Patents

Literature

74results about How to "Reduce effective thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

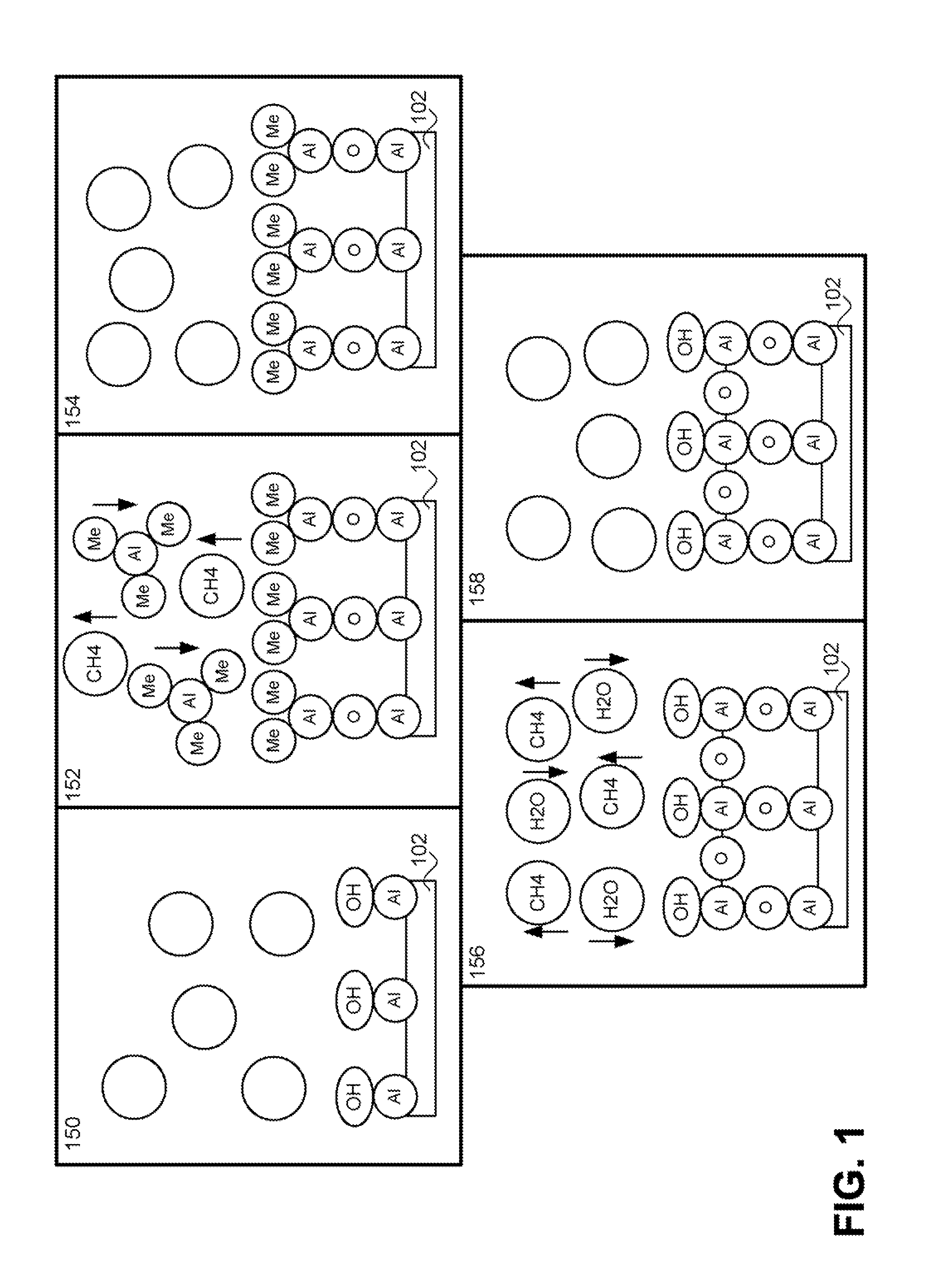

Systems for Atomic Layer Deposition of Oxides Using Krypton as an Ion Generating Feeding Gas

InactiveUS20070277735A1Great efficiencyGreat capabilitySolid-state devicesSemiconductor/solid-state device manufacturingIonOxide

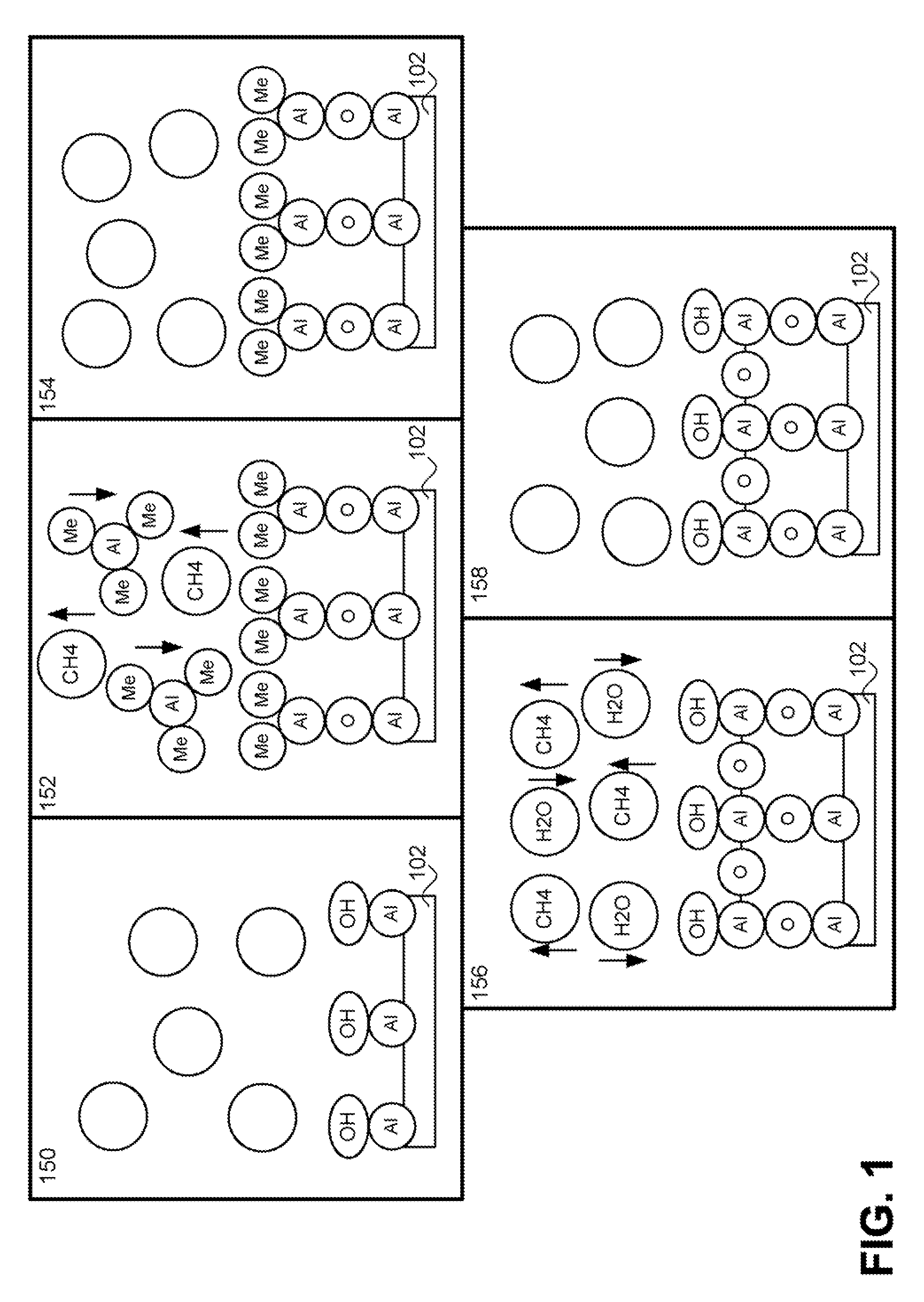

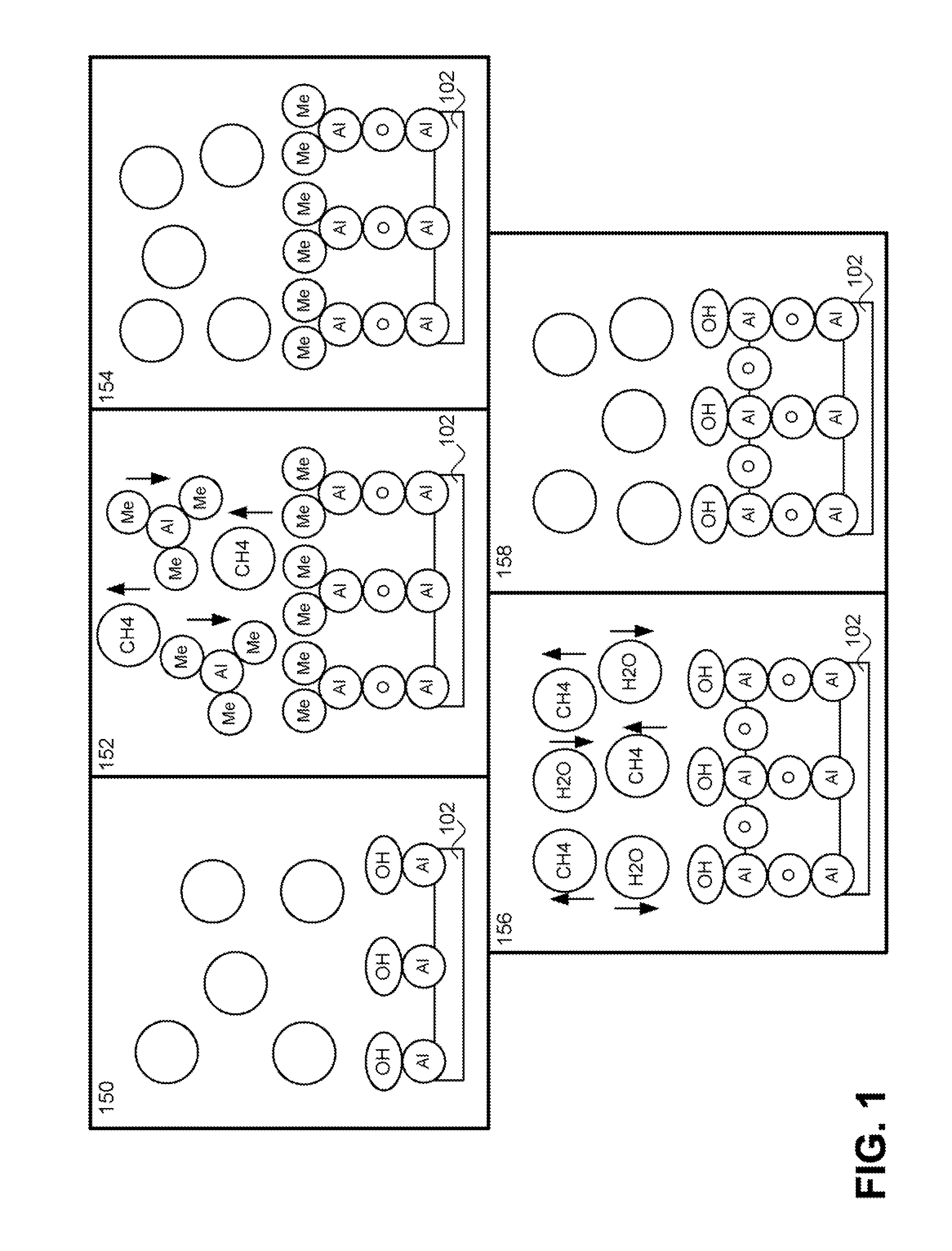

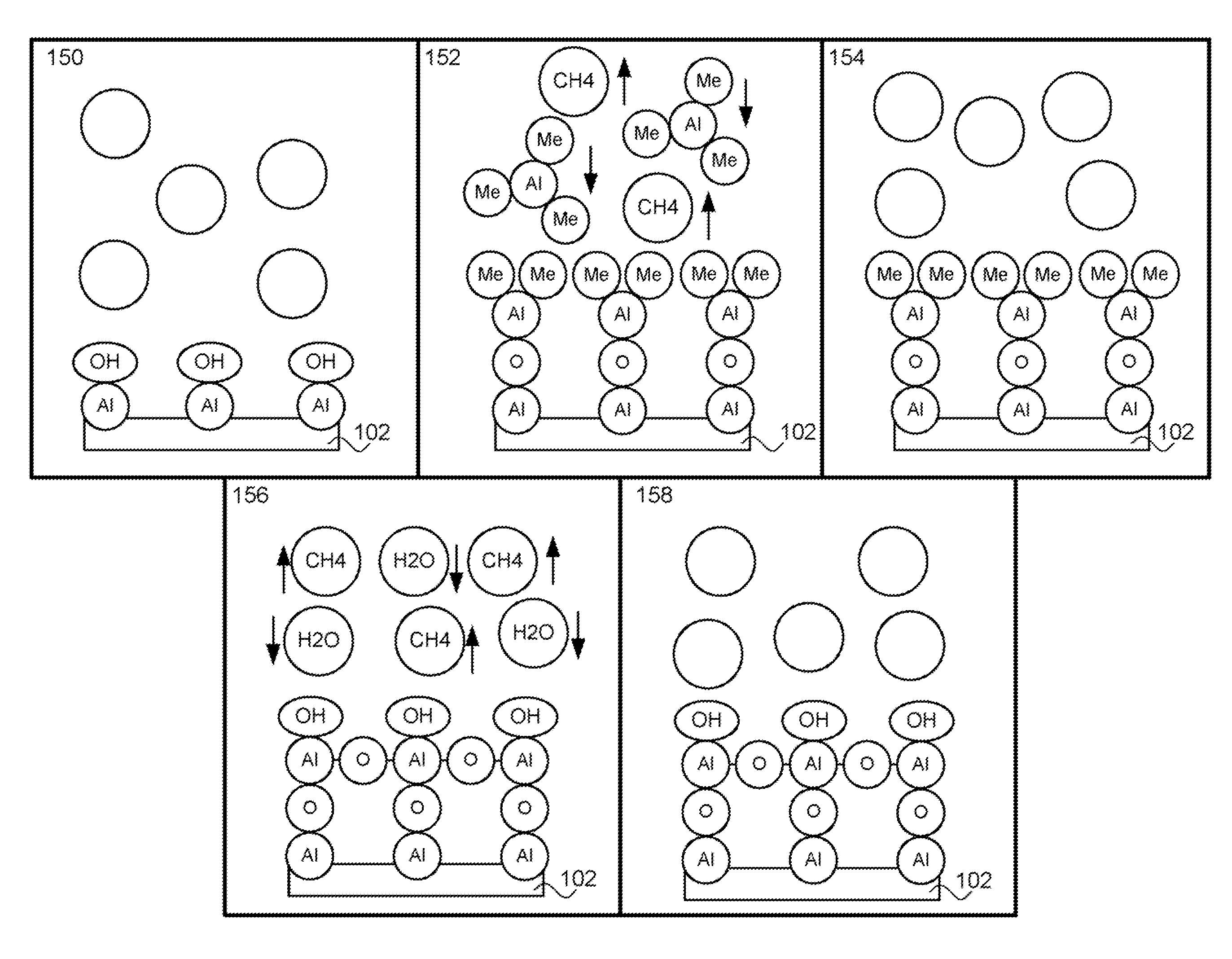

An atomic layer deposition system and method utilizing radicals generated from a high-density mixed plasma for deposition is disclosed. A high-quality oxide or oxynitride can be deposited by exposing a substrate to a first precursor which is adsorbed onto the substrate during a first phase of one deposition cycle. After purging the deposition chamber, the substrate is exposed to a second precursor which includes oxygen radicals and krypton ions formed from the high-density mixed plasma. The ions and radicals are formed by introducing a radical generating feed gas (e.g., O2) and an ion generating feed gas into a plasma chamber and exciting the gases to form the high-density mixed plasma. The radicals and ions are then introduced to the substrate where they react with the first precursor to deposit a layer of the desired film. Krypton is preferably used as the ion generating feed gas because the metastable states of krypton lead to an efficient dissociation of oxygen into oxygen radicals when compared with other inert gases.

Owner:SANDISK TECH LLC

Atomic Layer Deposition of Oxides Using Krypton as an Ion Generating Feeding Gas

InactiveUS20070281105A1Improve abilitiesImprove efficiencyChemical vapor deposition coatingPlasma techniqueKryptonHigh density

An atomic layer deposition system and method utilizing radicals generated from a high-density mixed plasma for deposition is disclosed. A high-quality oxide or oxynitride can be deposited by exposing a substrate to a first precursor which is adsorbed onto the substrate during a first phase of one deposition cycle. After purging the deposition chamber, the substrate is exposed to a second precursor which includes oxygen radicals and krypton ions formed from the high-density mixed plasma. The ions and radicals are formed by introducing a radical generating feed gas (e.g., O2) and an ion generating feed gas into a plasma chamber and exciting the gases to form the high-density mixed plasma. The radicals and ions are then introduced to the substrate where they react with the first precursor to deposit a layer of the desired film. Krypton is preferably used as the ion generating feed gas because the metastable states of krypton lead to an efficient dissociation of oxygen into oxygen radicals when compared with other inert gases.

Owner:SANDISK TECH LLC

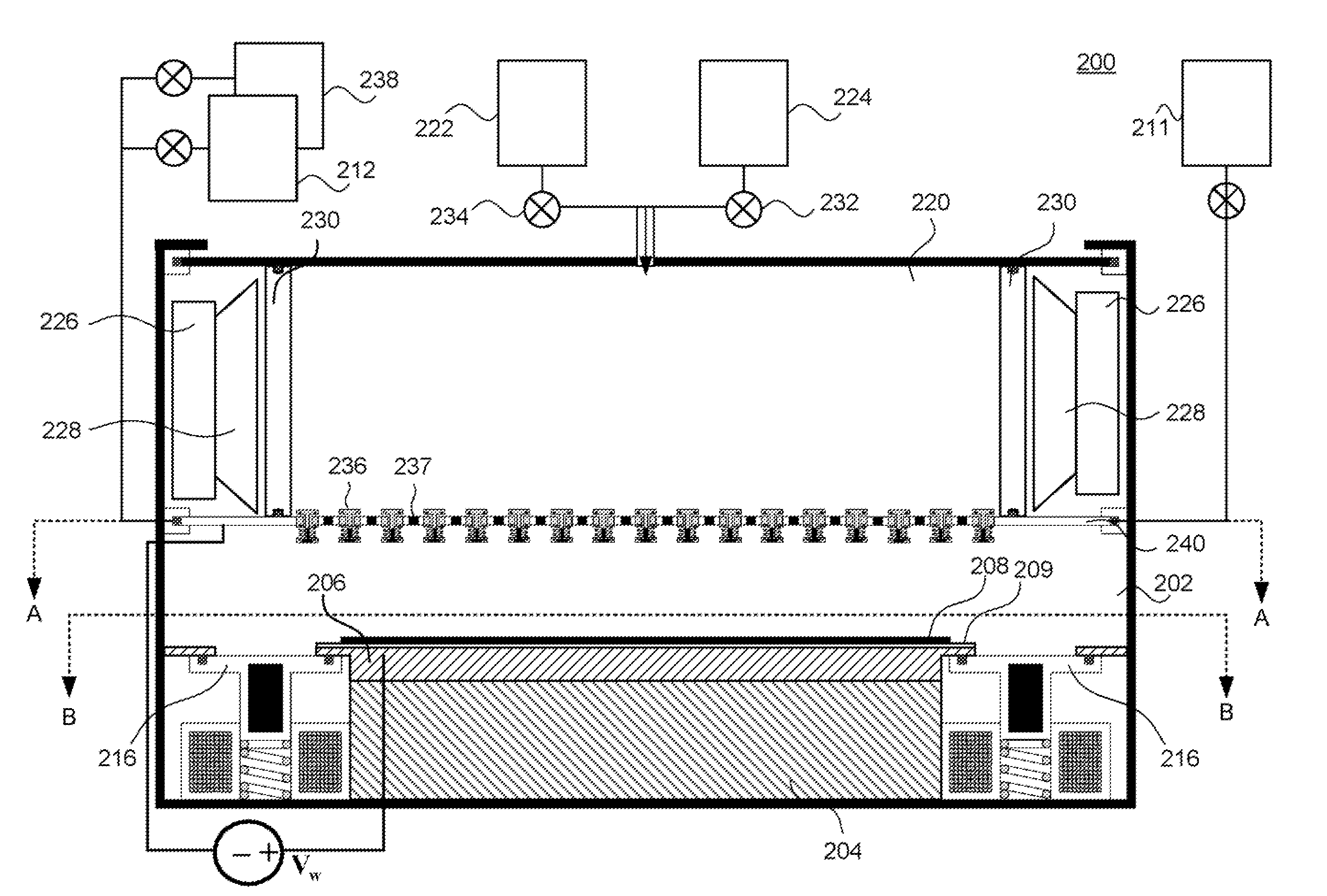

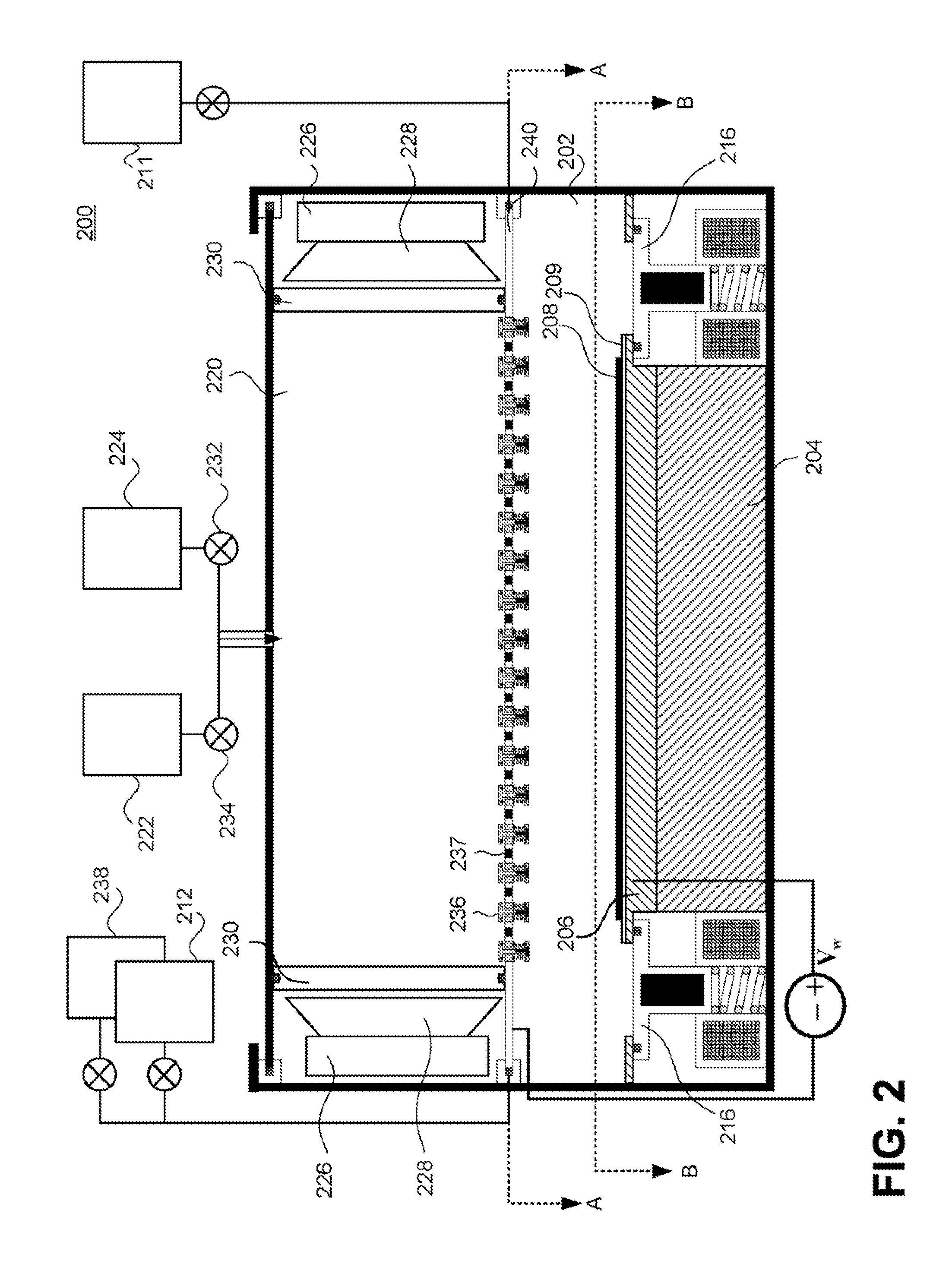

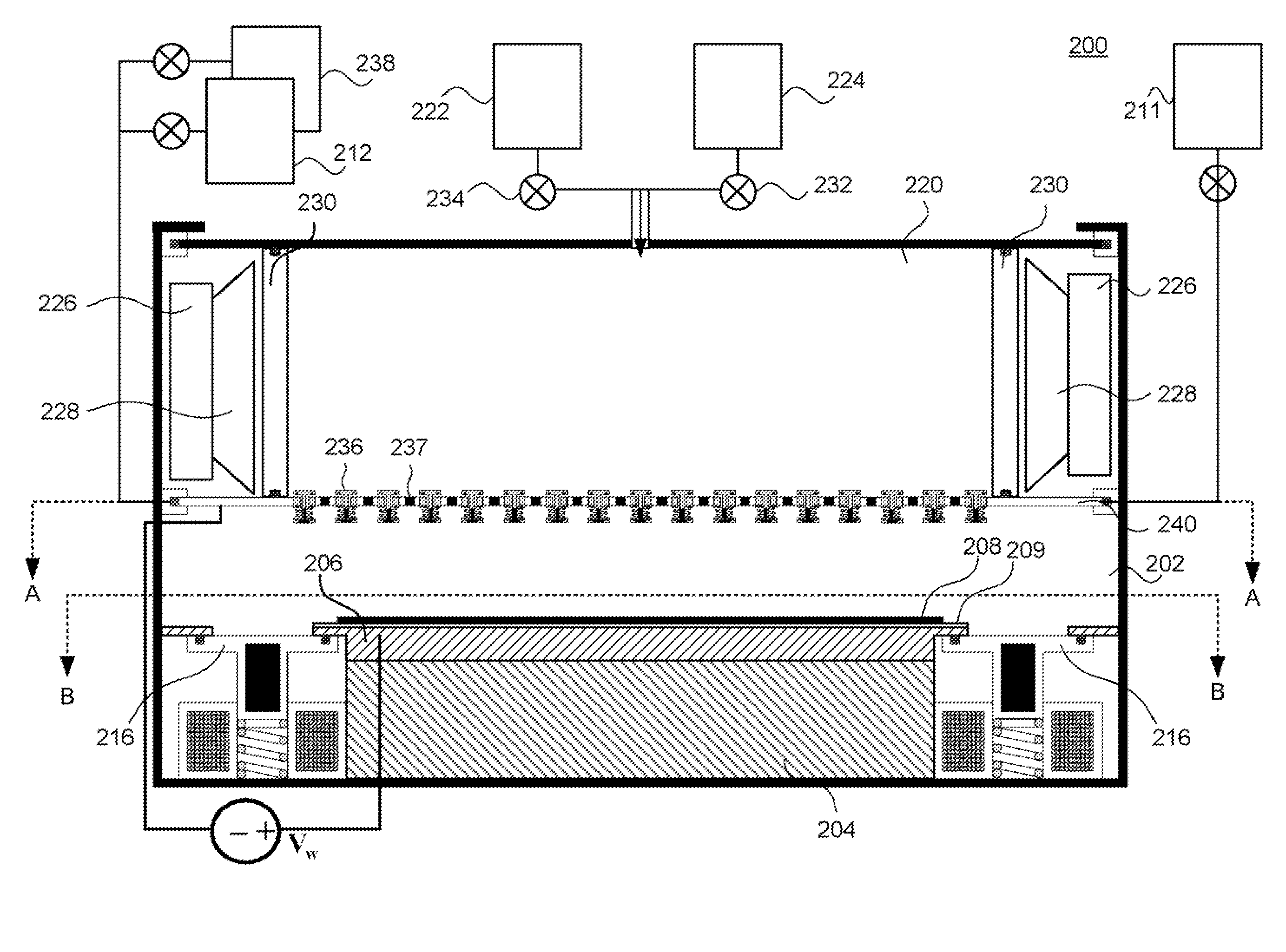

Flash Heating in Atomic Layer Deposition

InactiveUS20070281082A1Control performanceSave stepsSolid-state devicesPretreated surfacesMetallurgyAtomic layer deposition

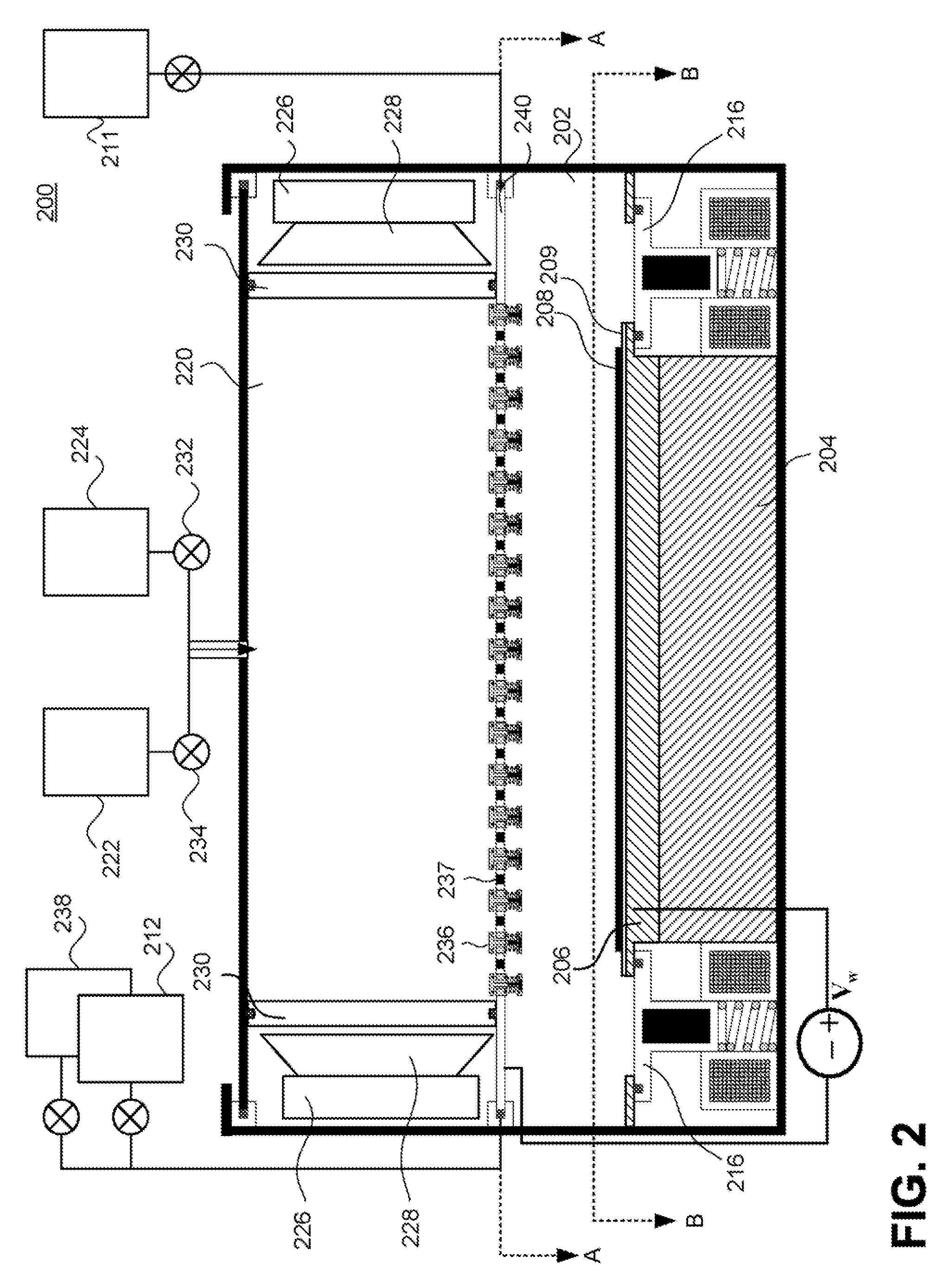

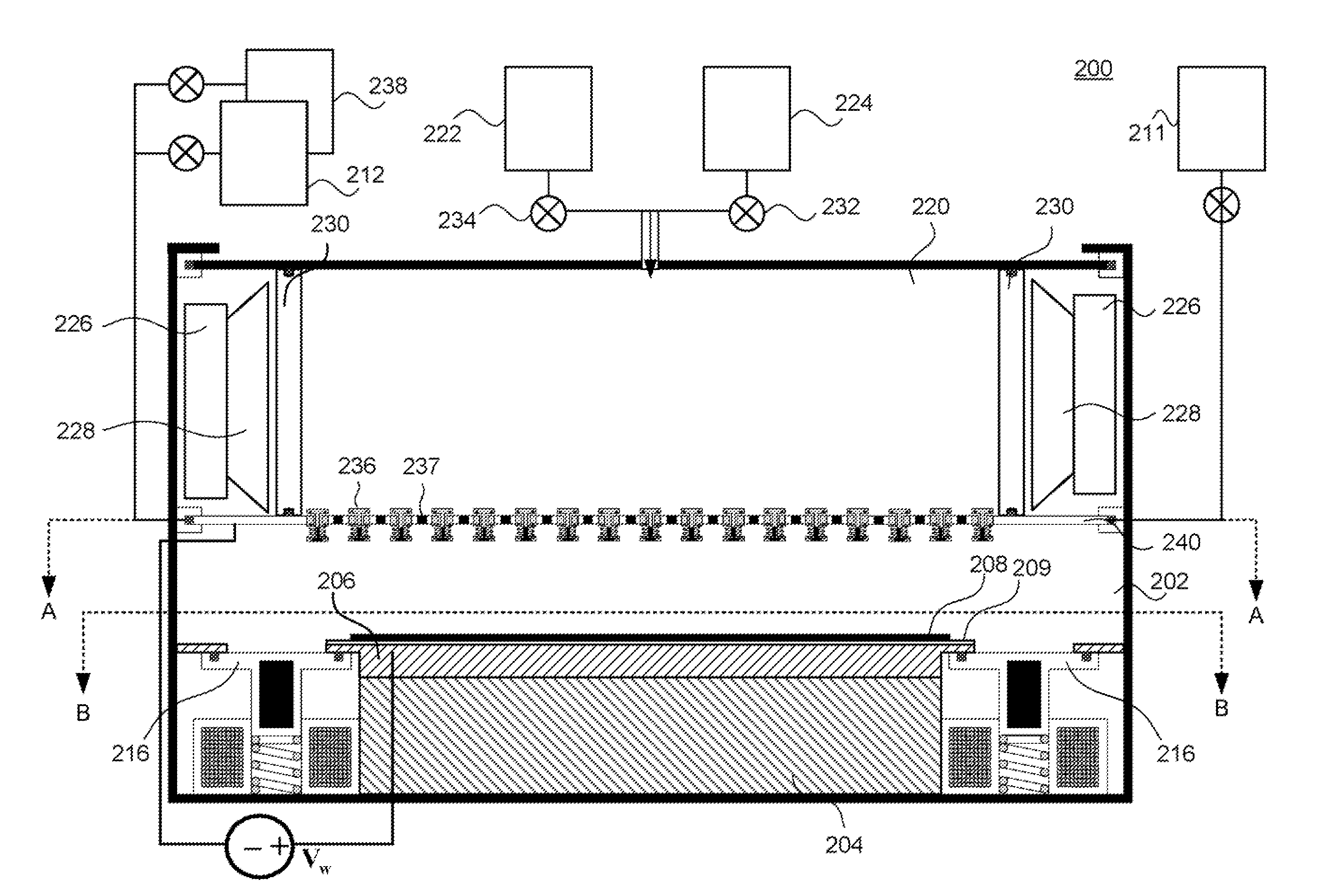

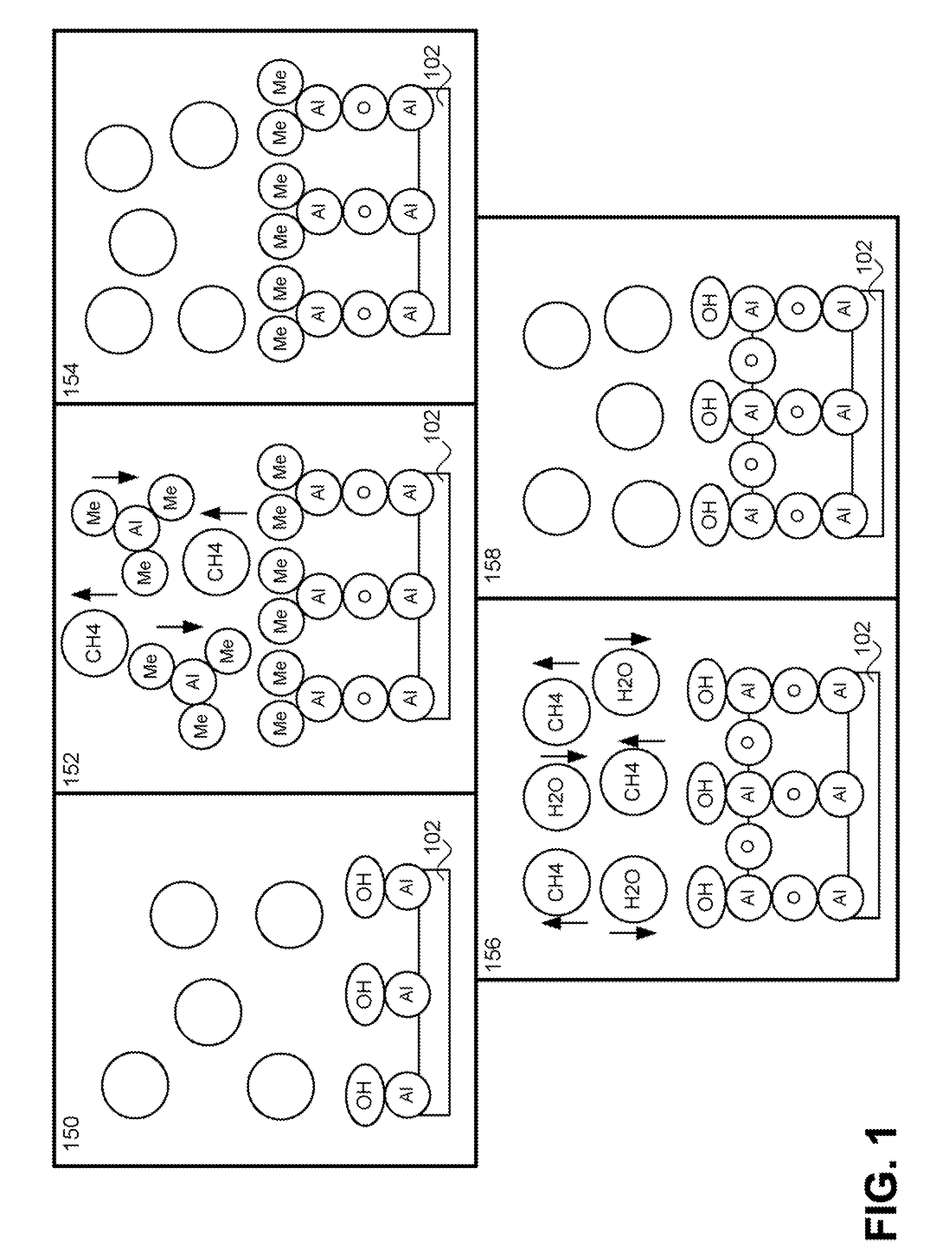

System and methods for flash heating of materials deposited using atomic layer deposition techniques are disclosed. By flash heating the surface of the deposited material after each or every few deposition cycles, contaminants such as un-reacted precursors and byproducts can be released from the deposited material. A higher quality material is deposited by reducing the incorporation of impurities. A flash heating source is capable of quickly raising the temperature of the surface of a deposited material without substantially raising the temperature of the bulk of the substrate on which the material is being deposited. Because the temperature of the bulk of the substrate is not significantly raised, the bulk acts like a heat sink to aid in cooling the surface after flash heating. In this manner, processing times are not significantly increased in order to allow the surface temperature to reach a suitably low temperature for deposition.

Owner:SANDISK TECH LLC

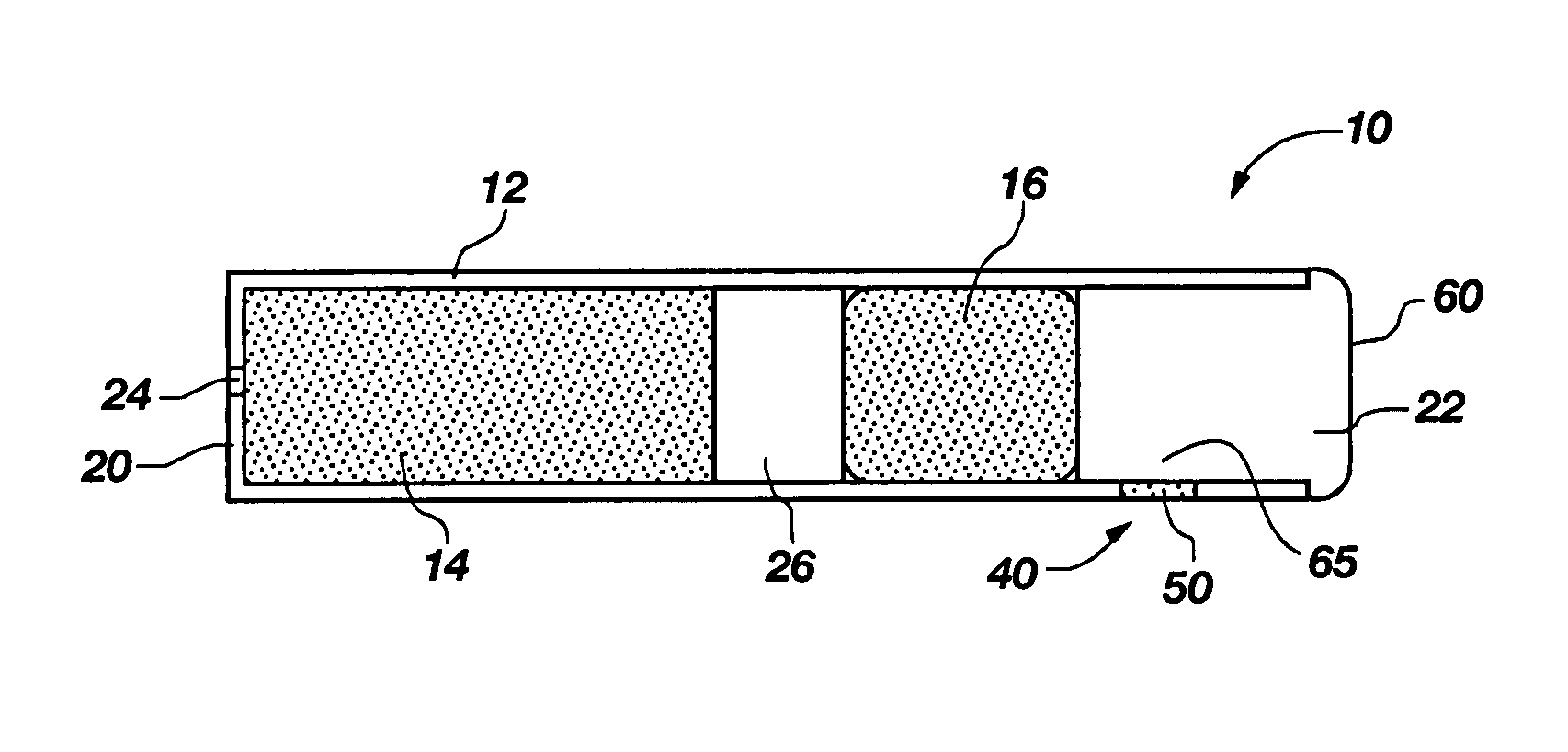

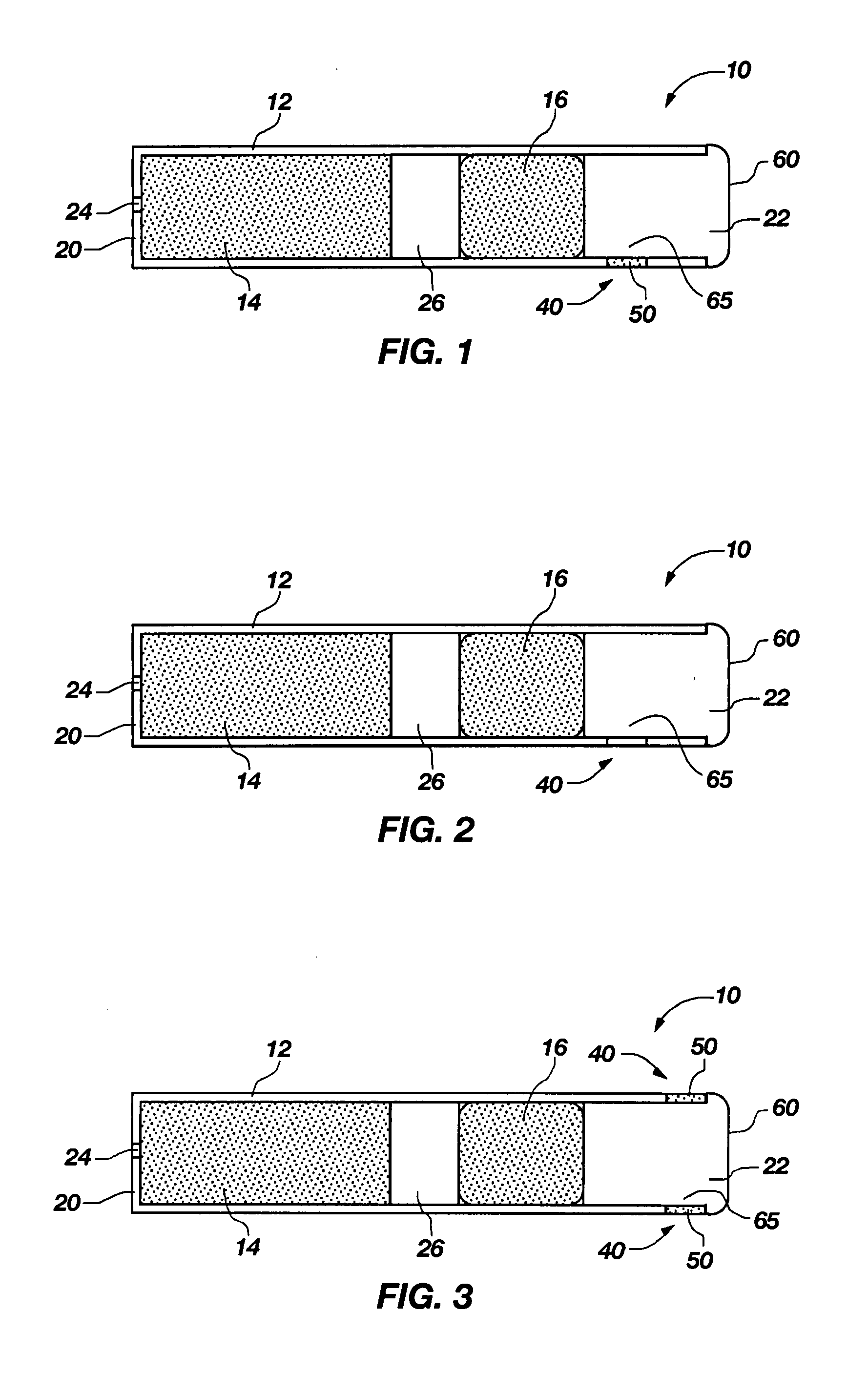

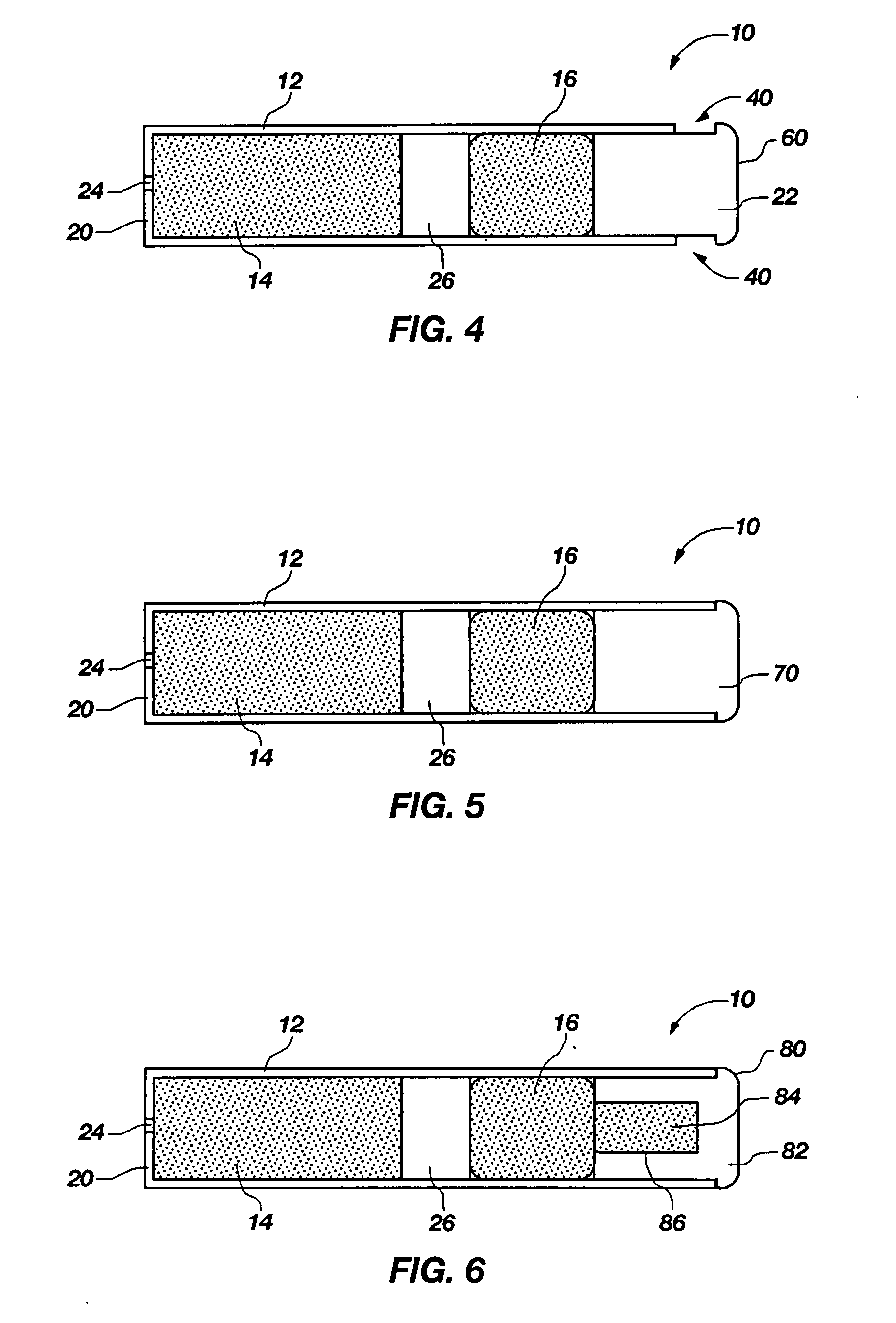

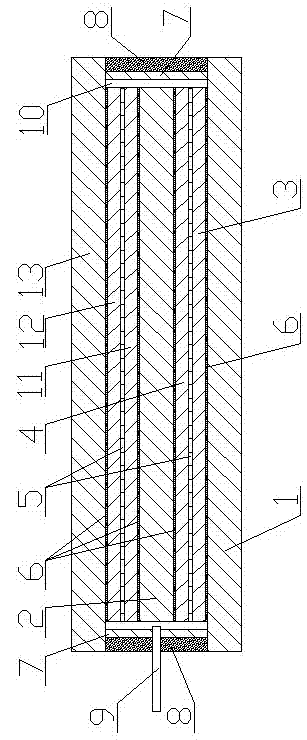

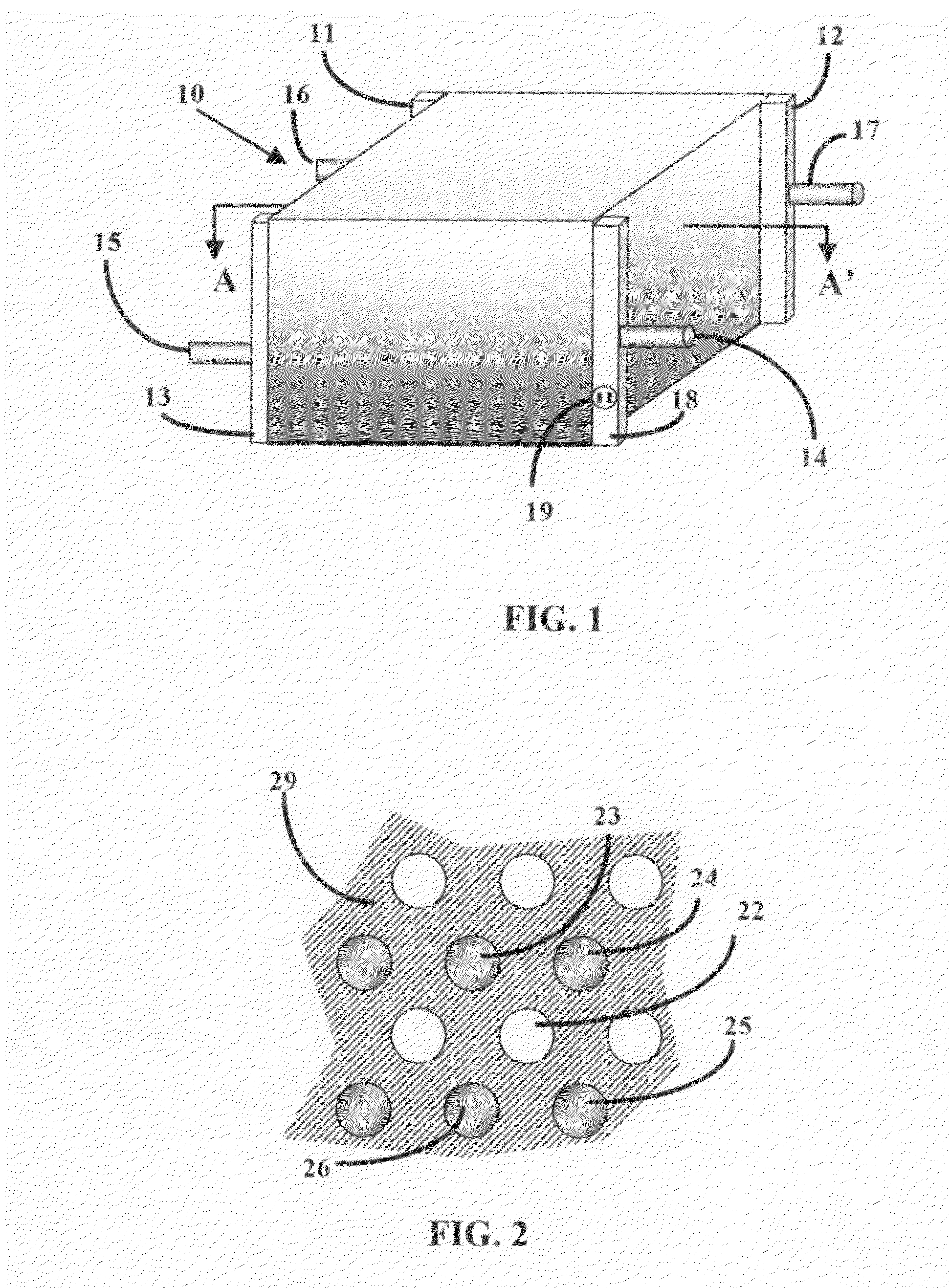

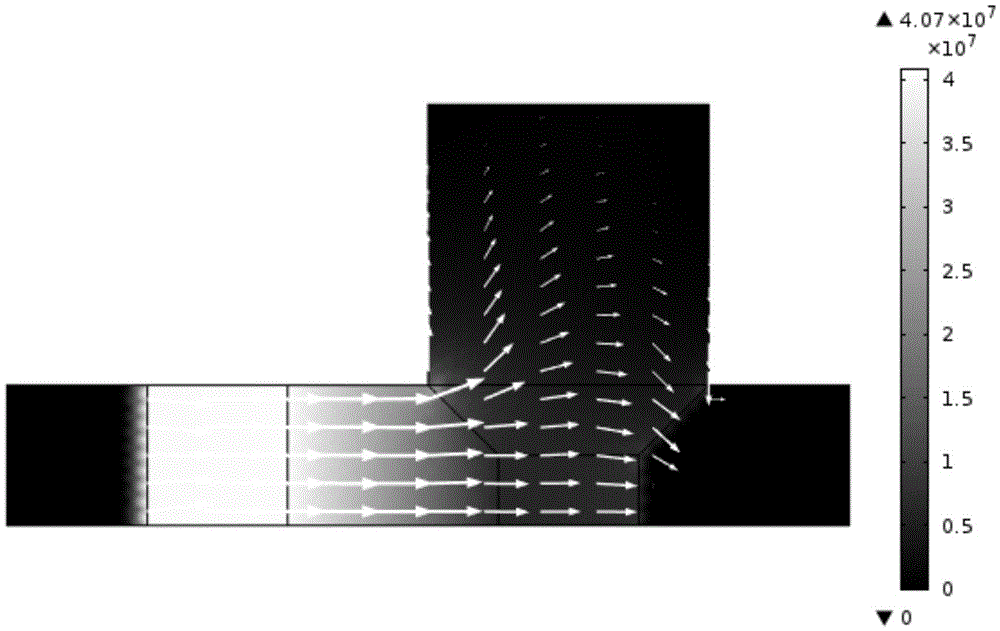

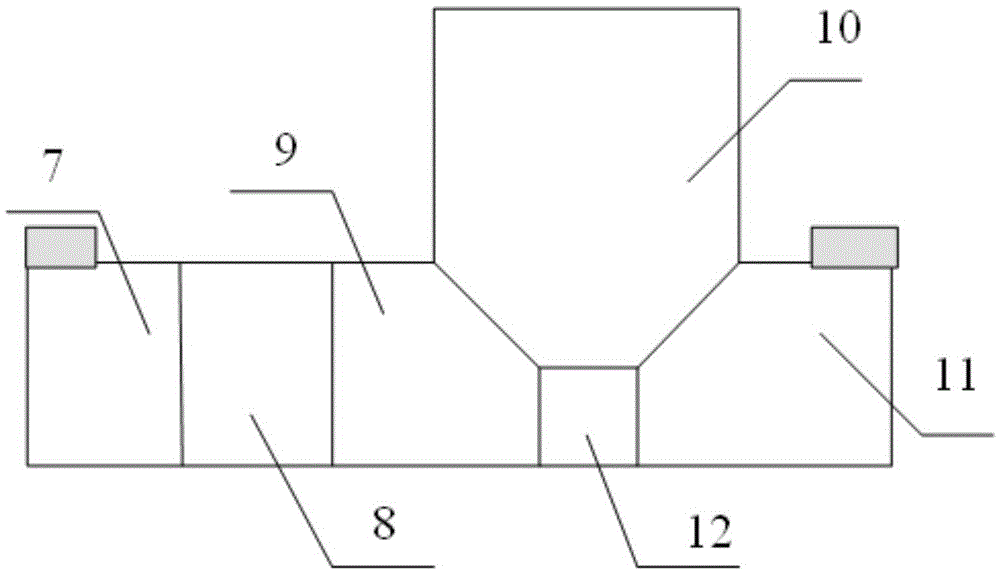

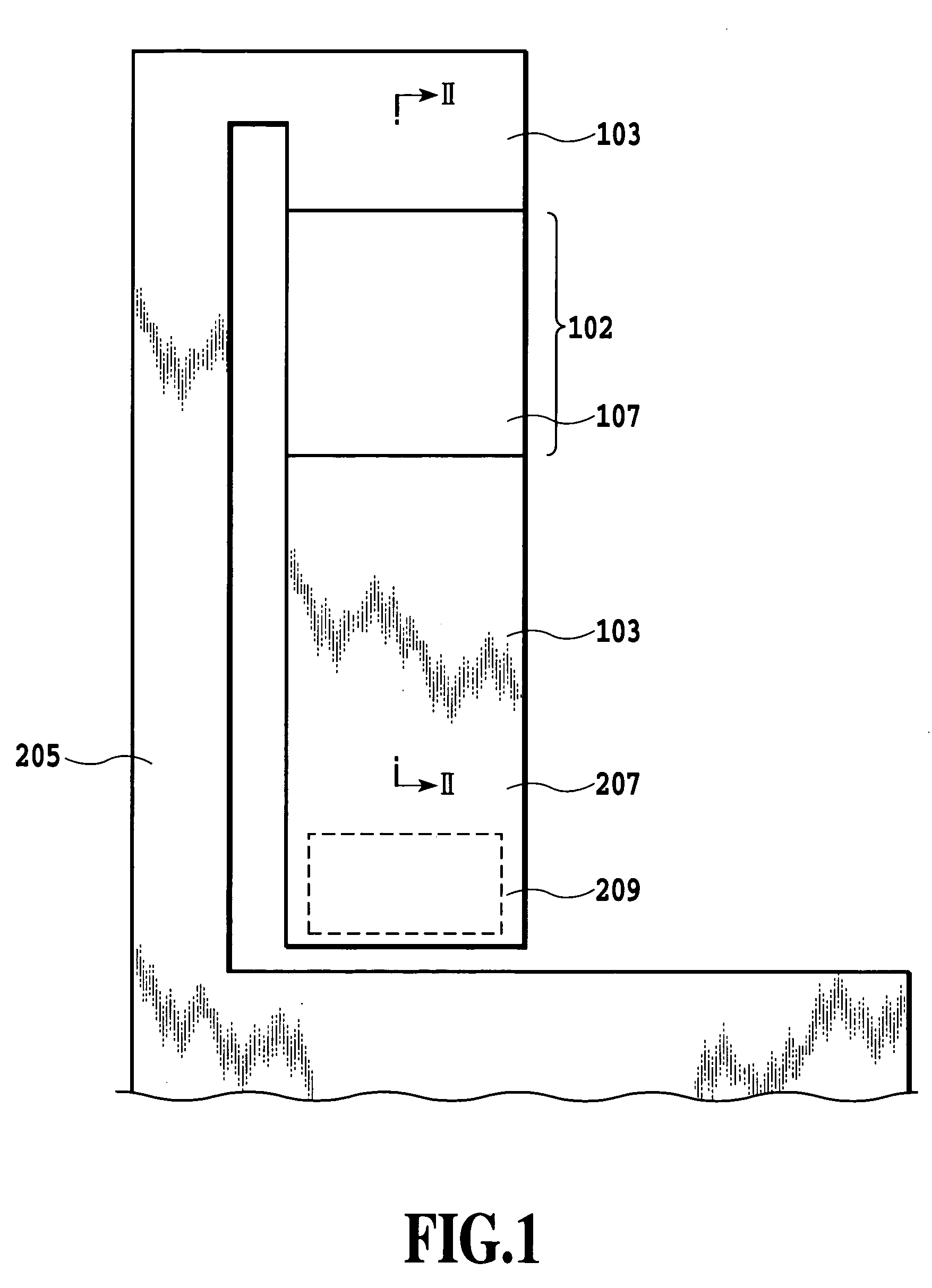

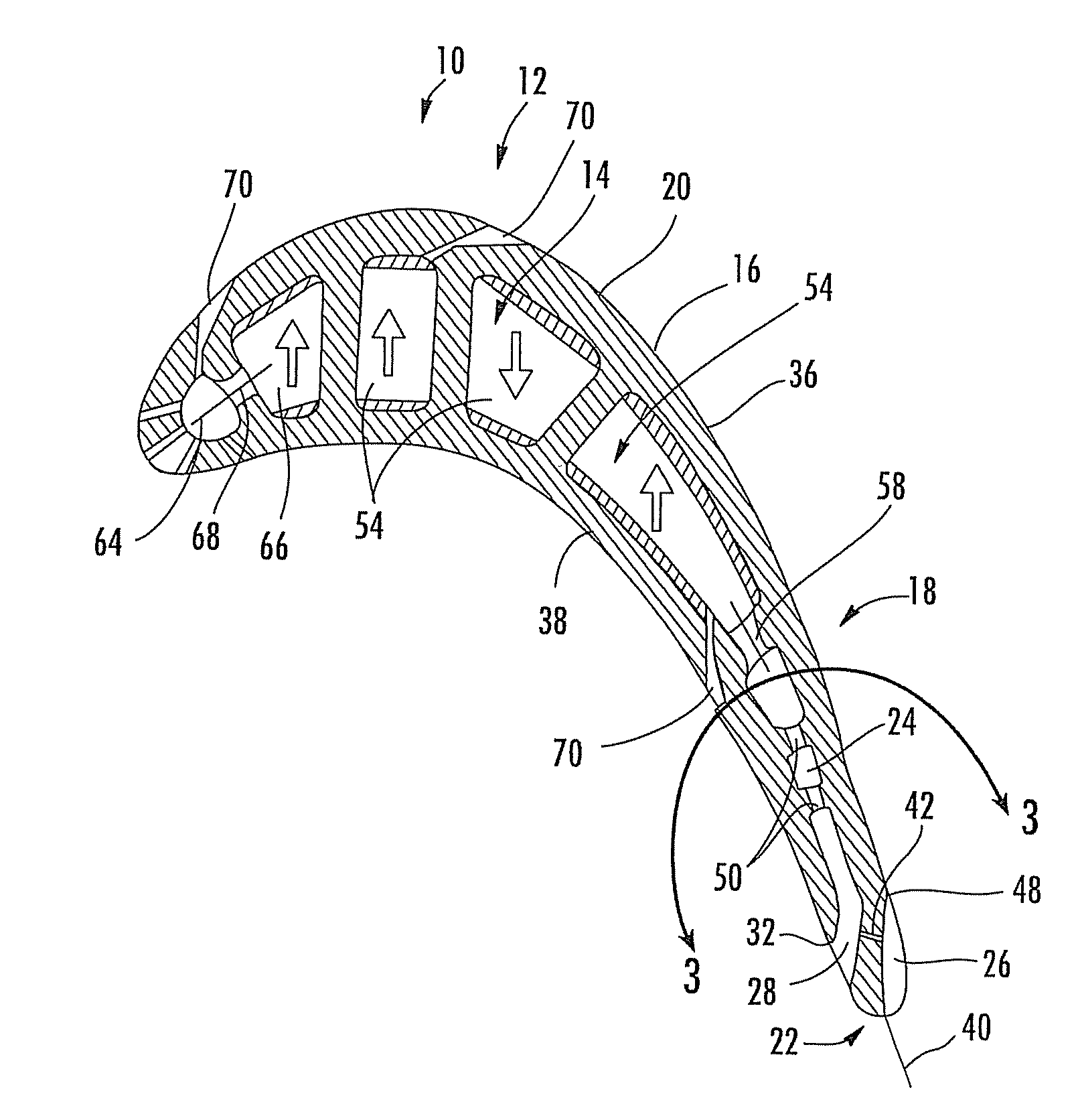

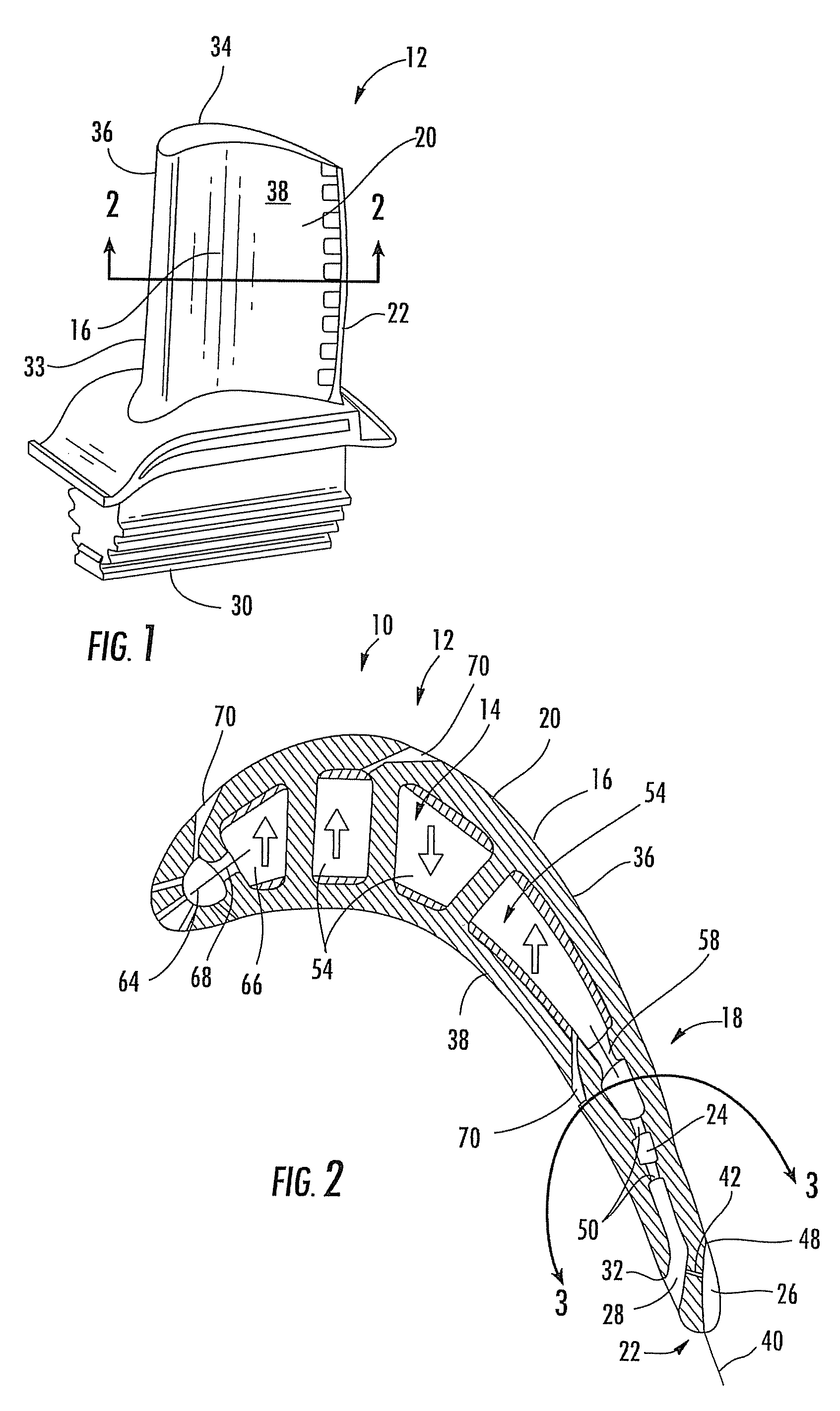

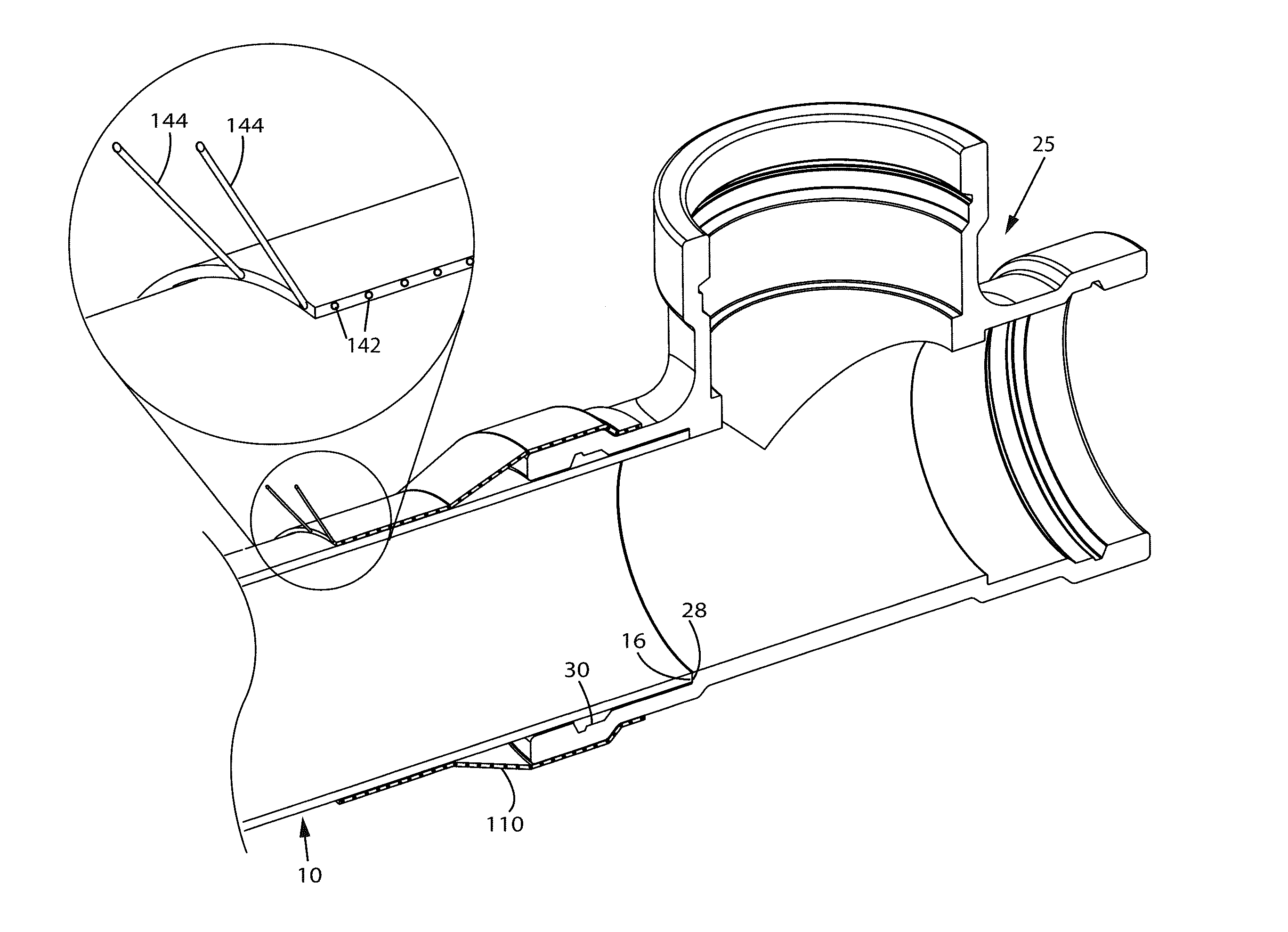

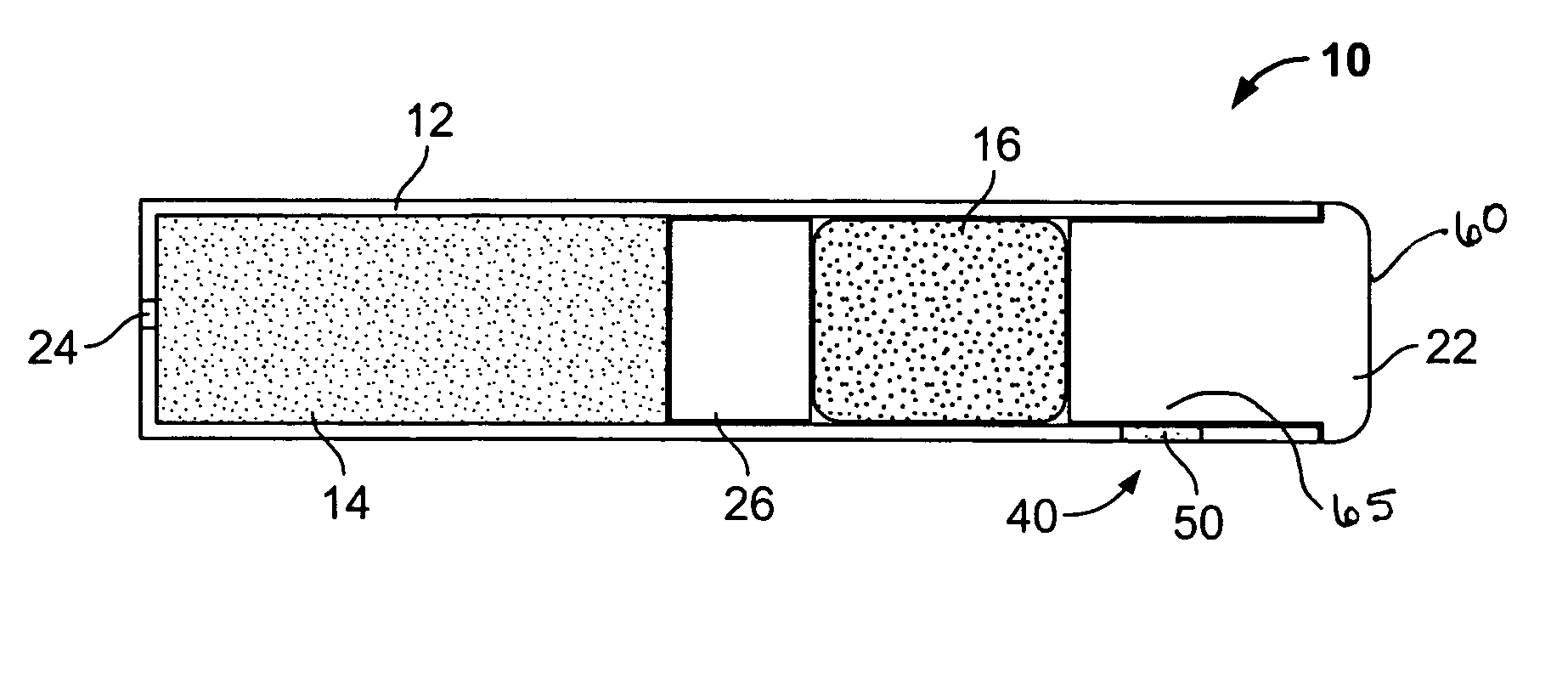

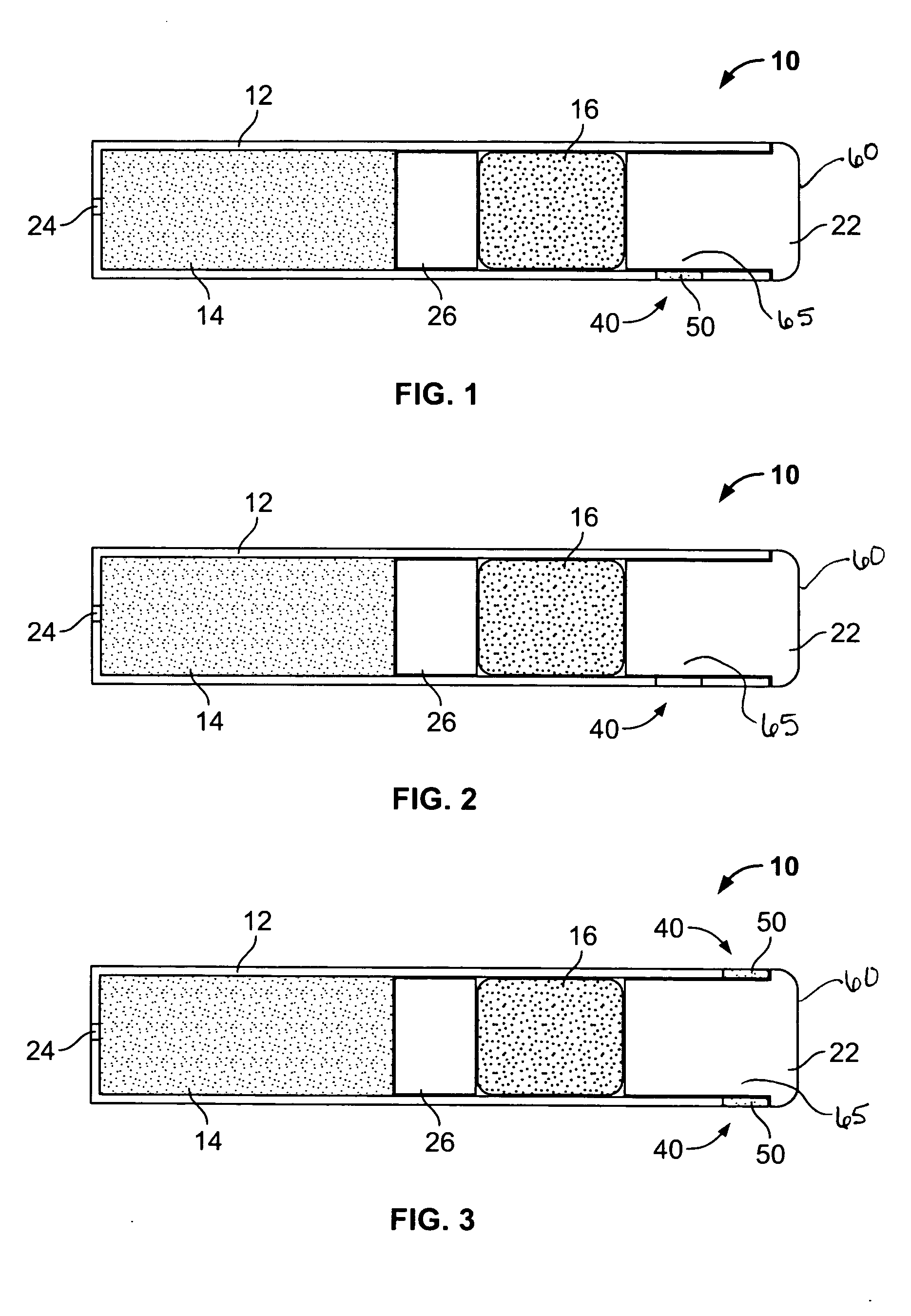

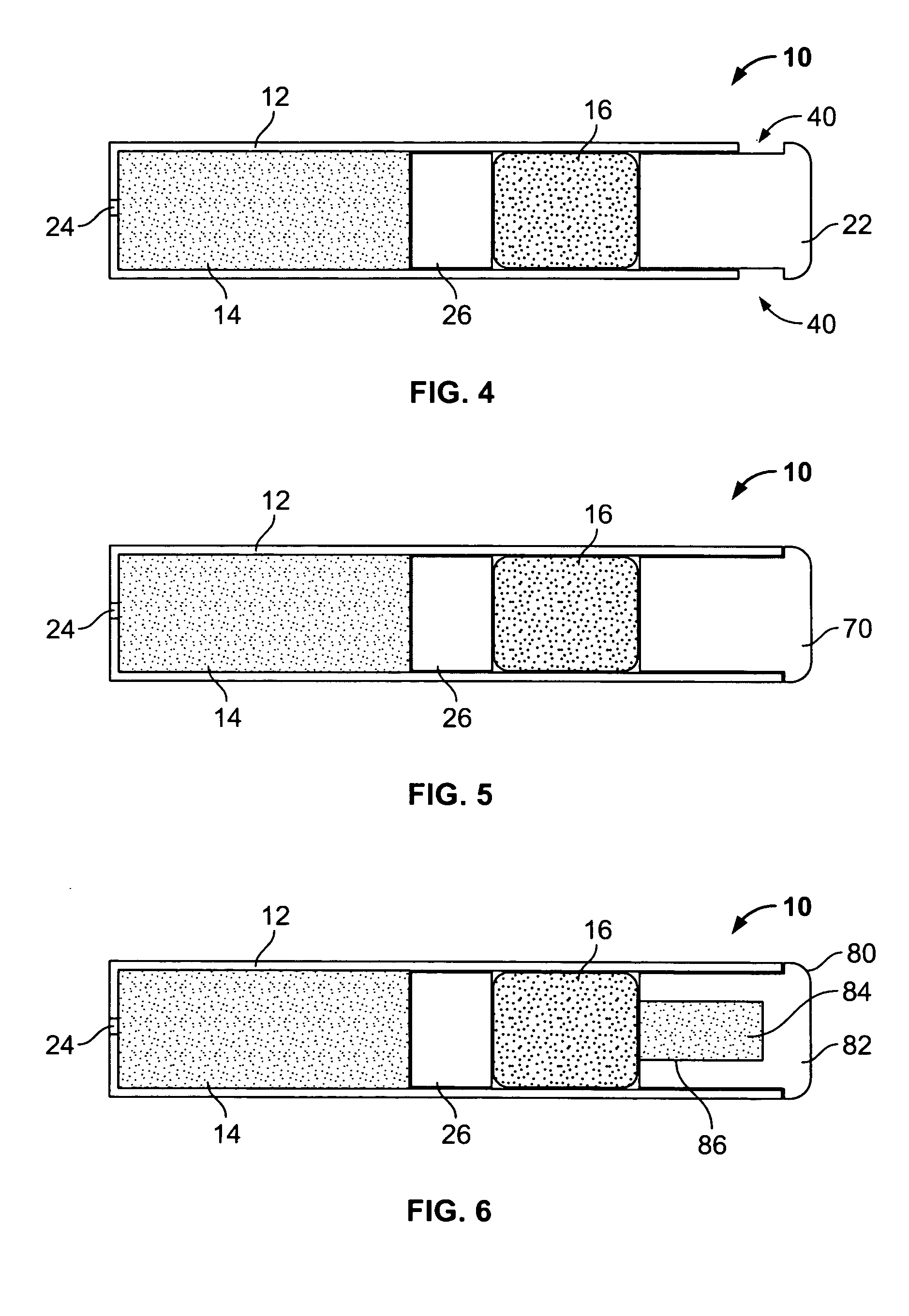

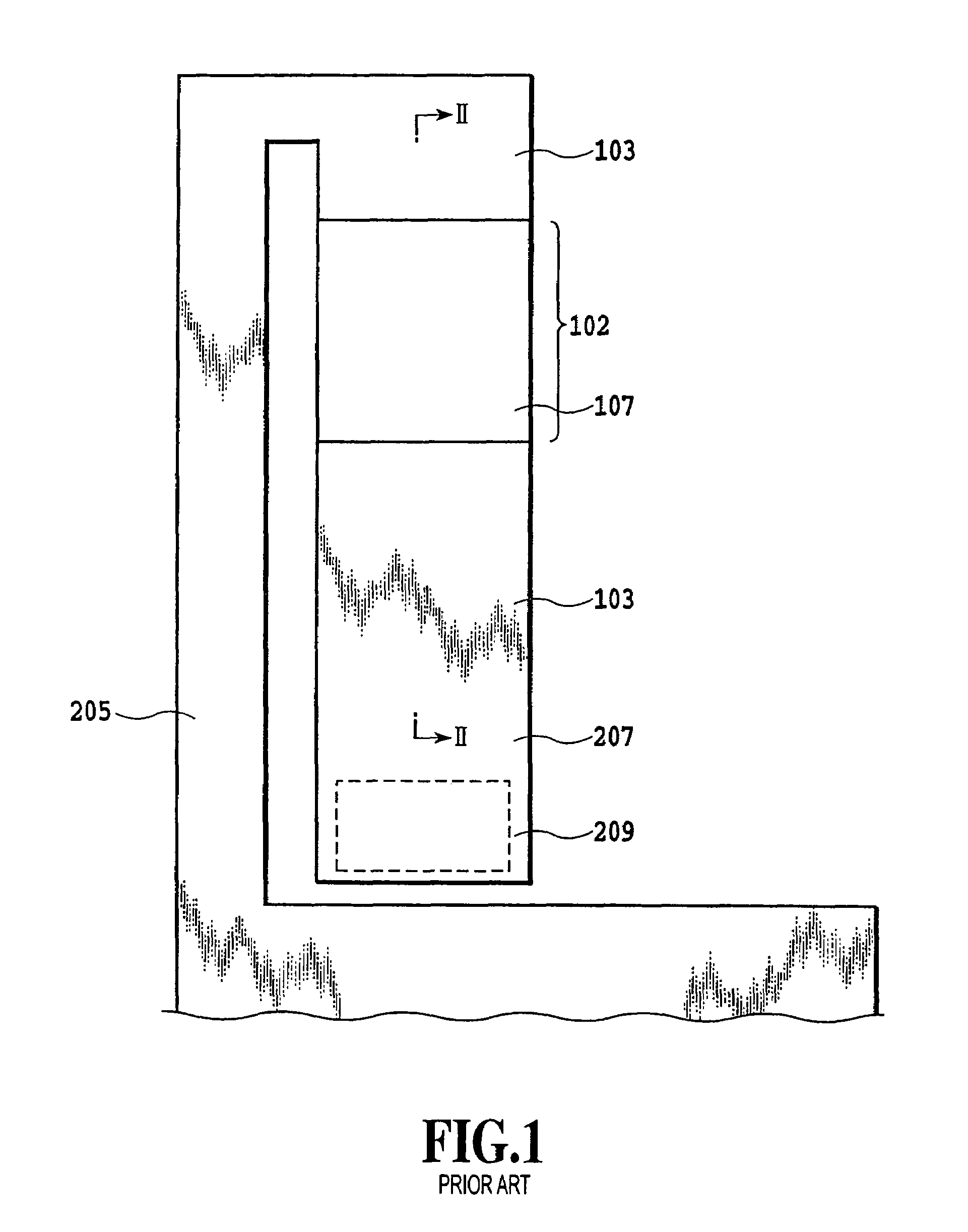

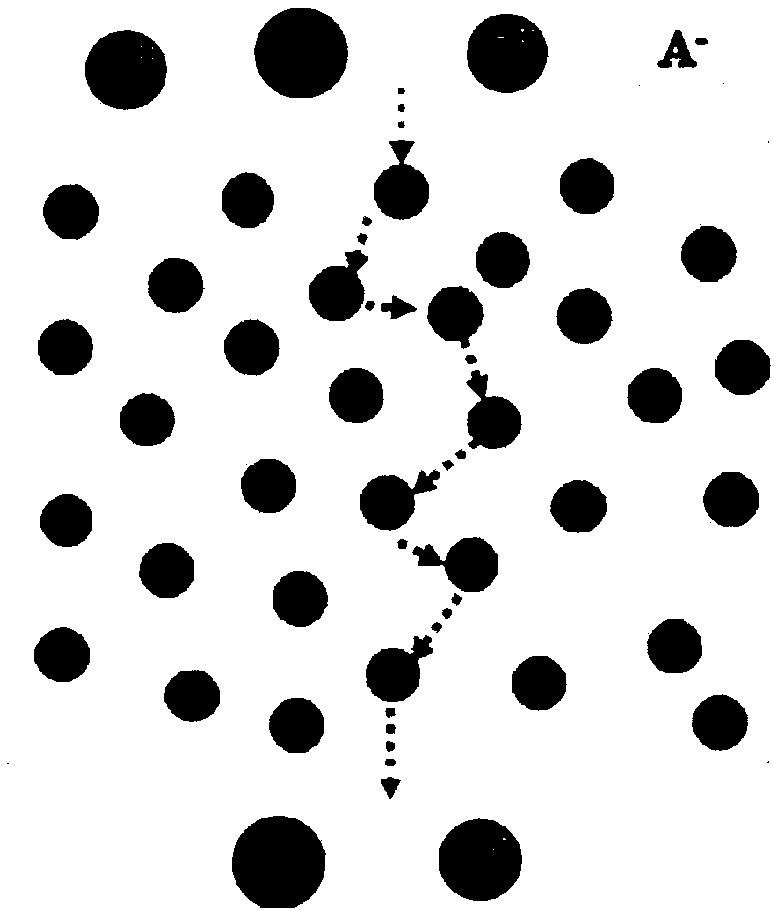

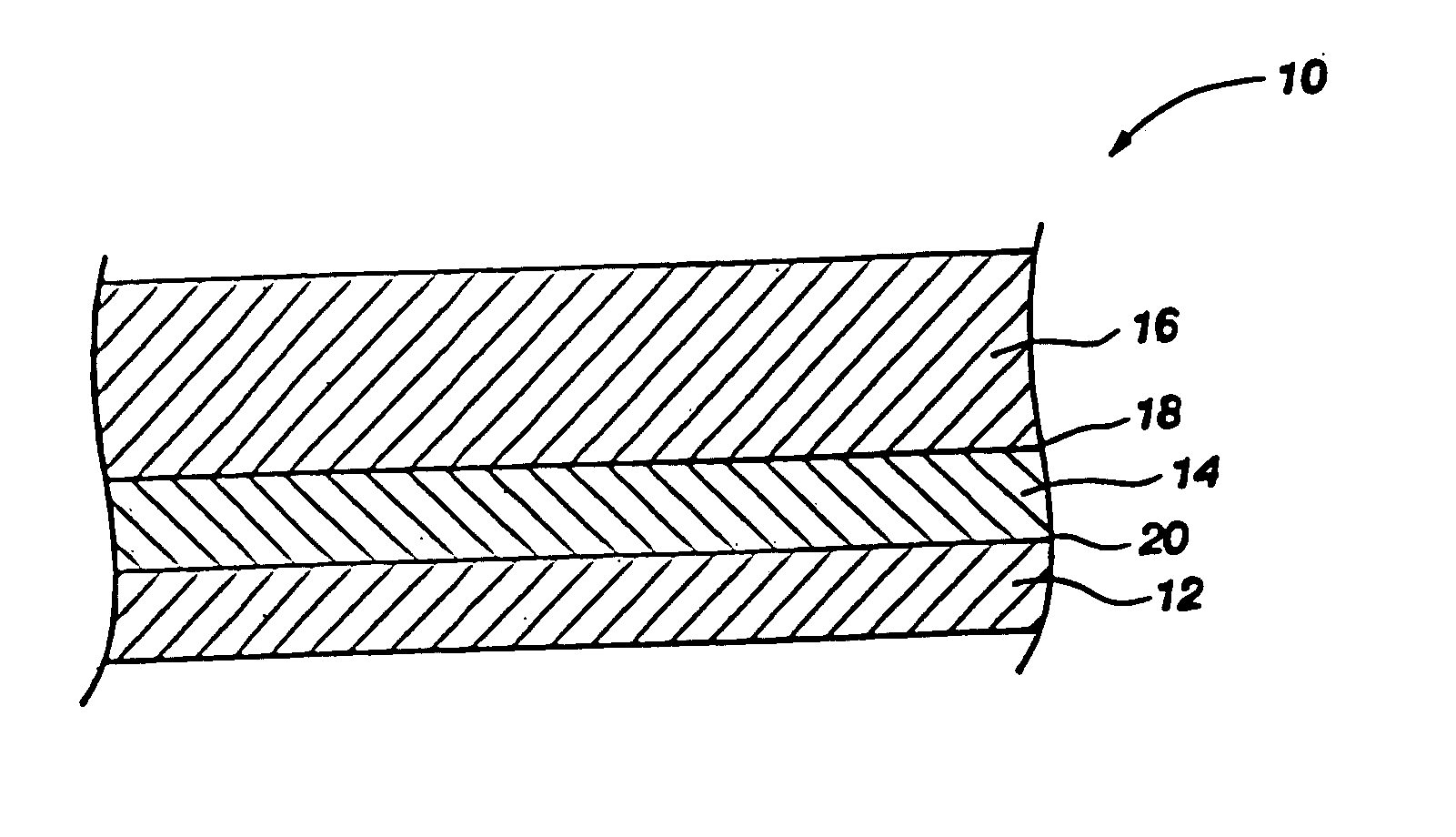

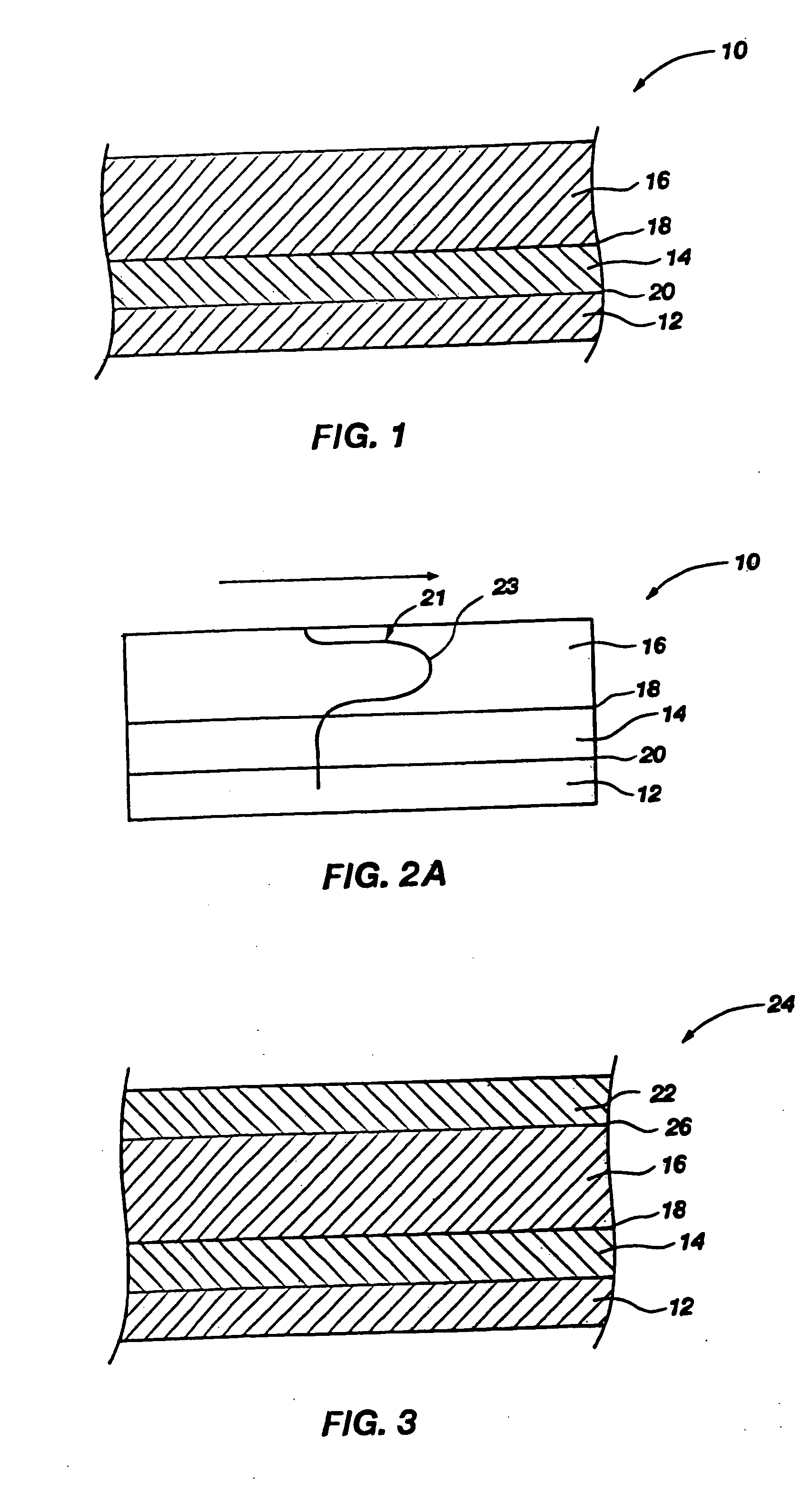

Osmotically driven active agent delivery device providing an ascending release profile

ActiveUS7241457B2Increase surface areaReduce effective thicknessPressure infusionOsmotic deliveryActive agentWater flow

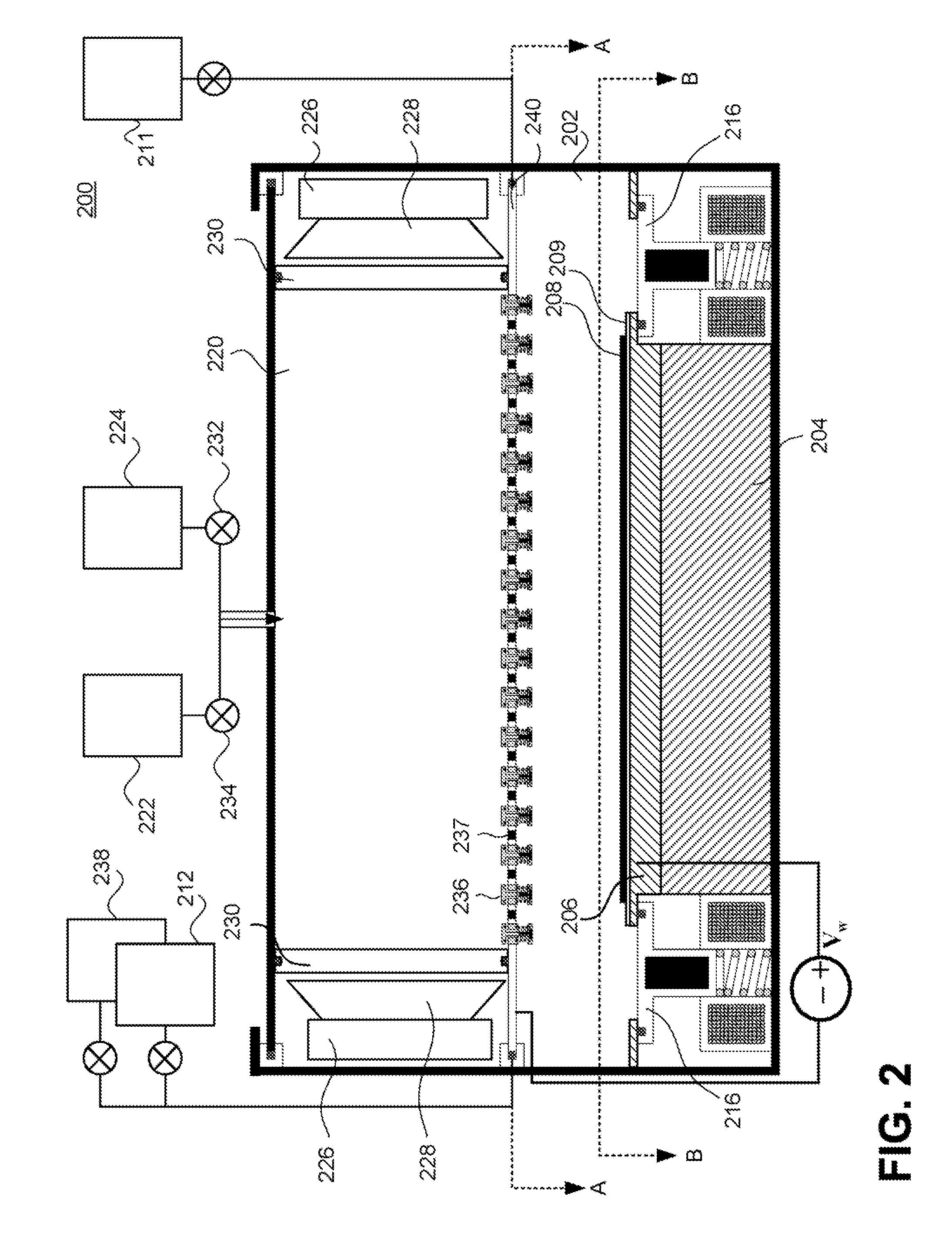

In one aspect, the present invention is directed to an osmotic pump that automatically provides an ascending release rate of active agent as the osmotic pump functions in an environment of operation and may be designed for implantation within a desired animal or human subject. An osmotic pump according to the present invention includes a reservoir, a rate controlling membrane, an expandable osmotic composition, an active agent formulation and an exit orifice. Once administered to an environment of operation, water passes through the rate controlling membrane and into the osmotic composition, which causes the osmotic composition to expand and expel the active agent formulation through the exit orifice at a rate that is directly proportional to the rate at which water passes through the rate controlling membrane. An osmotic pump according to the present invention permits the flow of water through the rate controlling membrane to increase automatically without the need for manipulation of the osmotic pump after administration. As the flow of water through the rate controlling membrane increases, the rate at which active agent is delivered from the osmotic pump will also increase proportionally.

Owner:INTARCIA THERAPEUTICS INC

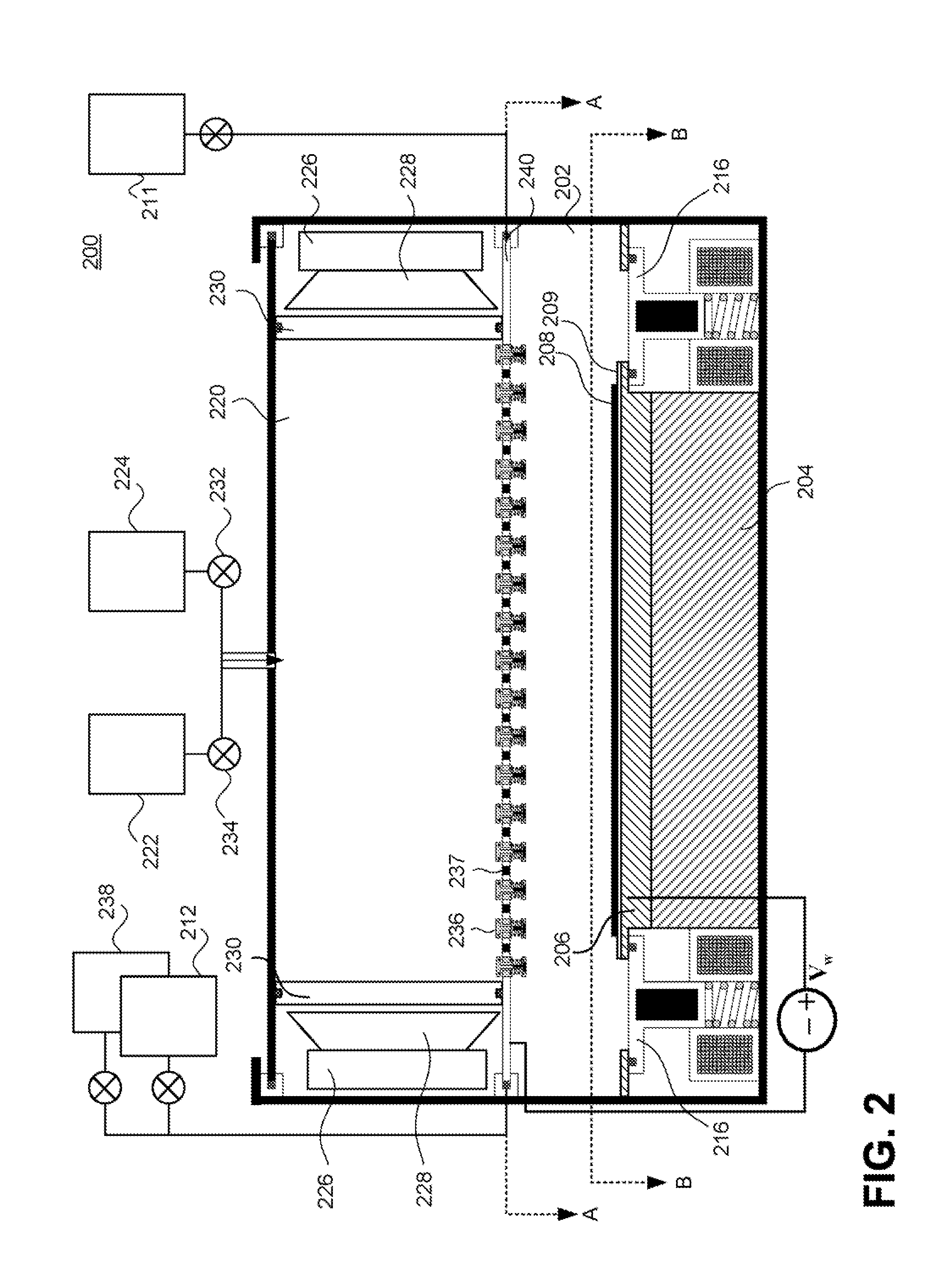

Systems for Flash Heating in Atomic Layer Deposition

InactiveUS20100024732A1Reduce incorporationQuality improvementElectric discharge tubesSemiconductor/solid-state device manufacturingMetallurgyAtomic layer deposition

System and methods for flash heating of materials deposited using atomic layer deposition techniques are disclosed. By flash heating the surface of the deposited material after each or every few deposition cycles, contaminants such as un-reacted precursors and byproducts can be released from the deposited material. A higher quality material is deposited by reducing the incorporation of impurities. A flash heating source is capable of quickly raising the temperature of the surface of a deposited material without substantially raising the temperature of the bulk of the substrate on which the material is being deposited. Because the temperature of the bulk of the substrate is not significantly raised, the bulk acts like a heat sink to aid in cooling the surface after flash heating. In this manner, processing times are not significantly increased in order to allow the surface temperature to reach a suitably low temperature for deposition.

Owner:SANDISK TECH LLC

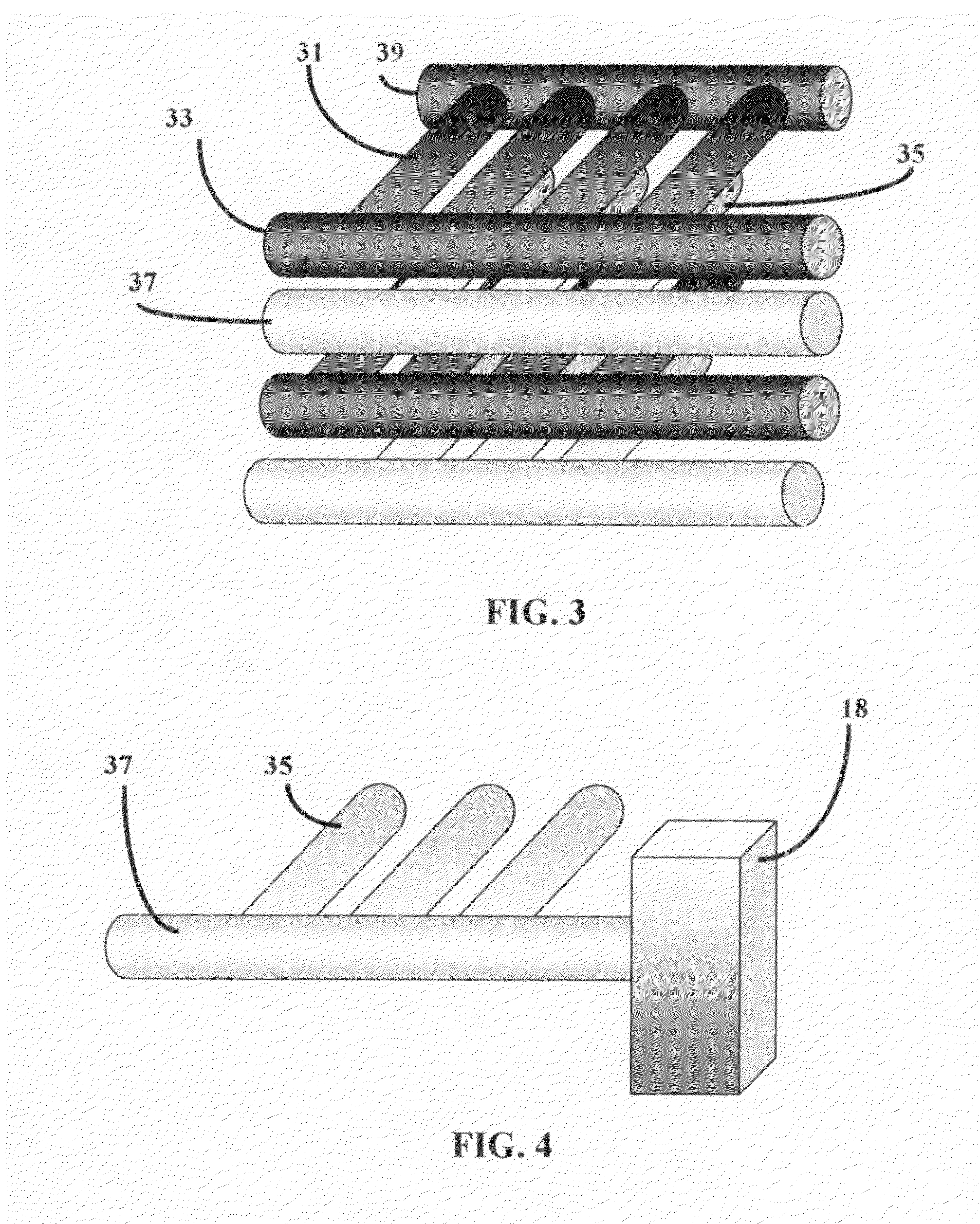

Preparation method of titanium-steel single-sided composite board

ActiveCN102773254AReasonable process designLow requirements for welding conditionsMetal rolling arrangementsLayer removalTechnical design

The invention discloses a preparation method of a titanium-steel single-sided composite board, comprising the following processing steps of: (1) respectively selecting two titanium plates with same size and two steel plates with same size and carrying out rust and oxide layer removal treatment on the surfaces of the plates; (2) assembling to form multiple layers of symmetrical combined blank sequentially including a steel plate, a transition layer, a titanium plate, a parting agent, a titanium plate, a transition layer and a steel plate, wherein a gap exists between the periphery of the titanium plate and a barrier strip in the combined blank; (3) compressing the combined blank and respectively welding the barrier strip with a first steel plate and a second steel plate to form a closed cavity among the first steel plate, the second steel plate and the barrier strip, drilling holes in the barrier strip and welding a steel tube in the holes, and communicating the steel tube and the closed cavity; (4) conveying the combined blank into a heating furnace to heat and vacuumizing; (5) sealing the outer end of the steel tube and then conveying the combined blank into a rolling mill; and (6) cutting the combined blank after rolling to obtain the titanium-steel single-sided composite board. The preparation method disclosed by the invention is rational in technical design and low in production cost.

Owner:河南盛荣金属复合新材料有限公司

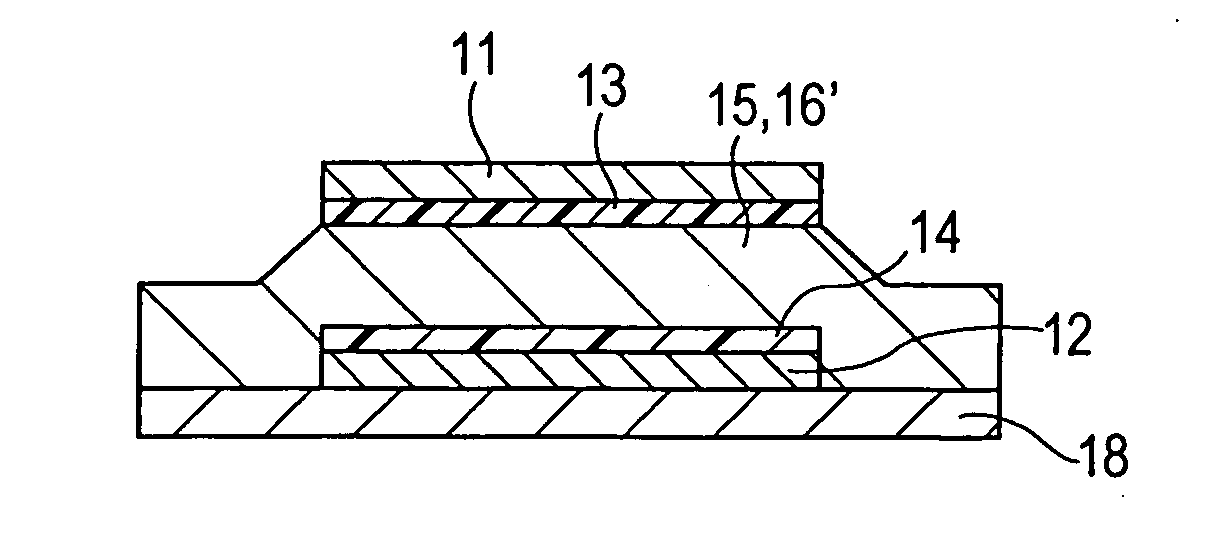

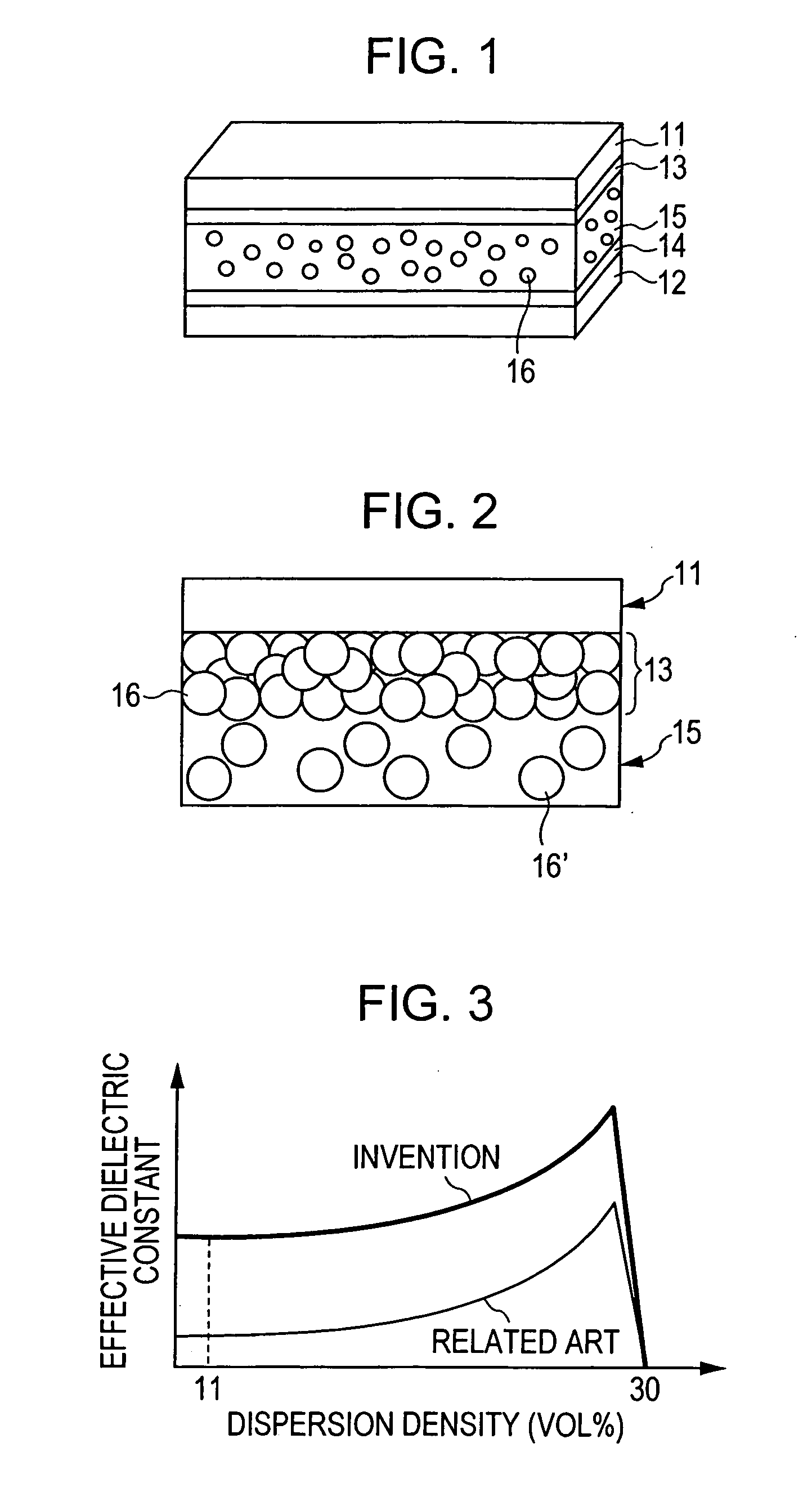

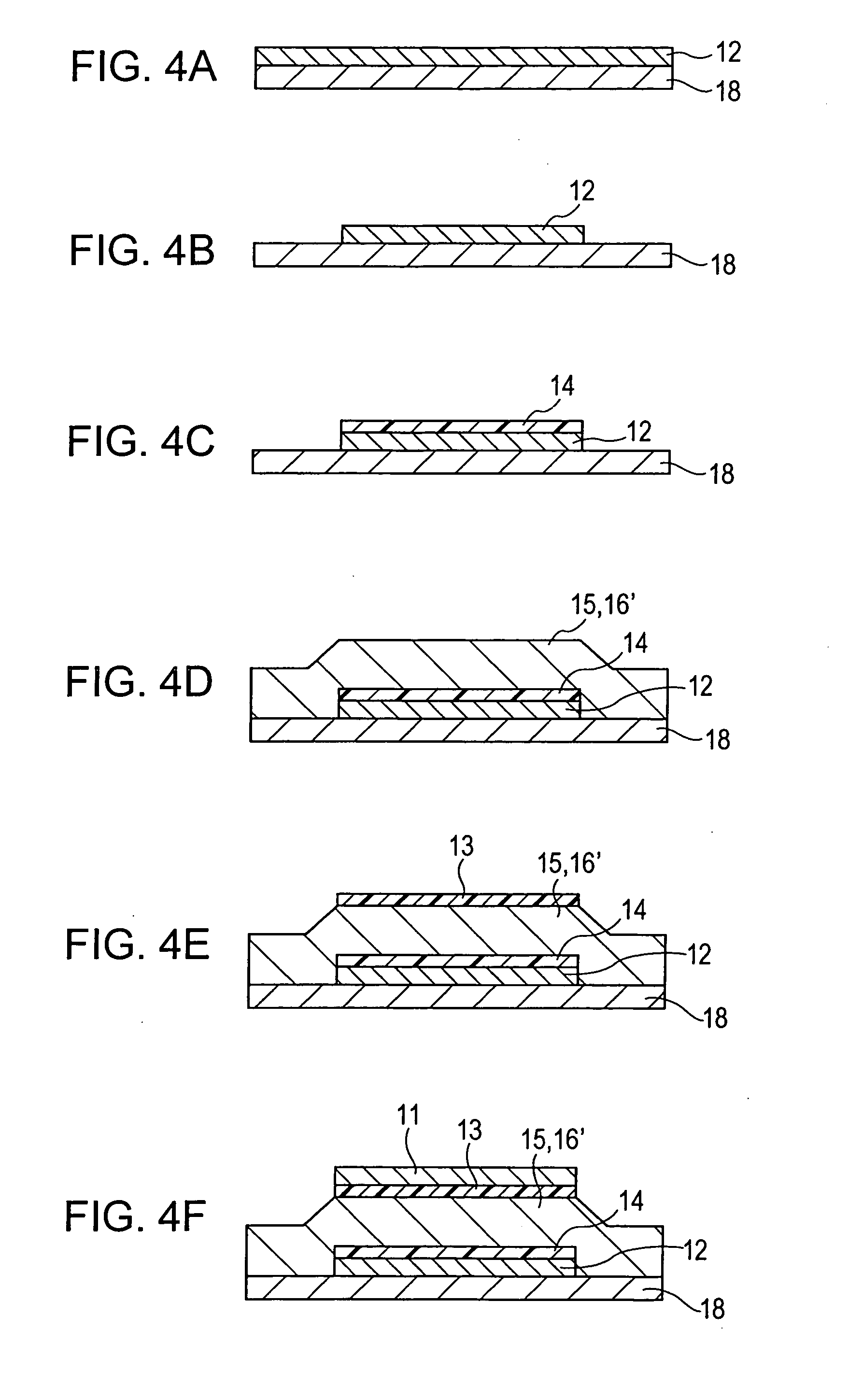

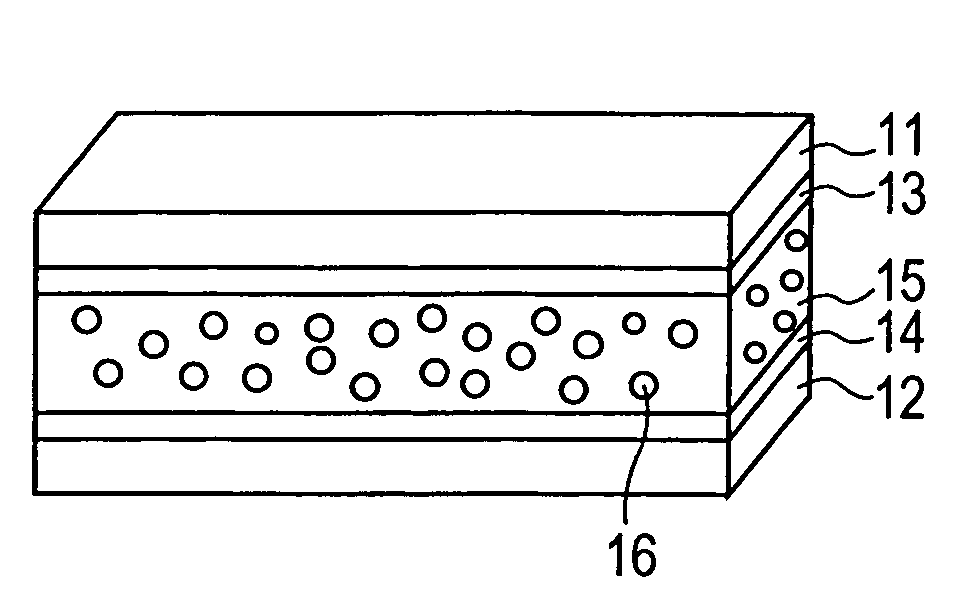

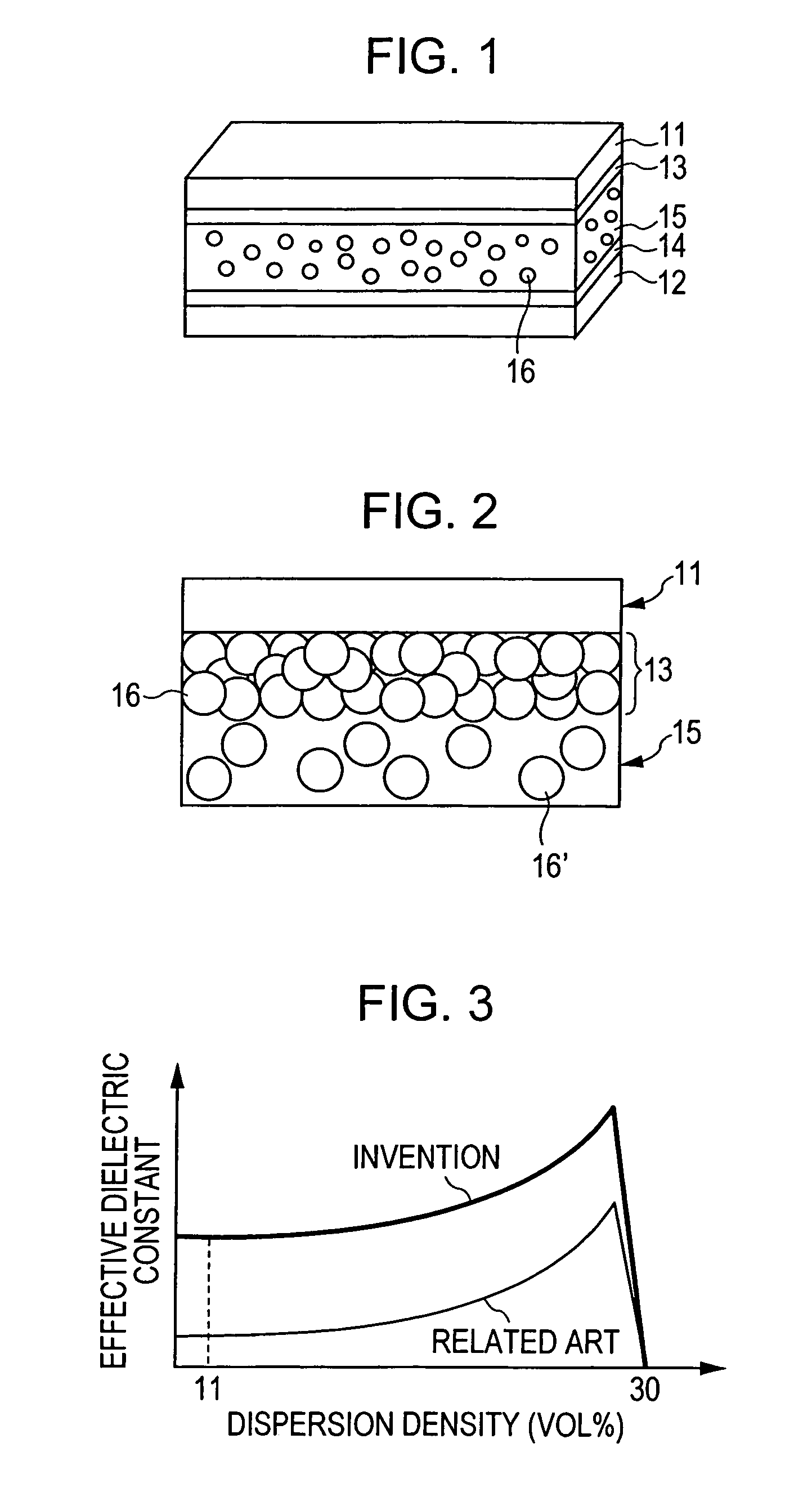

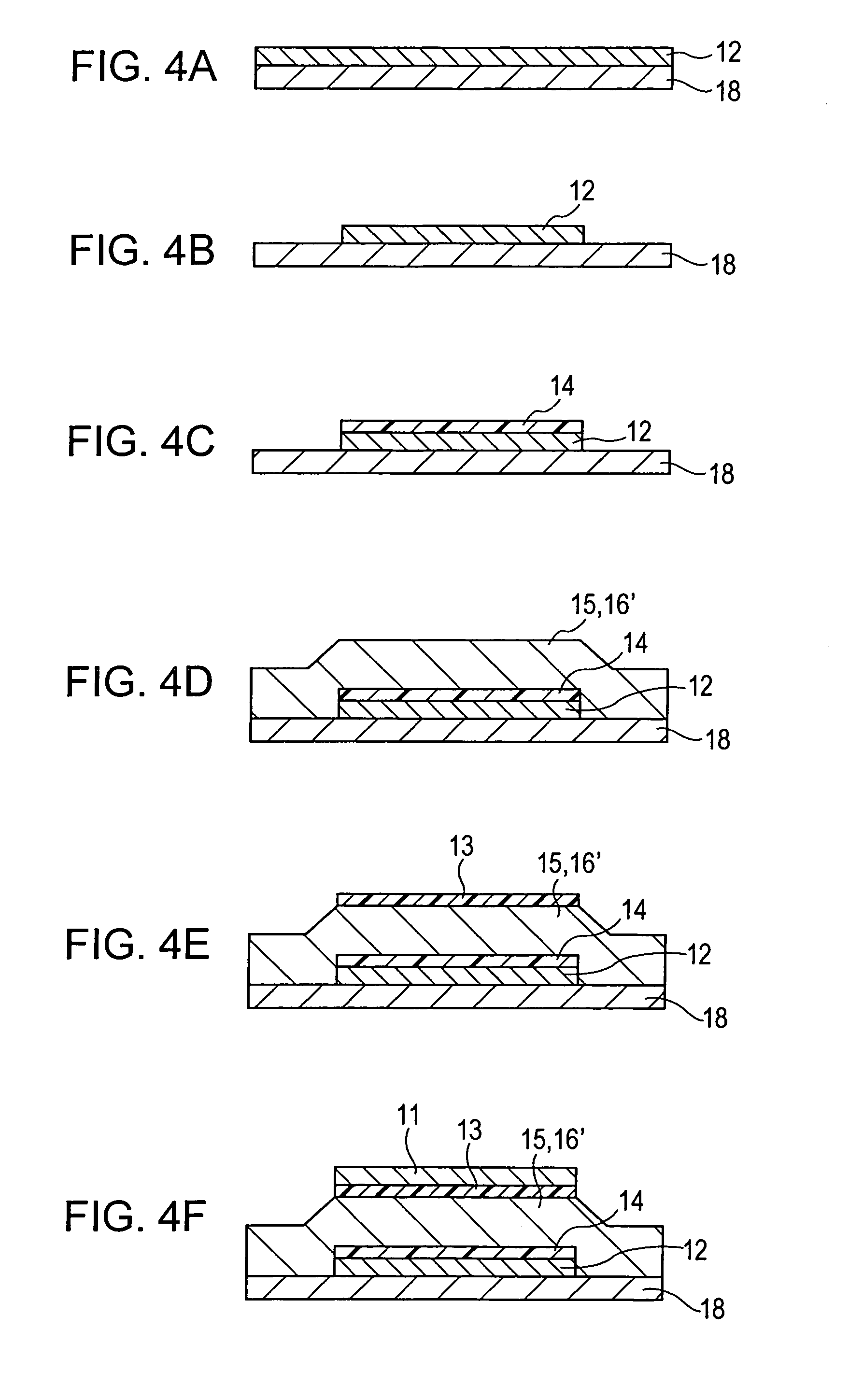

Capacitor

ActiveUS20070001258A1Thickness of dielectric layer decreaseIncrease dielectric constantTransistorFixed capacitor electrodesOptoelectronicsDielectric layer

A capacitor includes a first electrode and a second electrode arranged so that a main surface of the first electrode opposes a main surface of the second electrode, a first pseudo electrode layer disposed on the main surface of the first electrode, and a dielectric layer disposed between the first pseudo electrode layer and the main surface of the second electrode. The first pseudo electrode layer includes conductive particles electrically coupled to the first electrode.

Owner:ALPS ALPINE CO LTD

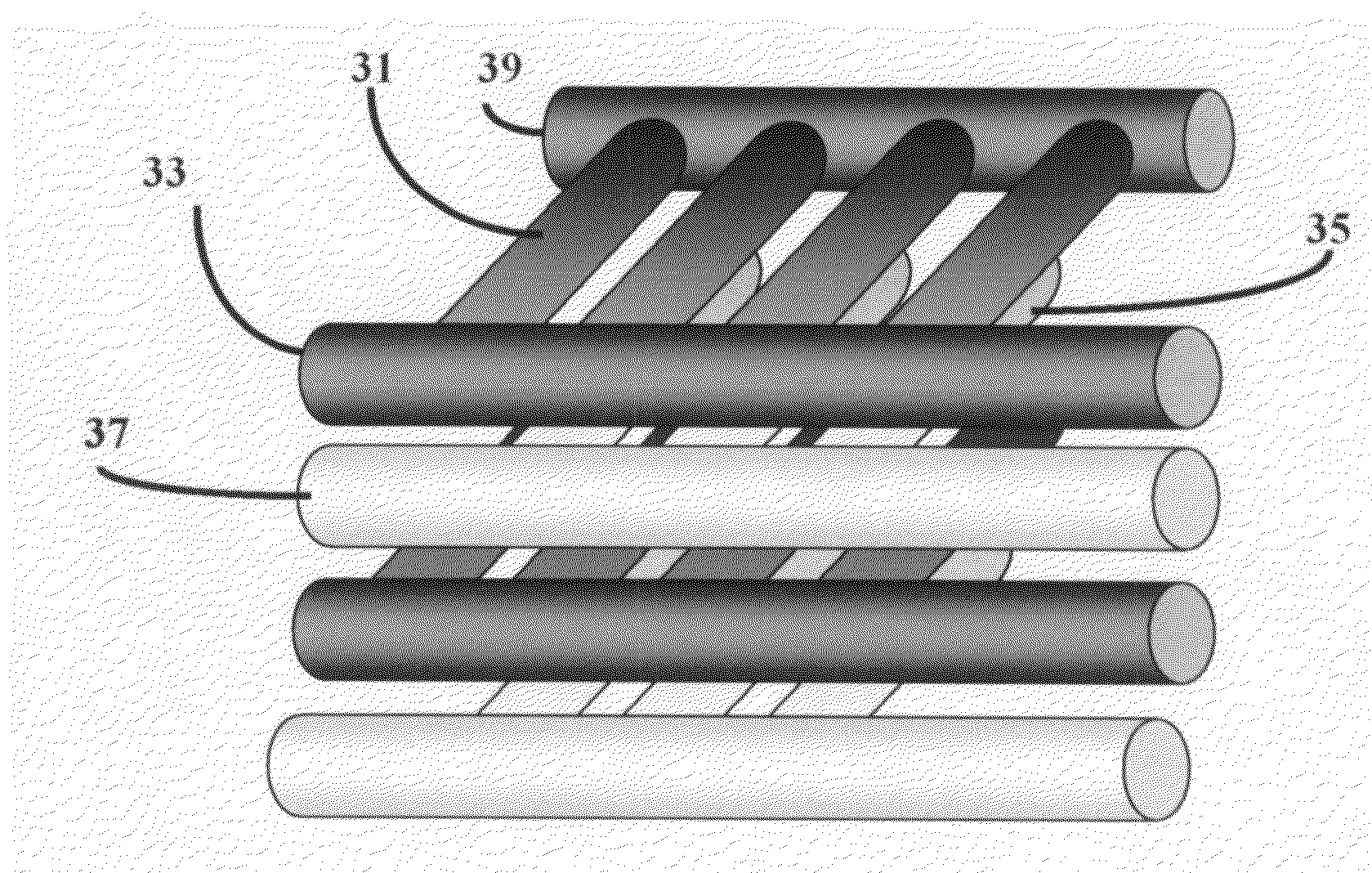

Manufacturing method of titanium-steel-titanium two-sided composite plate

ActiveCN102773670AReasonable process designLow requirements for welding conditionsSheet steelTitanium

The invention discloses a manufacturing method of a titanium-steel-titanium two-sided composite plate. The manufacturing method comprises the following processing steps: (1) four titanium plates with the same dimension and three steel plates with the same dimension are selected respectively, and rust and oxide layer removal processing is performed on the surfaces of the titanium plates and the steel plates; (2) a multilayer combination blank with three layers of steel plates, four layers of titanium plates and four layers of transition layers is formed through assembly, and gaps are arranged between the peripheries of the titanium plates and barrier strips in the combination blank; (3) the combination blank is pressed tightly and enables the barrier strips to be welded to a first steel plate and a third steel plate so as to enable the first steel plate, the second steel plate and the inner portions of the barrier strips to form a closed cavity, holes are drilled on the barrier strips, steel tubes are welded in the holes, and the steel tubes are communicated with the closed cavity; (4) the combination blank is sent to a heating furnace to be heated and vacuumized; (5) the combination blank is sent to a rolling mill to be rolled after the outer ends of the steel tubes are sealed; and (6) one titanium-steel-titanium two-sided composite plate and two titanium-steel single-sided composite plates are obtained by slitting the combination blank after the combination blank is rolled. The manufacturing method of the titanium-steel-titanium two-sided composite plate is reasonable in design and low in production cost.

Owner:河南盛荣金属复合新材料有限公司

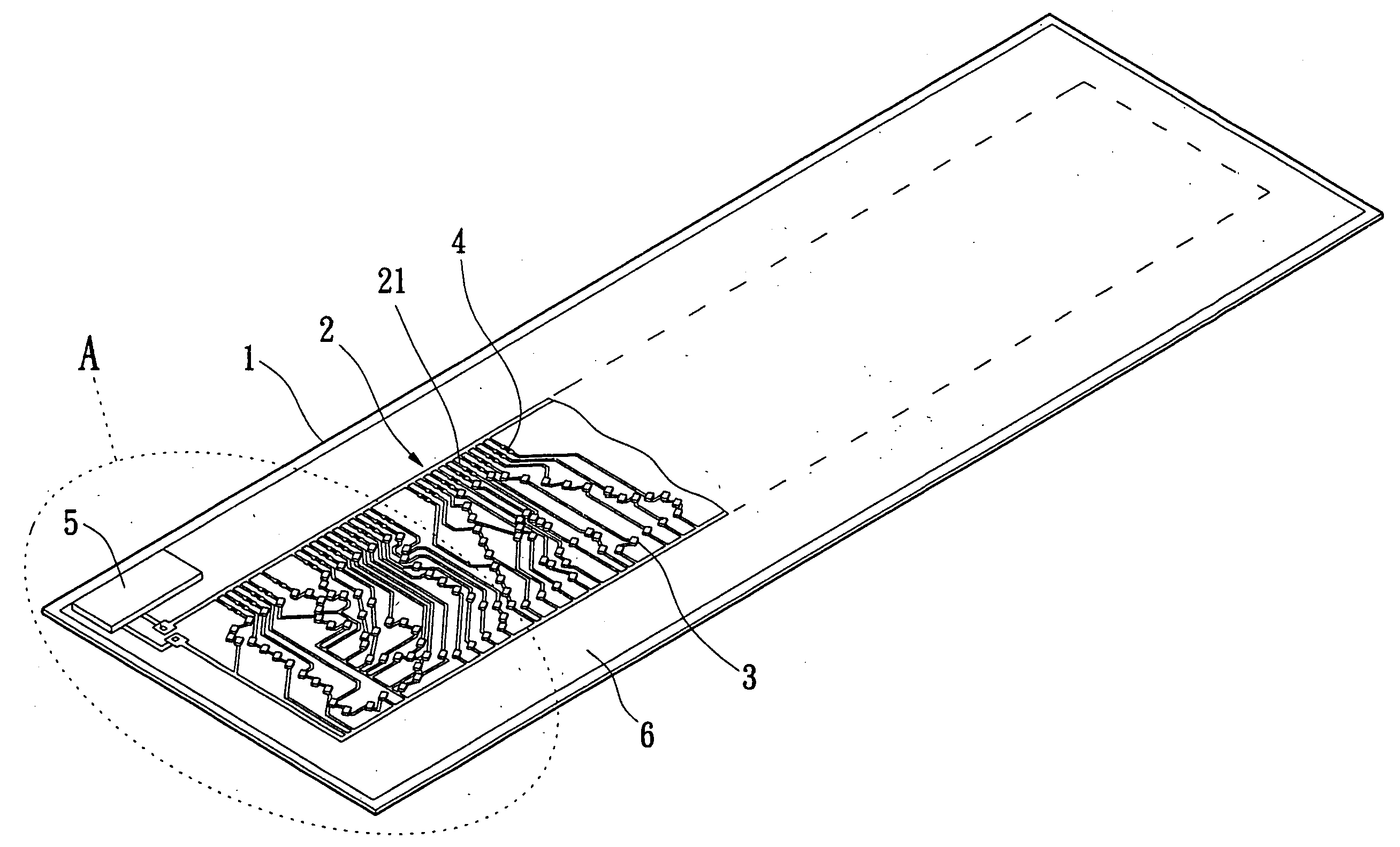

Laminated light-emitting diode display device and manufacturing method thereof

InactiveUS7563641B2Reduce effective thicknessEasy to installDischarge tube luminescnet screensFinal product manufactureDisplay deviceEngineering

A laminated light-emitting diode display device and a manufacturing method thereof are described. The laminated light-emitting diode display device has an insulator, a circuitry device placed on the insulator and having of a plurality of circuits interconnected with each other, and a plurality of SMT-type light-emitting diodes electrically connected to the circuits of the circuitry unit.

Owner:HARVATEK CORPORATION

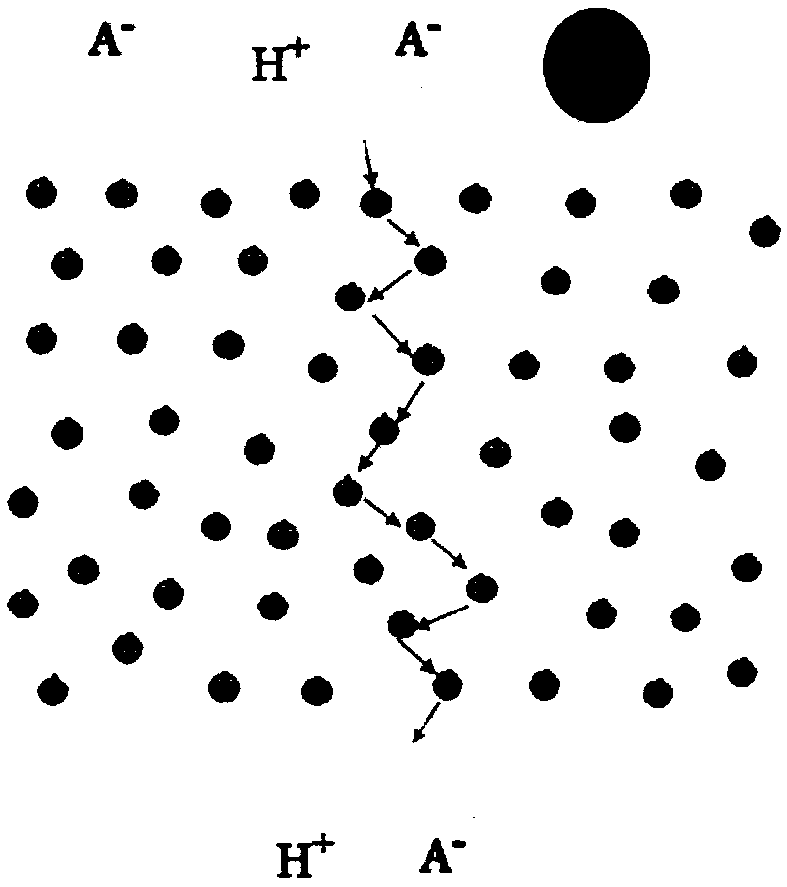

Novel fuel cells and methods of manufacturing the same

InactiveUS20080003481A1Increase charging rateImprove reaction efficiencyElectrolyte holding meansFinal product manufactureFuel cellsElectrolysis

A fuel cell, comprising an electrolyte body and, embedded within it, at least two separate electrodes capable of conducting electrons; the electrodes being sufficiently porous to allow gas flow through them; one electrode being an electrically negative anode and the other electrode being an electrically positive cathode, and the electrolyte body being capable of carrying charged particles between the anode and cathode; the anode and cathode being electrically connected to form an electrical circuit.

Owner:APPLIEDUS CORP

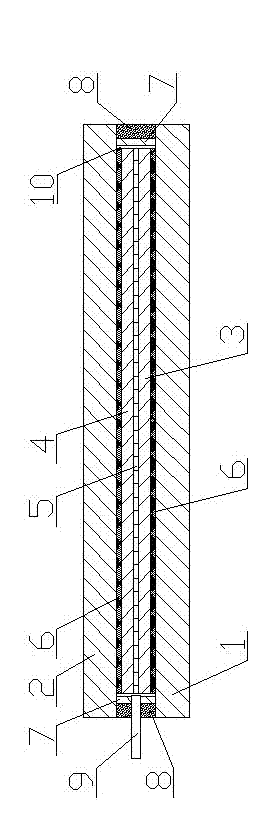

Low-noise avalanche photodetector and preparation method thereof

ActiveCN105576072AImprove quantum efficiencyReduce effective thicknessFinal product manufactureSemiconductor devicesLow noisePhotovoltaic detectors

The invention discloses a low-noise avalanche photodetector and a preparation method thereof. The low-noise avalanche photodetector comprises an N-type ohmic contact layer / P-type ohmic contact layer, a multiplication layer, a charge layer and a P-type ohmic contact layer / N-type ohmic contact layer with different doping types which are formed through diffusion and ion injection, and a substrate is formed at the bottom between the charge layer and the P-type ohmic contact layer / N-type ohmic contact layer; an inverted trapezoidal groove is formed among the charge layer, the P-type ohmic contact layer / N-type ohmic contact layer and the substrate; and an absorbed layer is formed in the inverted trapezoidal groove. A P-type electrode and an N-type electrode are arranged on the P-type ohmic contact layer and the N-type ohmic contact layer respectively. The low-noise avalanche photodetector has the characteristic that a one-dimensional longitudinal avalanche photodetector is of a two-dimensional transverse structure, and the effective thickness of the multiplication layer is reduced to a nanometer size, so that the k value is reduced by using the dead-time effect of a nanometer multiplication area.

Owner:WUHAN IND INST FOR OPTOELECTRONICS

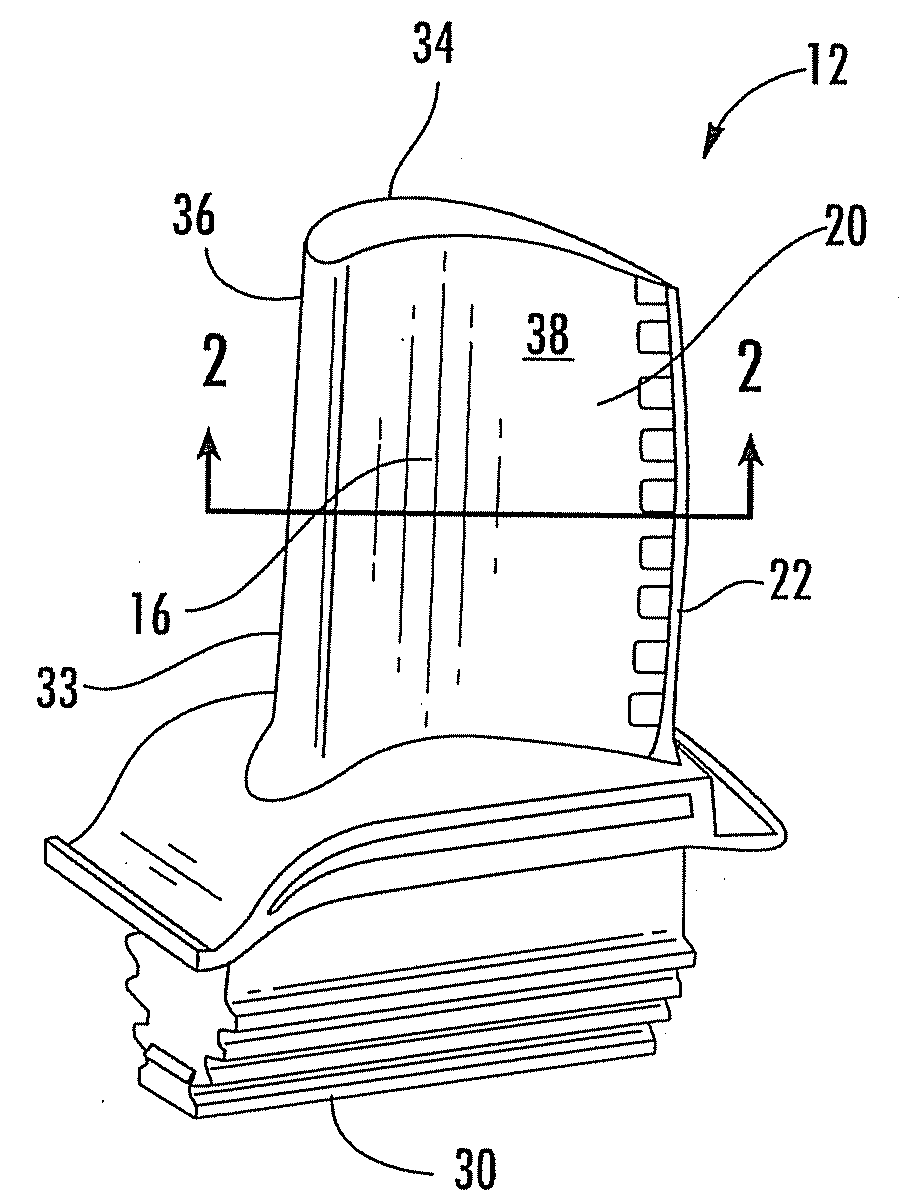

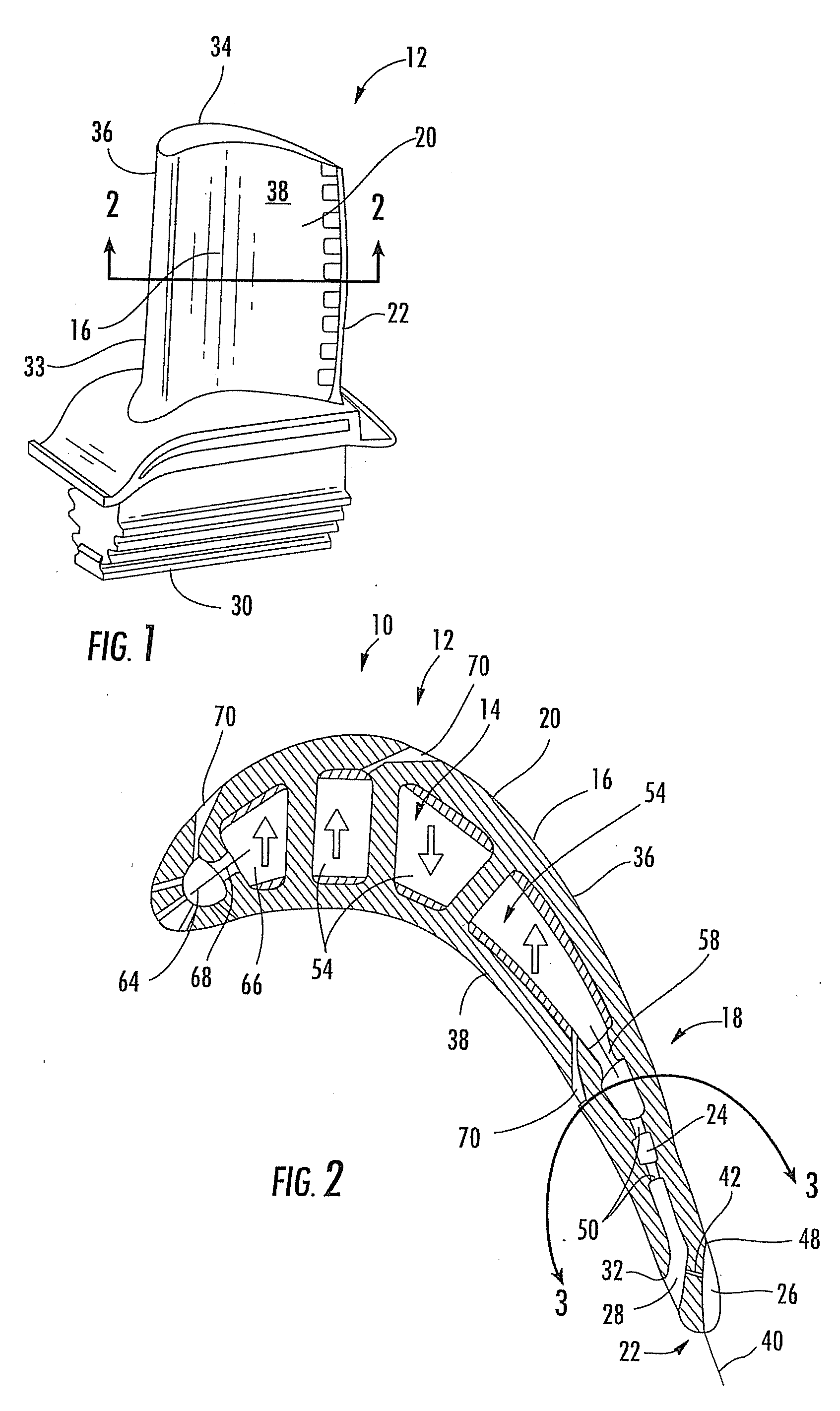

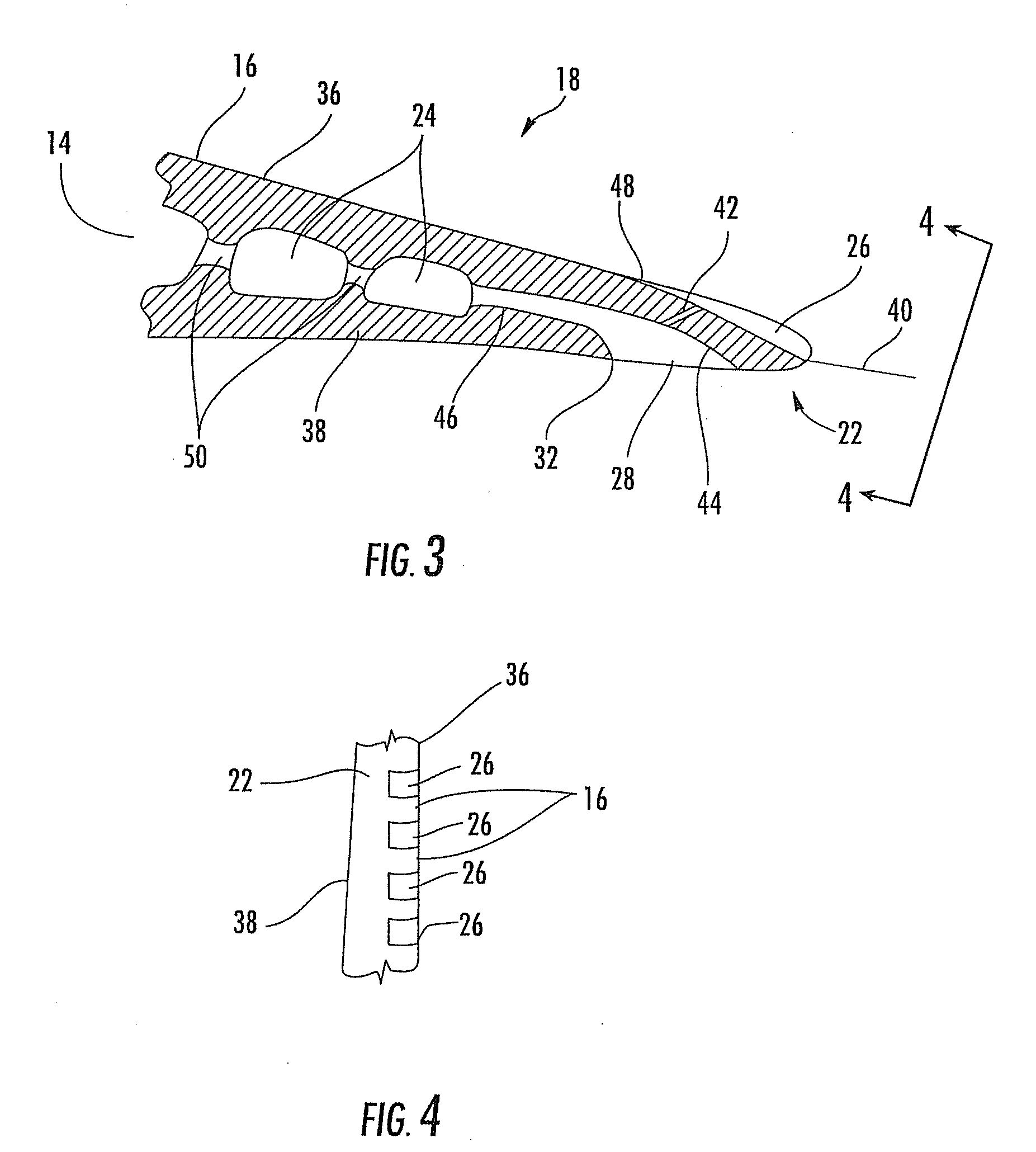

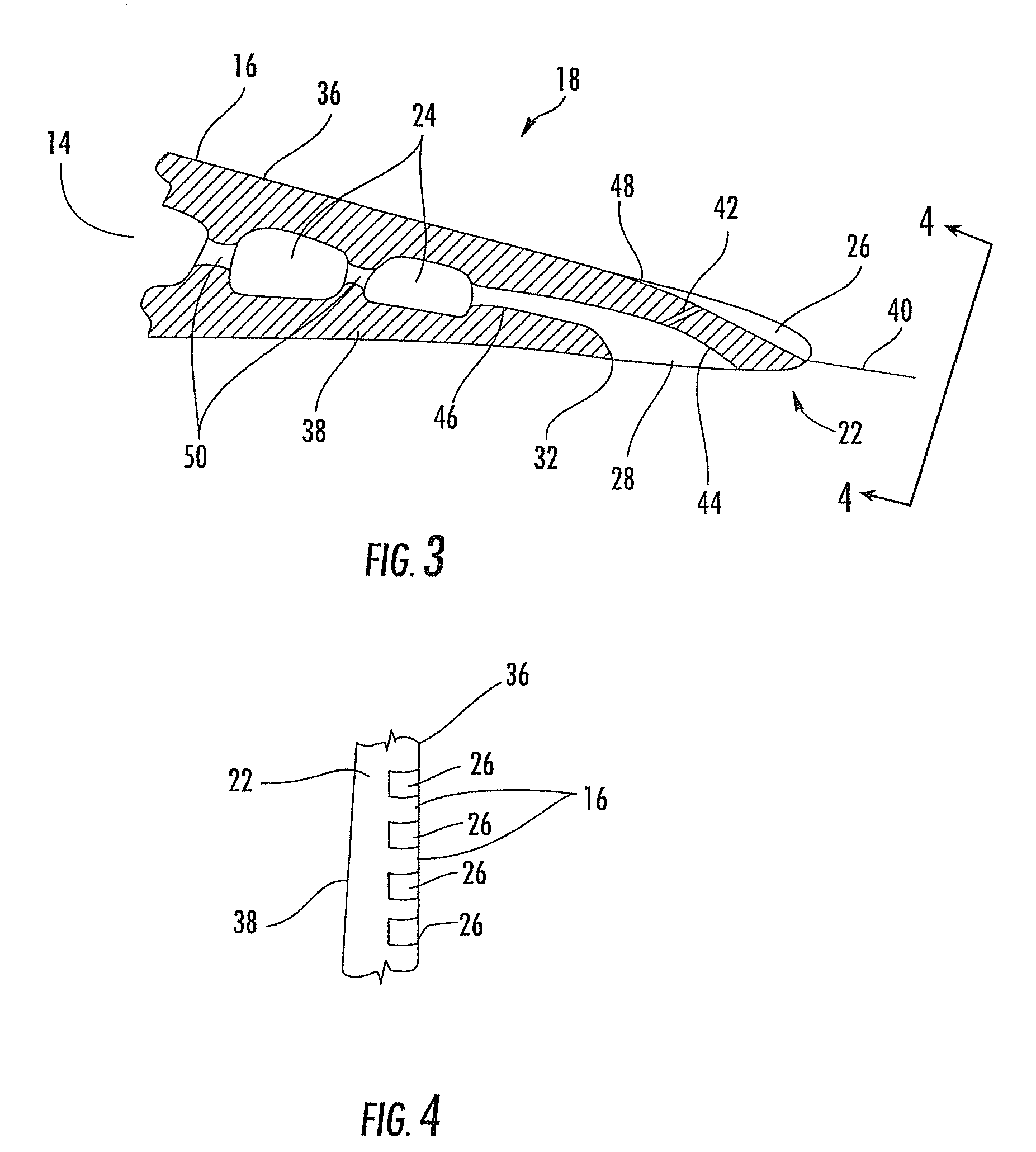

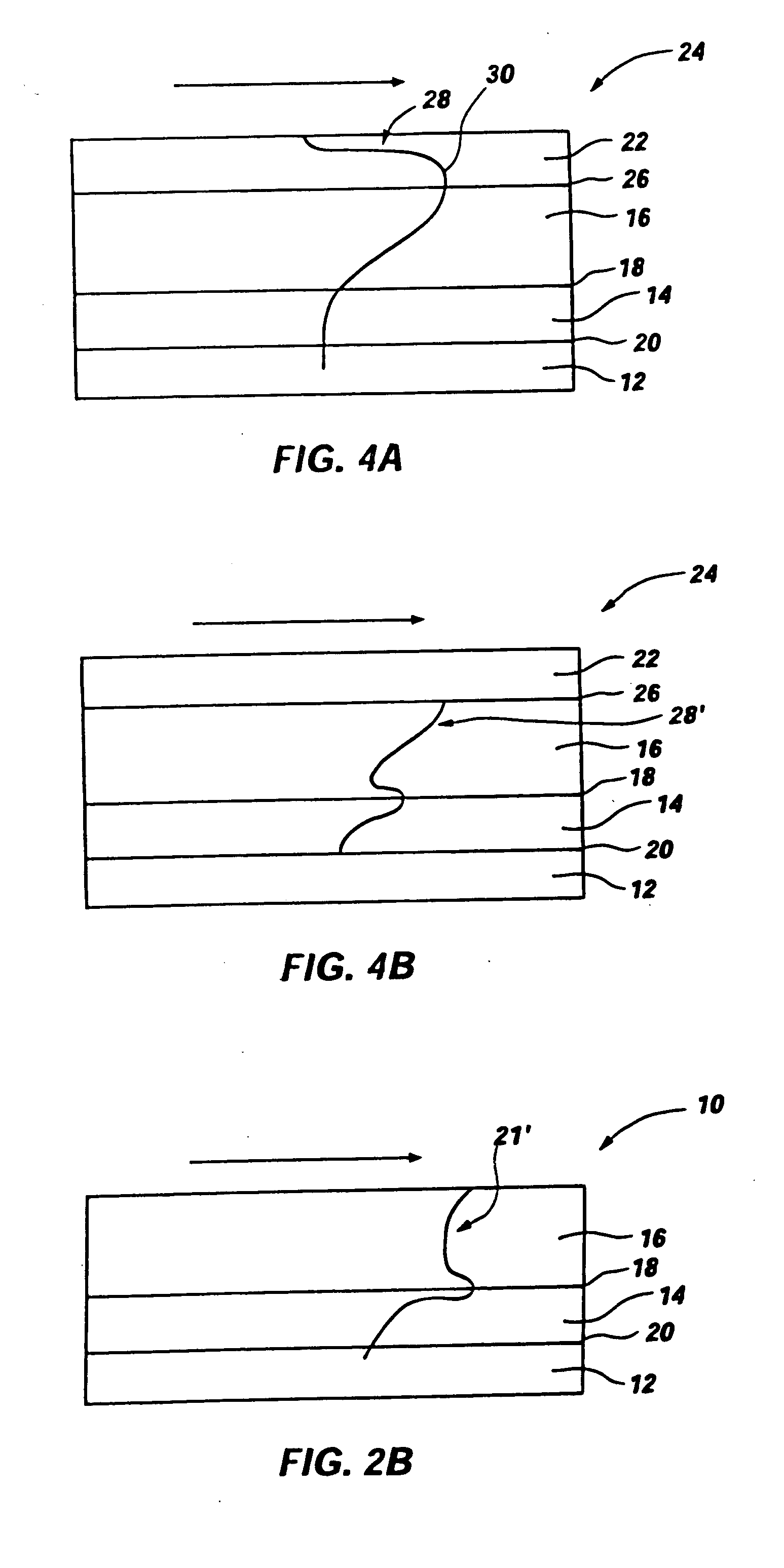

Turbine blade with multiple trailing edge cooling slots

InactiveUS20100183429A1Reduce airfoil trailing edge effective thicknessReducing base region heat loadEngine manufacturePump componentsTurbine bladeTrailing edge

A cooling system for a turbine airfoil of a turbine engine has a multiple suction side cooling slots extending from a front edge on the suction side to the center of the trailing edge or even to the pressure side of the center line and a pressure side cooling slot curving to a pressure side outlet forward of the trailing edge and having a front pressure side lip that is aligned with or forward of the front edge of the suction side cooling slots. The suction side cooling slots receive cooling flow from the pressure side cooling slots through a boundary layer bleed valve, which is also aligned with or rearward of the pressure side lip. The cooling system may also combine double impingement cooling with these features. The cooling system minimizes shear mixing, reduces hot spots and can reduce the trailing edge thickness, resulting in more efficient stage performance and extended operational life.

Owner:SIEMENS ENERGY INC

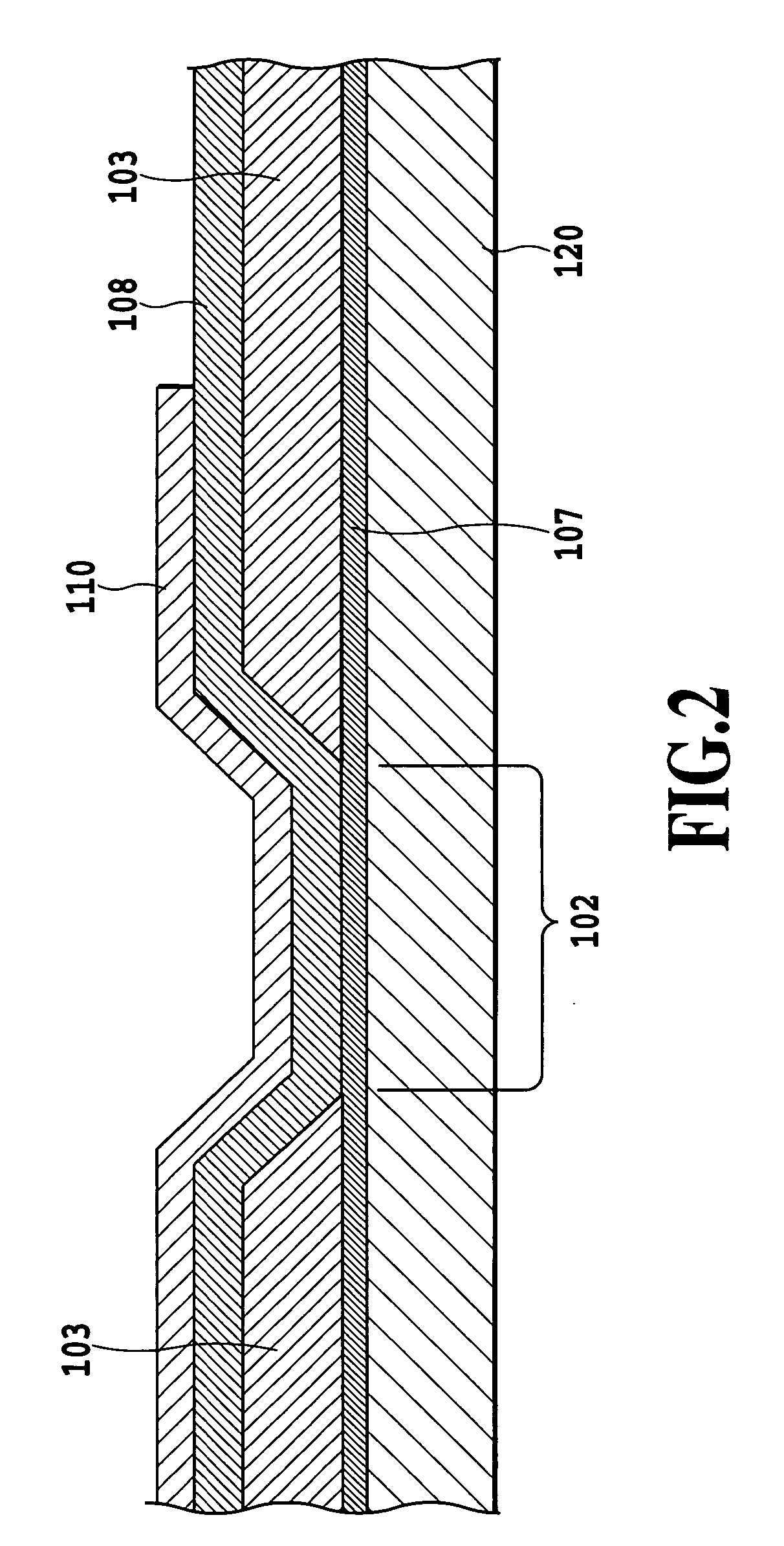

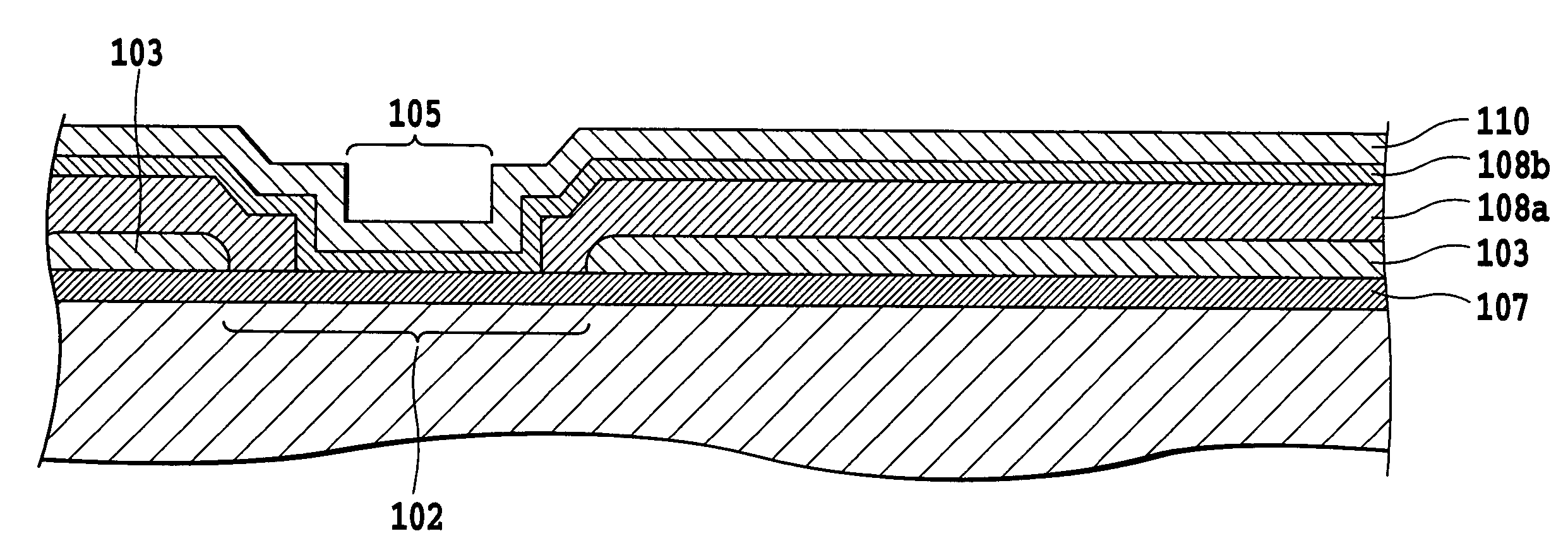

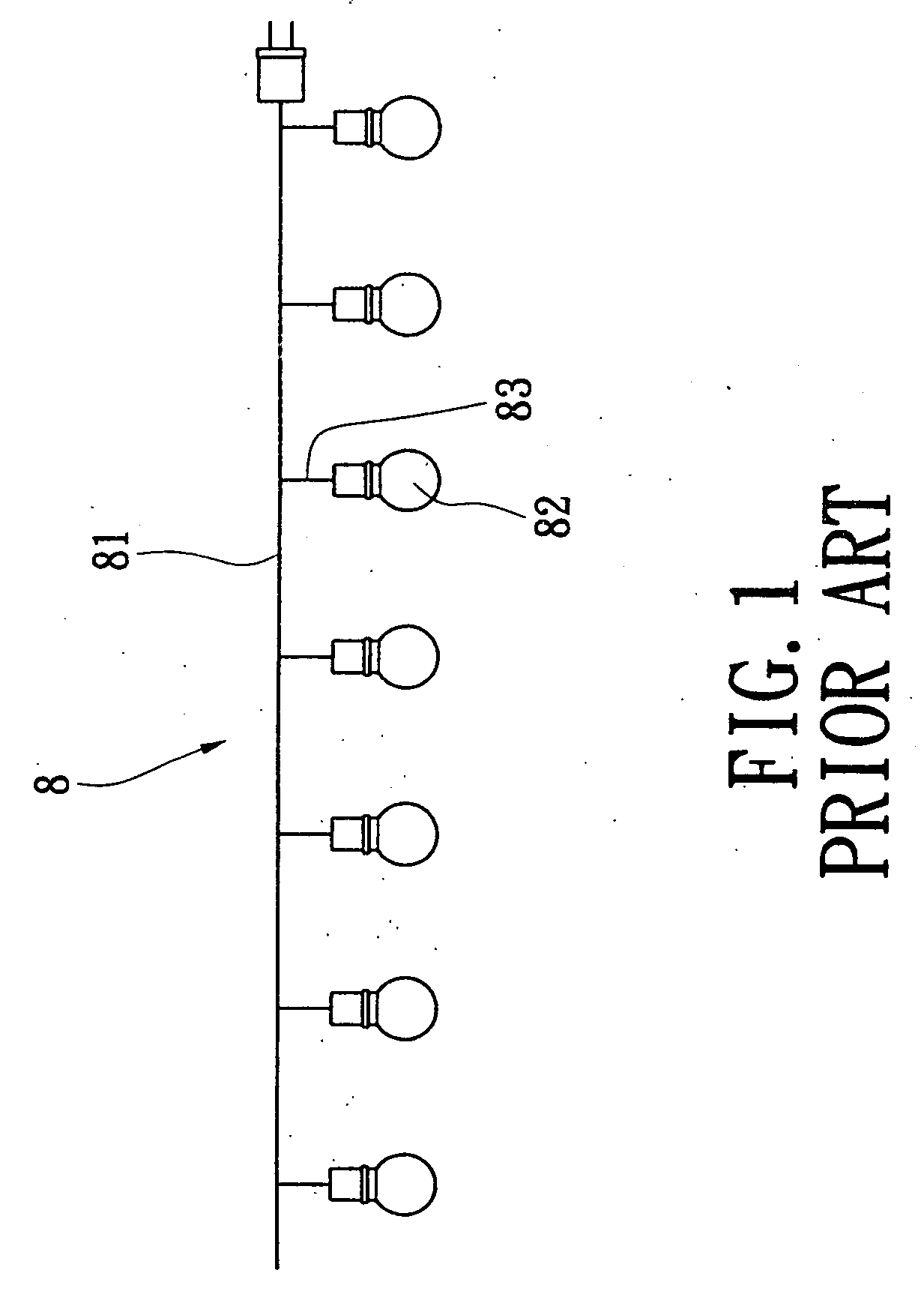

Ink jet head circuit board, method of manufacturing the same and ink jet head using the same

InactiveUS20060033782A1Reduce areaPrevent thermal degradationSemiconductor/solid-state device detailsSolid-state devicesThermal energyInsulation layer

An ink jet head circuit board is provided which has heaters to generate thermal energy for ink ejection as they are energized. This circuit board reduces areas of the heaters to achieve higher printing resolution and image quality. This board also prevents a degradation of thermal energy efficiency and reduces power consumption. The protective insulation layer for the electrode wire layer is formed of two layers and one of the two layers is removed from above the heater to improve the heat energy efficiency. The resistor layer is deposited over the electrode wire layer. The patterning for removing the protective insulation layer is done in a wider range than a gap of the electrode wire layer, the gap being used to form the heater. Further, by forming the electrode wires in two layers, a possible reduction in an effective bubble generation area of the heater can be prevented.

Owner:CANON KK

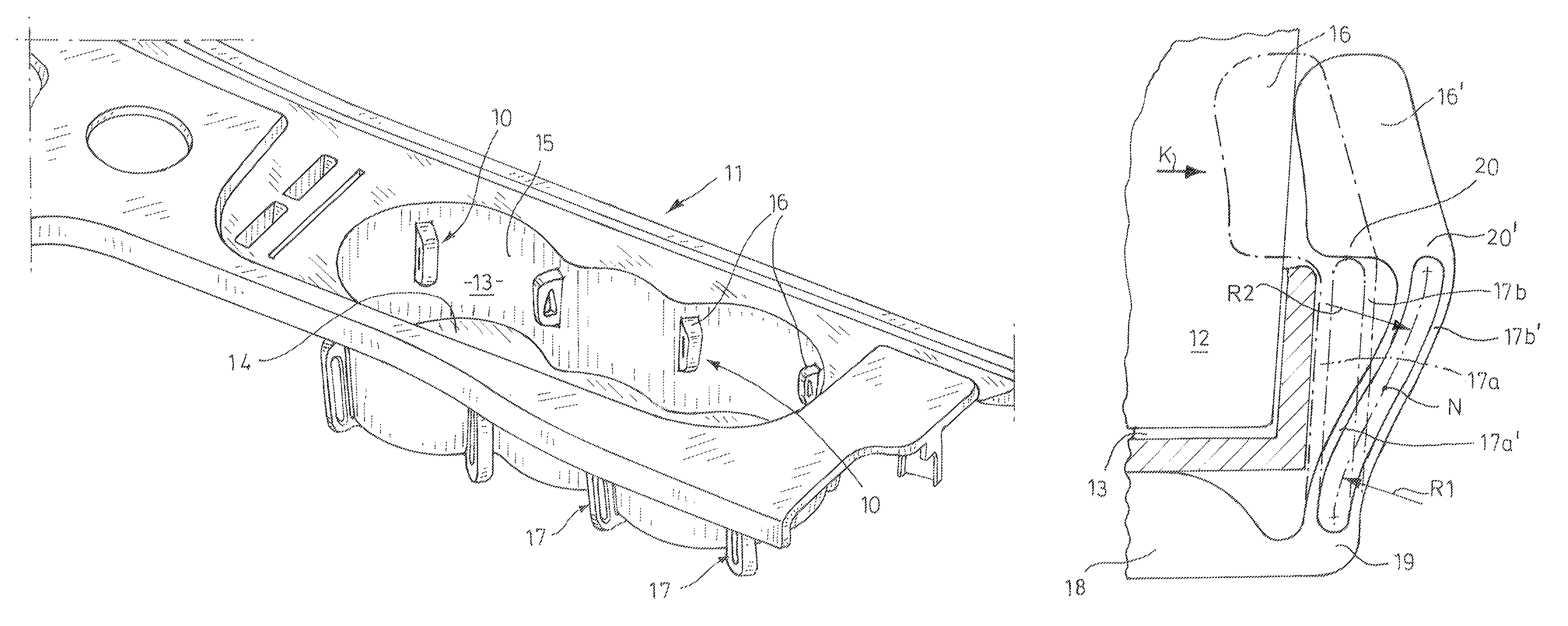

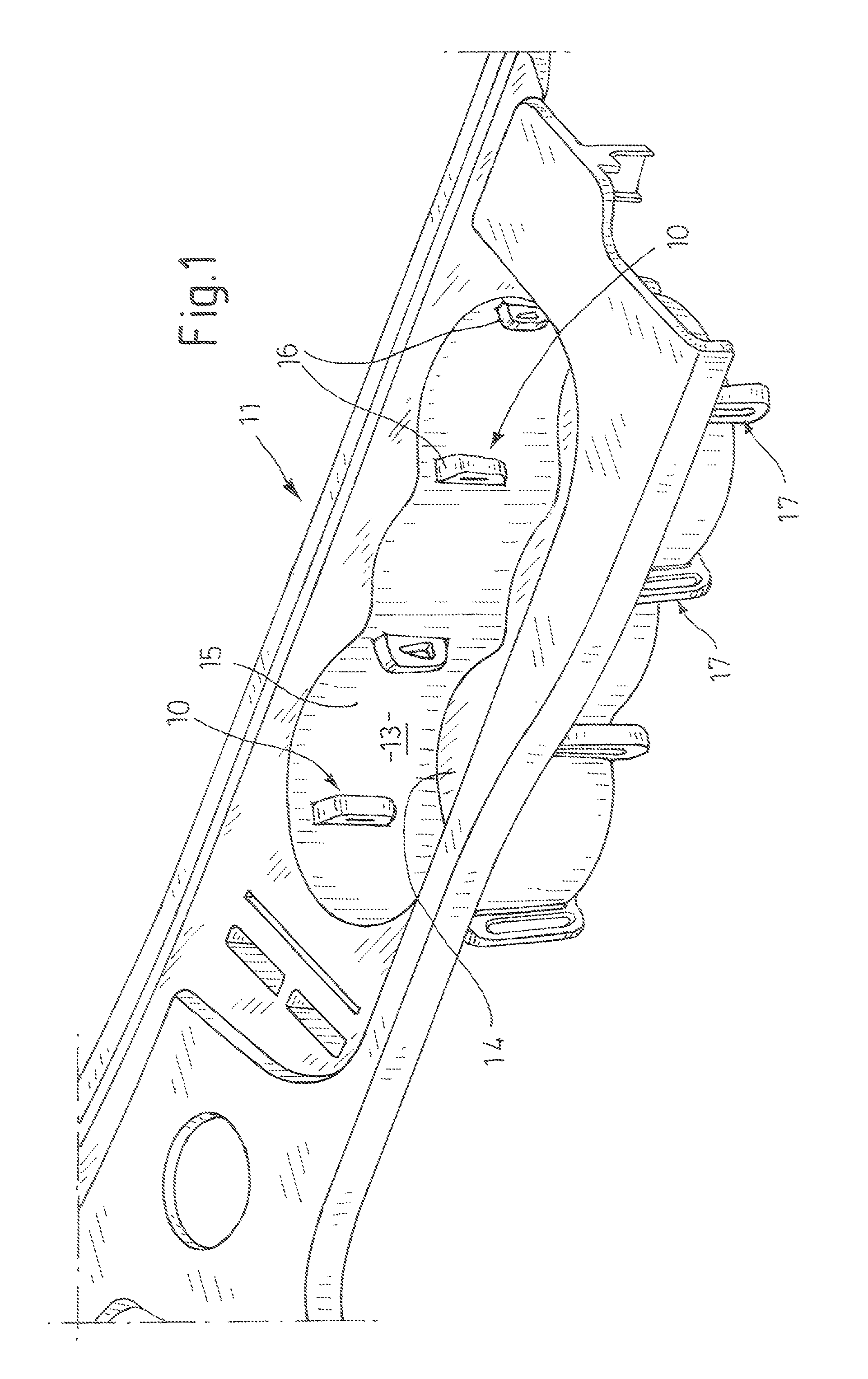

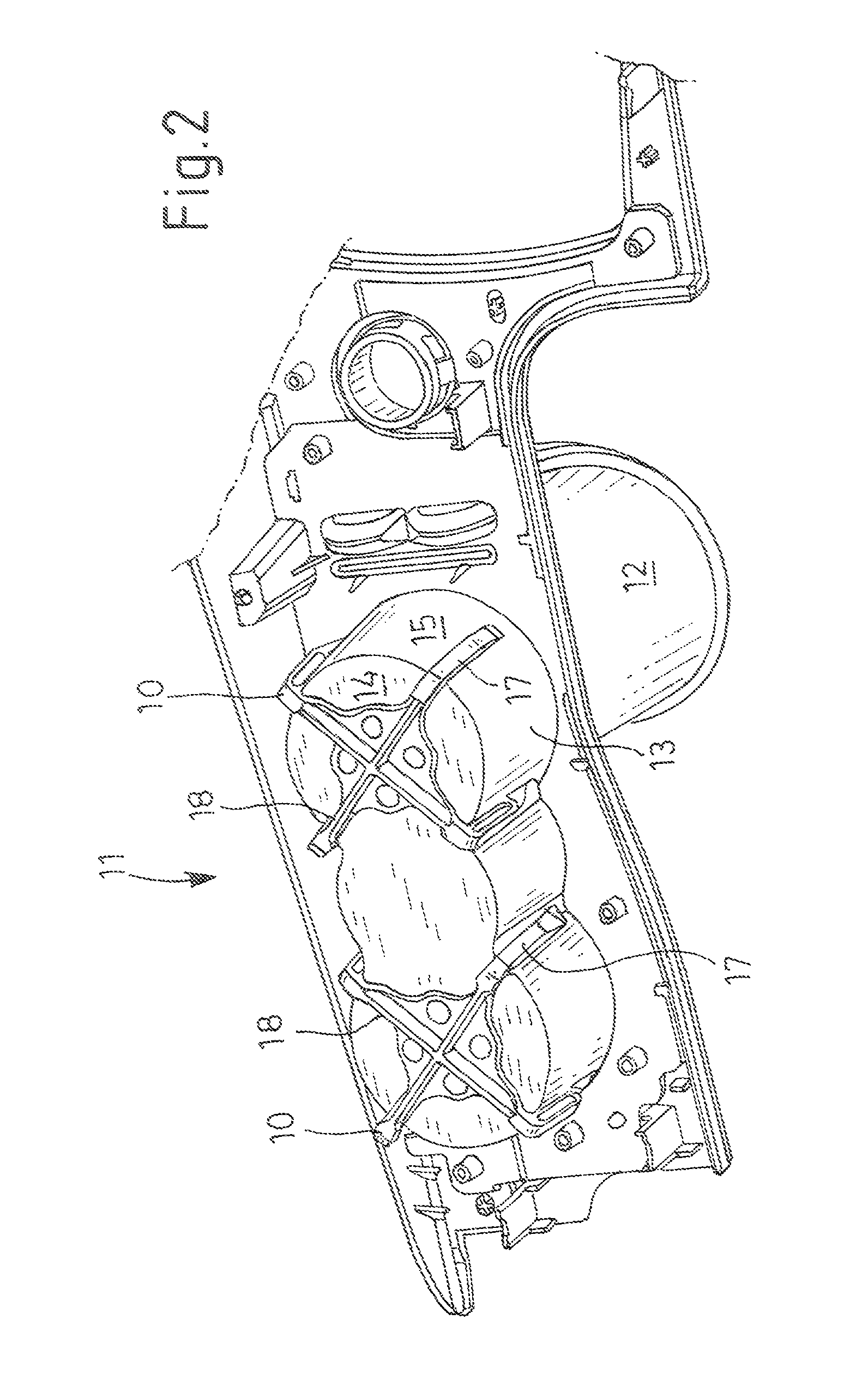

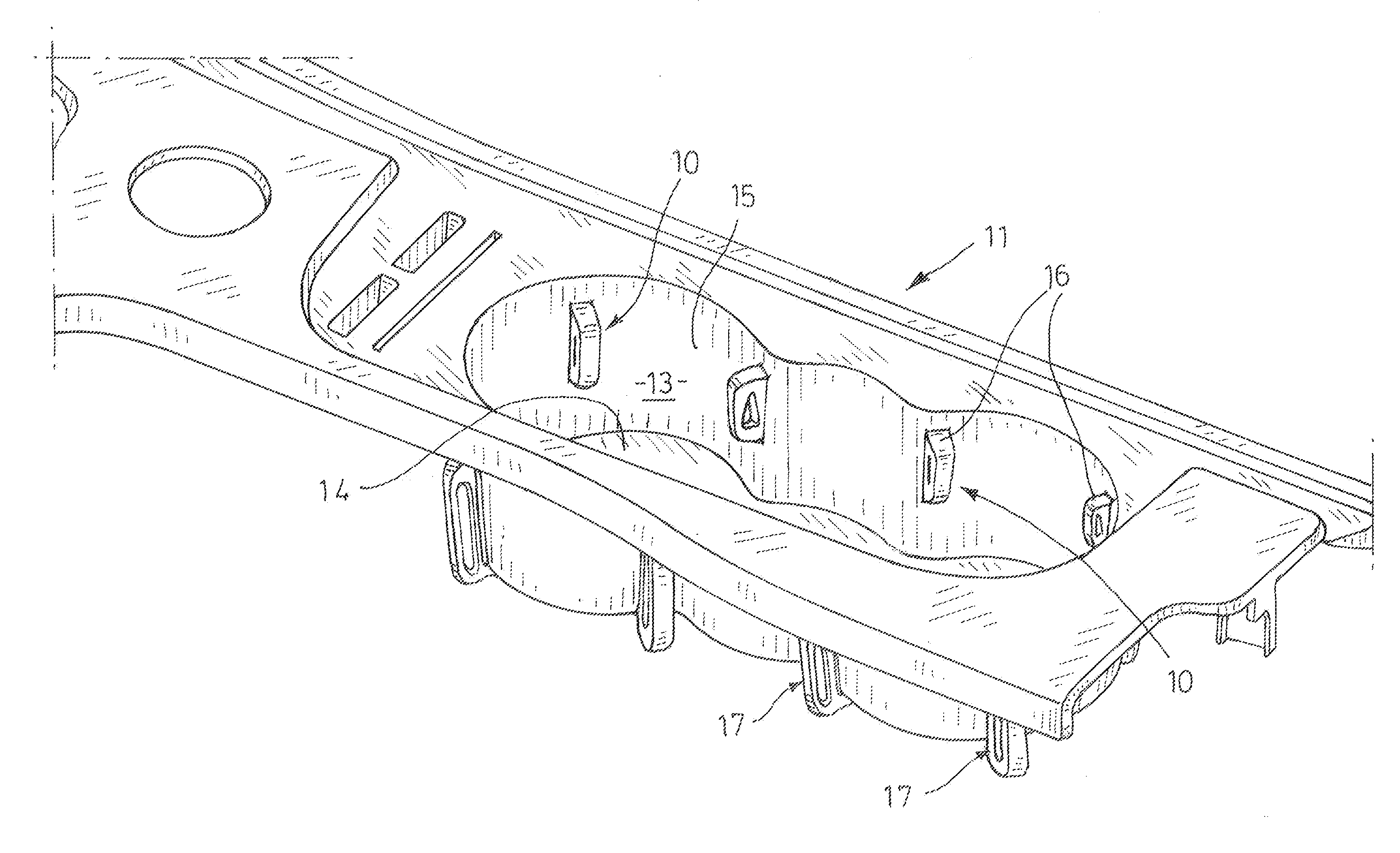

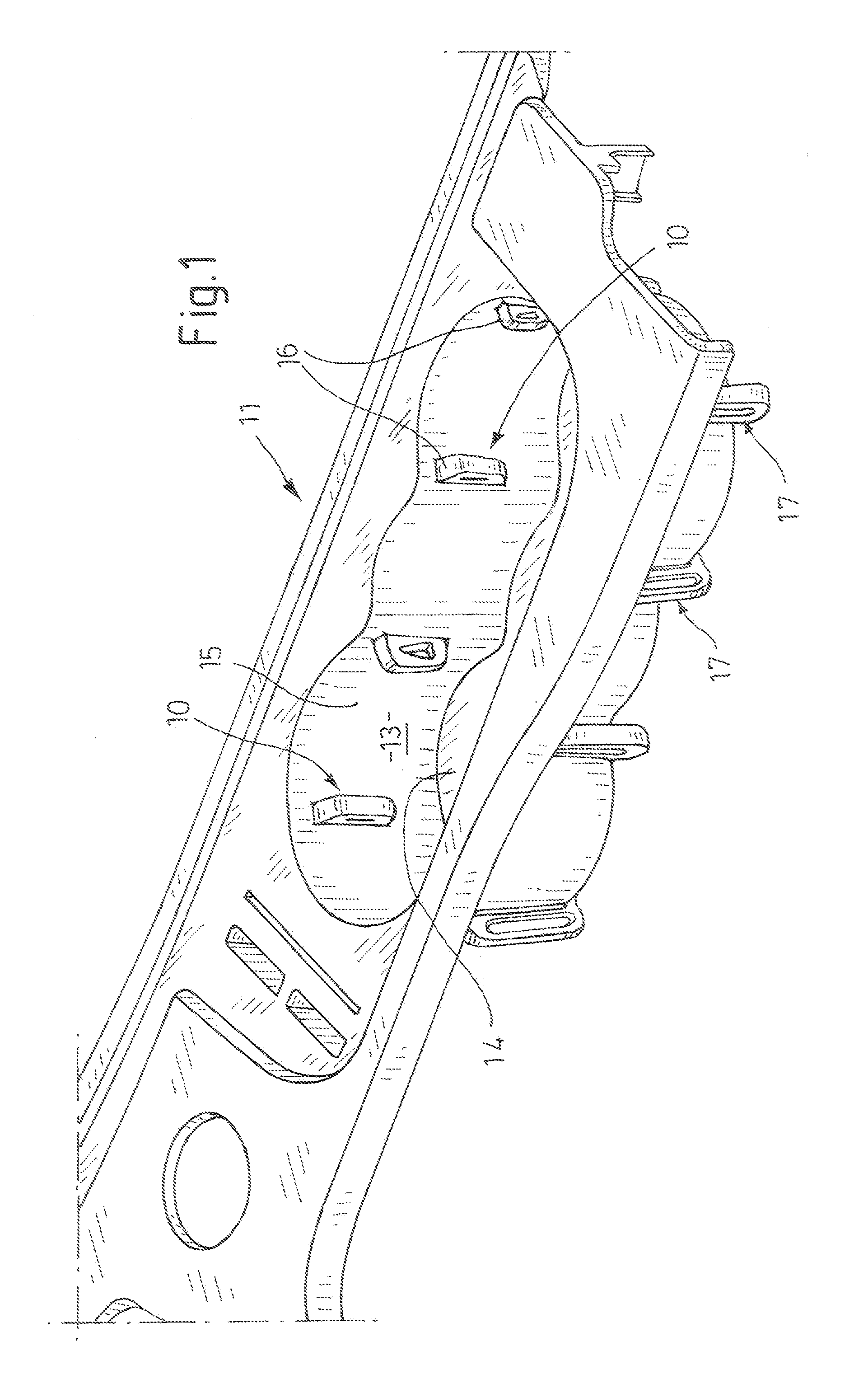

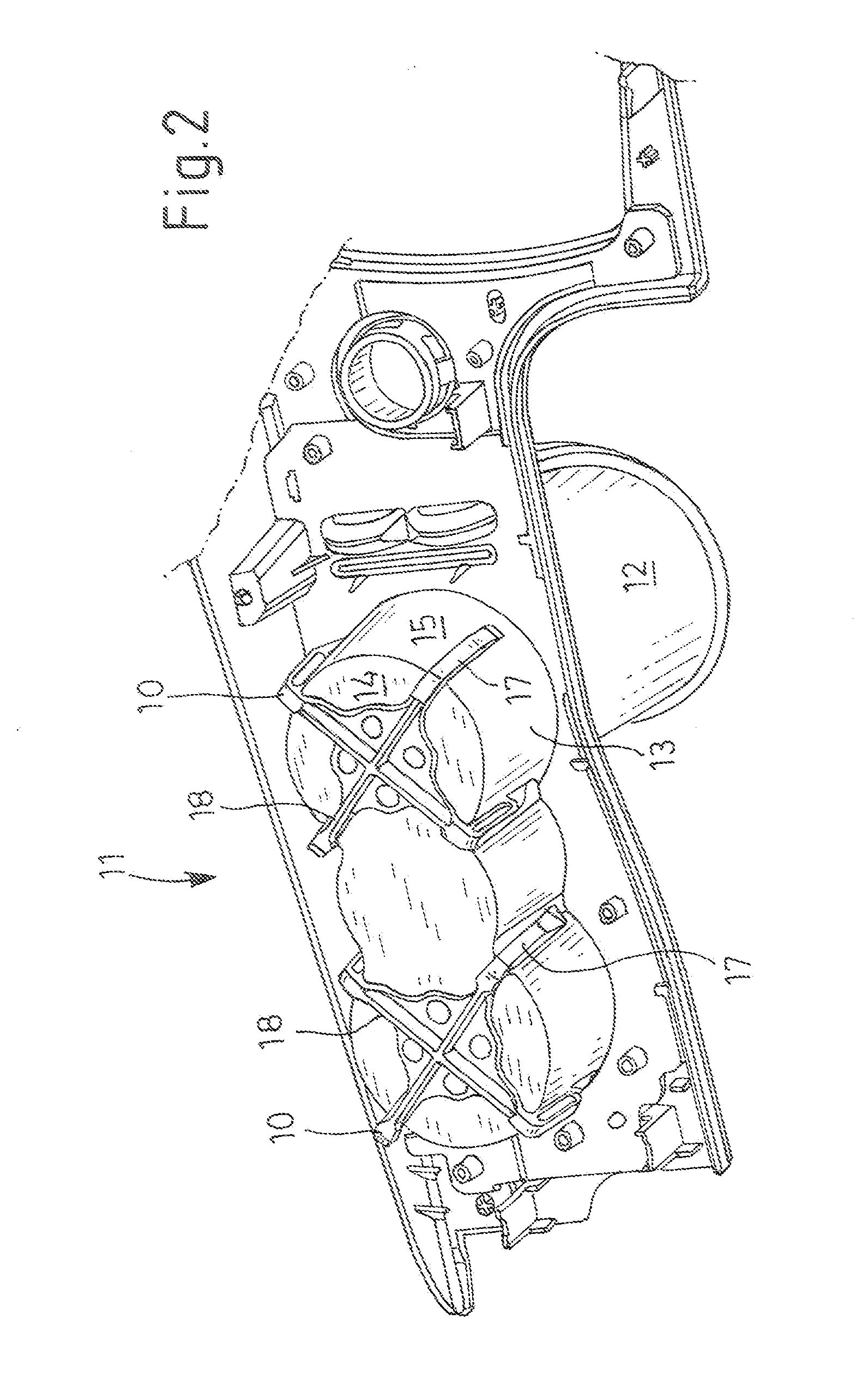

One-piece plastic clamping device for holder for beverage containers

InactiveUS8733724B2Improve clamping devicesSolve the blockageVehicle arrangementsPicture framesMobile vehicleEngineering

Owner:FORD GLOBAL TECH LLC

Circuit board for ink jet head, method of manufacturing the same, and ink jet head using the same

InactiveUS20060033780A1Reduce wire resistanceOverall small sizePrintingThermal energyElectrical resistance and conductance

An ink jet head circuit board is provided which has heaters to generate thermal energy for ejecting ink as they are energized. This circuit board is so constructed as to reduce wire resistances for the heaters while at the same time preventing an increase in the size of the board and realizing a high-density integration of the heaters required for high resolution printing. This construction is made possible by forming electrode wires of first and second electrode wire layers to reduce an area that the wire patterns for the heater occupy on the circuit board. In reducing the effective thickness of protective insulation layer formed on the heater to prevent a possible degradation of thermal efficiency, one of the protective insulation layers over the electrode wires is removed from the heater, depending on the thickness of the electrode wires.

Owner:CANON KK

Turbine blade with multiple trailing edge cooling slots

A cooling system for a turbine airfoil of a turbine engine has a multiple suction side cooling slots extending from a front edge on the suction side to the center of the trailing edge or even to the pressure side of the center line and a pressure side cooling slot curving to a pressure side outlet forward of the trailing edge and having a front pressure side lip that is aligned with or forward of the front edge of the suction side cooling slots. The suction side cooling slots receive cooling flow from the pressure side cooling slots through a boundary layer bleed valve, which is also aligned with or rearward of the pressure side lip. The cooling system may also combine double impingement cooling with these features. The cooling system minimizes shear mixing, reduces hot spots and can reduce the trailing edge thickness, resulting in more efficient stage performance and extended operational life.

Owner:SIEMENS ENERGY INC

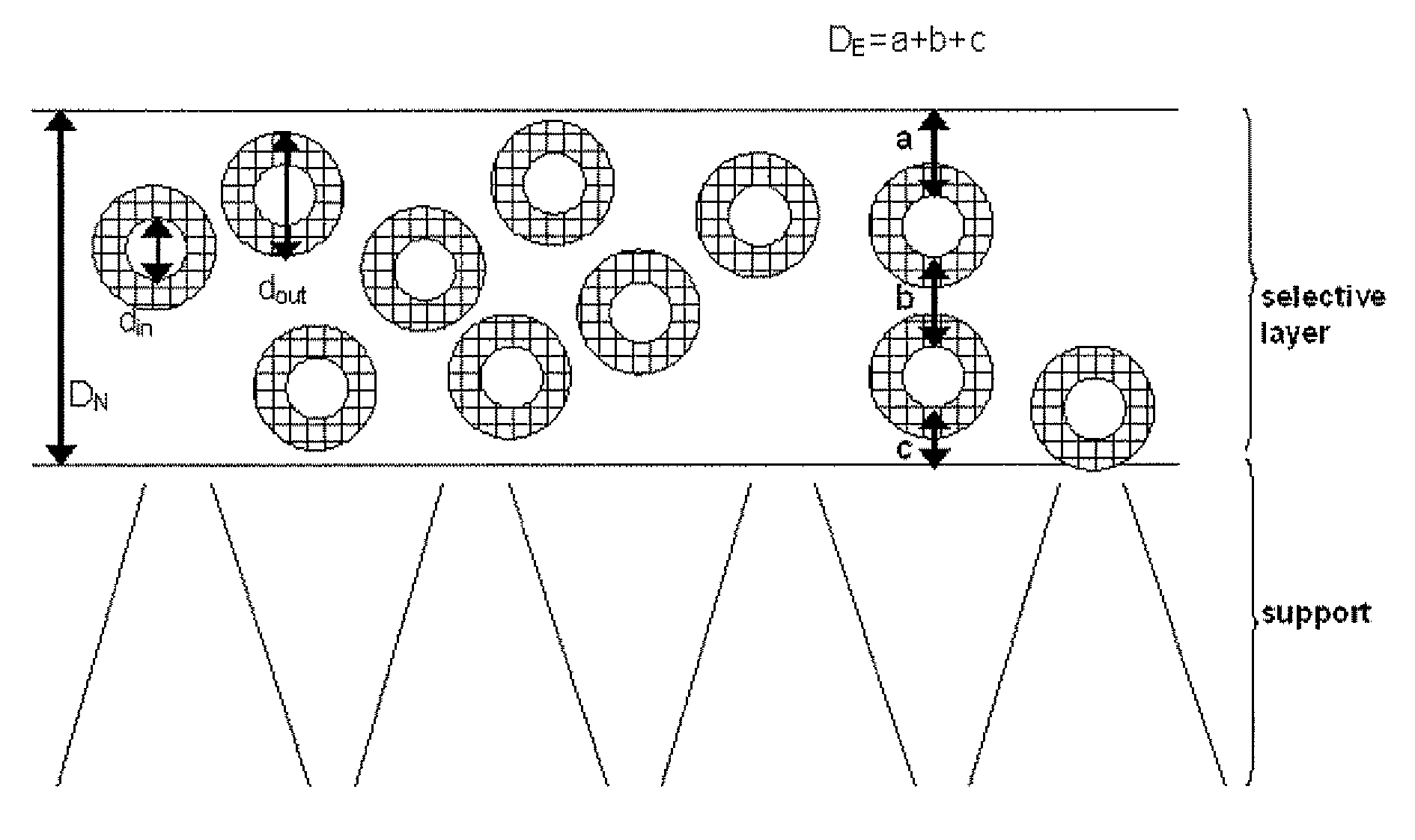

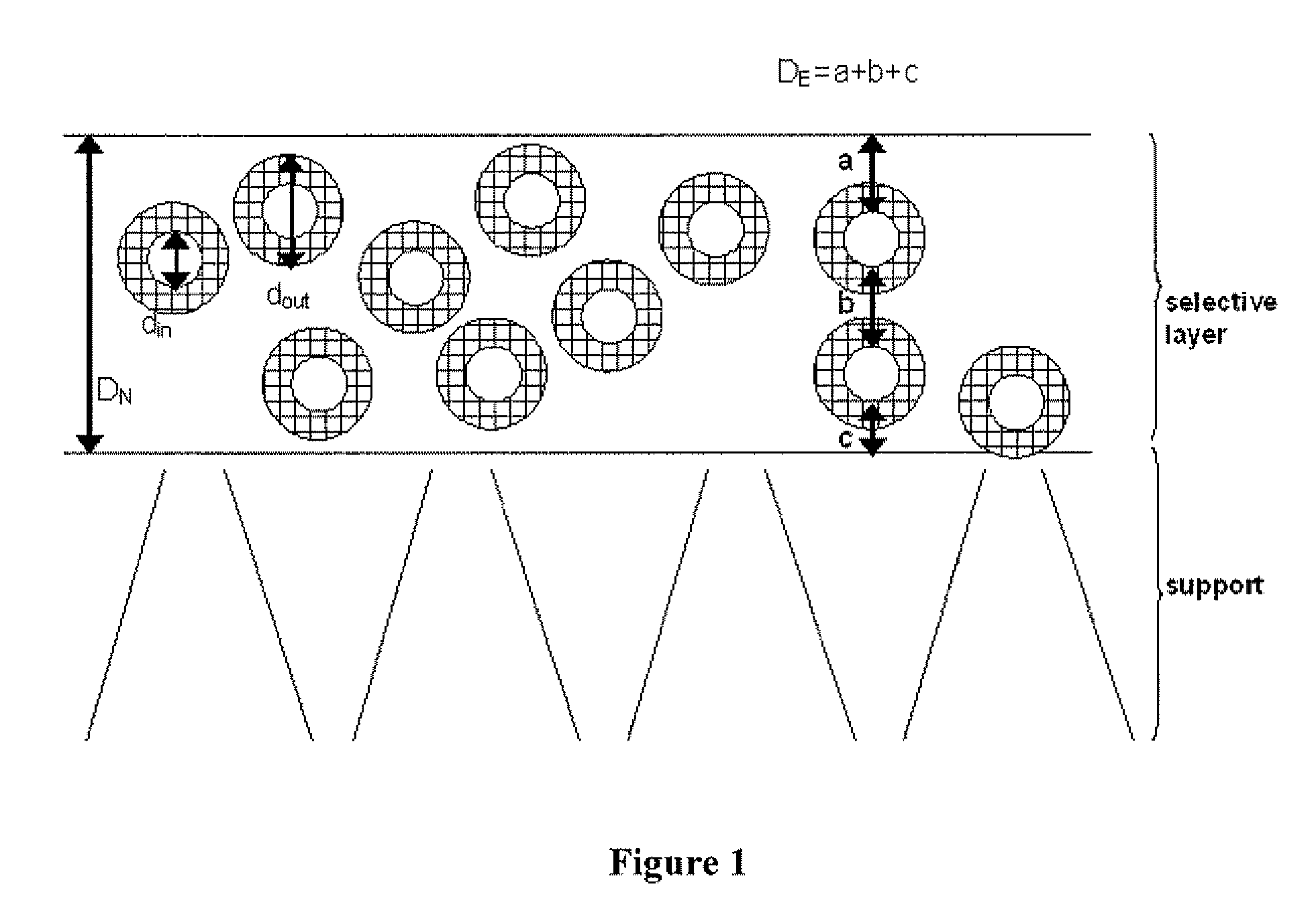

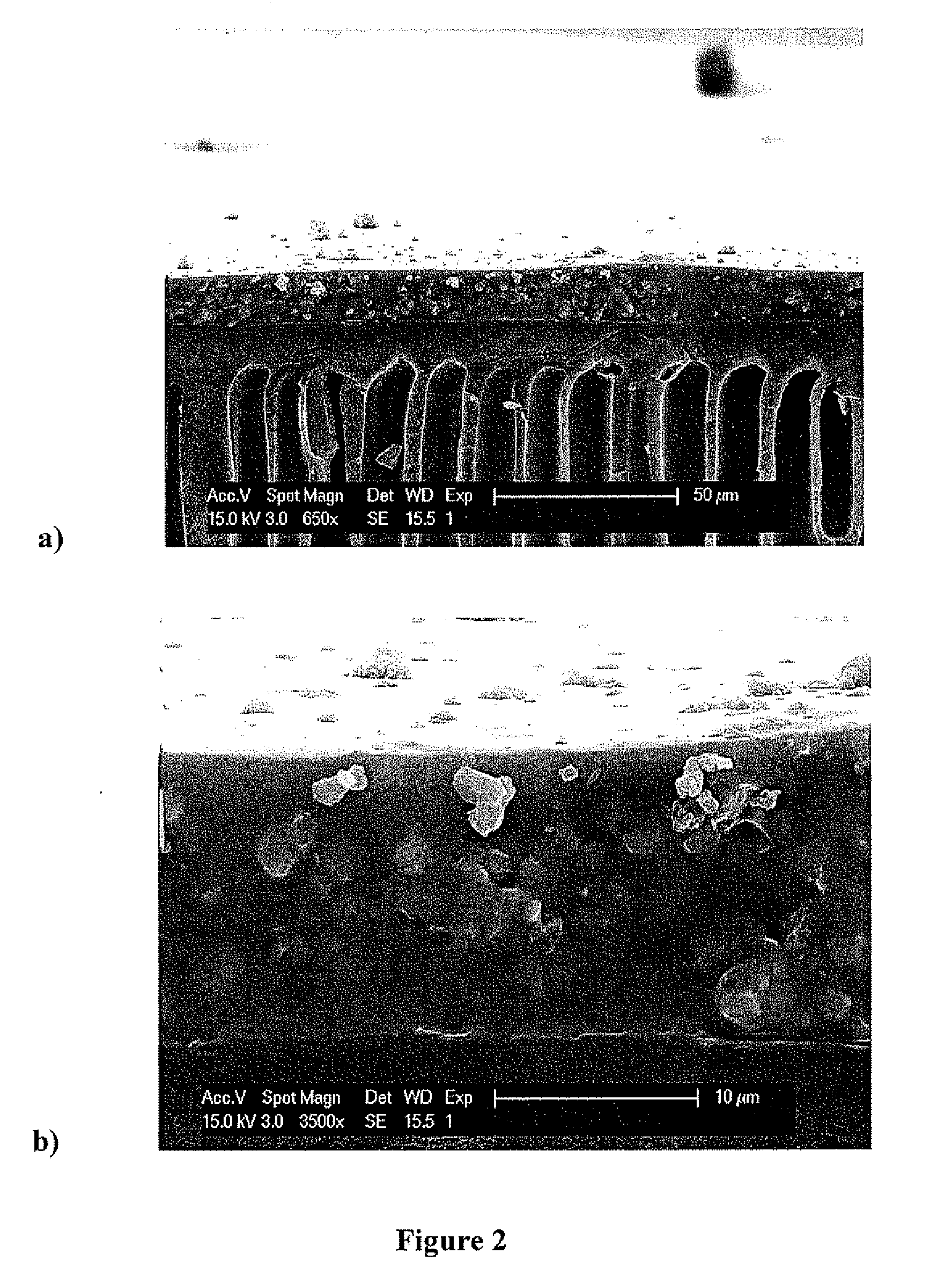

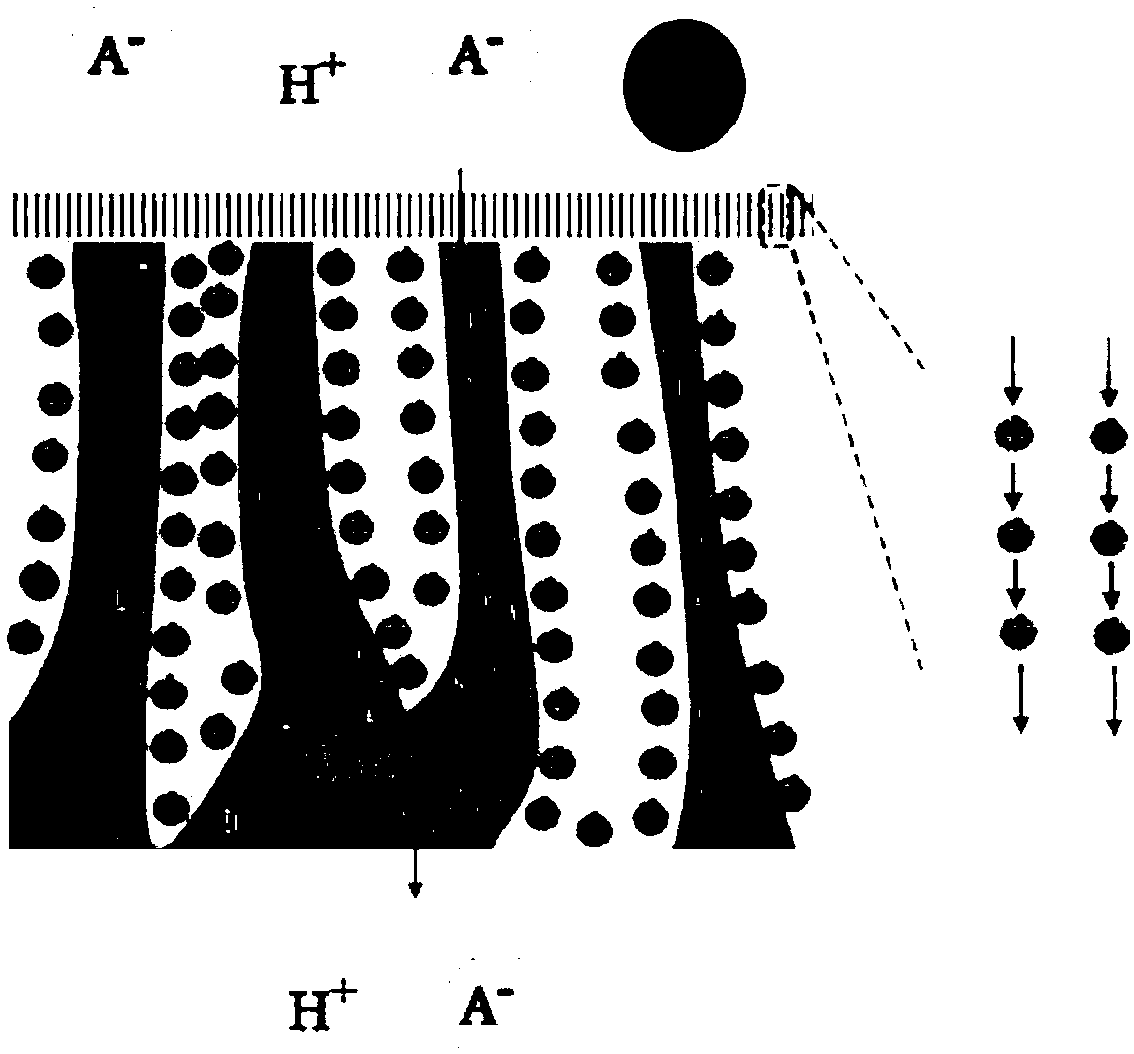

Membranes filled with porous hollow particles

InactiveUS20100108604A1Improve film propertiesFast shippingMembranesUltrafiltrationMolecular sievePorous particle

The present invention provides a new composite material comprising a polymer matrix comprising dispersed molecular sieve porous particles of which at least part are hollow particles, meaning that the particles comprise a shell enclosing cavities, of which the volume is at least two times larger than the average volume of the pores comprised in the shell of such particle. The invention further relates to membranes comprising such materials as well as the use of such membranes.

Owner:KATHOLIEKE UNIV LEUVEN

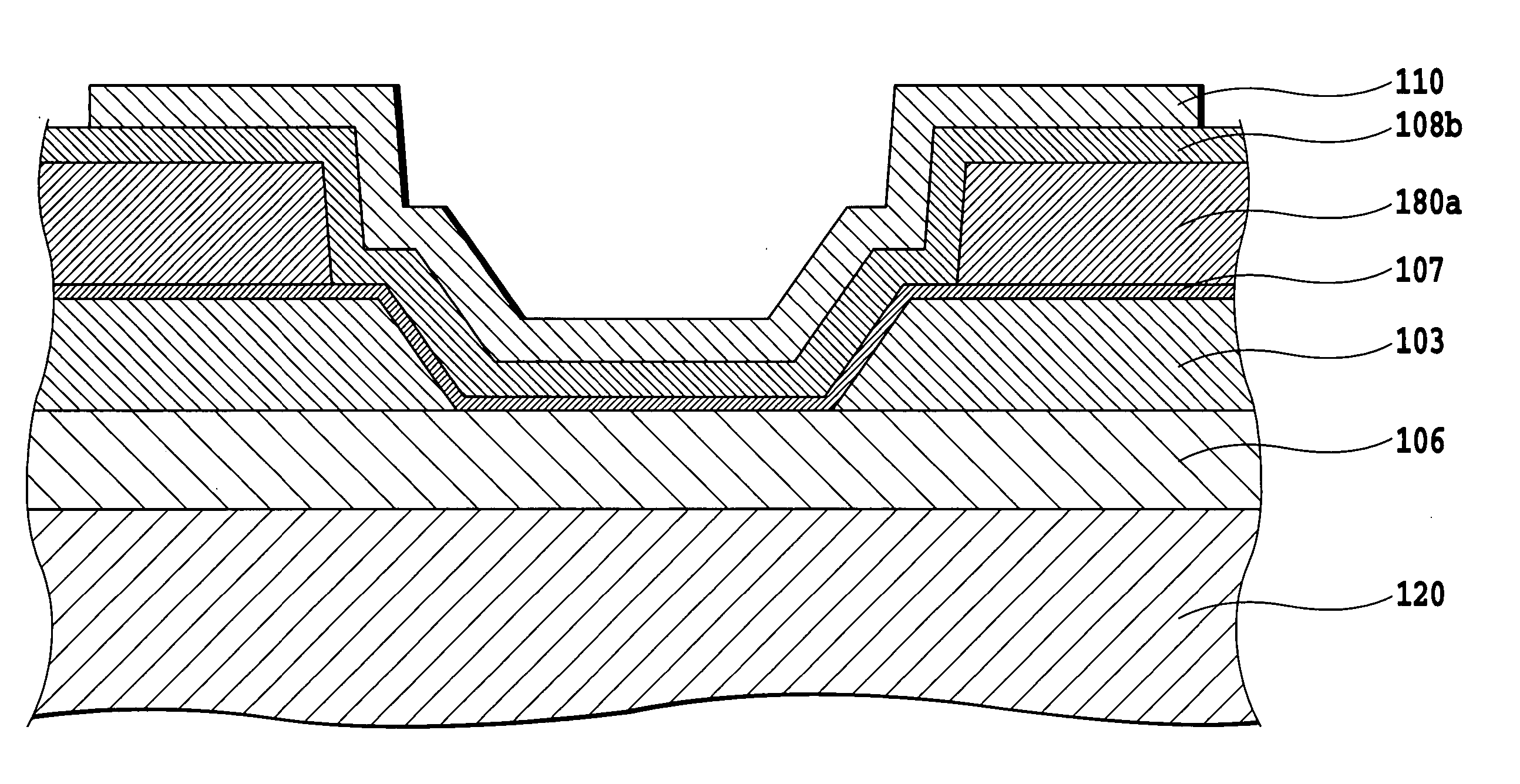

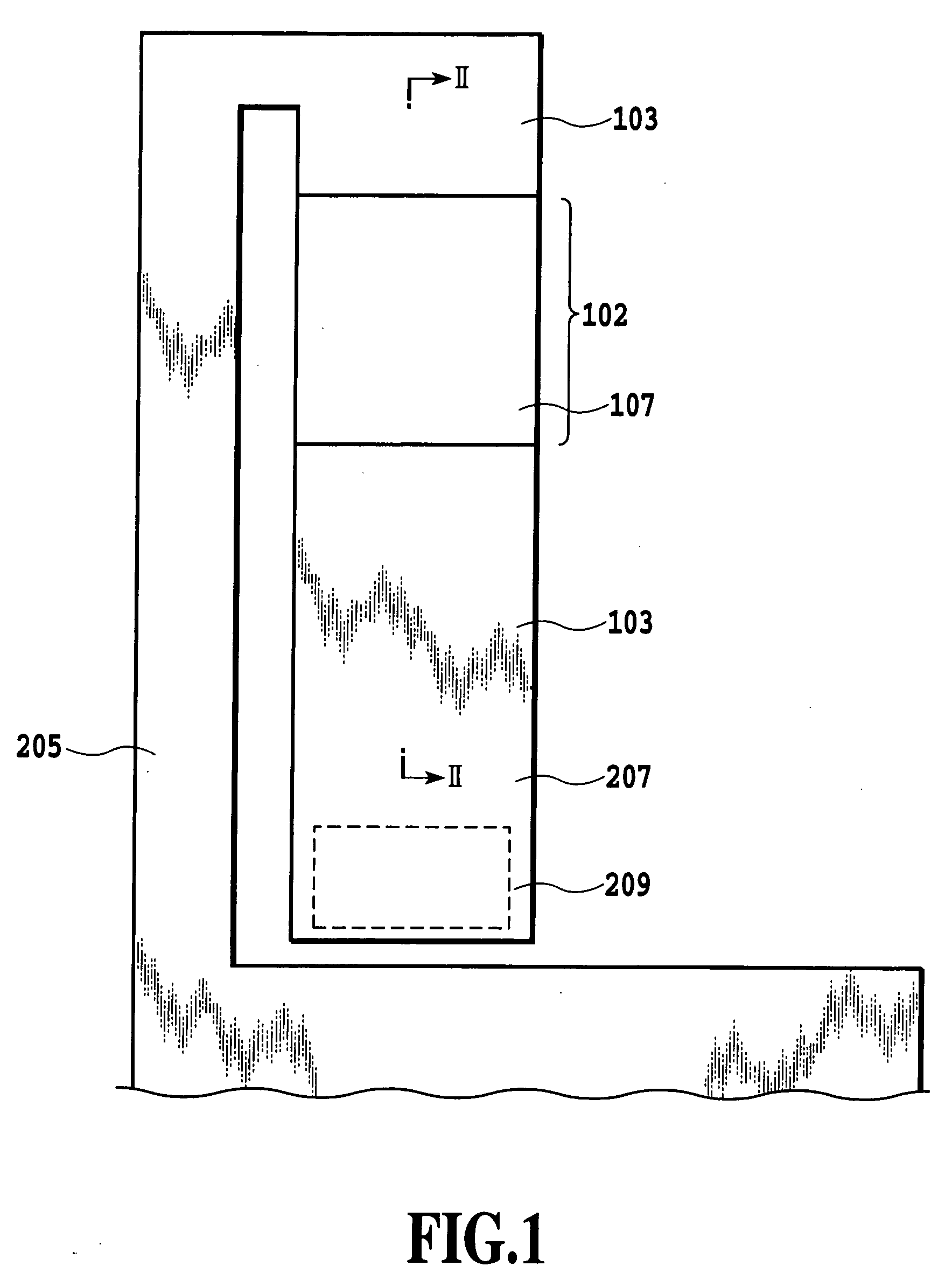

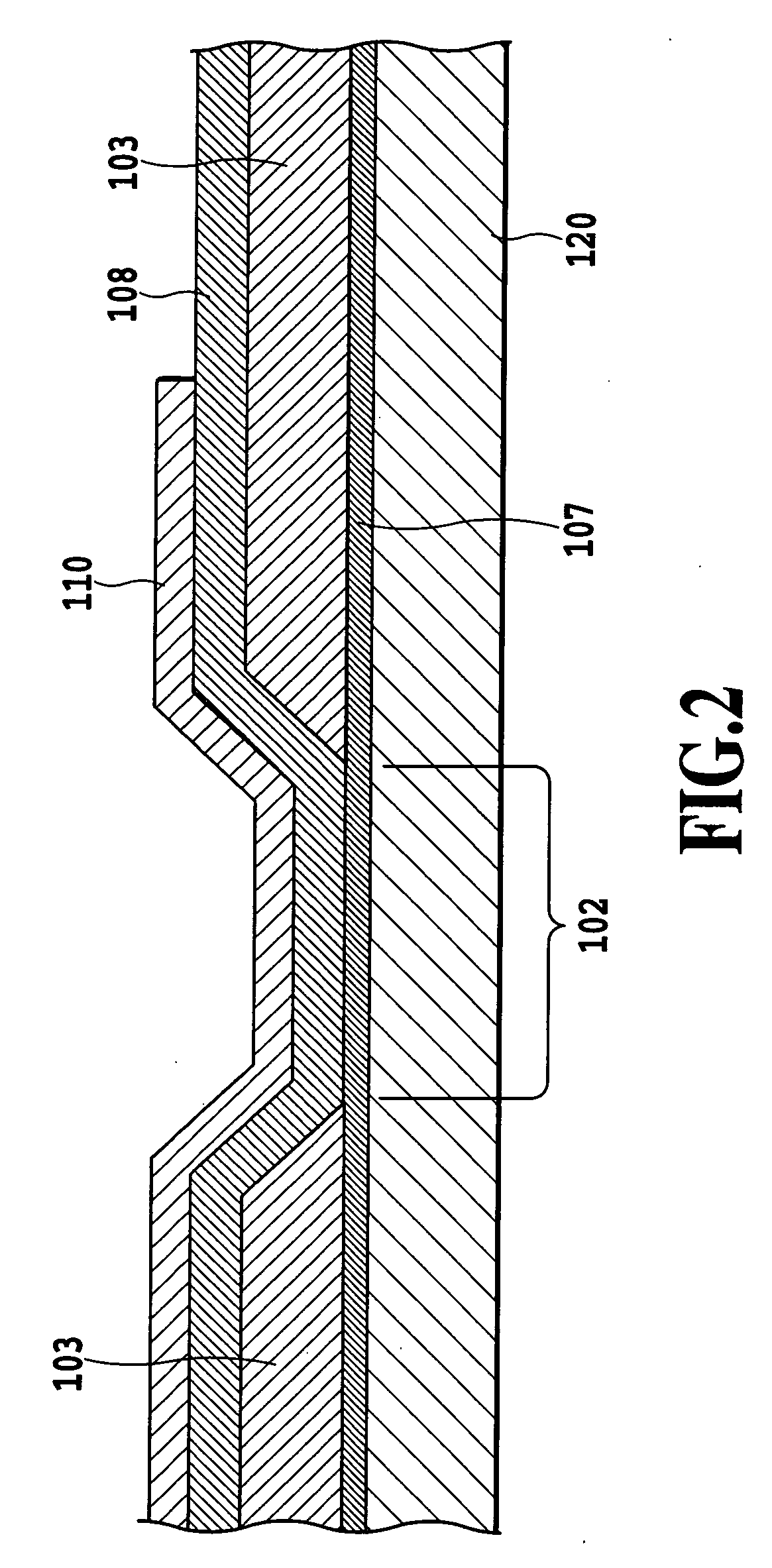

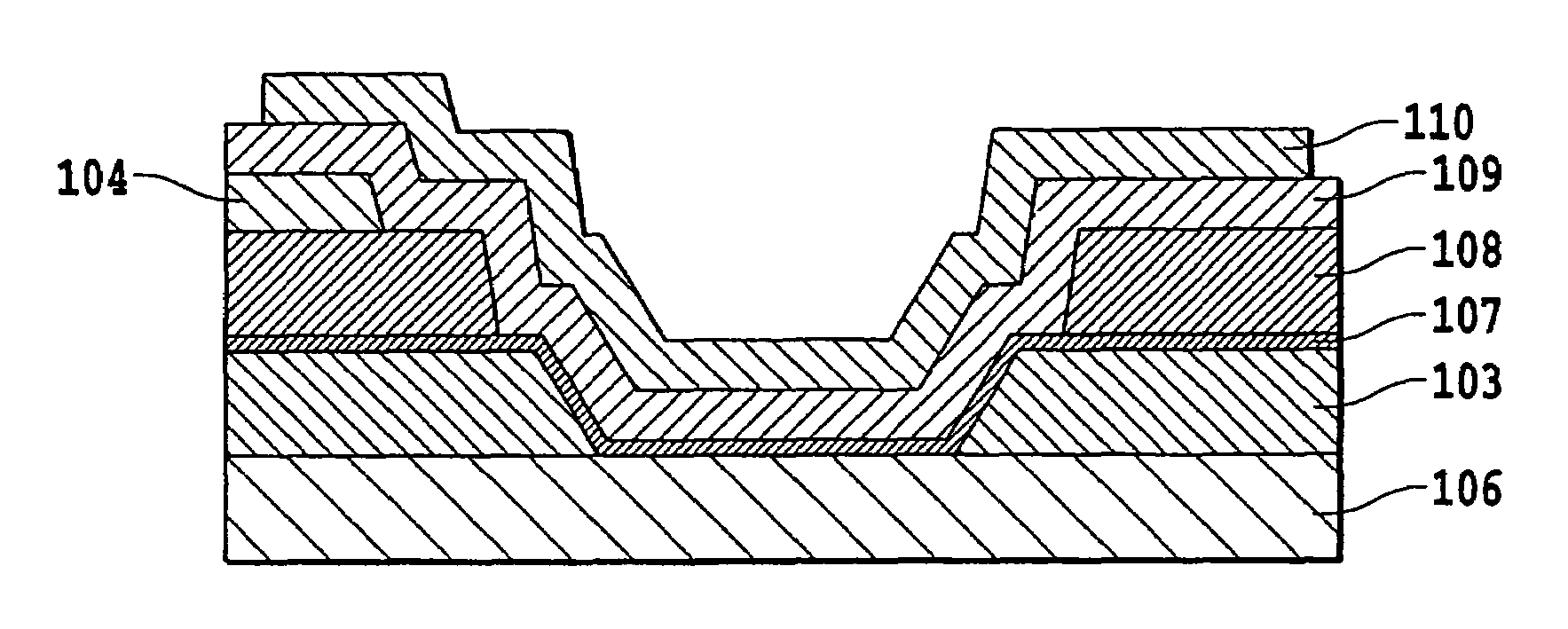

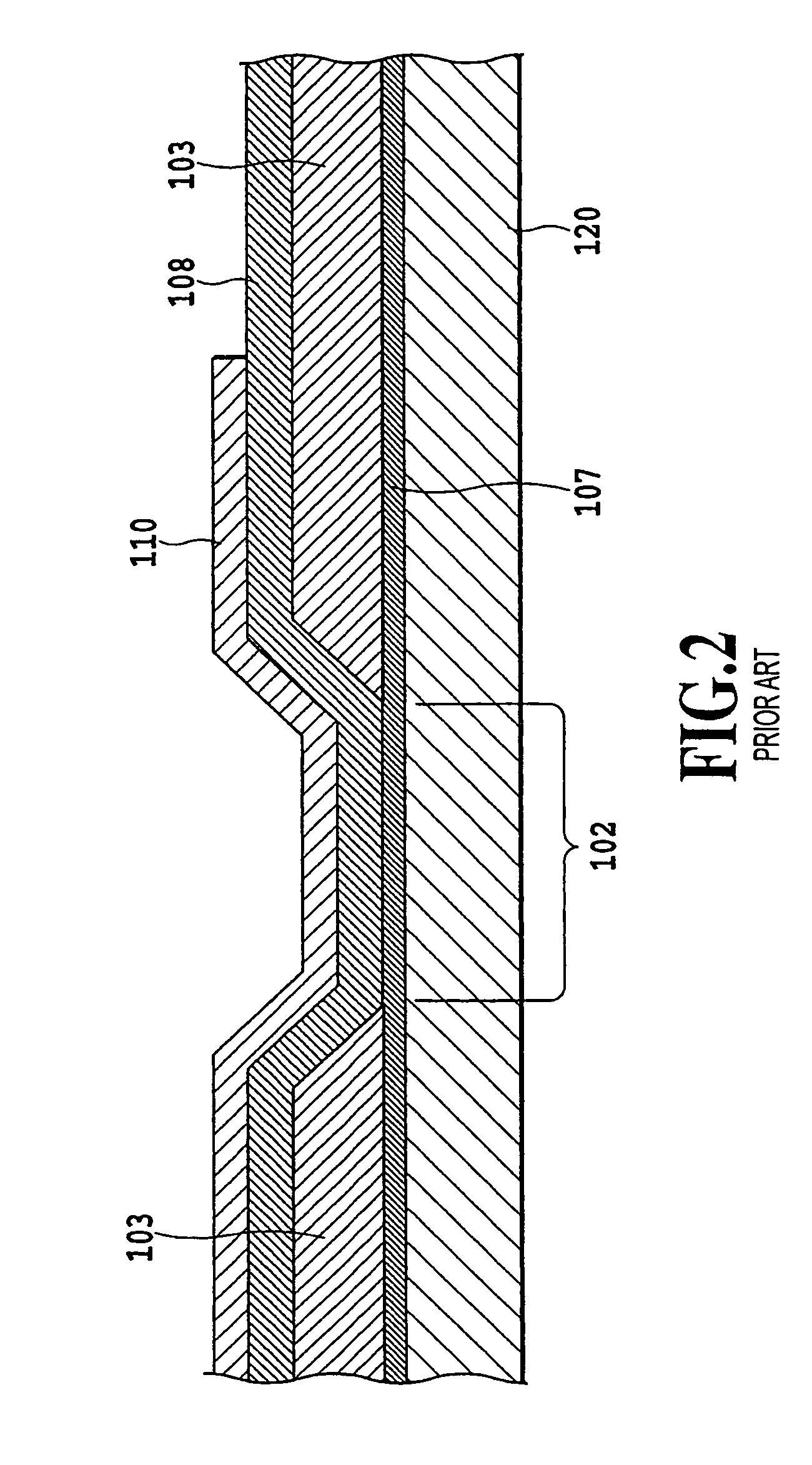

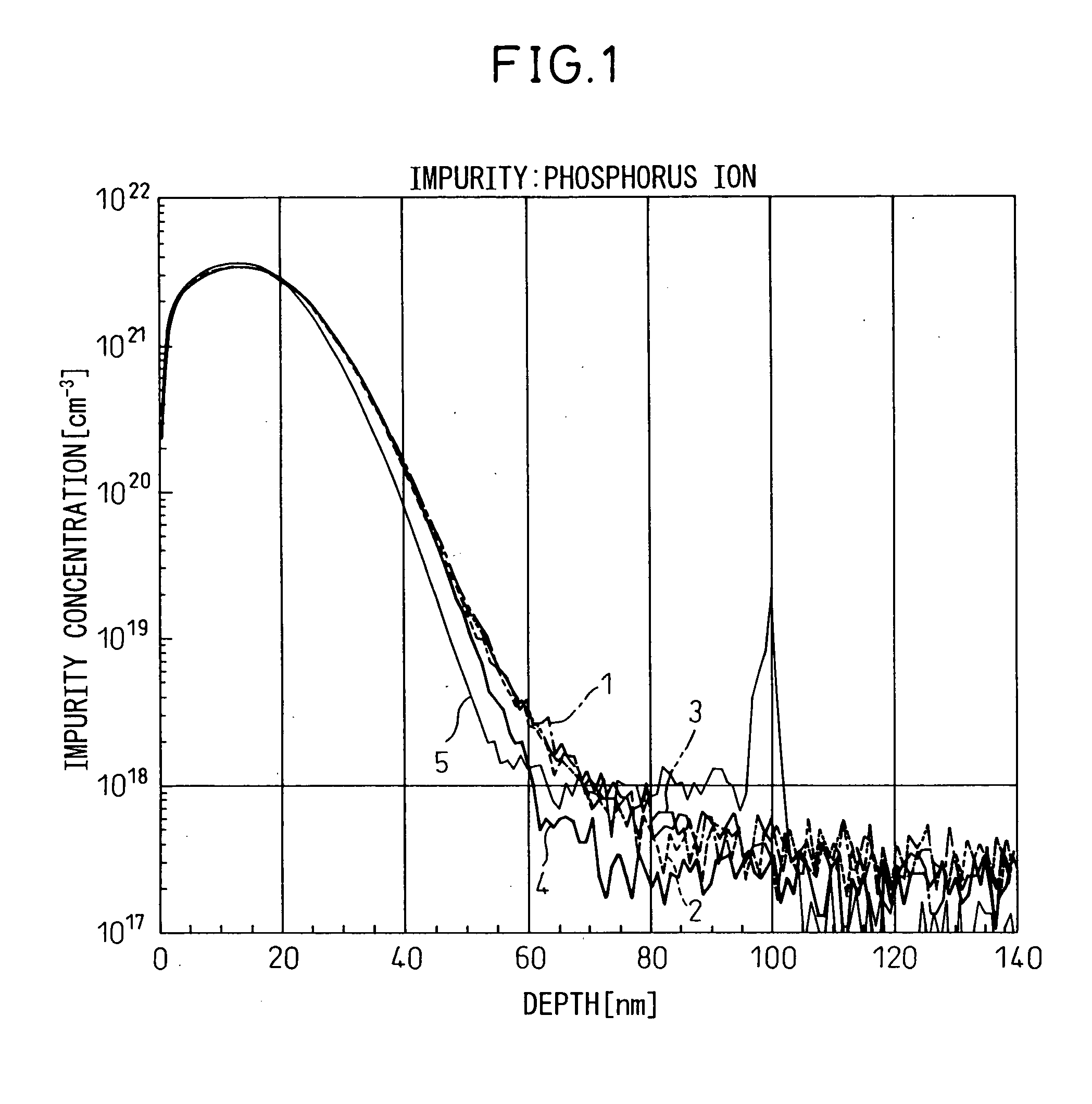

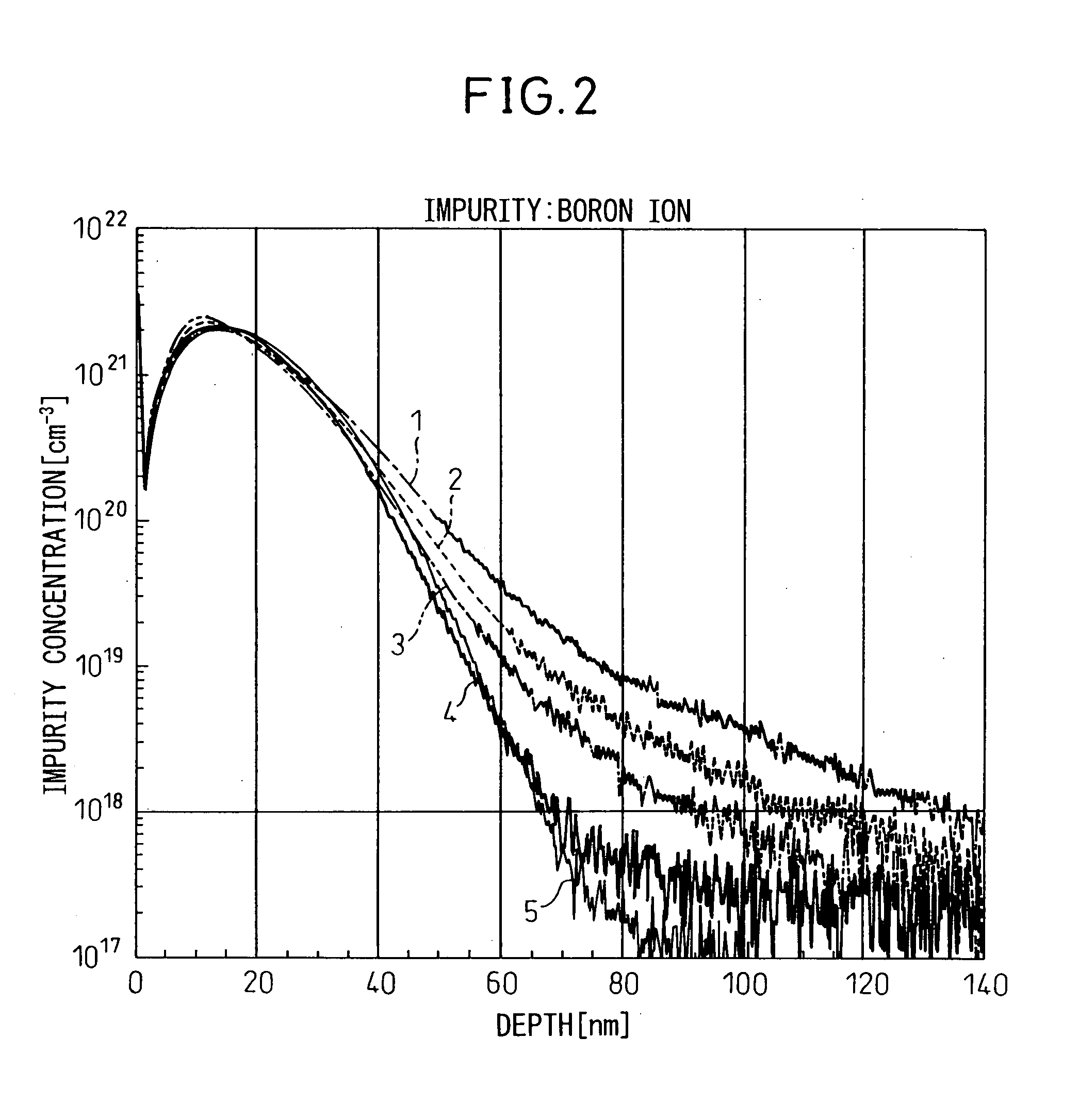

Method for reducing the effective thickness of gate oxides by nitrogen implantation and anneal

InactiveUS20050048746A1Inhibited DiffusionImpair device performanceSemiconductor/solid-state device manufacturingSemiconductor devicesDopantDevice material

A method for reducing the effective thickness of a gate oxide using nitrogen implantation and anneal subsequent to dopant implantation and activation is provided. More particularly, the present invention provides a method for fabricating semiconductor devices, for example, transistors, which include a hardened gate oxide and which may be characterized by a relatively large nitrogen concentration at the polysilicon / gate oxide interface and a relatively small nitrogen concentration within the gate oxide and at the gate oxide / substrate interface. Additionally, the present invention provides a method for fabricating a semiconductor device having a metal gate strap (e.g., a metal silicide layer) disposed over the polysilicon layer thereof, which device includes a hardened gate oxide and which may be characterized by a relatively large nitrogen concentration at the silicide / polysilicon interface to substantially prevent cross-diffusion.

Owner:MICRON TECH INC

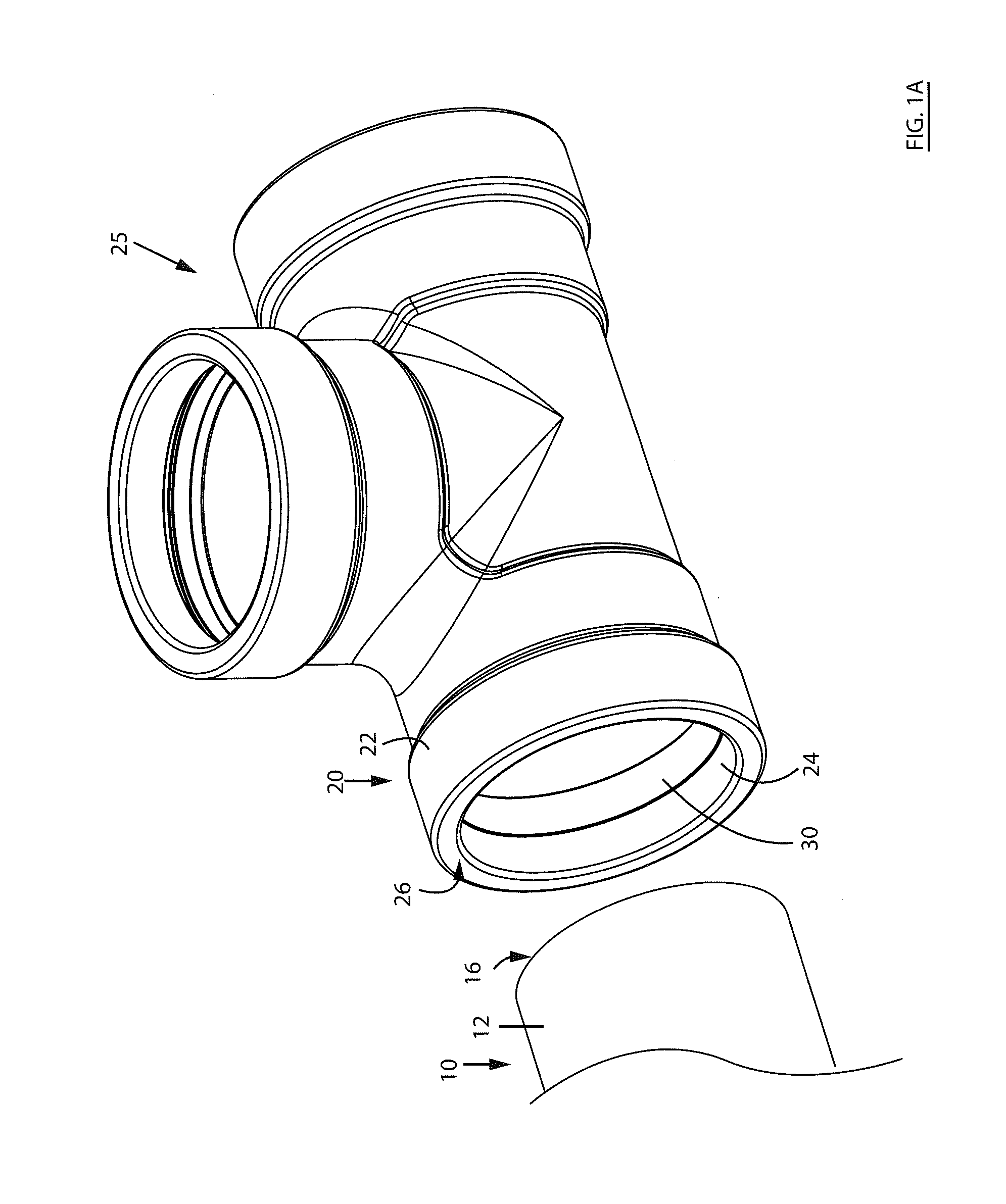

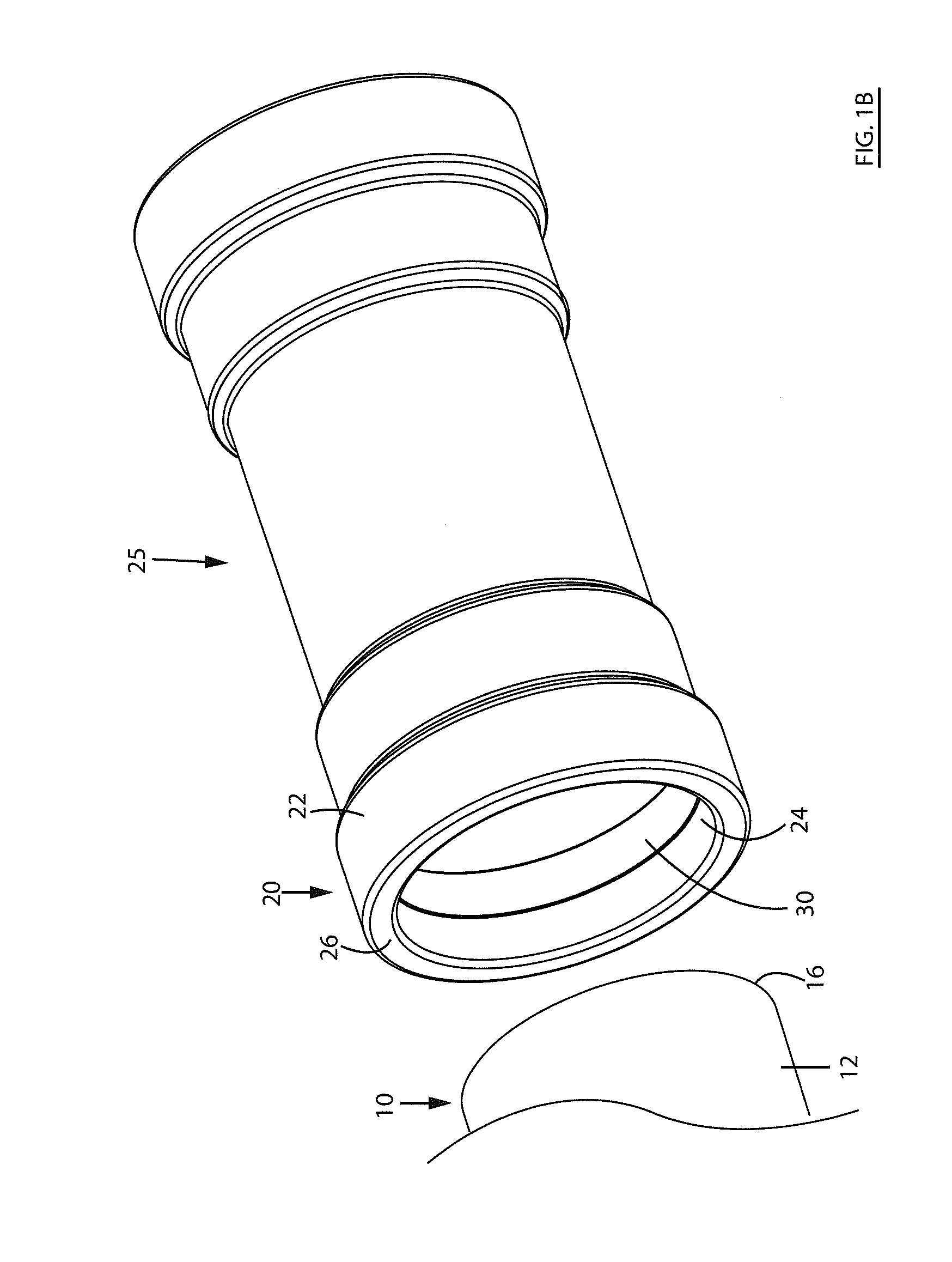

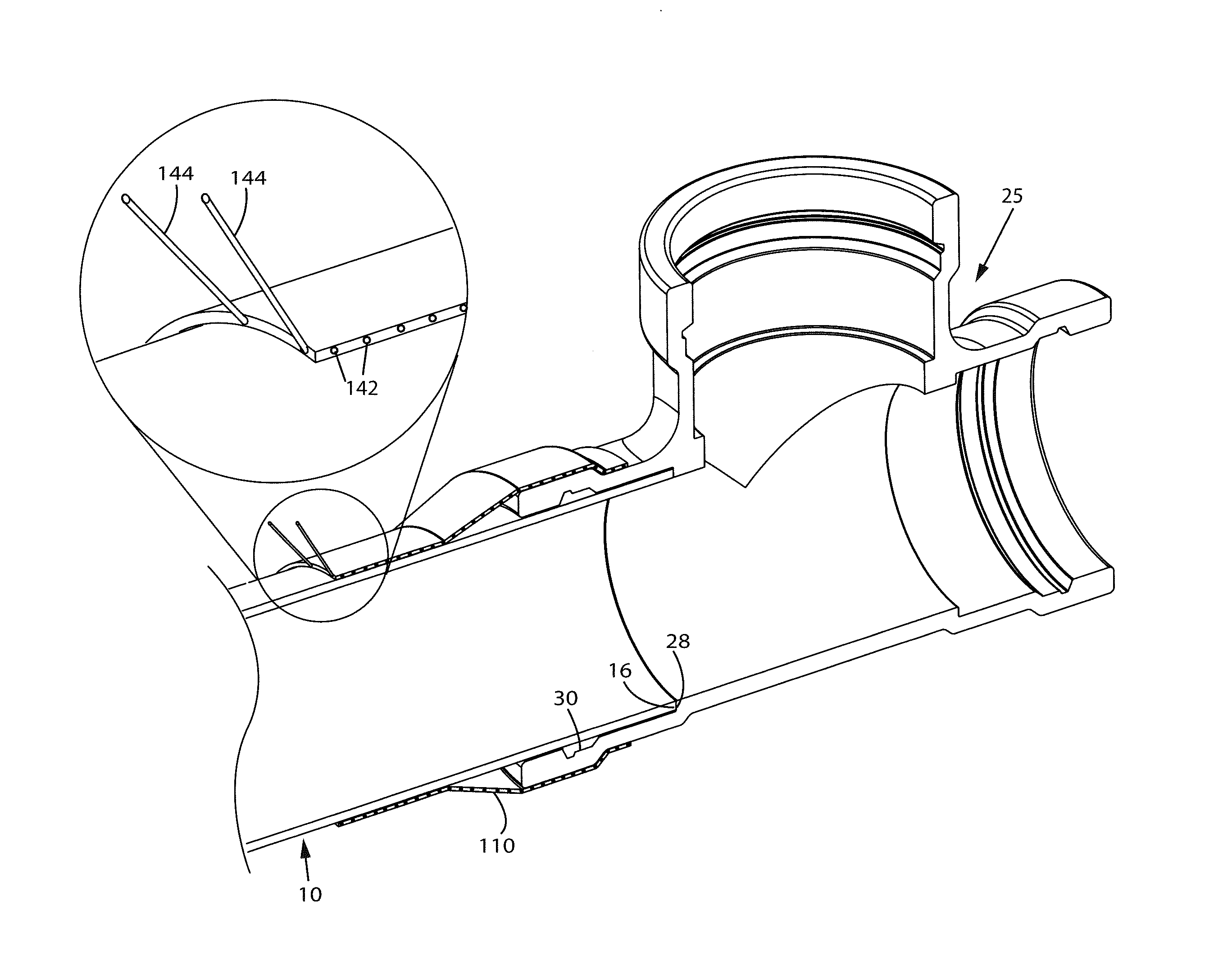

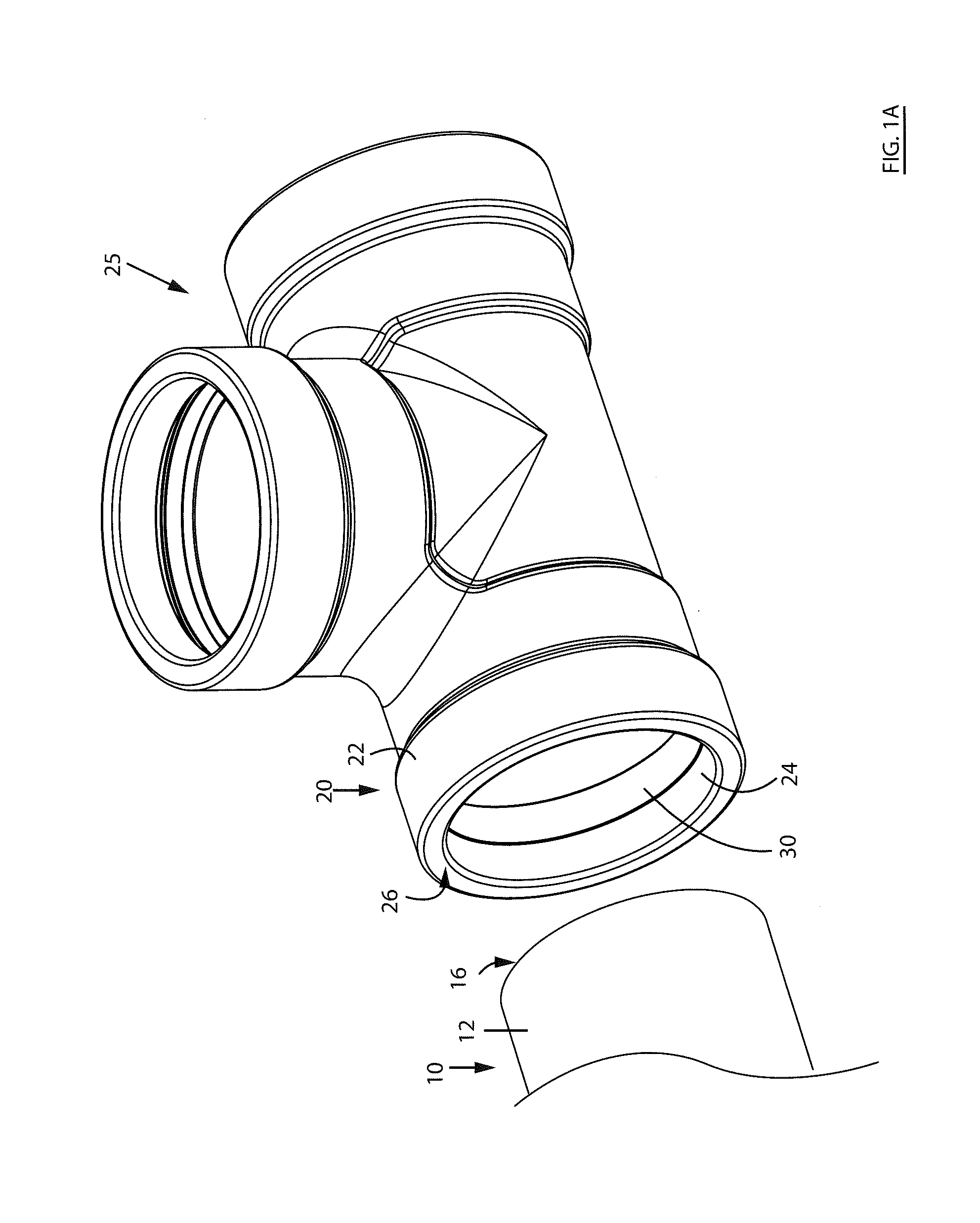

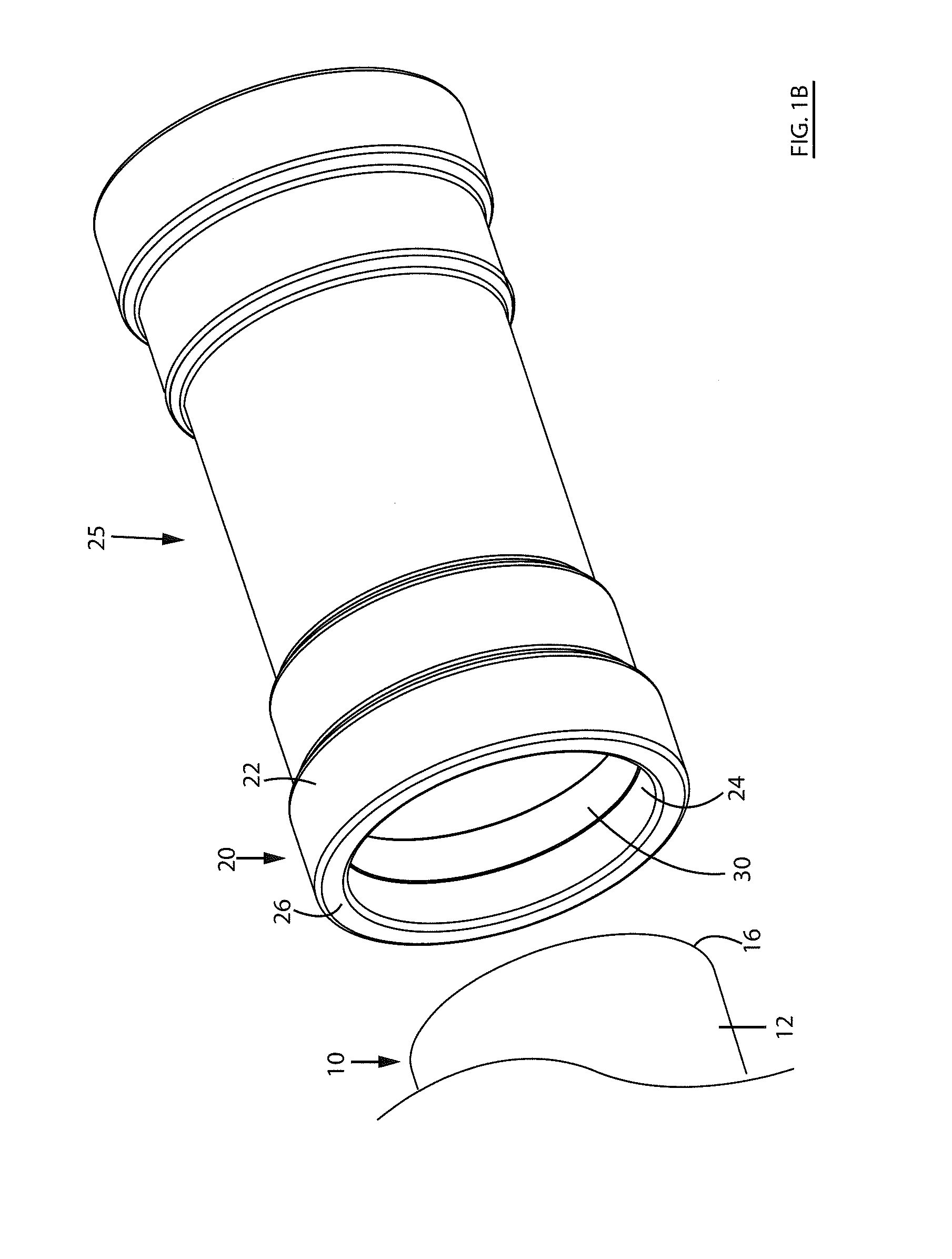

Method of joining pipes and fittings

ActiveUS20160076682A1Reduce riskPoint be alleviated and eliminatedSleeve/socket jointsFluid pressure sealed jointsEngineeringGasket

A method for joining a first conduit section with a second conduit section. The method includes: a) inserting a first end of the second conduit section in an open first end of the first conduit section with a gasket extending between an inner surface of the first conduit section and an outer surface of the second conduit section; b) positioning a flexible substrate having a bonding agent provided on at least a portion of an inner side of the flexible substrate to extend from an outer surface of the first conduit to an outer surface of the second conduit; c) applying pressure to the flexible substrate whereby the bonding agent is pressed against an outer surface of the first and second conduit sections; and d) heating the bonding agent whereby the bonding agent is secured to the outer surface of the first and second conduit sections.

Owner:OMACHRON INTPROP

One-piece plastic clamping device for holder for beverage containers

InactiveUS20120153113A1Increase heightSolve the blockageVehicle arrangementsPicture framesEngineeringMechanical engineering

Owner:FORD GLOBAL TECH LLC

Capacitor applicable to a device requiring large capacitance

ActiveUS7244999B2Increase capacitanceImprove reliabilityTransistorFixed capacitor electrodesCapacitanceOptoelectronics

A capacitor includes a first electrode and a second electrode arranged so that a main surface of the first electrode opposes a main surface of the second electrode, a first pseudo electrode layer disposed on the main surface of the first electrode, and a dielectric layer disposed between the first pseudo electrode layer and the main surface of the second electrode. The first pseudo electrode layer includes conductive particles electrically coupled to the first electrode.

Owner:ALPS ALPINE CO LTD

Osmotically driven active agent delivery device providing an ascending release profile

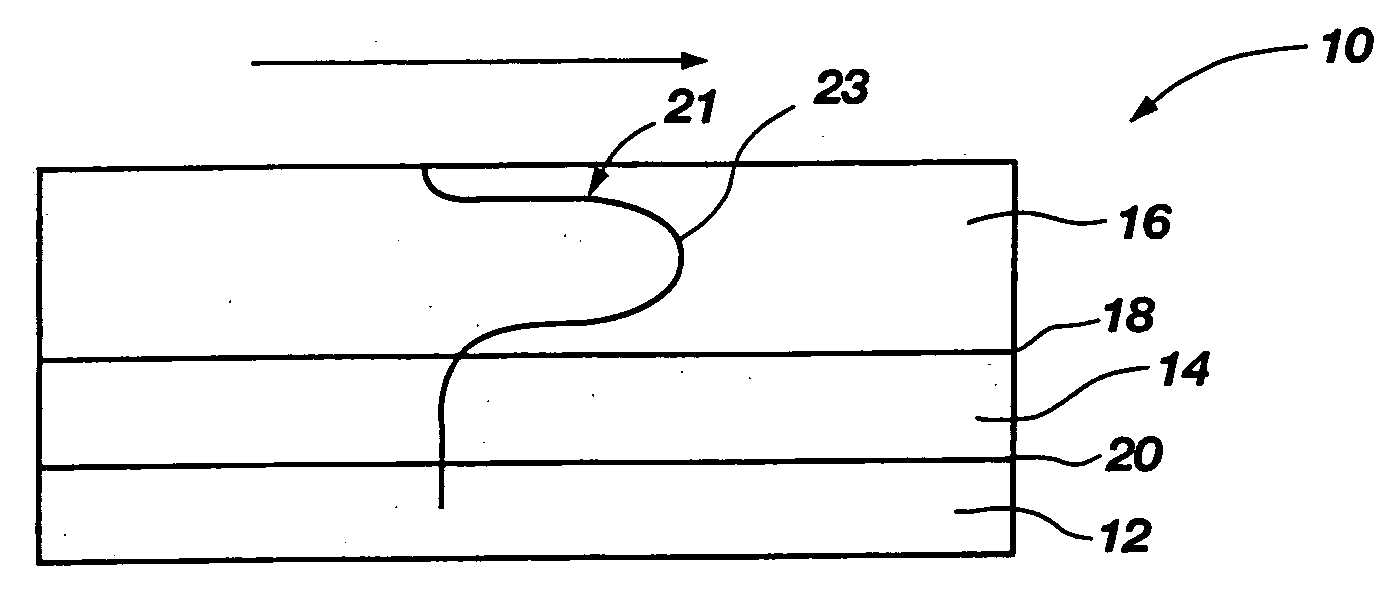

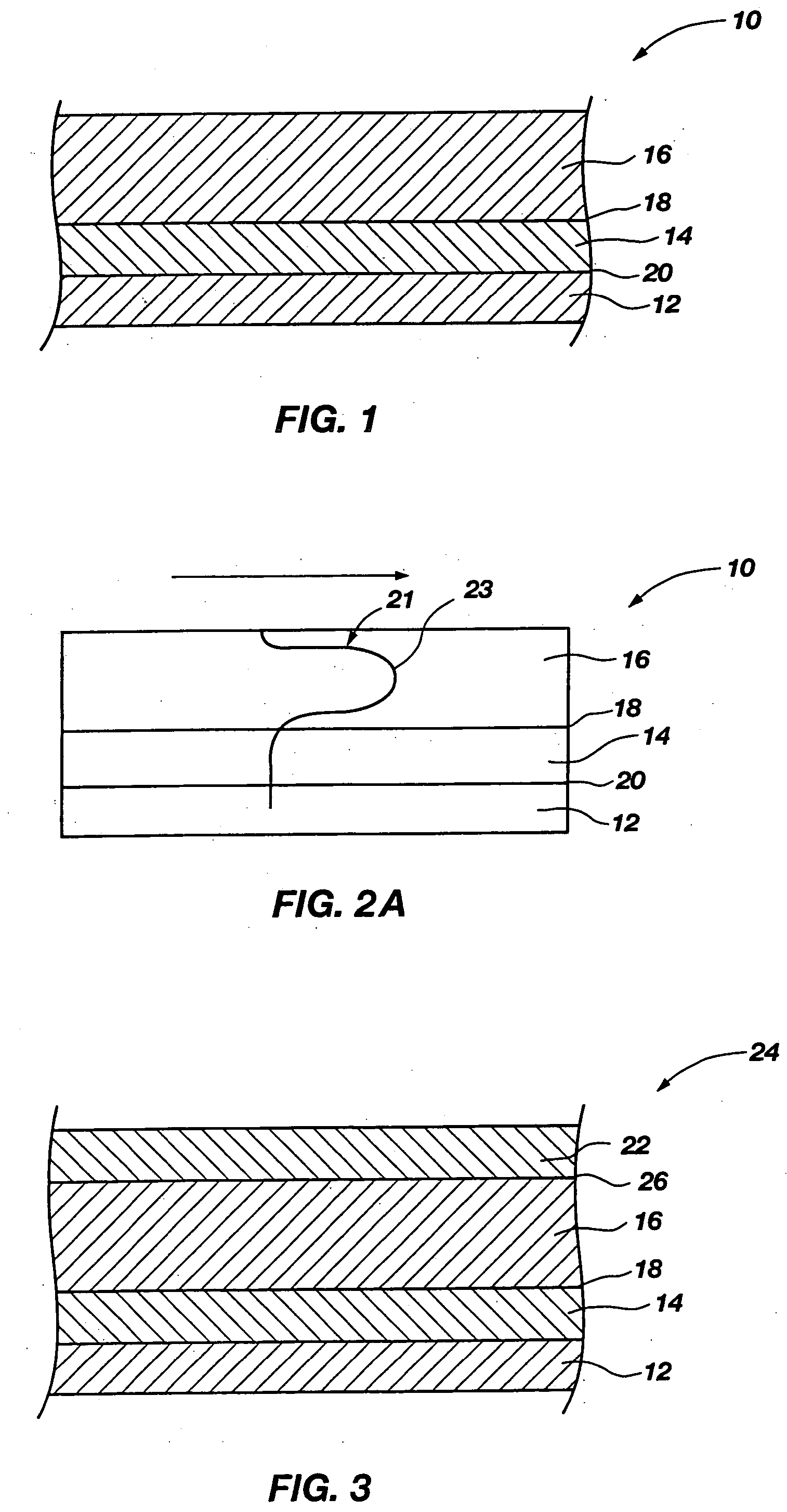

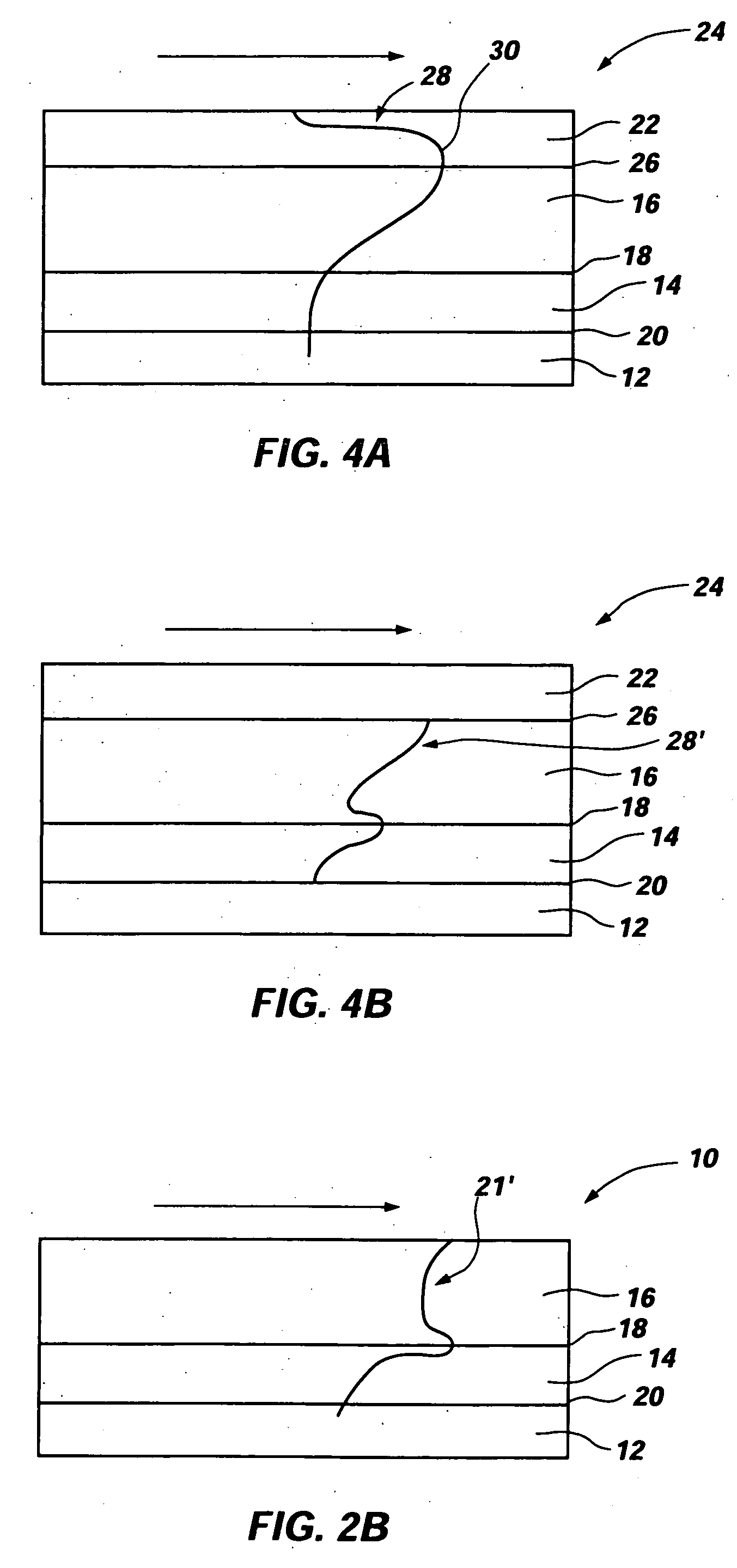

ActiveUS20050107772A1Increase surface areaReduce effective thicknessPressure infusionOsmotic deliveryActive agentWater flow

In one aspect, the present invention is directed to an osmotic pump that automatically provides an ascending release rate of active agent as the osmotic pump functions in an environment of operation and may be designed for implantation within a desired animal or human subject. An osmotic pump according to the present invention includes a reservoir, a rate controlling membrane, an expandable osmotic composition, an active agent formulation and an exit orifice. Once administered to an environment of operation, water passes through the rate controlling membrane and into the osmotic composition, which causes the osmotic composition to expand and expel the active agent formulation through the exit orifice at a rate that is directly proportional to the rate at which water passes through the rate controlling membrane. An osmotic pump according to the present invention permits the flow of water through the rate controlling membrane to increase automatically without the need for manipulation of the osmotic pump after administration. As the flow of water through the rate controlling membrane increases, the rate at which active agent is delivered from the osmotic pump will also increase proportionally.

Owner:INTARCIA THERAPEUTICS INC

Ink jet head circuit board, method of manufacturing the same and ink jet head using the same

InactiveUS7641316B2Reduce areaPrevent thermal degradationSemiconductor/solid-state device detailsSolid-state devicesThermal energyInsulation layer

An ink jet head circuit board is provided which has heaters to generate thermal energy for ink ejection as they are energized. This circuit board reduces areas of the heaters to achieve higher printing resolution and image quality. This board also prevents a degradation of thermal energy efficiency and reduces power consumption. The protective insulation layer for the electrode wire layer is formed of two layers and one of the two layers is removed from above the heater to improve the heat energy efficiency. The resistor layer is deposited over the electrode wire layer. The patterning for removing the protective insulation layer is done in a wider range than a gap of the electrode wire layer, the gap being used to form the heater. Further, by forming the electrode wires in two layers, a possible reduction in an effective bubble generation area of the heater can be prevented.

Owner:CANON KK

Laminated light-emitting diode display device and manufacturing method thereof

ActiveUS20070072506A1Reduce effective thicknessEasy to installDischarge tube luminescnet screensFinal product manufactureDisplay deviceEngineering

A laminated light-emitting diode display device and a manufacturing method thereof are described. The laminated light-emitting diode display device has an insulator, a circuitry device placed on the insulator and having of a plurality of circuits interconnected with each other, and a plurality of SMT-type light-emitting diodes electrically connected to the circuits of the circuitry unit.

Owner:HARVATEK CORPORATION

Asymmetrically porous ion exchange membranes and their method of manufacture

ActiveCN108348864ASimple methodIncrease capacitySemi-permeable membranesMembranesIon-exchange membranesUF - Ultrafiltration

The invention relates to a membrane and method for its manufacture, the method including the steps of (1) providing of an ultrafiltration membrane, and (2) modification of the resultant ultrafiltration membrane to provide an asymmetric porous ion exchange membrane. The modification of the ultrafiltration membrane is typically carried out by (i) exposing said ultrafiltration membrane to a first functional reagent to provide a cross-linked ultrafiltration membrane, and then (ii) exposing said cross-lined ultrafiltration membrane to a second functional reagent to introduce positive charged groupsto produce an anion exchange membrane.

Owner:MONASH UNIV

Mechanical restraint member

ActiveUS20160076677A1Reduce riskPoint be alleviated and eliminatedSleeve/socket jointsFluid pressure sealed jointsEngineeringPiping

A mechanical restraint member for retaining the relative position of a first conduit in a piping system relative to a second conduit in the piping system. The mechanical restraint member has a flexible substrate having a first outer side, a second inner side and first and second axially spaced apart ends, and a first bonding agent provided on at least a portion of the second inner side.

Owner:OMACHRON INTPROP

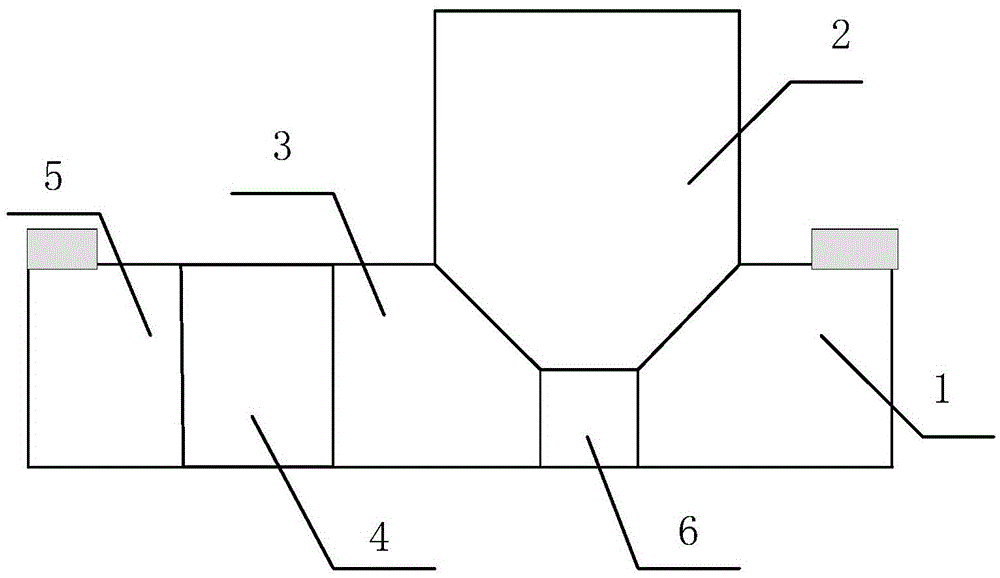

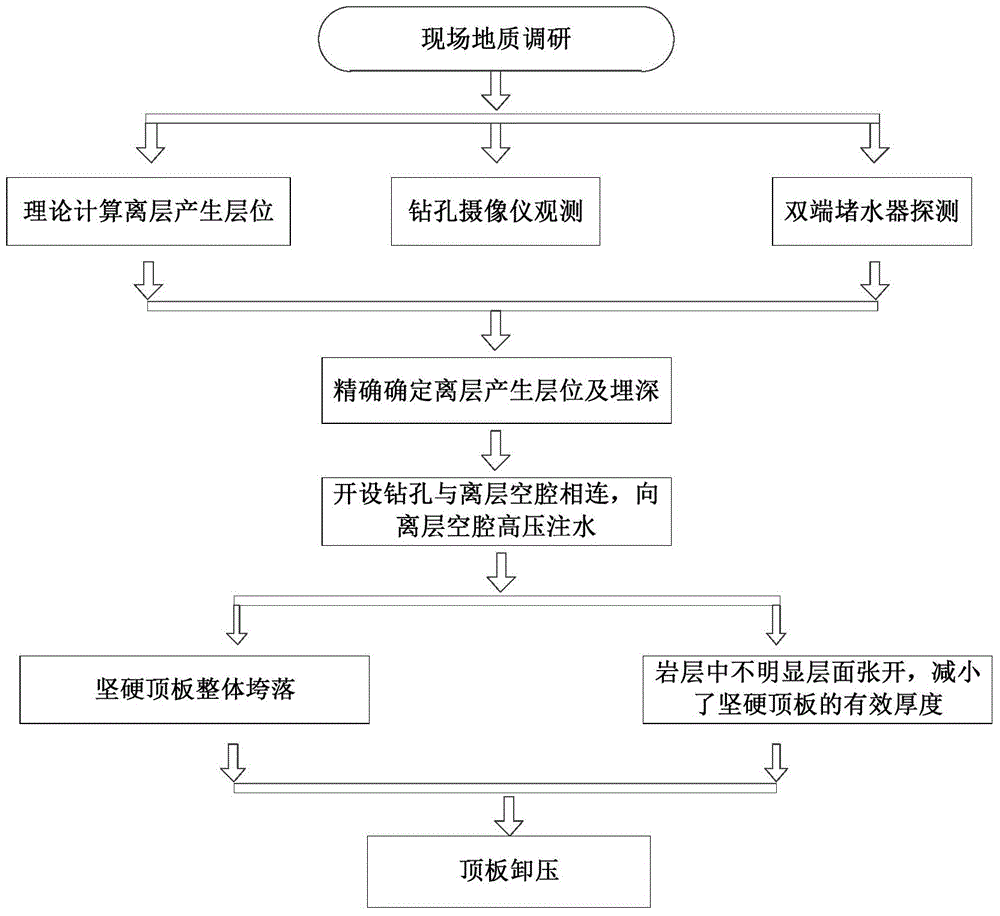

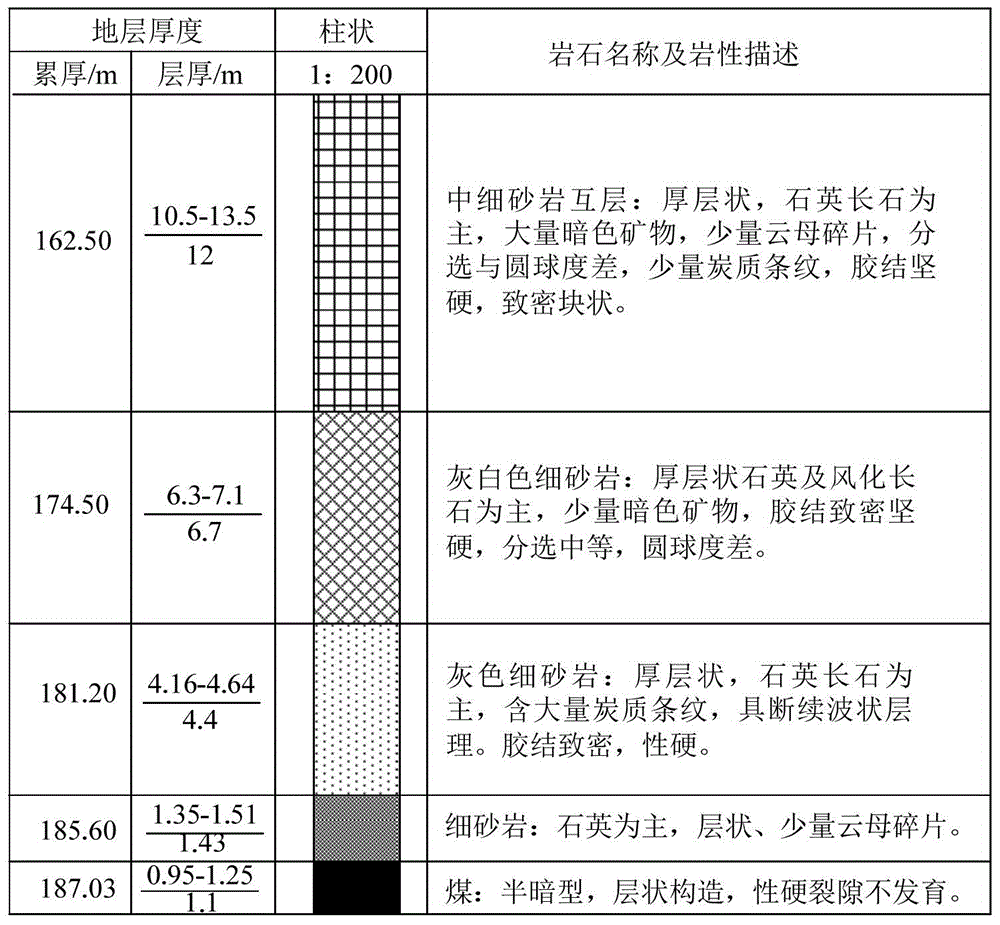

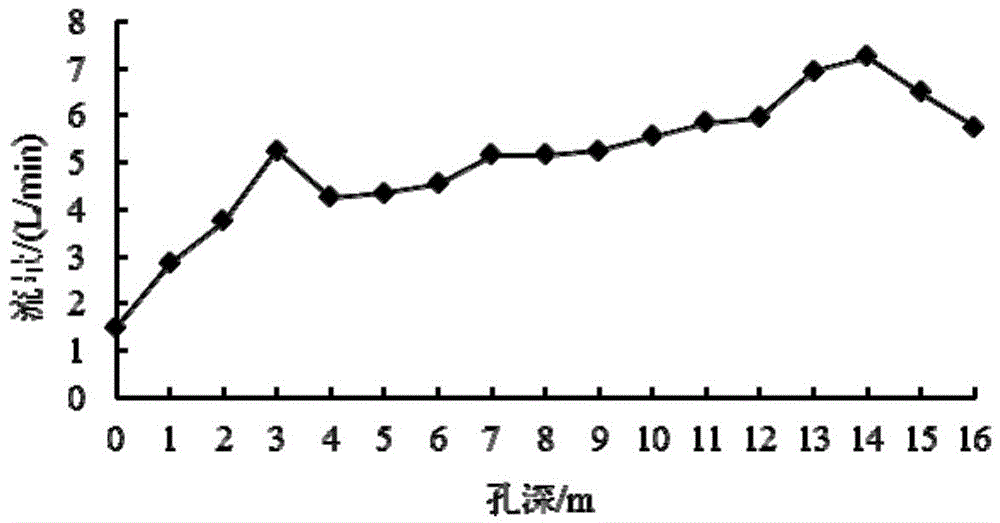

Hard top plate waterflooding pressure relief treatment method

InactiveCN104594898AGrasp the development of cracksStratified in timeDisloding machinesUnderground miningPlate pressureEngineering

The invention discloses a hard top plate waterflooding pressure relief treatment method. The method comprises the following steps of S1, according to a stratum histogram, through combination with a rock mechanical property test, carrying out preliminary analysis on positions and development case of top plate separation fractures, S2, when cutting depth at an open-off cut on the work surface is in a range of 13-17m, drilling a row of holes on the top plate at a certain angle along a work surface advance direction, and observing top plate rock stratum crack development case by a borehole camera, S3, further detecting top board crack development case by a double-head water-plugging device detection system, S4, determining a top plate rock stratum crack development range and depth according to the results of the above three steps, and pouring high pressure water into the cracks by a high pressure water pump so that hard top plate integrity is broken and rock strength is reduced, and S5, after top plate pressure is released, sequentially pushing the work surface and repeating the above processes until work surface exploitation is finished. The method can realize accurate positioning of a pre-cracked top plate position and full utilization of a top plate separation layer crack space and is frees of artificial arrangement of a pre-cracking space.

Owner:SHANDONG UNIV OF SCI & TECH

Method for reducing the effective thickness of gate oxides by nitrogen implantation and anneal

InactiveUS20050062114A1Inhibited DiffusionHigh dielectric constantSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialMetal silicide

A method for reducing the effective thickness of a gate oxide using nitrogen implantation and anneal subsequent to dopant implantation and activation is provided. More particularly, the present invention provides a method for fabricating semiconductor devices, for example, transistors, which include a hardened gate oxide and which may be characterized by a relatively large nitrogen concentration at the polysilicon / gate oxide interface and a relatively small nitrogen concentration within the gate oxide and at the gate oxide / substrate interface. Additionally, the present invention provides a method for fabricating a semiconductor device having a metal gate strap (e.g., a metal silicide layer) disposed over the polysilicon layer thereof, which device includes a hardened gate oxide and which may be characterized by a relatively large nitrogen concentration at the silicide / polysilicon interface to substantially prevent cross-diffusion.

Owner:MICRON TECH INC

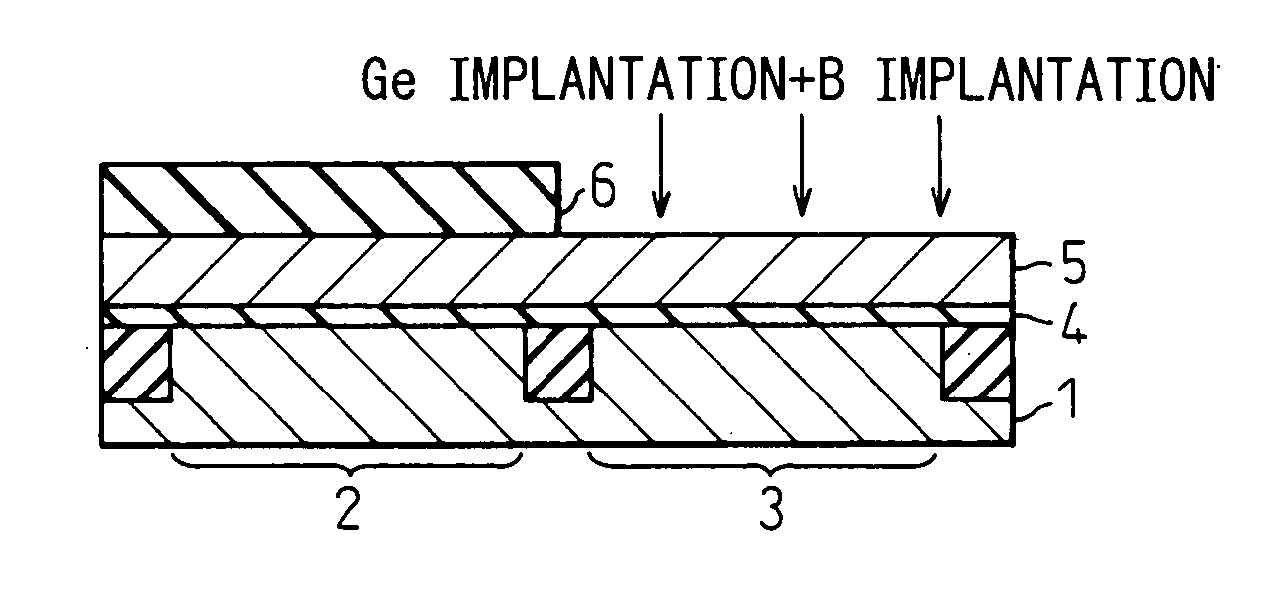

Method of manufacturing CMOS semiconductor device

ActiveUS20040132240A1Sufficient activationReduce effective thicknessTransistorSolid-state devicesCMOSImpurity

A method of manufacturing a CMOS semiconductor device able to reduce the effective thickness of the gate insulating film and able to secure stable performance is provided. The method in one embodiment comprises the steps of: forming a polycrystalline silicon film on a gate insulating film; introducing an n-type impurity into the polycrystalline silicon film in an nMOS formation region before gate processing of the polycrystalline silicon film; performing heat treatment so that the impurity diffuses in the polycrystalline silicon film and is activated; and patterning the polycrystalline silicon to form a gate pattern before introducing an impurity into the polycrystalline silicon film at a pMOS formation region.

Owner:FUJITSU SEMICON LTD

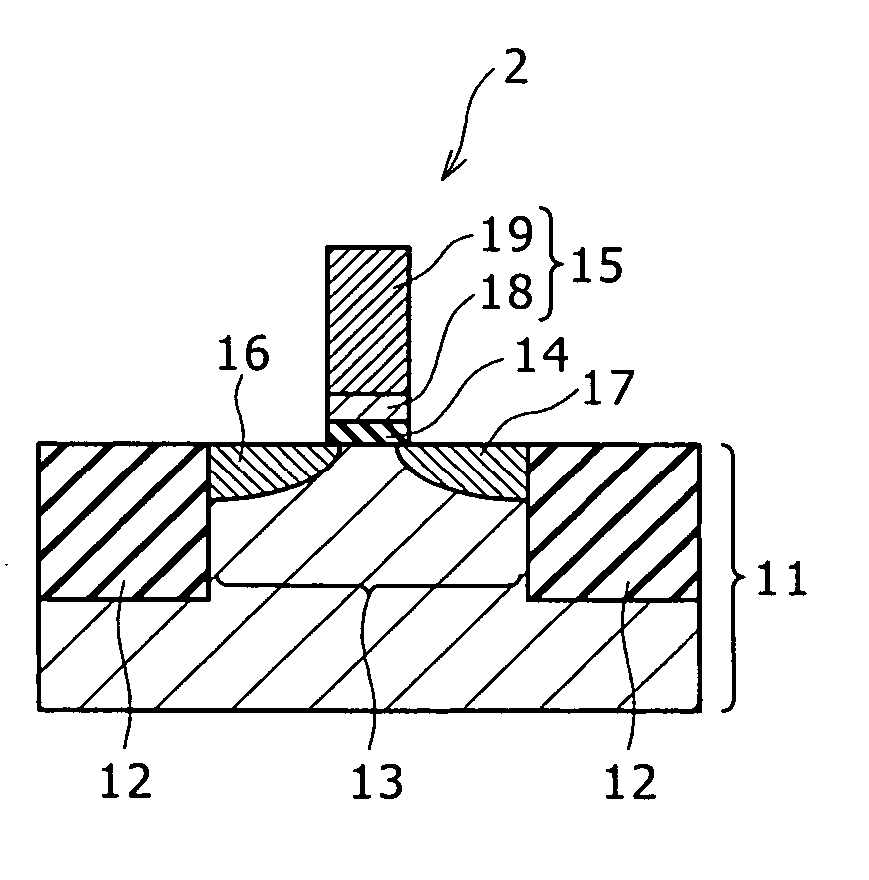

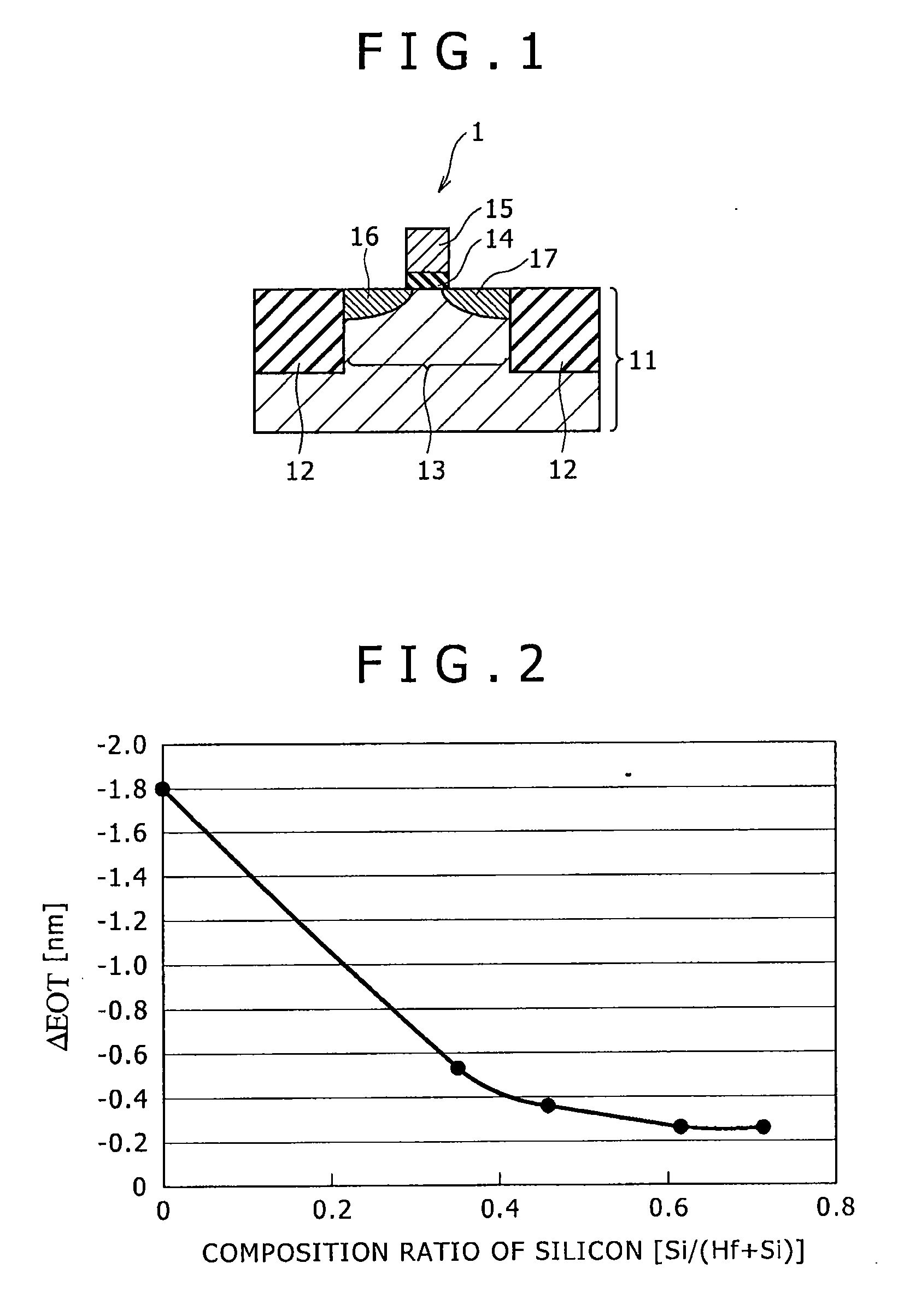

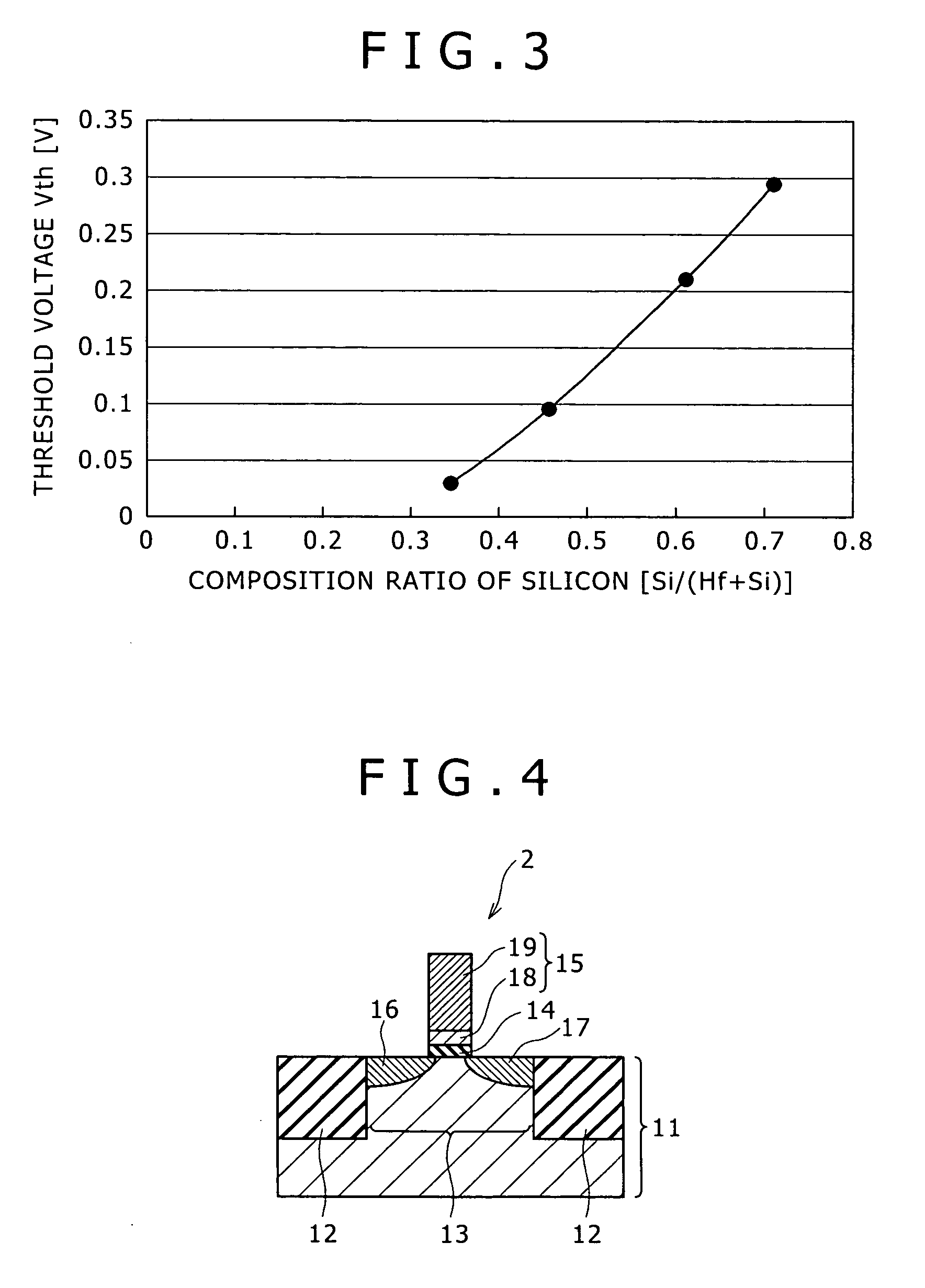

Semiconductor device and method of manufacturing the same

ActiveUS20060197166A1Reduced insulation performanceRestrain gate leakageSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialField-effect transistor

A semiconductor device which includes a field effect transistor having a gate electrode on the upper side of a semiconductor substrate, with a gate insulation film therebetween, wherein at least the gate insulation film side of the gate electrode includes a film containing hafnium and silicon.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com