having gate lines situated therebelow does not undergo irradiation of a backlight, no photoconductive effect can be obtained. A photoresist is disposed below the alignment film situated over the gate lines in order to transfer the charges in the region to an opening portion of the alignment film in an early stage. Since the photoresist has a thickness of about 1.5 μm, which is 20 times or more the 70 nm thickness of the alignment film, the resistance in the lateral direction is low in a portion where the photoresist is present. Accordingly, since the charges on the alignment film present over the gate line transfer to the opening portion of the alignment film and are eliminated in an early stage, the residual image is eliminated in the early stage.

Owner:JAPAN DISPLAY INC

Liquid crystal display device

ActiveUS8497002B2Shorten the disappearance timeLong stabilityLiquid crystal compositionsLayered productsLiquid-crystal displayPolyamide

An alignment film is given a 2-layer structure comprising a photoalignment film that is photoalignable and a low-resistivity alignment film whose resistivity is smaller than that of the photoalignment film. The photoalignment film is formed by a polyimide whose precursor is polyamide acid alkyl ester, the number molecular weight of the photoalignment film is large, and the stability of alignment of the photoalignment film by photoalignment is excellent. The low-resistivity alignment film is formed by a polyimide whose precursor is polyamide acid, the number molecular weight of the low-resistivity alignment film is small, and the resistivity of the low-resistivity alignment film is small. The 2-layer structure alignment film can be maintaining an excellent photoalignment characteristic, so DC afterimages can be controlled.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA +1

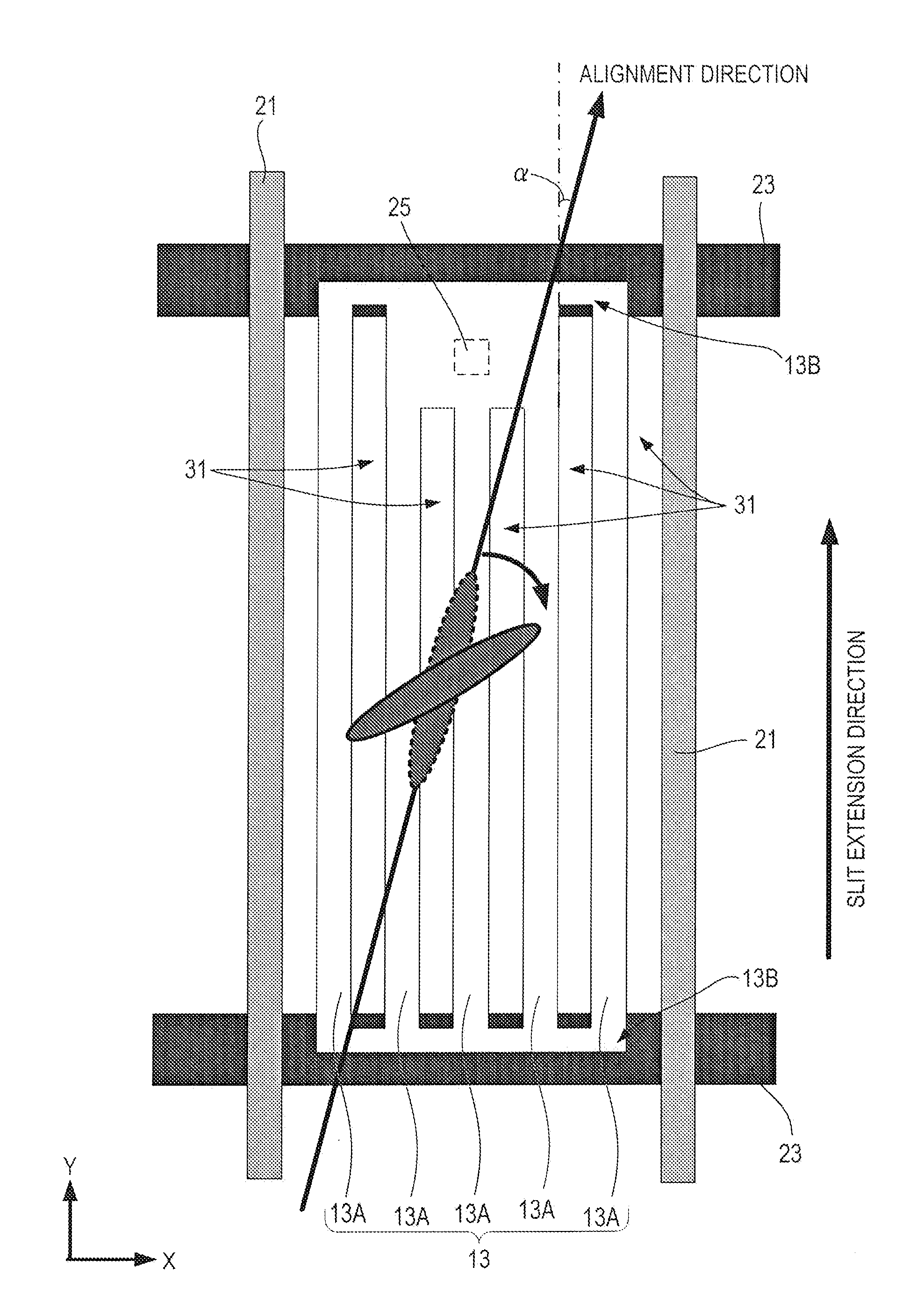

Liquid crystal panel and electronic apparatus

ActiveUS20140232973A1Improve alignment stabilityStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal panel includes: first and second substrates arranged to be opposite each other at a predetermined gap; a liquid crystal layer filled between the first and second substrates; alignment films; a counter electrode pattern formed on the first substrate; and a pixel electrode pattern formed on the first substrate so as to have a plurality of electrode branches, the extension direction of which is bent at one bend point provided near an upper pixel portion from the center of a pixel region, and which are connected at the end portion of at least the upper pixel portion or lower pixel portion, wherein the extension direction of a slit formed near the upper pixel portion from the bend point from among slits formed in the pixel electrode pattern crosses the alignment direction of the liquid crystal layer at an angle of 7° or larger.

Owner:JAPAN DISPLAY INC

Liquid crystal display device

ActiveUS20130300967A1Shorten the disappearance timeLong stabilityLiquid crystal compositionsLayered productsLiquid-crystal displayPolyamide

An alignment film is given a 2-layer structure comprising a photoalignment film that is photoalignable and a low-resistivity alignment film whose resistivity is smaller than that of the photoalignment film. The photoalignment film is formed by a polyimide whose precursor is polyamide acid alkyl ester, the number molecular weight of the photoalignment film is large, and the stability of alignment of the photoalignment film by photoalignment is excellent. The low-resistivity alignment film is formed by a polyimide whose precursor is polyamide acid, the number molecular weight of the low-resistivity alignment film is small, and the resistivity of the low-resistivity alignment film is small. The 2-layer structure alignment film can be maintaining an excellent photoalignment characteristic, so DC afterimages can be controlled.

Owner:JAPAN DISPLAY INC

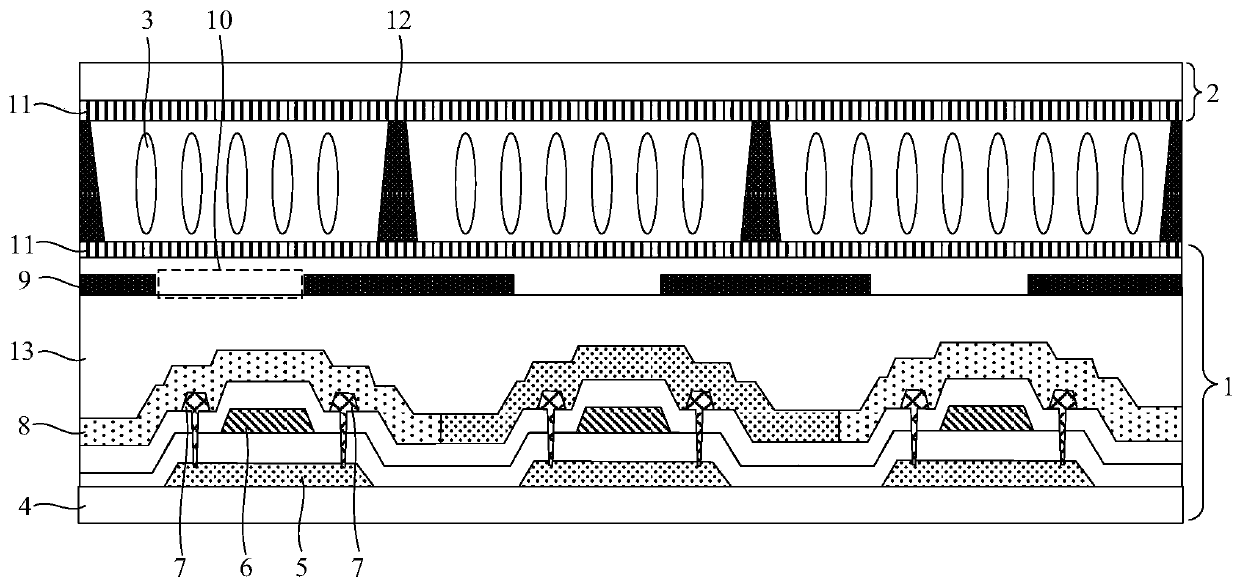

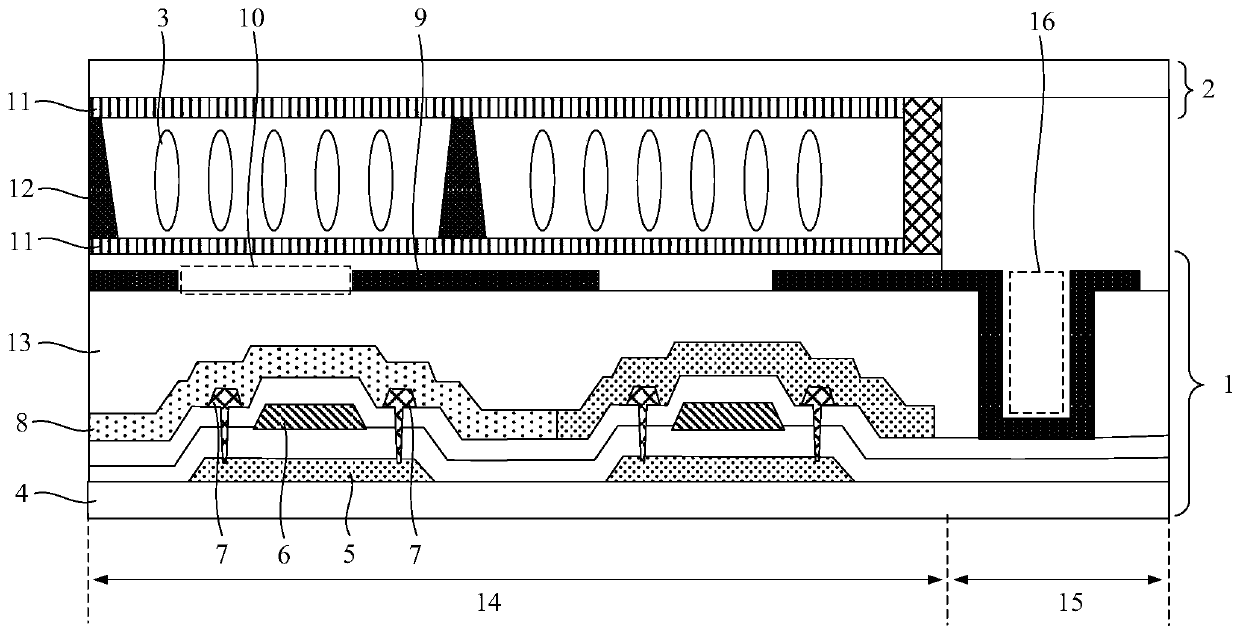

Low-temperature polycrystalline silicon display panel, manufacturing method thereof and liquid crystal display device

ActiveCN111367128AImprove light leakageIncrease opening ratioNon-linear opticsInput/output processes for data processingLiquid-crystal displayColor film

The embodiment of the invention provides a low-temperature polycrystalline silicon display panel, a manufacturing method of the low-temperature polycrystalline silicon display panel and a liquid crystal display device, relates to the technical field of display, and effectively improves a metal light leakage phenomenon on the premise of ensuring relatively high display performance. The low-temperature polycrystalline silicon display panel comprises an array substrate and a box aligning substrate which are oppositely arranged, and liquid crystals filled between the array substrate and the box aligning substrate. The array substrate comprises a substrate body, and a low-temperature polycrystalline silicon active layer, a grid electrode layer and a source and drain electrode layer are sequentially arranged on the substrate body in the light emitting direction. The low-temperature polycrystalline silicon display panel further comprises a color film layer, the color film layer being arrangedon the array substrate, and the color film layer being located on the side, back on to the substrate, of the source-drain electrode layer; a shading layer, used for limiting an opening area of the low-temperature polycrystalline silicon display panel, at least part of the shading layer being arranged on the array substrate, and the shading layer on the array substrate being located on the side, back on to the substrate, of the source-drain electrode layer.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Polymer composition having photoalignable group, liquid crystal alignment film formed of the polymer composition, and optical device having phase difference plate formed of the liquid crystal alignment film

InactiveUS20150322346A1High sensitivityImprove Optical UniformityLiquid crystal compositionsPolarising elementsCrystallographyMaterials science

To provide a photoalignable material that can yield a photoalignable film having a high optical uniformity and no alignment defect, and is excellent in sensitivity to allow photoalignment even with exposure in a short period of time, and a liquid crystal alignment film having a high alignment stability of a liquid crystal compound from the photoalignable material. A photoalignable polymer composition containing a specific photoalignable polymer and a specific polymer that is reactive with the photoalignable polymer is manufactured, and the photoalignable film is manufactured by applying the polymer composition onto a base material or the like, drying the applied composition thereon, and irradiating the dried composition with light. Furthermore, the liquid crystal alignment film is manufactured by allowing alignment of molecules of the liquid crystal compound in the photoalignment film.

Owner:JNC CORP +1

Light absorption layer for a display device

ActiveUS8149357B2Improve alignment stabilityAvoid alignmentLiquid crystal compositionsThin material handlingLiquid-crystal displayDisplay device

A liquid crystal display is presented. The liquid crystal display includes: a first substrate; a pixel electrode formed on the first substrate; a first alignment layer formed on the pixel electrode; a second substrate facing the first substrate; a common electrode formed on the second substrate; a second alignment layer formed on the common electrode; a liquid crystal layer formed between the first alignment layer and the second alignment layer; and a light absorption layer formed between the first substrate and the first alignment layer, or the second substrate and the second alignment layer, wherein the light absorption layer absorbs light having a UV wavelength between about 280 nm and about 450 nm.

Owner:SAMSUNG DISPLAY CO LTD

Centering unit for aligning at least two grouped vessels and method for aligning two grouped vessels

InactiveUS8935903B2Improve convenienceImprove alignment stabilityRotary pressesButter manufactureEngineeringStructural engineering

Owner:KRONES AG

Polymer composition having photoalignable group, liquid crystal alignment film formed of the polymer composition, and liquid crystal display device having phase difference plate formed of the liquid crystal alignment film

InactiveUS8867002B2High sensitivityImprove Optical UniformityLiquid crystal compositionsPolarising elementsLiquid-crystal displayPhase difference

Owner:JNC CORP +1

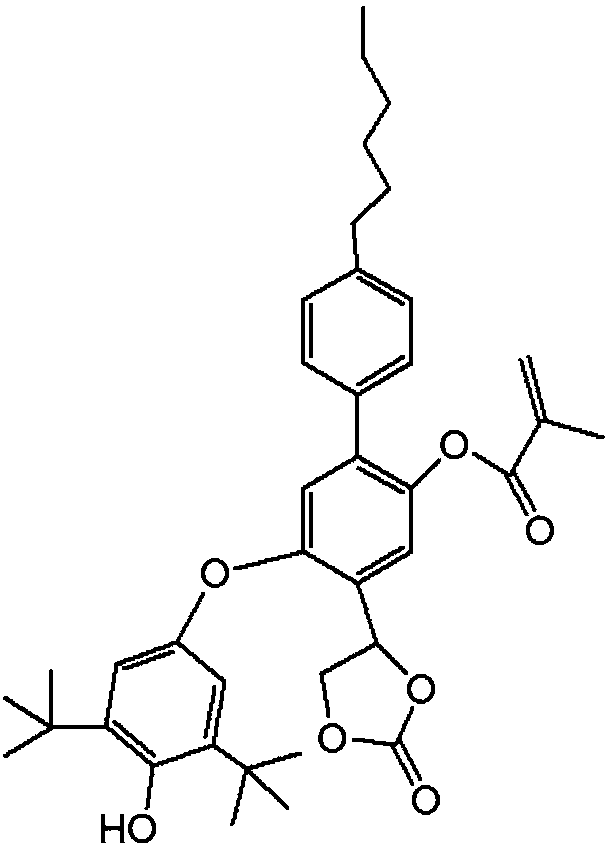

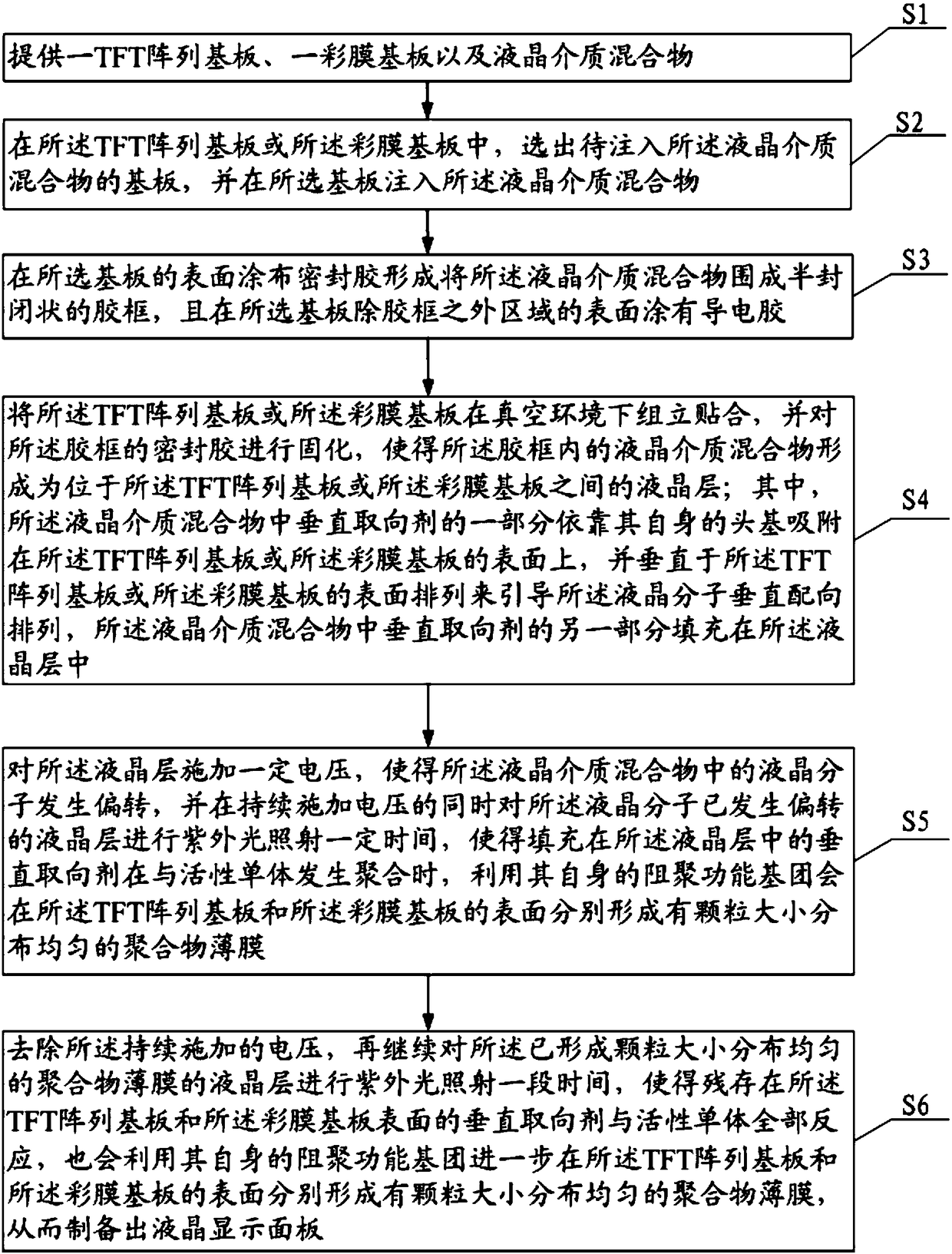

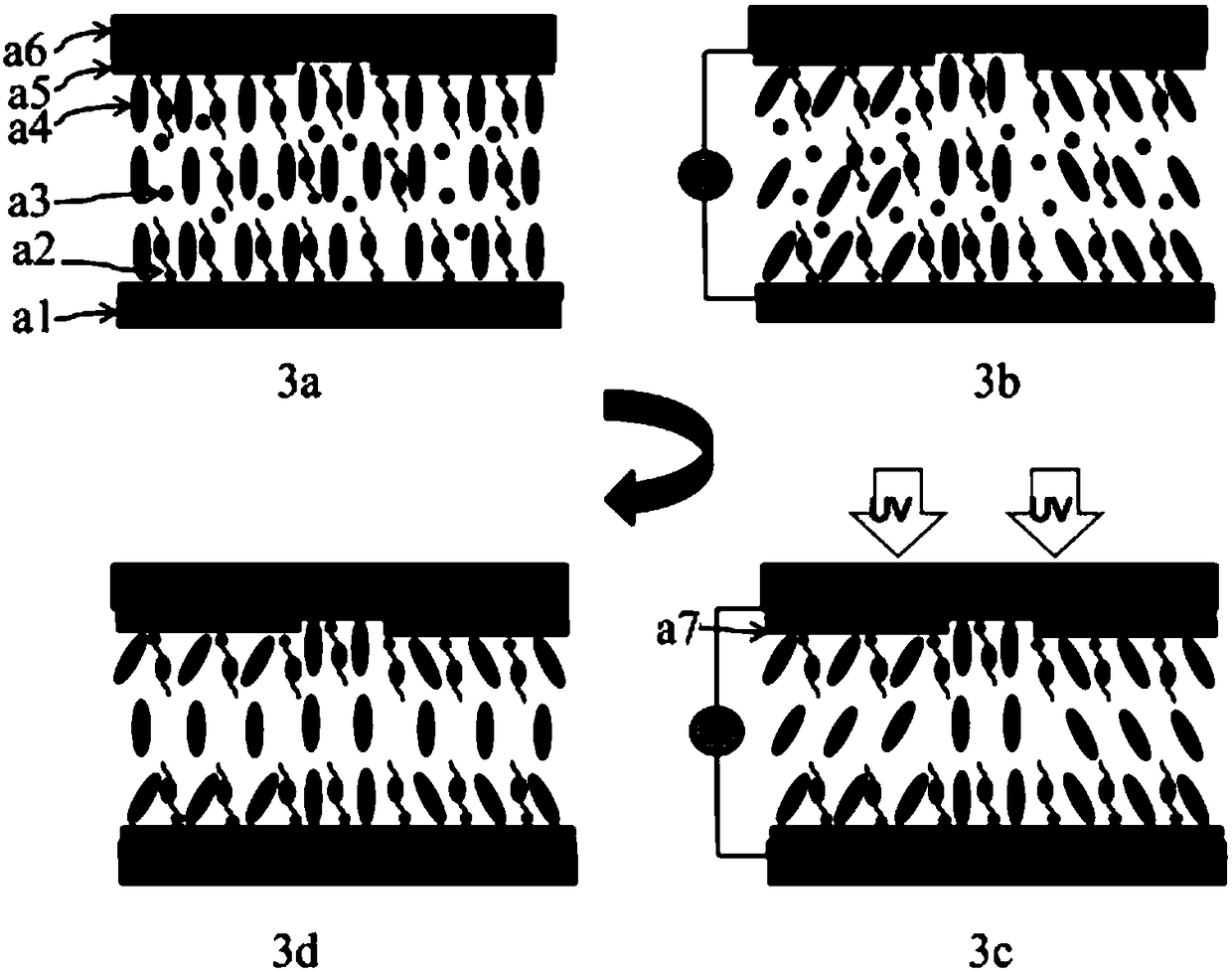

Liquid crystal medium mixture, liquid crystal display panel and preparation method of liquid crystal display panel

InactiveCN108559528AReduce reactivityUniform size distributionLiquid crystal compositionsNon-linear opticsMiddle groupFunction group

The invention provides a liquid crystal medium mixture which comprises liquid crystal molecules, an active monomer and a vertical orientation agent, wherein the vertical orientation agent comprises ahead group, a middle group, a tail group, a polymerization group and a polymerization inhibition function group; the head group is anchored on the surface of a substrate of a liquid crystal display panel, and then a vertical orientation function on the liquid crystal molecules can be achieved; the middle group and the tail group are used for leading liquid crystal molecule arrangement; the polymerization group is used for forming a polymer granule membrane layer under ultrasonic light radiation, and then the liquid crystal molecules have pretilt angles. Due to adoption of the polymerization inhibition function group, polymer granules formed under ultrasonic light radiation are uniform in size distribution by reducing reaction activity of the polymerization group, then broke bright points can be reduced, and the surface capability of the substrate of the anchored liquid crystal display panel can be improved. By adopting the liquid crystal medium mixture, the anchoring capability of thevertical orientation agent in the liquid crystal layer and the uniformity of the polymer granules formed through polymerization reactions under UV (Ultraviolet) radiation can be improved, then the liquid crystal orientation stability can be improved, and phenomena of dark states and easy light leakage can be avoided.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

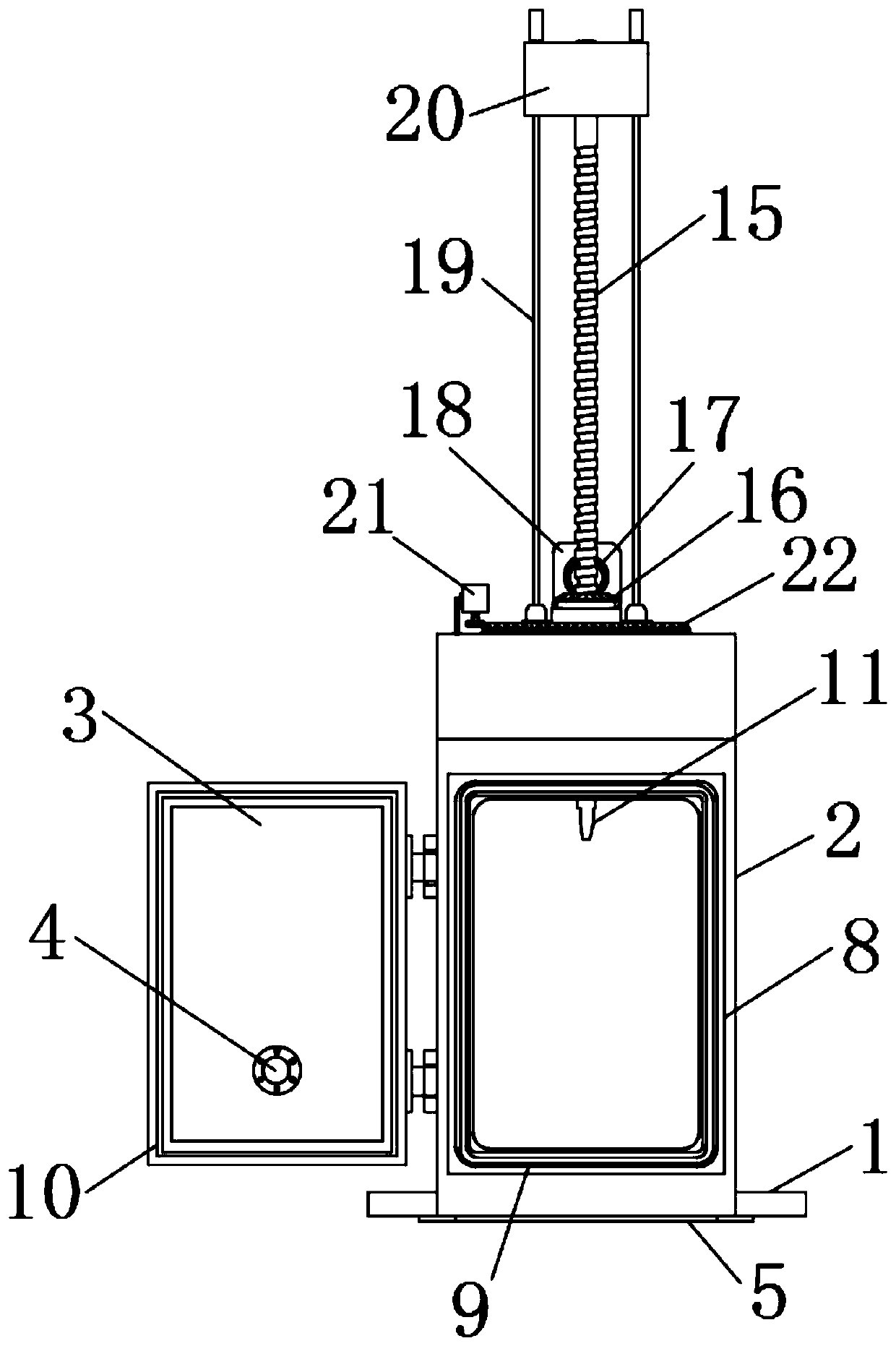

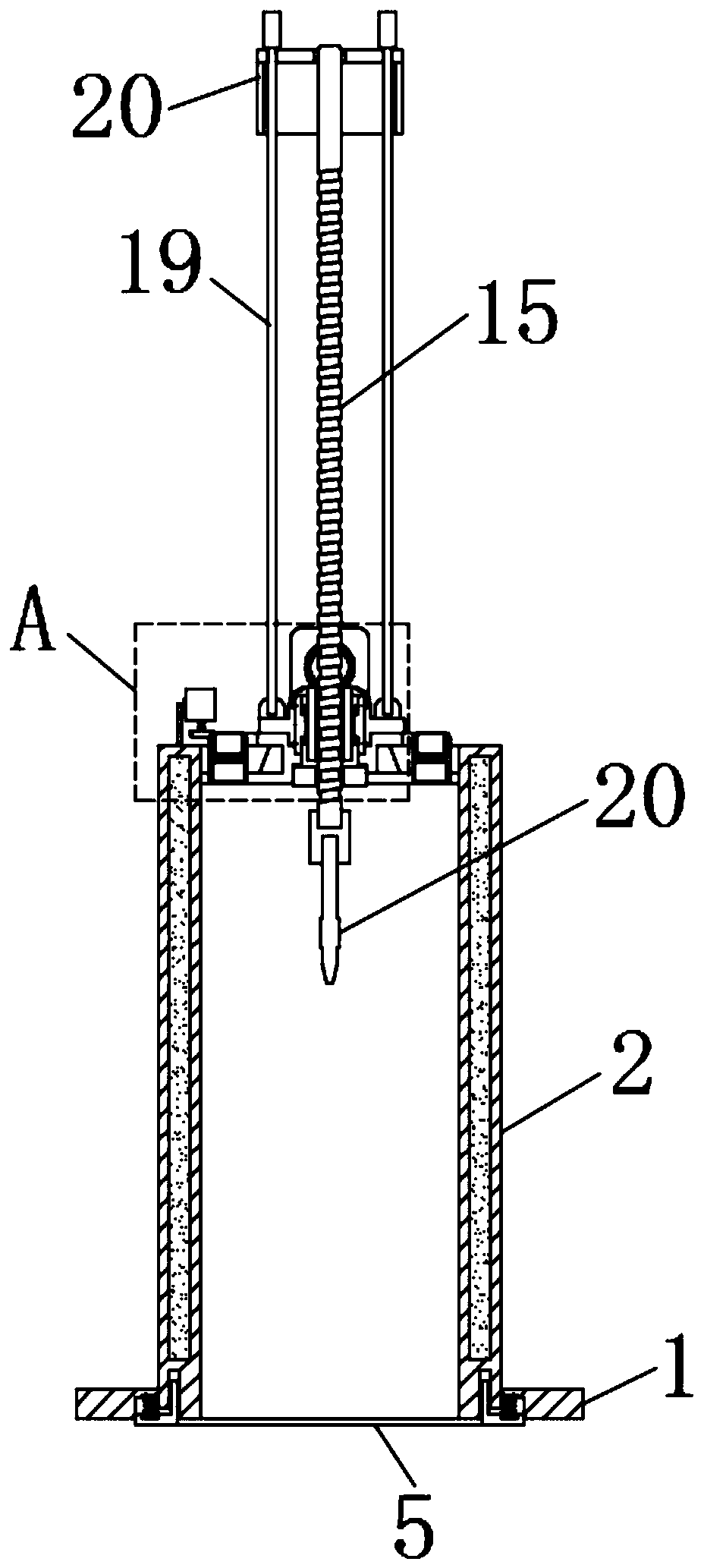

Novel semiconductor crystal bar arrangement forming die

InactiveCN111379030AImprove yieldImprove stabilityAfter-treatment apparatusPolycrystalline material growthPhysicsElectric machinery

The invention discloses a novel semiconductor crystal bar arrangement forming die. The die comprises a base, a mold box, a seed crystal, a first stepping motor and a second stepping motor, the mold box is welded to the upper surface of the base, and a box door is connected to the outer surface of the front end of the mold box through hinges. A protective cover is fixed to the top end of the mold box through screws. Air inlet pipes are fixed to the two sides of the protective cover through screws. A fixed seat is fixed on the upper surface of the mold box through screws; a screw sleeve is arranged on the inner side of the fixed seat in a penetrating manner; the inner side of the screw sleeve is connected with a screw sleeve through a bearing; a screw rod is arranged on the inner side of thescrew sleeve in the penetrating mode, the bottom end of the screw rod is sleeved with a permanent magnet ring, the top end of the screw sleeve is sleeved with a driven bevel gear, the outer surface of the driven bevel gear is meshed with a driving bevel gear, a guide rod is fixed to the upper surface of the fixing base, and the top end of the screw rod is sleeved with an electromagnetic disc. Thearrangement stability is improved, and the crystal bar forming yield is increased.

Owner:朱雪玉

Low-temperature polysilicon display panel, manufacturing method thereof, and liquid crystal display device

ActiveCN111367128BImprove light leakageIncrease opening ratioNon-linear opticsInput/output processes for data processingLiquid-crystal displayEngineering

Embodiments of the present invention provide a low-temperature polysilicon display panel, a manufacturing method thereof, and a liquid crystal display device, which relate to the field of display technology and effectively improve metal light leakage on the premise of ensuring high display performance. The above-mentioned low-temperature polysilicon display panel includes: an array substrate and a box substrate arranged oppositely, and a liquid crystal filled between the array substrate and the box substrate; wherein, the array substrate includes a base substrate, and the base substrate is sequentially arranged along the light emitting direction. Low-temperature polysilicon active layer, gate layer, and source-drain layer; the low-temperature polysilicon display panel also includes: a color filter layer, the color filter layer is arranged on the array substrate, and the color filter layer is located on the side of the source-drain layer facing away from the substrate substrate Side: light-shielding layer, the light-shielding layer is used to limit the opening area of the low-temperature polysilicon display panel, at least part of the light-shielding layer is provided on the array substrate, and the light-shielding layer on the array substrate is located on the side of the source-drain layer facing away from the base substrate.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Steel ingot mold for steel ingot pouring

The invention relates to the technical field of pouring equipment, and discloses a steel ingot mold for steel ingot pouring. The steel ingot mold comprises a body, a pouring cavity is formed in the top face of the body, a transverse plate is fixedly connected to the side face of the body, a threaded rod is fixedly connected to the top face of the transverse plate, the outer surface of the threadedrod is movably sleeved with a connecting plate, a mark plate is fixedly connected to the side face of the connecting plate, the mark plate is located inside the pouring cavity, and a sleeve plate isfixedly connected to the bottom face of the connecting plate. According to the steel ingot mold for steel ingot pouring, the transverse plate is fixedly connected to the side face of the body, the threaded rod is fixedly connected to the top face of the transverse plate, the outer surface of the threaded rod is sleeved with the connecting plate, the side face of the connecting plate is fixedly connected with the mark plate, the connecting plate is controlled to slide up and down by rotating an adjusting cap, the mark plate slides up and down along the side face of the pouring cavity, and is used for marking the pouring height, the control effect is improved, the size accuracy of steel ingot pouring is improved, and the using effect is good.

Owner:LIANFENG STEEL (ZHANGJIAGANG) CO LTD

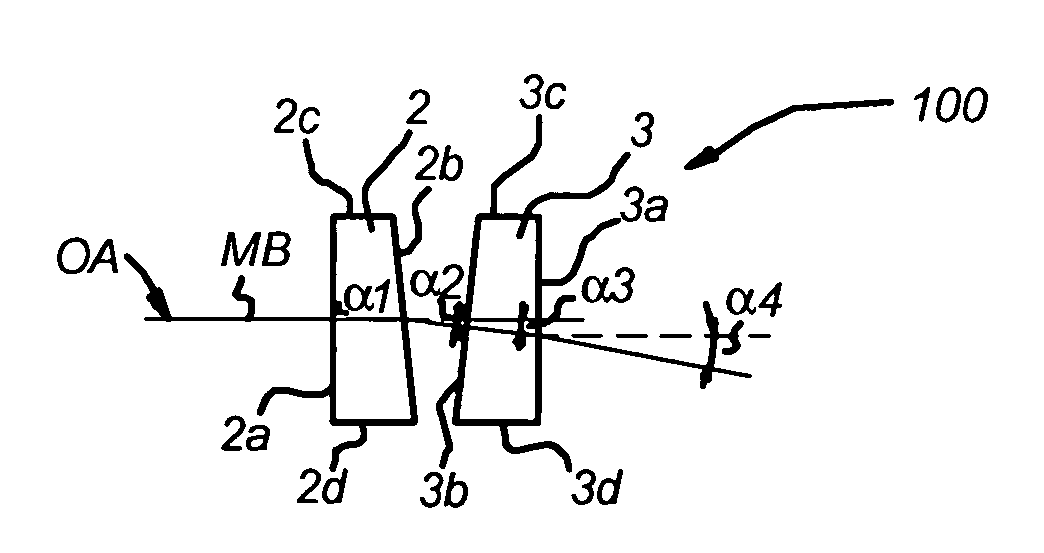

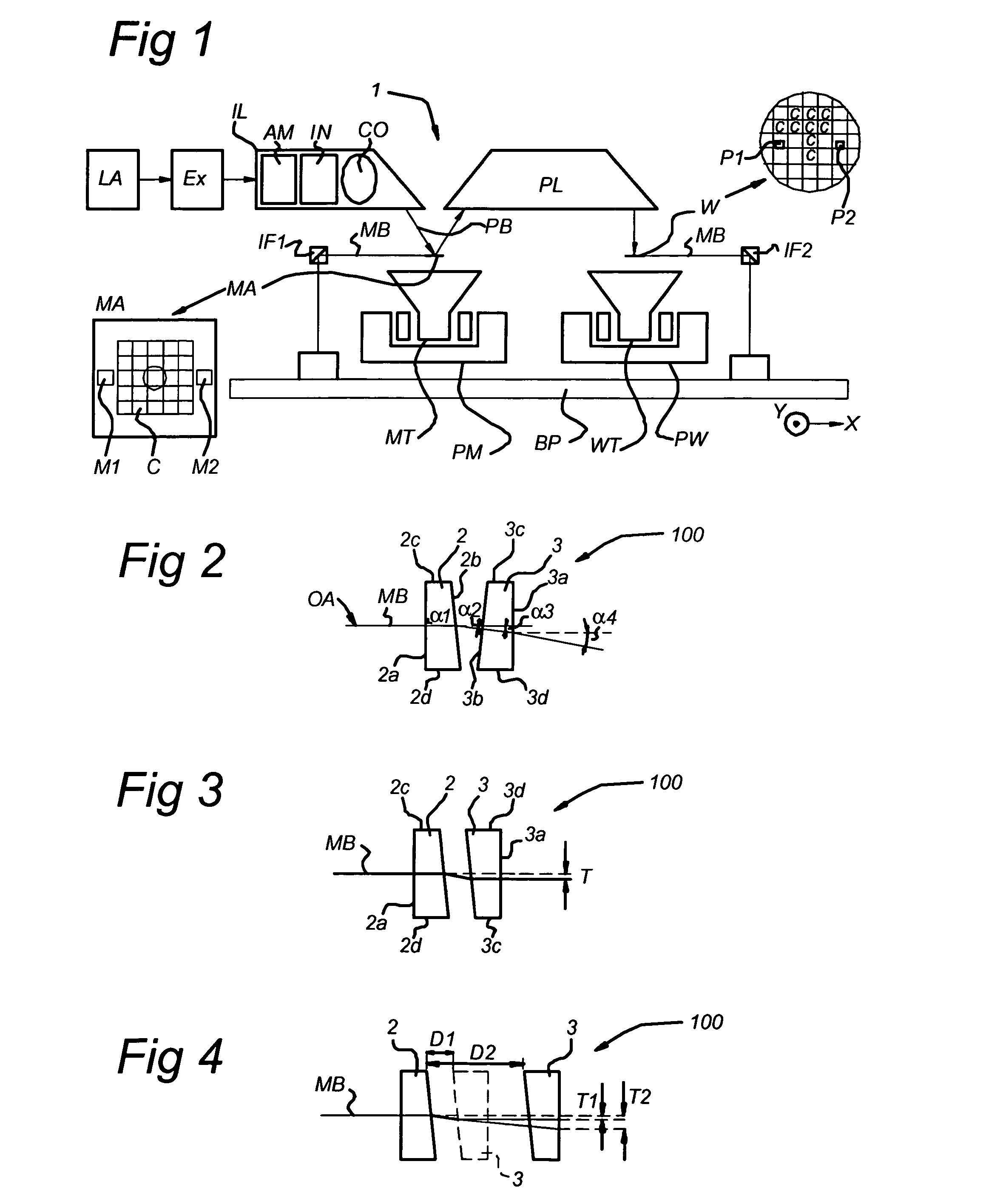

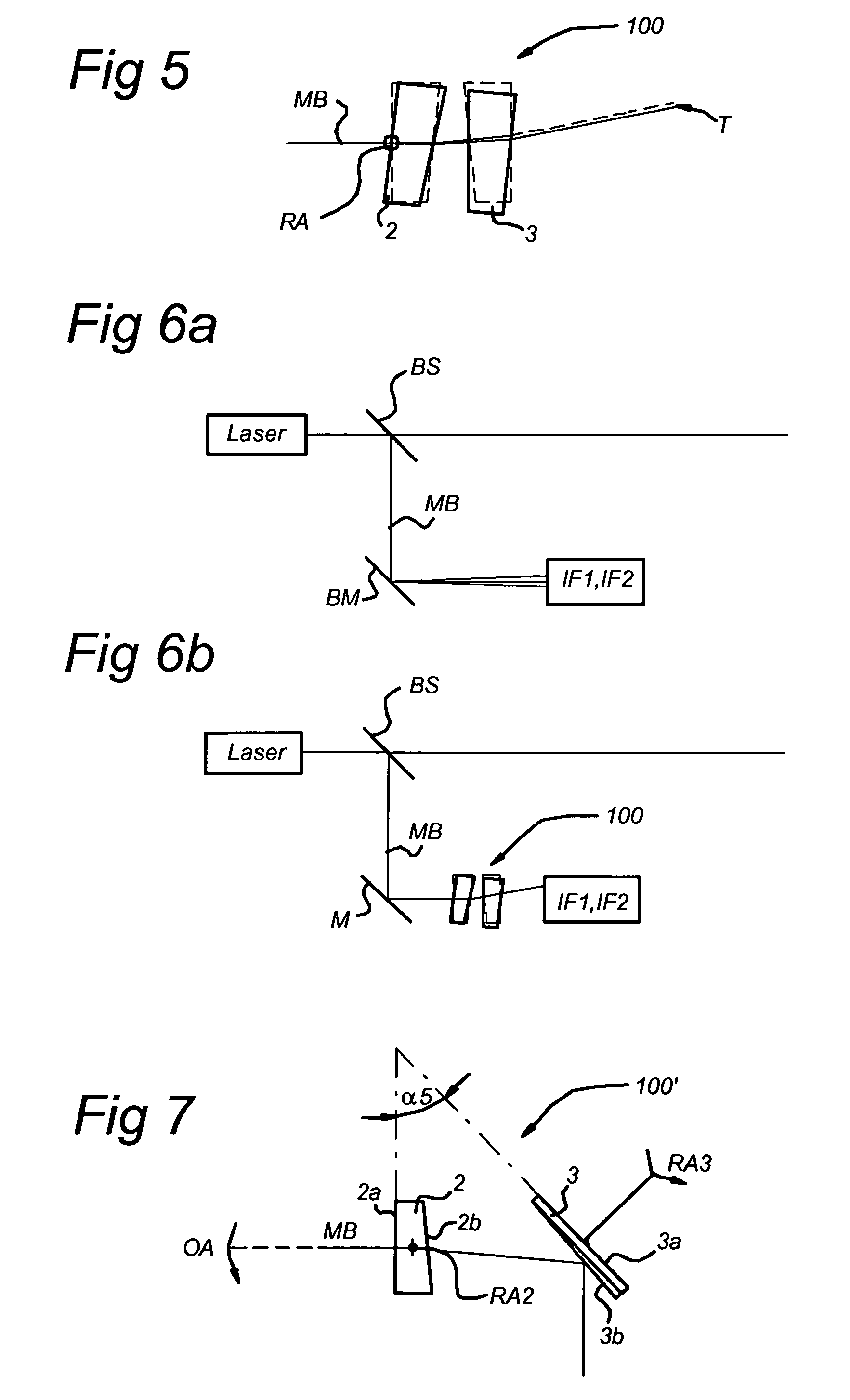

Device and method for manipulation and routing of a metrology beam

ActiveUS7177059B2Improve stabilityImprove alignment stabilityPrismsSemiconductor/solid-state device manufacturingMetrologyOptical axis

A lithographic projection apparatus is equipped with a device for manipulation and routing of at least one portion of a metrology beam of radiation. The device includes a first and a second optical wedge, wherein the second optical wedge and the first optical wedge having a relative position with respect to each other. The at least one portion of the metrology beam enters the device along an incoming optical axis at a first major surface of the first optical wedge, passes through the first and second optical wedges, and exits at a second major surface of the second optical wedge. The first and second optical wedges are arranged to at least one of rotate and translate the at least one portion of the metrology beam relative to the incoming optical axis by changing the relative position of the first and the second optical wedges.

Owner:ASML NETHERLANDS BV

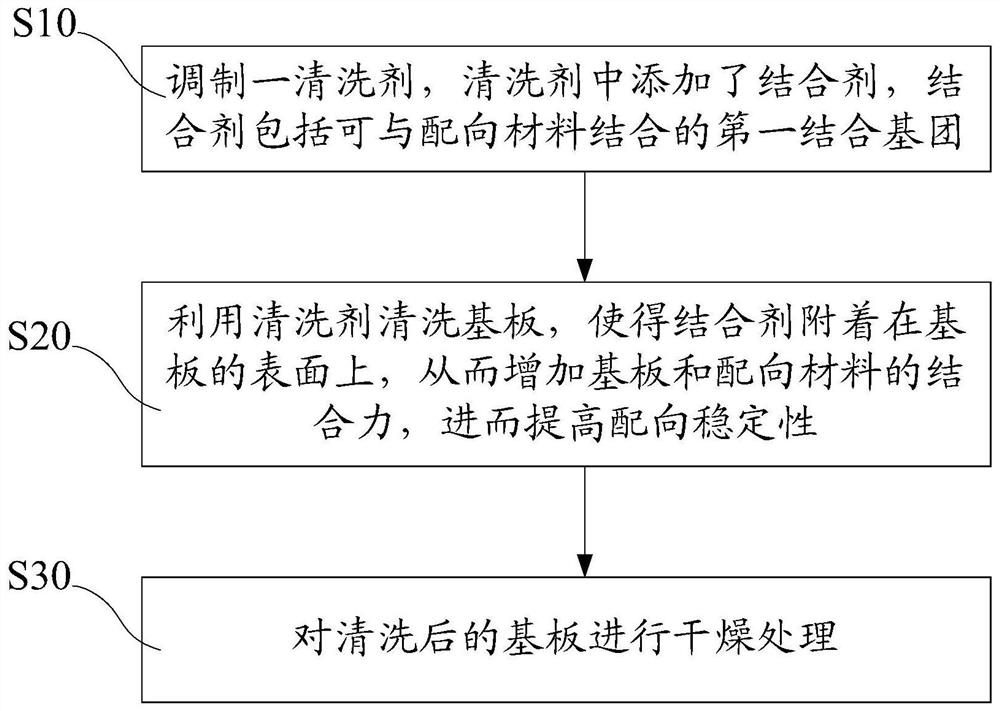

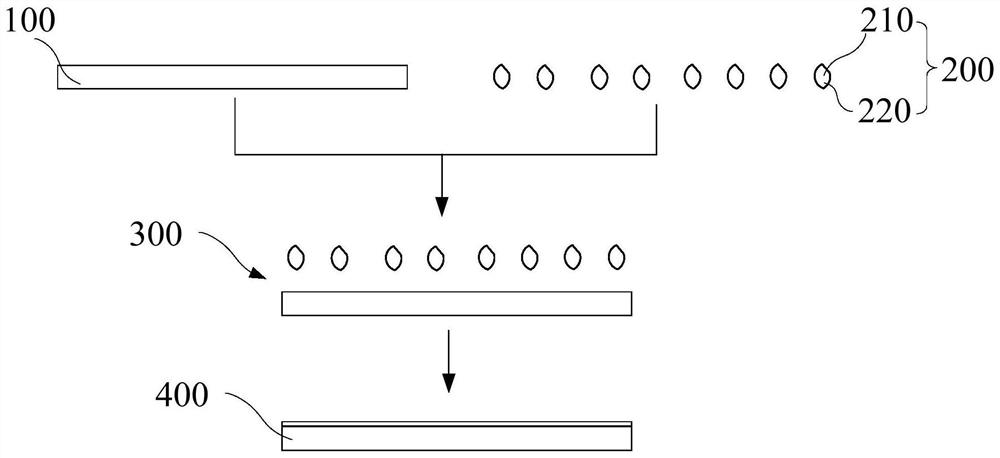

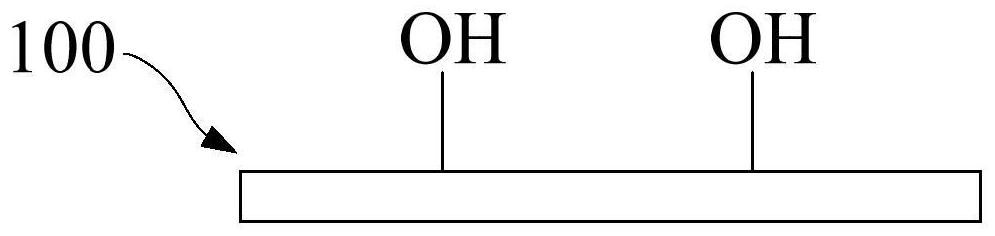

A kind of processing method of self-orientation liquid crystal display panel and its substrate

ActiveCN108333837BSolve uneven brightnessImprove bindingNon-linear opticsCrystallographyMaterials science

The application discloses a self-aligned liquid crystal display panel and a processing method thereof. Alignment material is added to liquid crystal molecules. The processing method comprises: a cleaning agent is prepared, the bonding agent is added to the cleaning agent, and the bonding agent comprises a first binding group which can be combined with the alignment material; the substrate is cleaned with the cleaning agent so that the bonding agent adheres to the surface of the substrate, thereby increasing the bonding force between the substrate and the alignment material, thereby improving the alignment stability; the cleaned substrate is dried. The bonding agent attached to the surface of the substrate is combined with the alignment material to increase the bonding force between the substrate and the alignment material, thereby improving the alignment stability.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

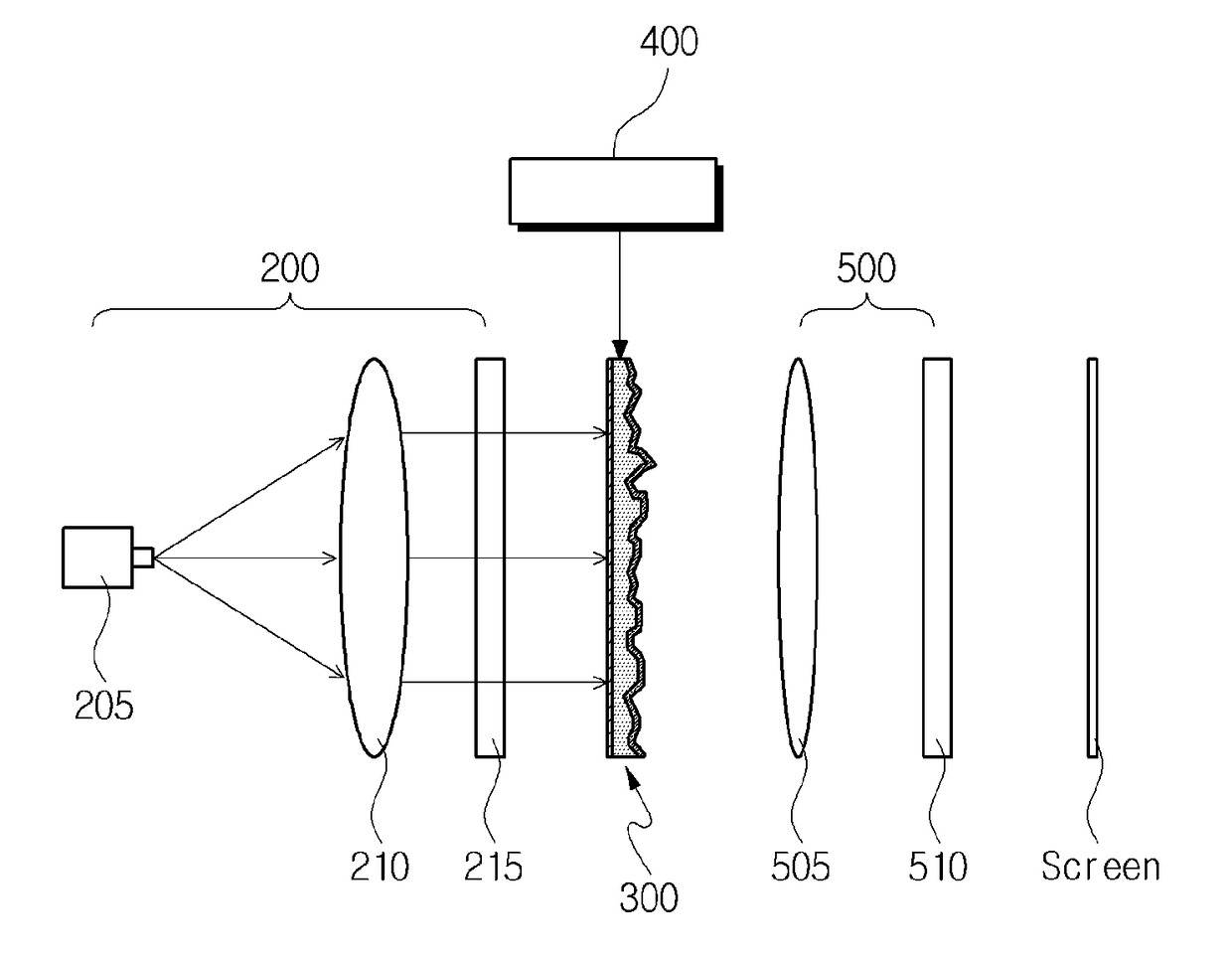

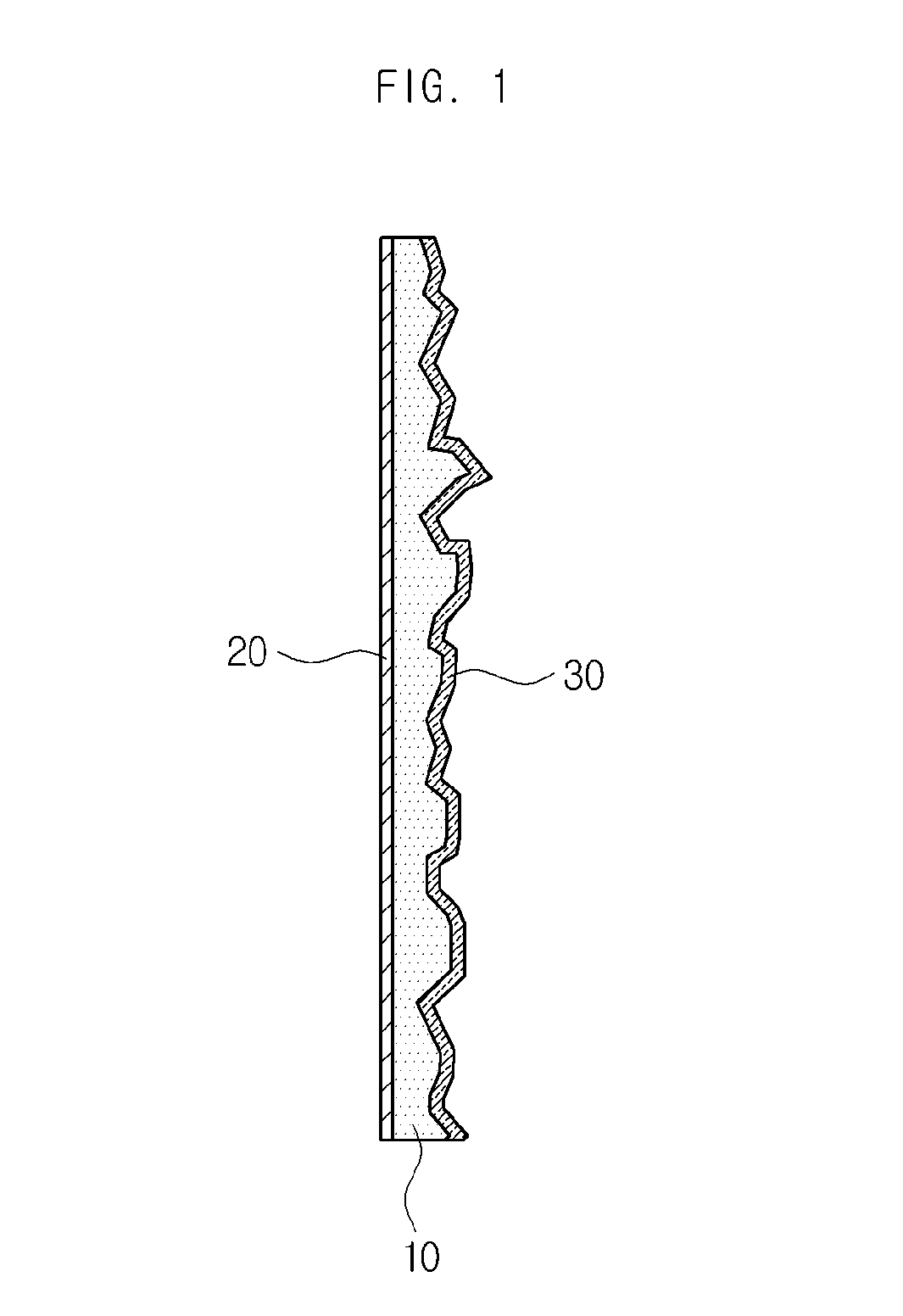

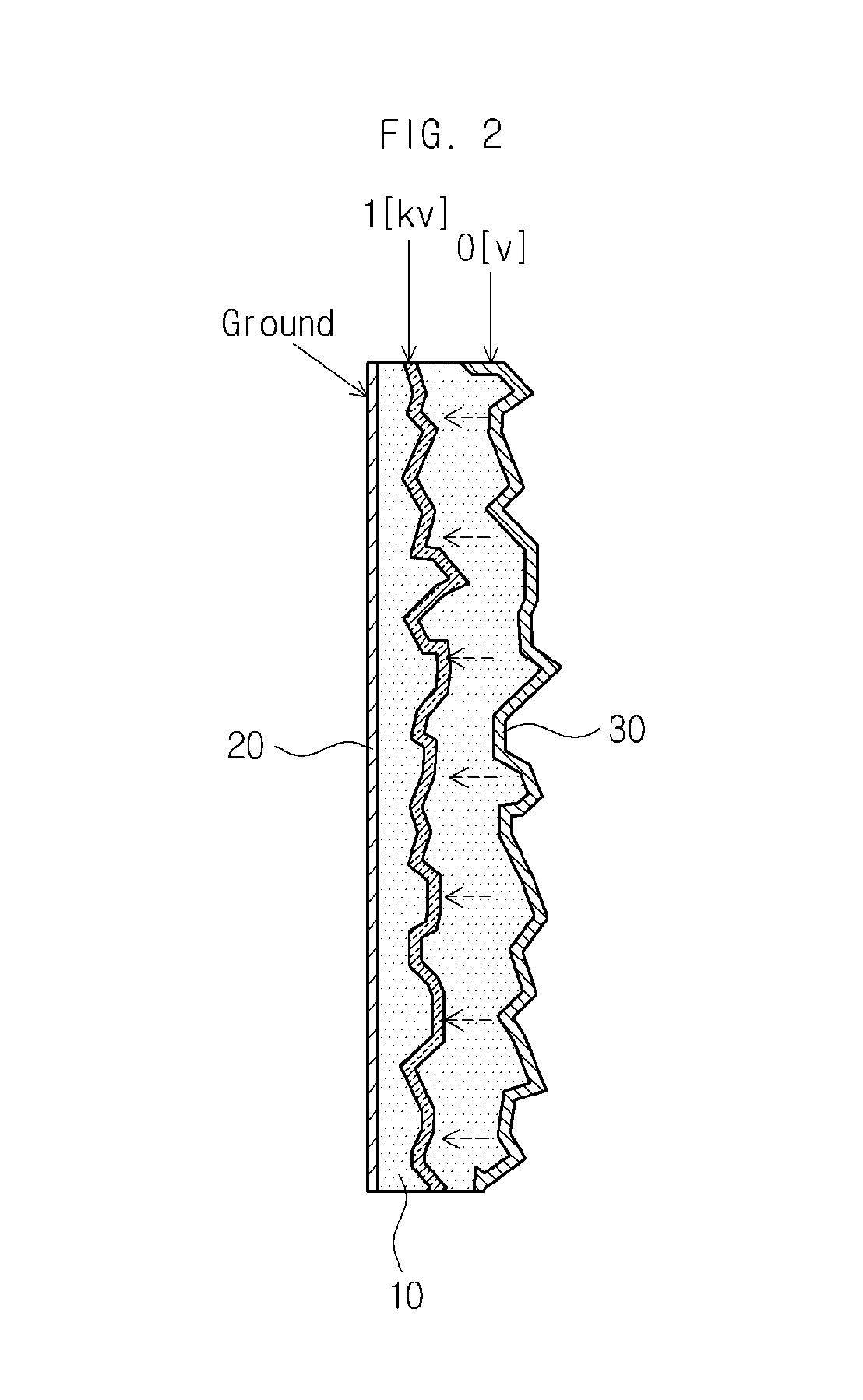

Active diffuser for reducing speckle and laser display device having active diffuser

ActiveUS9638928B2Reduce a laser speckleSpeckle can be reducedDiffusing elementsNon-linear opticsDisplay deviceOptoelectronics

An active diffuser for reducing a speckle in accordance with an embodiment of the present invention includes: an electroactive polymer film having at least one or more scattering patterns; a first transparent electrode coated on one surface of the electroactive polymer film; and a second transparent electrode coated on the other surface of the electroactive polymer film, and a shape of the scattering pattern of the electroactive polymer film is varied by voltage applied through the first transparent electrode and the second transparent electrode.

Owner:ELECTRONICS & TELECOMM RES INST

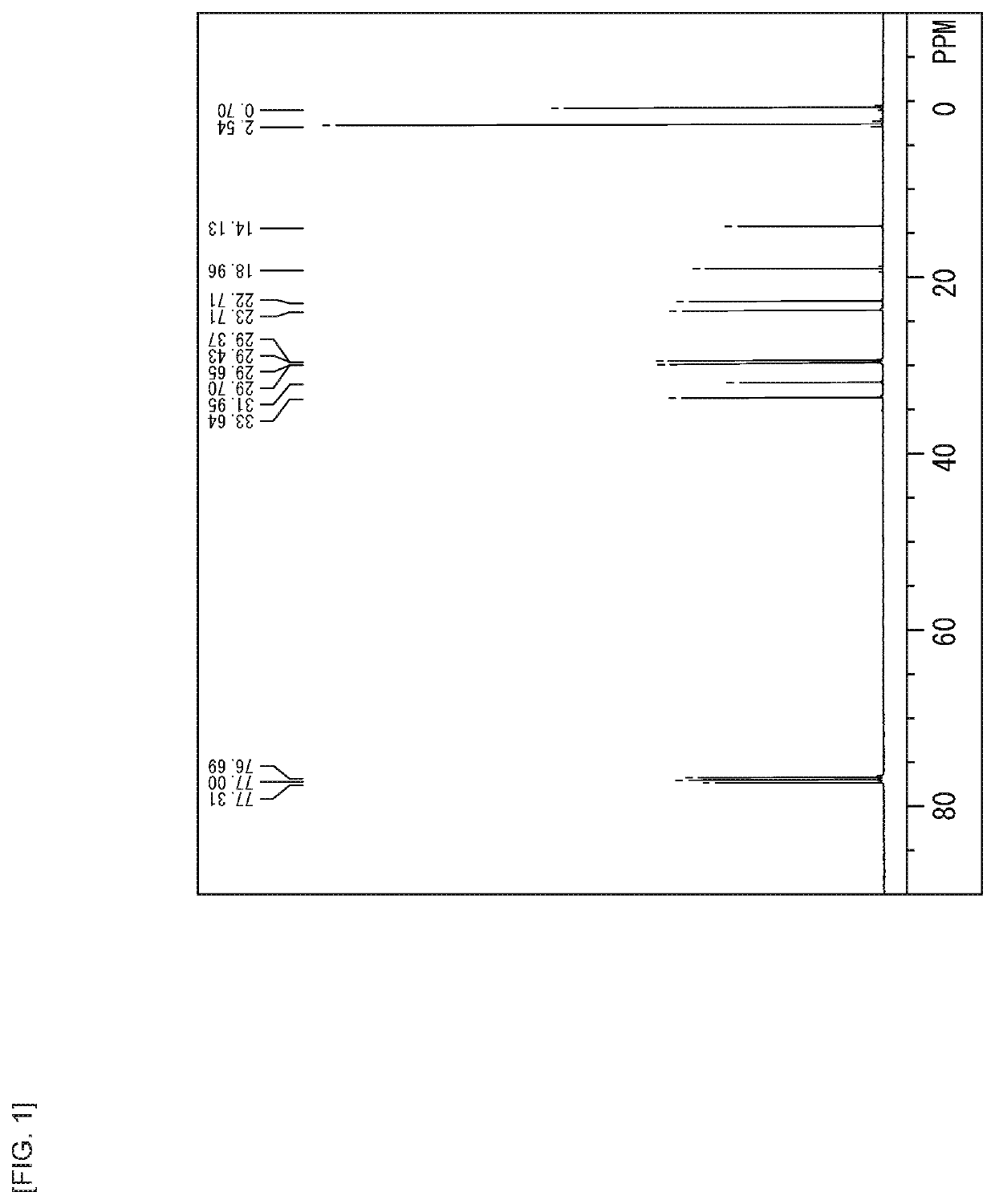

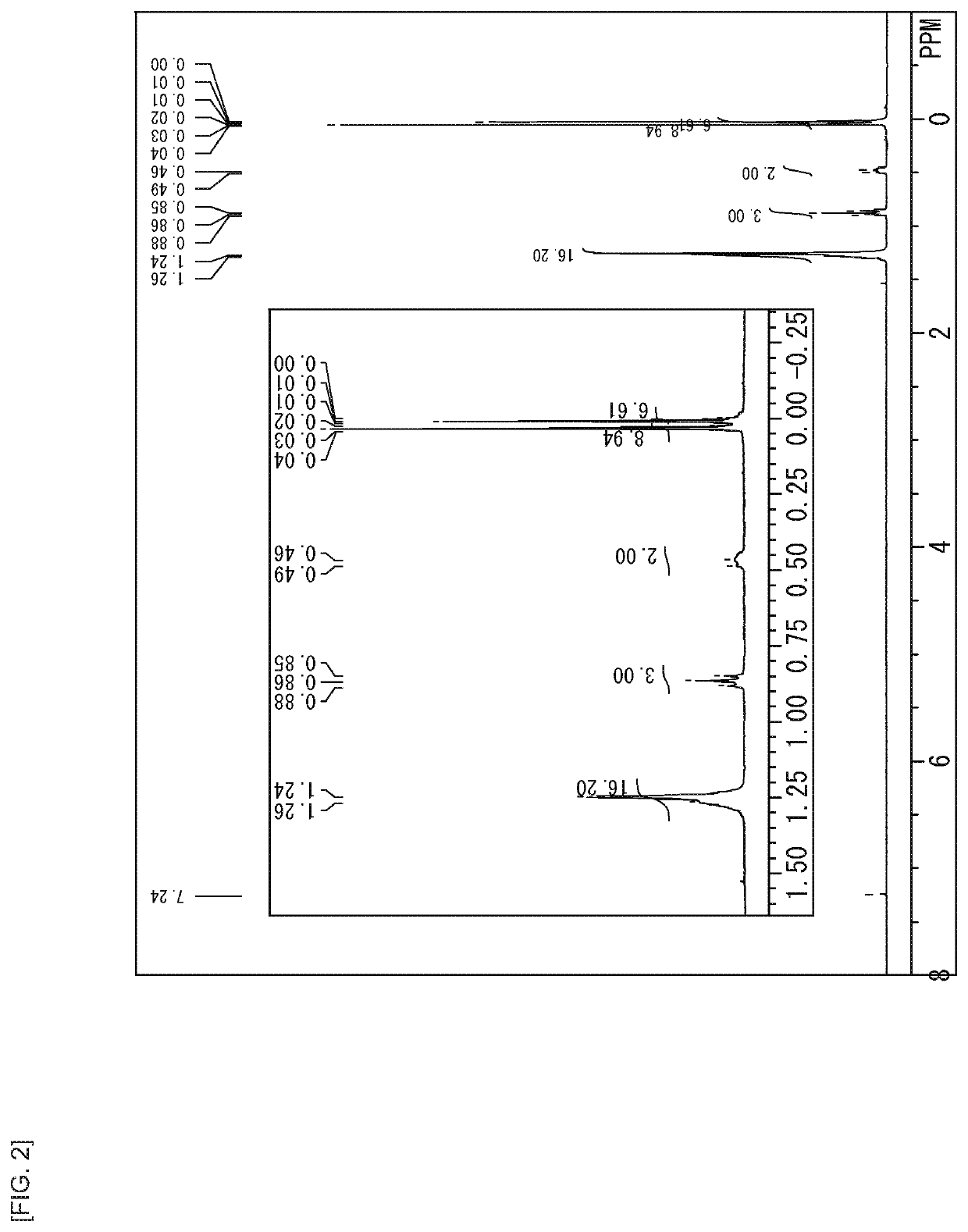

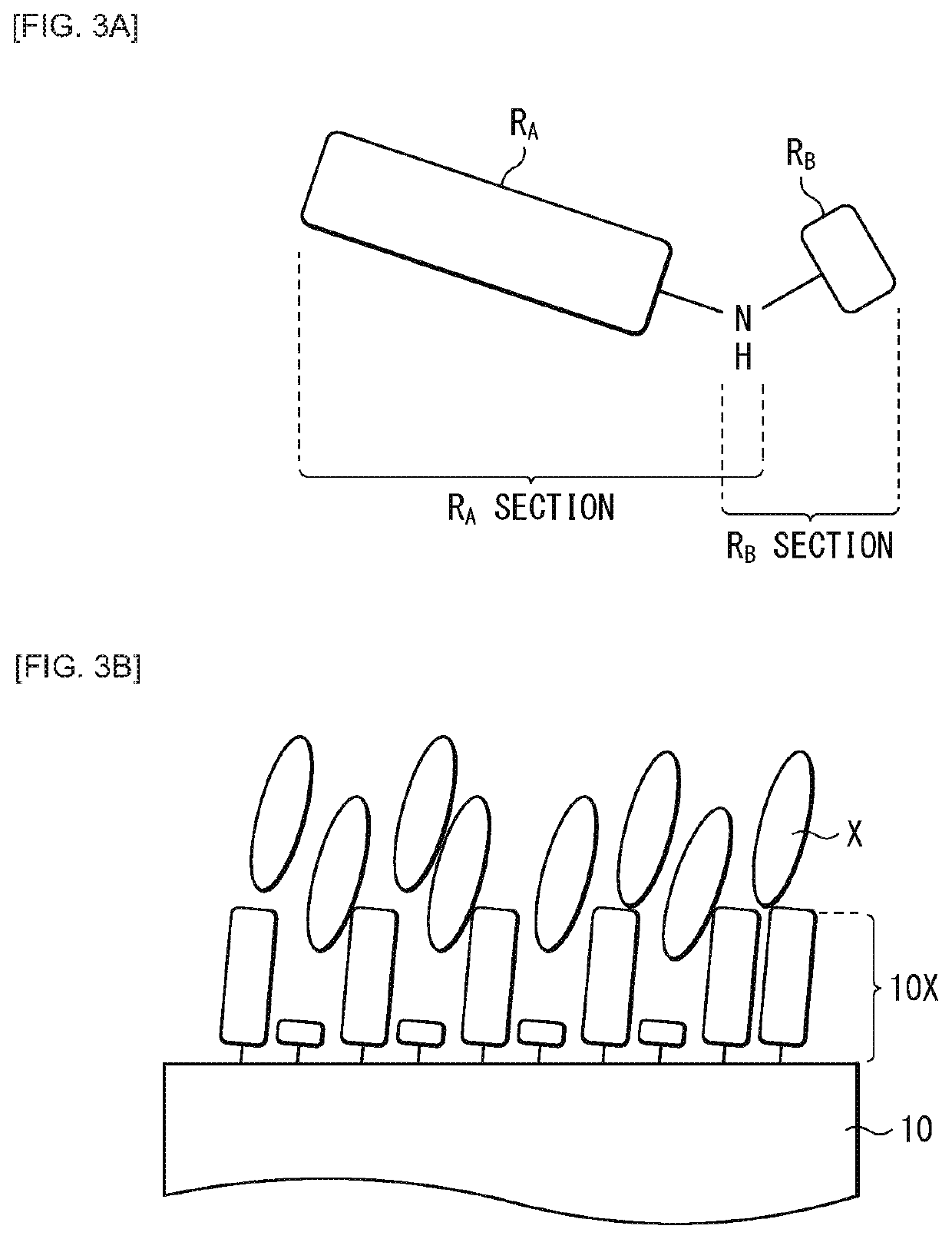

Silane coupling material, substrate, and device

PendingUS20210002309A1Improve light resistanceImprove moisture resistanceGroup 4/14 element organic compoundsProjectorsPolymer scienceSilanes

A silane coupling material according to an embodiment of the present disclosure is represented by the following general formula (1) and includes hydrocarbon groups having numbers of carbon atoms different from each other in A and B.

Owner:SONY CORP

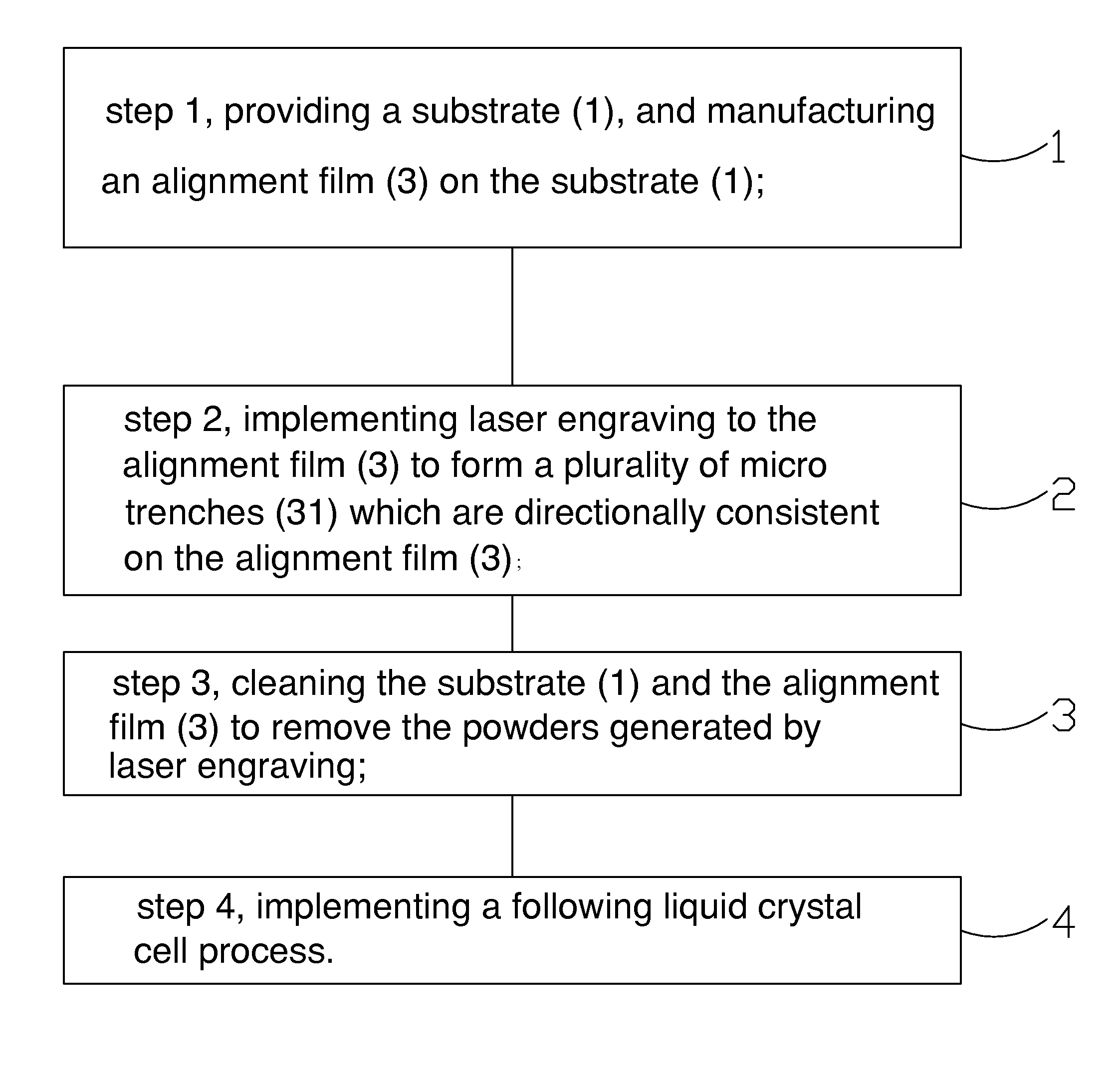

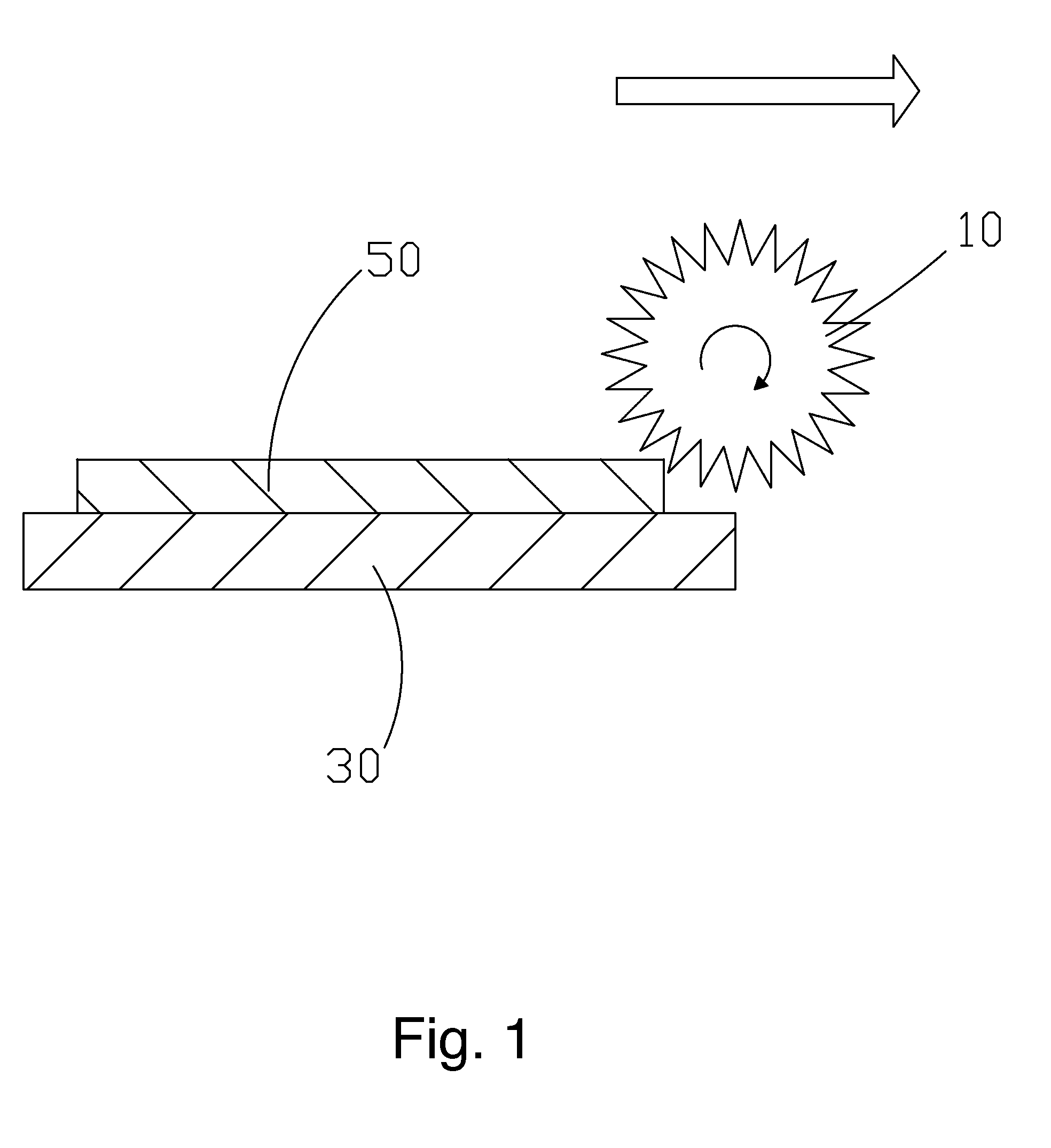

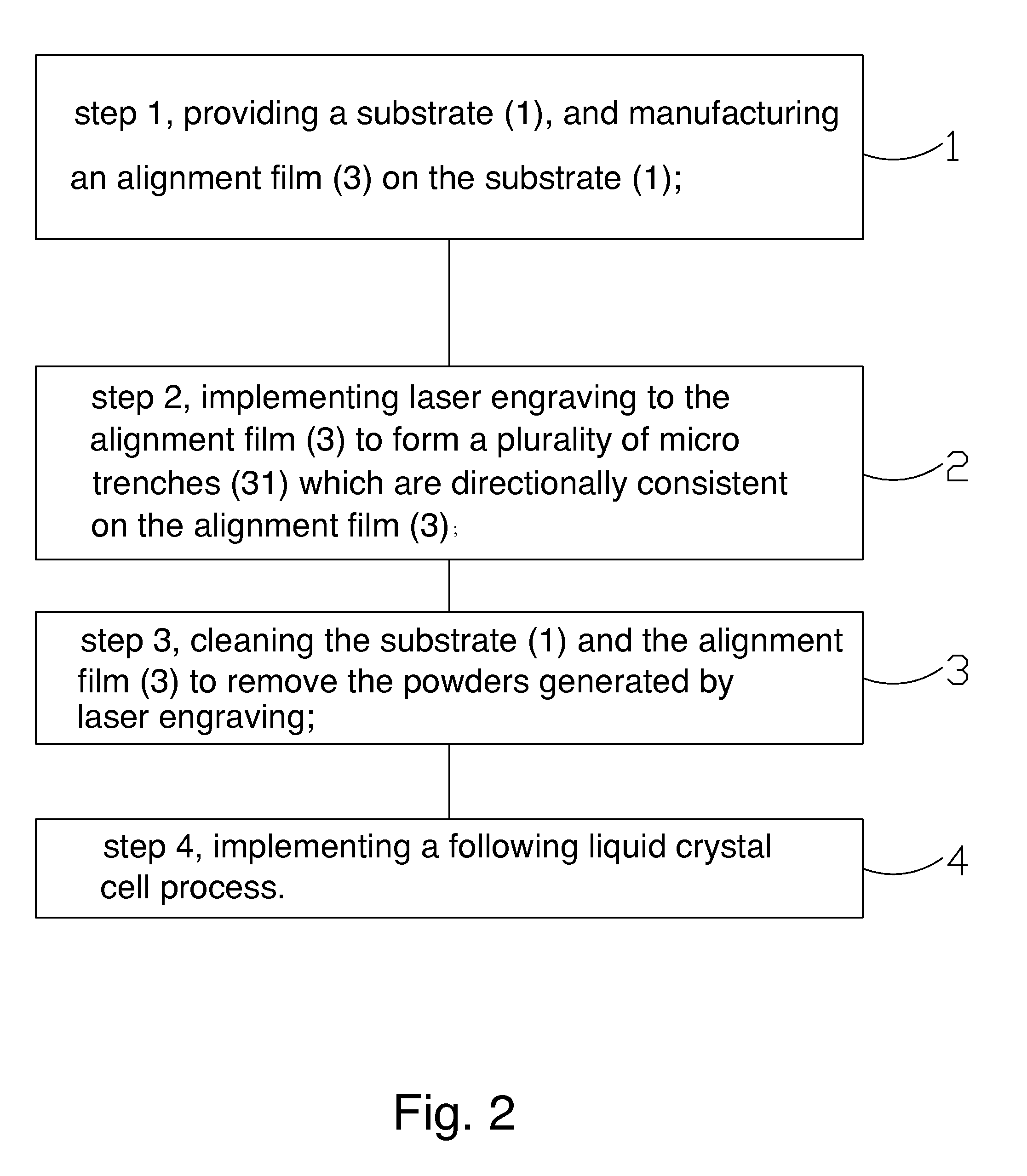

Alignment method of alignment film

ActiveUS9310649B2Easy to handleImprove alignment stabilitySolid-state devicesSemiconductor/solid-state device manufacturingLaser engravingEngineering

An alignment method of an alignment film is provided, including: providing a substrate and manufacturing an alignment film on the substrate; implementing laser engraving to the alignment film to form a plurality of micro trenches which are directionally consistent on the alignment film; cleaning the substrate and the alignment film to remove the powders generated by laser engraving; and implementing a following liquid crystal cell process. The method is easy to handle and is capable of preventing the non-uniform rubbing issue existing in the alignment method according to prior art to raise the stability of the alignment and promote the effect of the alignment.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Directional illumination apparatus and privacy display

ActiveUS20210072595A1Low costReduce device thicknessSolid-state devicesNon-linear opticsLight equipmentDisplay device

A directional illumination apparatus comprises a waveguide with a reflective surface comprising reflective pairs of light input facets, reflective light extraction facets and an output transmissive surface. An array of micro-LEDs is arranged to illuminate the reflective surface in a rearwards direction. The pairs of light input facets direct light within the waveguide and reflective light extraction facets cooperate to provide a uniform output illumination across the output aperture of the waveguide with collimated light. A thin and efficient illumination apparatus may be used for high dynamic range display backlighting, privacy display or environmental illumination applications.

Owner:REALD SPARK LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com