Liquid crystal medium mixture, liquid crystal display panel and preparation method of liquid crystal display panel

A liquid crystal display panel and liquid crystal medium technology, which is applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problems of unevenness, low reliability of liquid crystal display panels, and increase the diffusivity of liquid crystals, and achieve uniform size distribution. Reliability, the effect of enhancing the surface ability of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

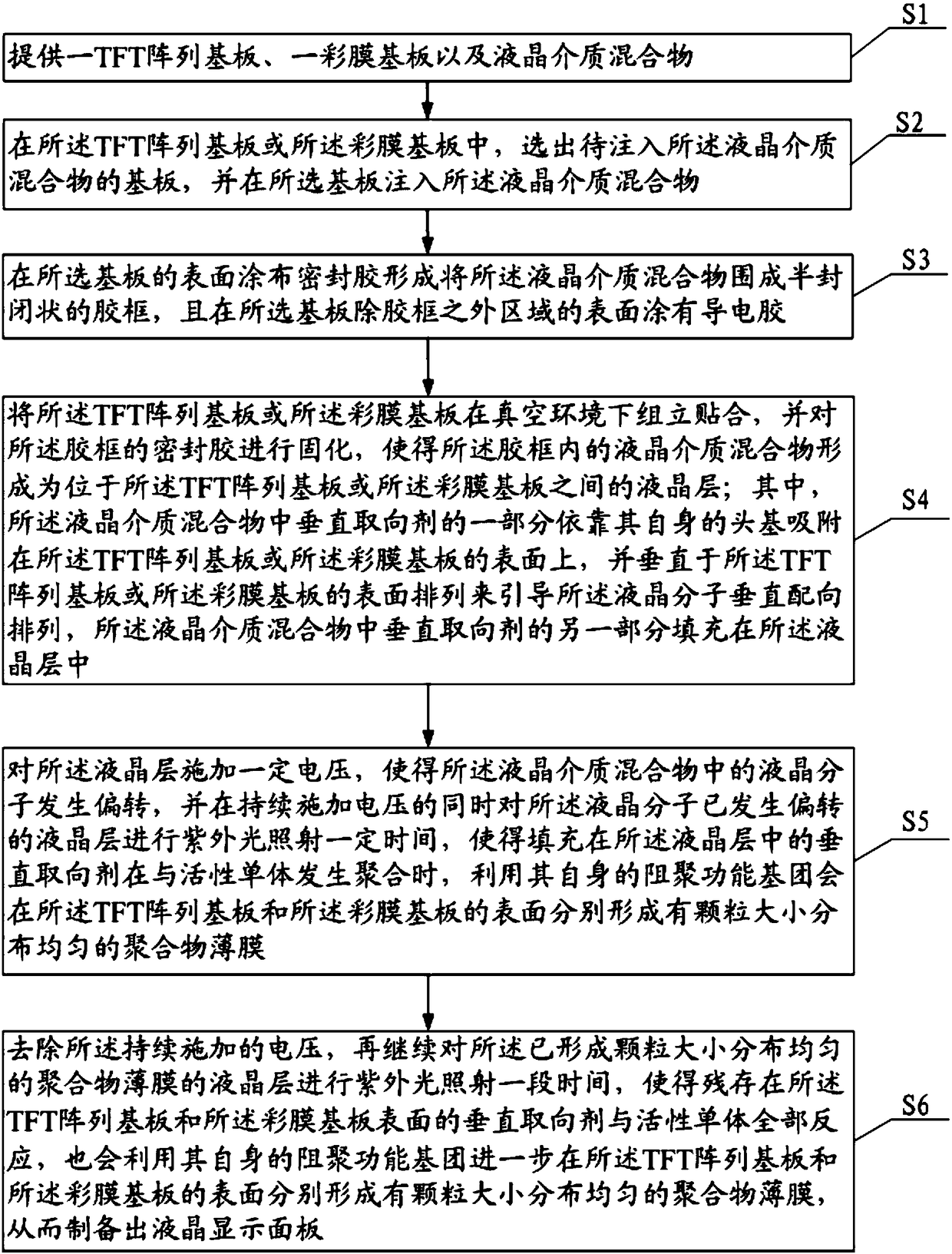

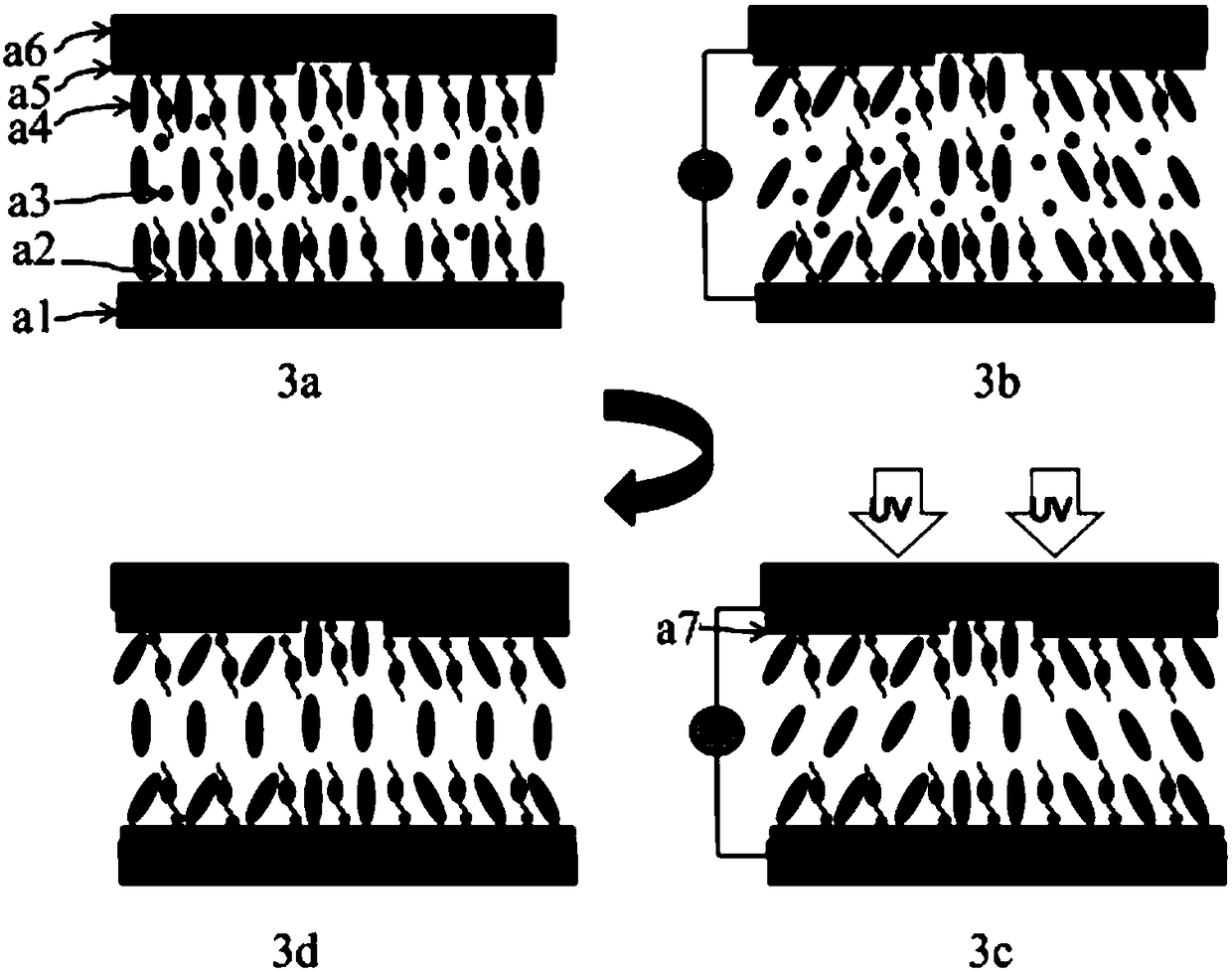

[0045] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

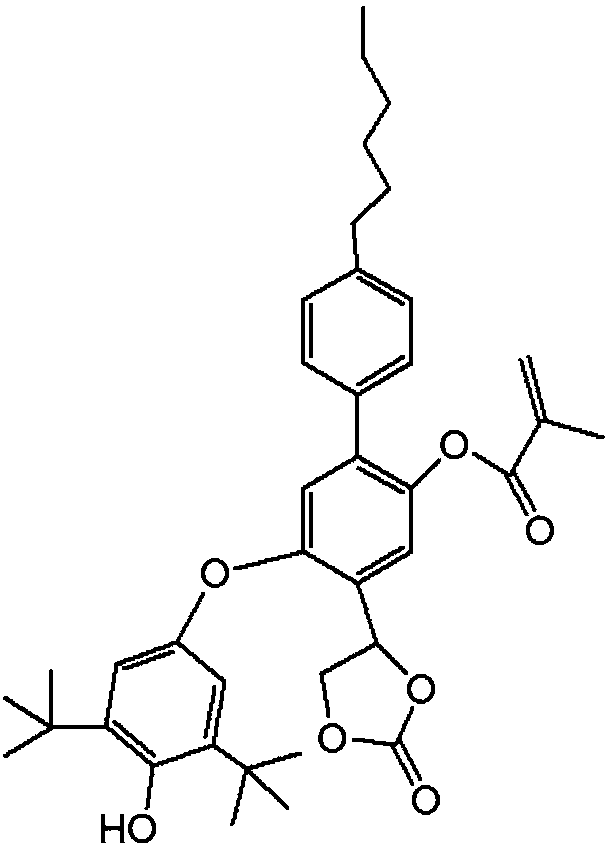

[0046] Such as figure 1 As shown, in Embodiment 1 of the present invention, a liquid crystal medium mixture is provided, which is arranged in the liquid crystal layer of the liquid crystal display panel, and includes liquid crystal molecules 1, active monomers 2 and a vertical alignment agent 3, and the vertical alignment agent 3 includes Head group, intermediate group, tail group, polymerizable group and polymerization inhibitor functional group;

[0047] Wherein, the general structural formula of the vertical alignment agent 3 is one of; among them,

[0048] A refers to the head group used to anchor the substrate surface of the liquid crystal display panel to realize the vertical alignment effect on the liquid crystal molecules 1, and its structure is expre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com