Low-noise avalanche photodetector and preparation method thereof

A technology of avalanche optoelectronics and detectors, applied in circuits, electrical components, semiconductor devices, etc., can solve the problem of low working bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

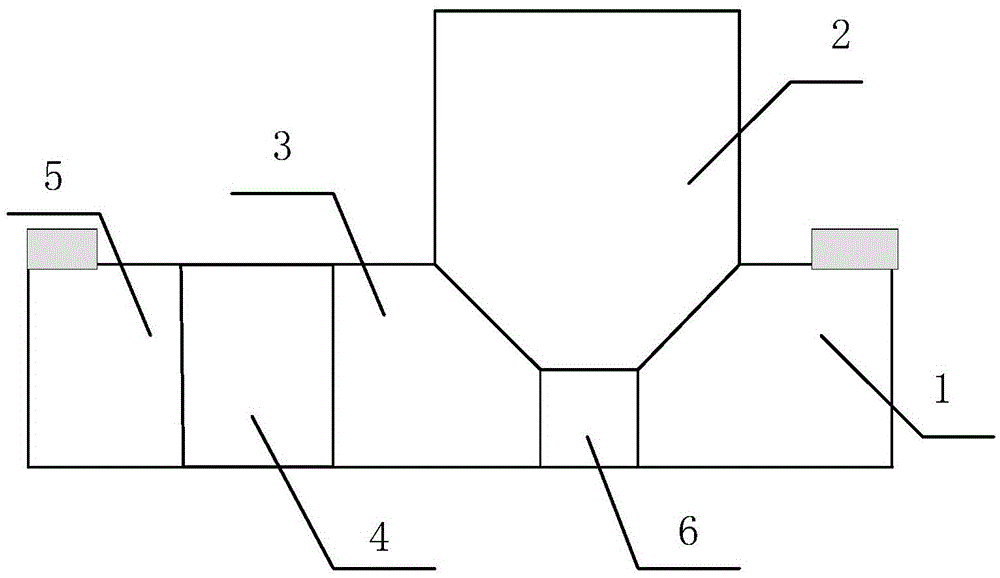

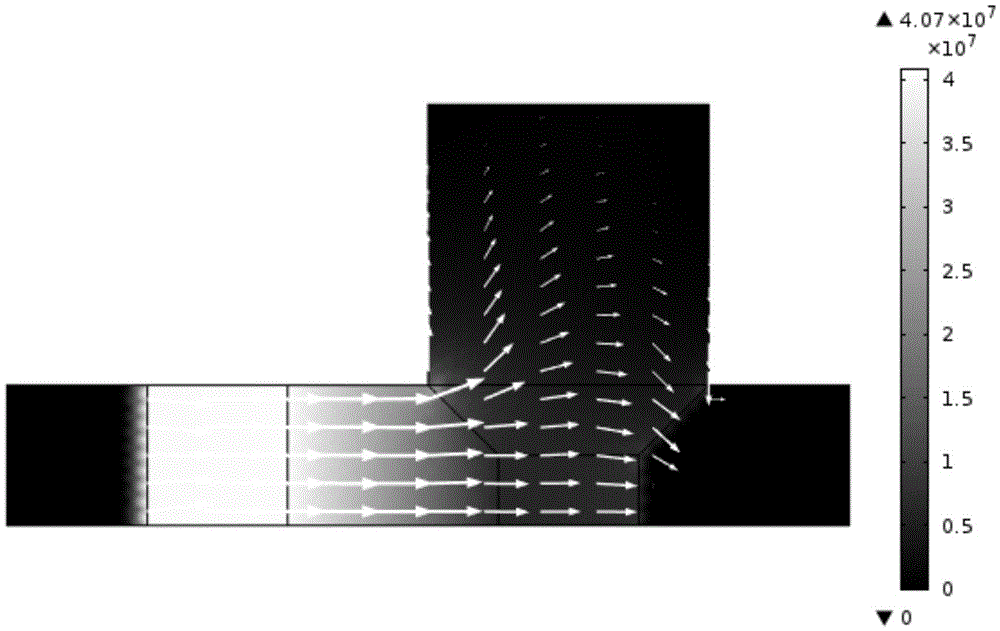

[0022] As embodiment 1, the present invention discloses a Si / Ge avalanche photodetector, its structure is as attached figure 1 shown. The structure of this detector includes but is not limited to: P-type ohmic contact layer 1, absorption layer 2, charge layer 3, multiplication layer 4, heavily doped N-type ohmic contact layer 5 and Si substrate 6, wherein the specific structural parameters As shown in Table 1.

[0023]

[0024]

[0025] Table 1

[0026] The present invention is characterized in that the one-dimensional avalanche photodetector is improved into a two-dimensional structure, and the k value is reduced by using the dead zone effect. The N-type and P-type ohmic contact layers are formed by high doping at both lateral ends of the low-doped silicon layer, and the doping concentration is higher than 1.0×10 18 / cm 3 . The charge layer is formed between the P-type and N-type ohmic contact layers using precisely controlled P-type or N-type doping, and the dopin...

Embodiment 2

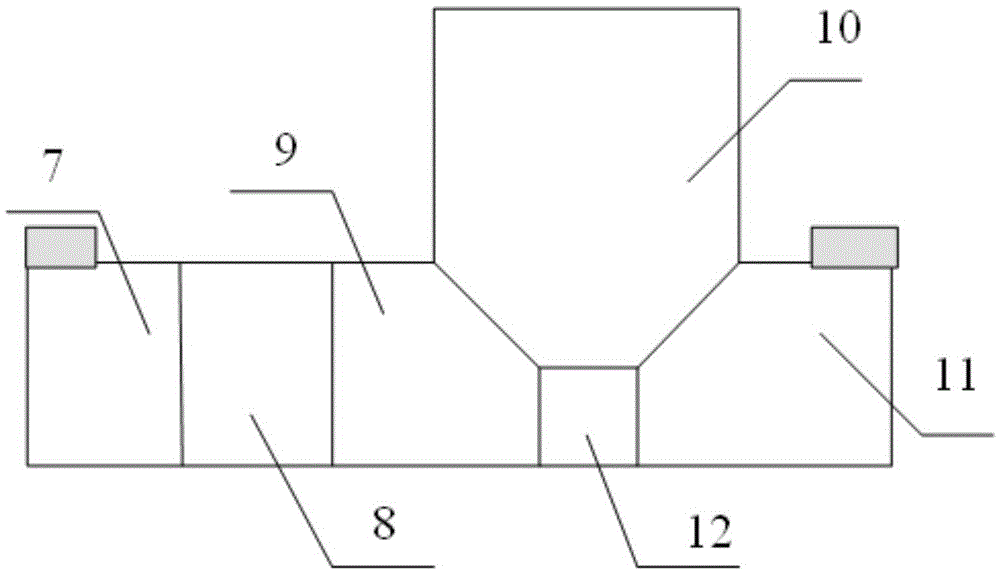

[0033] As embodiment 2, the present invention discloses an InP / InGaAs avalanche photodetector, the structure of which is shown in the attached image 3 . The structure of this detector includes but is not limited to: P-type ohmic contact layer 7, multiplication layer 8, charge layer 9, absorption layer 10, heavily doped N-type ohmic contact layer 11 and InP substrate 12, wherein the specific structural parameters As shown in table 2.

[0034]

[0035] Table 2

[0036] Embodiment 2 provides a method for manufacturing the above-mentioned InP / InGaAs avalanche photodetector, including the following steps:

[0037] S1. Make regions of different doped InP materials, and sequentially form P-type ohmic contact layer 7, multiplication layer 8, charge layer 9, and heavily doped N-type ohmic contact layer on InP by diffusion, ion implantation and other processes. 11; and an InP substrate 12 is formed at the bottom between the charge layer 9 and the heavily doped N-type ohmic contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com