Patents

Literature

99results about How to "Reduce incorporation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermalization of gaseous precursors in CVD reactors

InactiveUS20090214785A1Speed up the processLow efficiencySemiconductor/solid-state device manufacturingFrom chemically reactive gasesSemiconductor materialsEngineering

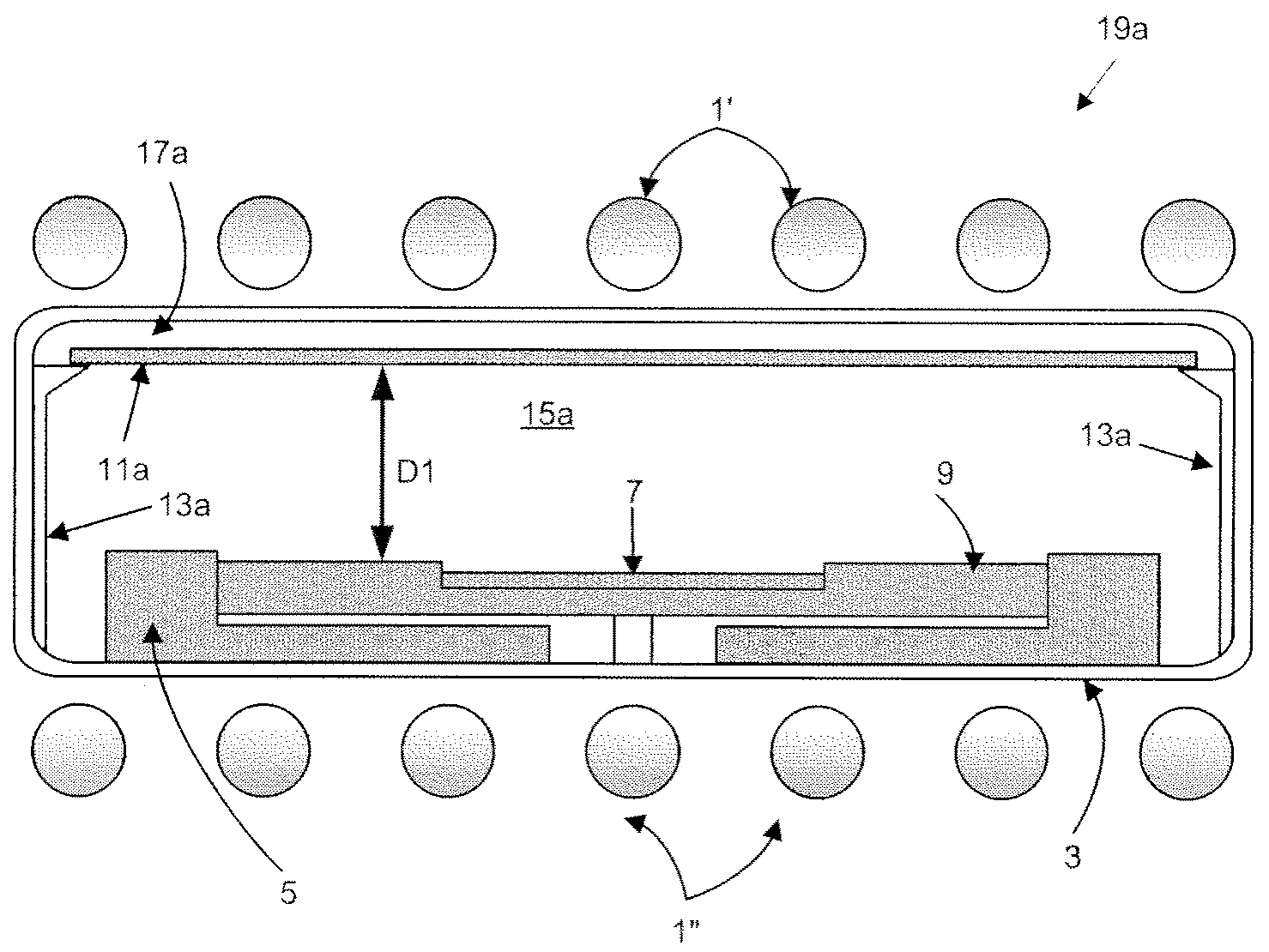

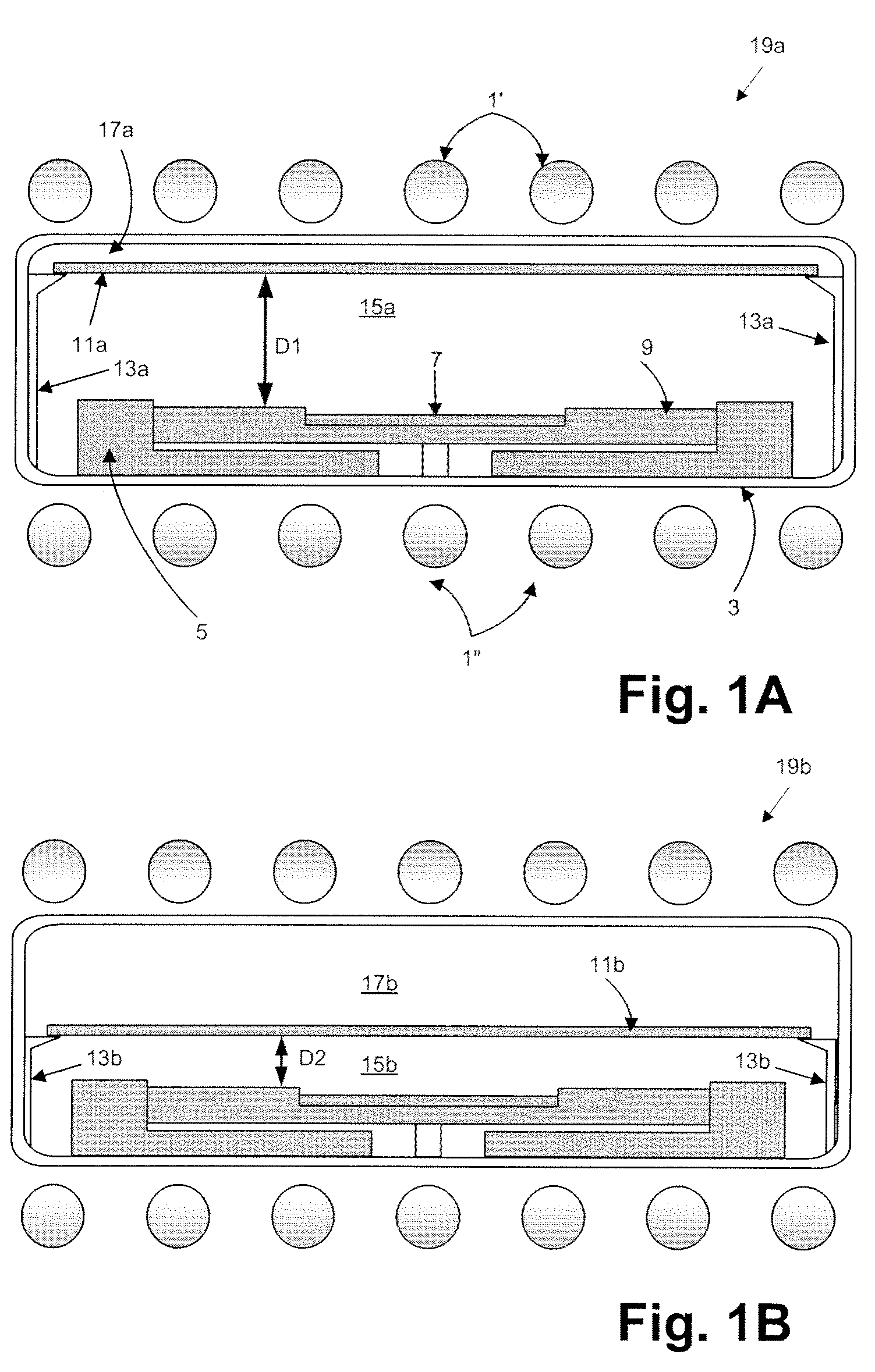

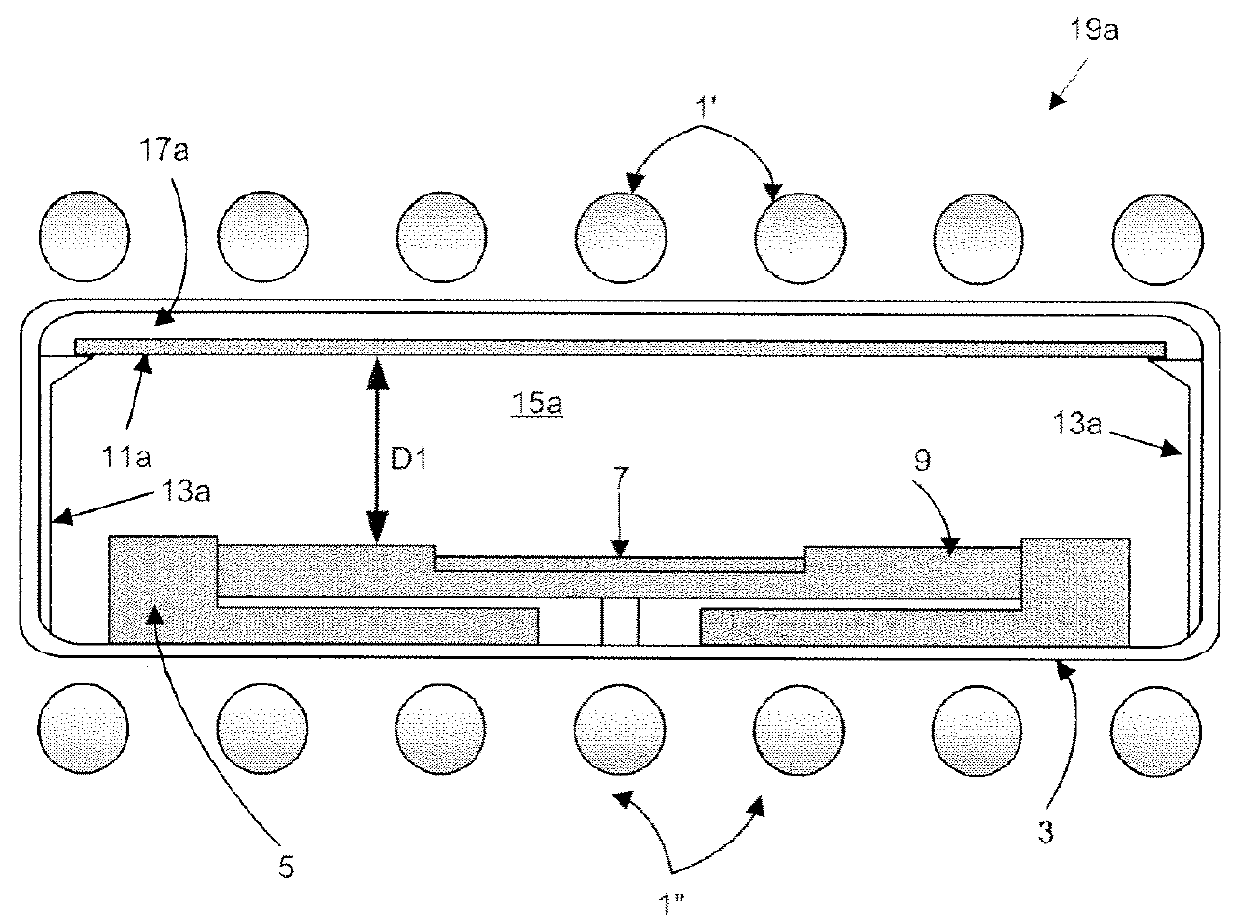

The present invention relates to the field of semiconductor processing and provides apparatus and methods that improve chemical vapor deposition (CVD) of semiconductor materials by promoting more efficient thermalization of precursor gases prior to their reaction. In preferred embodiments, the invention comprises heat transfer structures and their arrangement within a CVD reactor so as to promote heat transfer to flowing process gases. In certain preferred embodiments applicable to CVD reactors transparent to radiation from heat lamps, the invention comprises radiation-absorbent surfaces placed to intercept radiation from the heat lamps and to transfer it to flowing process gases.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

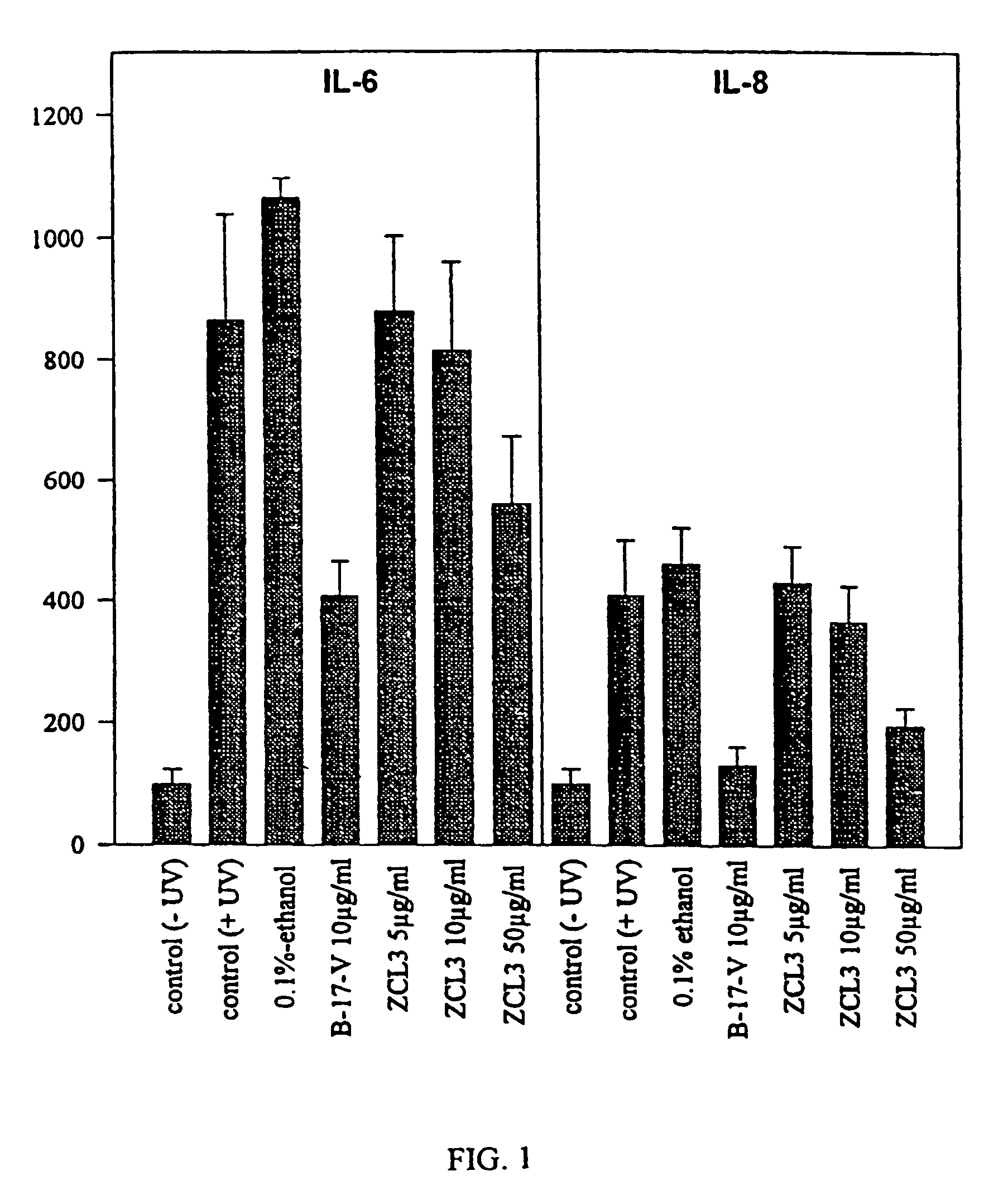

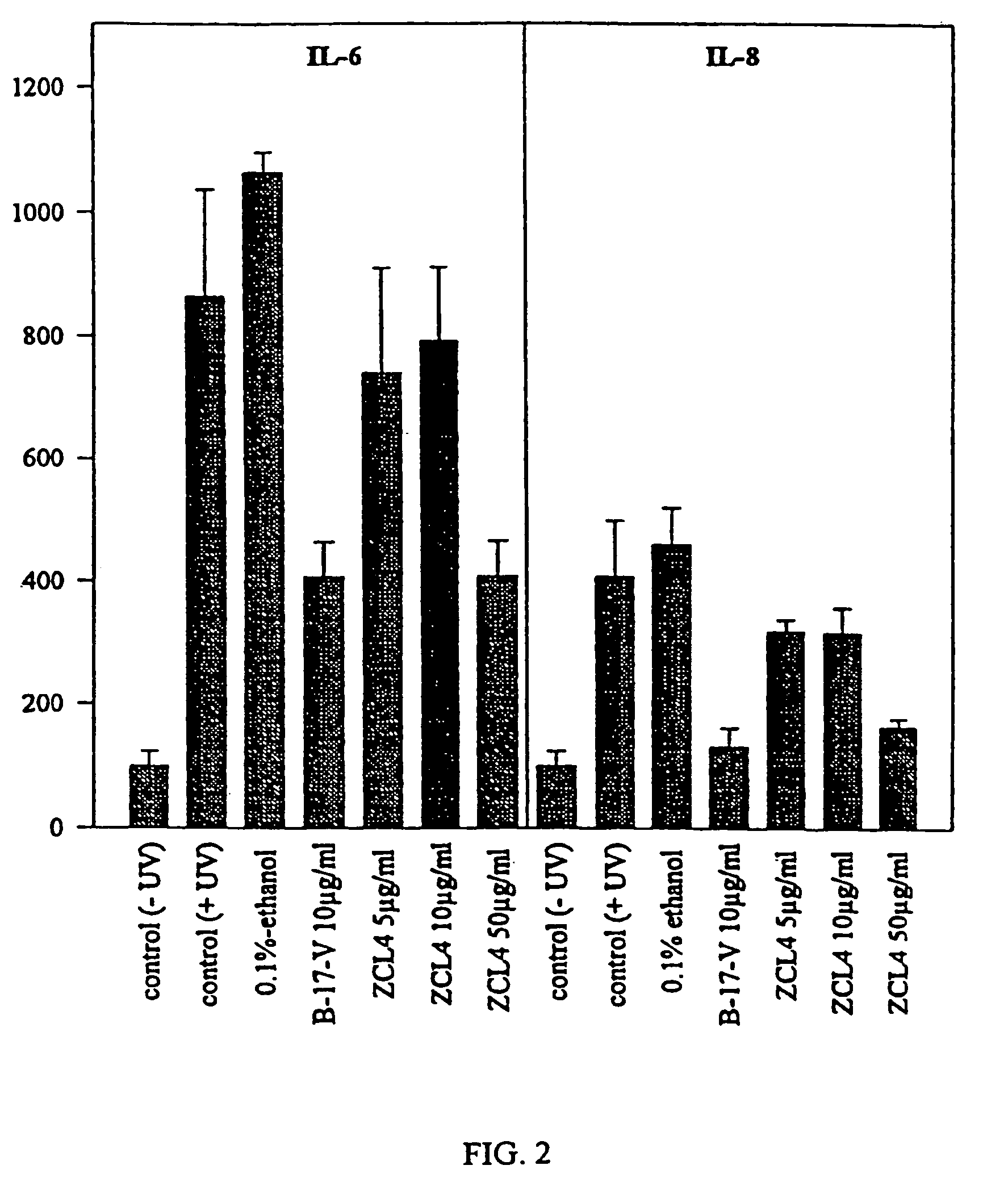

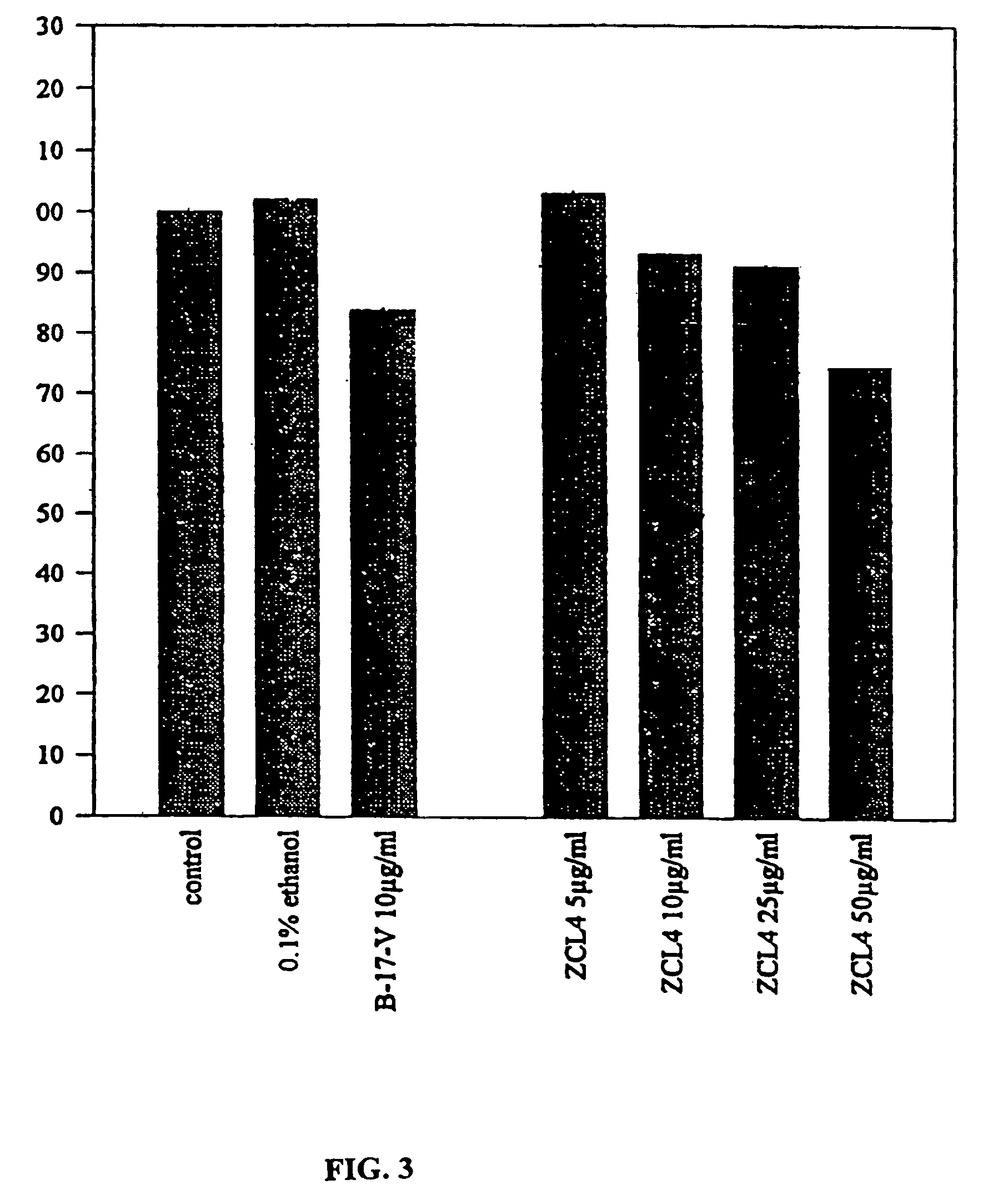

Pharmacological activities of Curcuma longa extracts

InactiveUS7220438B2Increase proliferative activityHigh activityBiocideDrug compositionsCurcuma longa extractWater soluble

This invention concerns to a topical pharmaceutical composition comprising an water soluble Curcuma extract, and suitable excipients for said topical administration; the process for obtaining said pharmaceutical compositions; the use of different Curcuma extracts as photosensitizing agents for the treatment of proliferative diseases; and the use of Curcuma extract or curcuminoids in combination with a radiation for the treatment of proliferative diseases on eukaryote cells.

Owner:ASAC COMPANIA DE BIOTECHA E INVESTIGACION

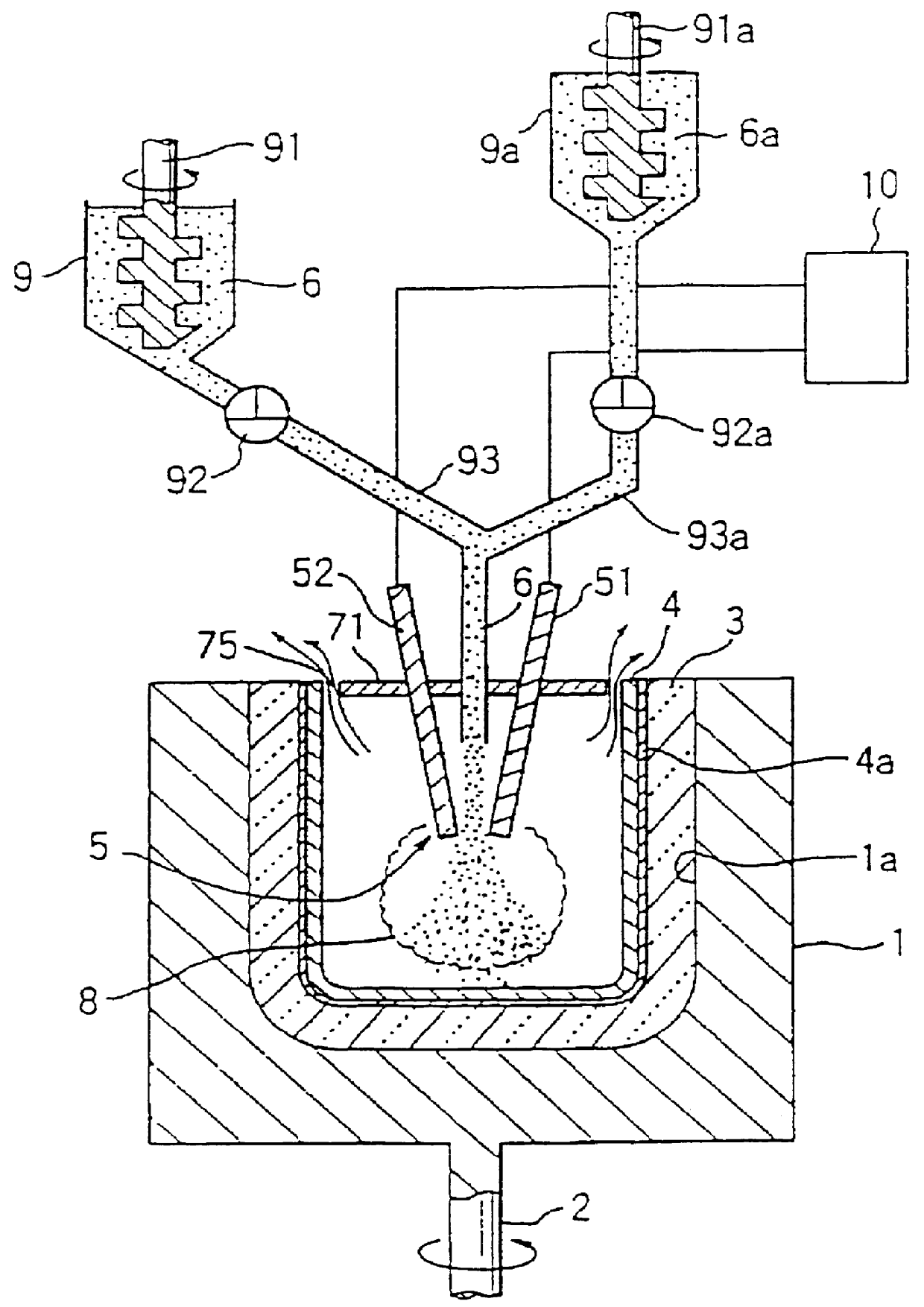

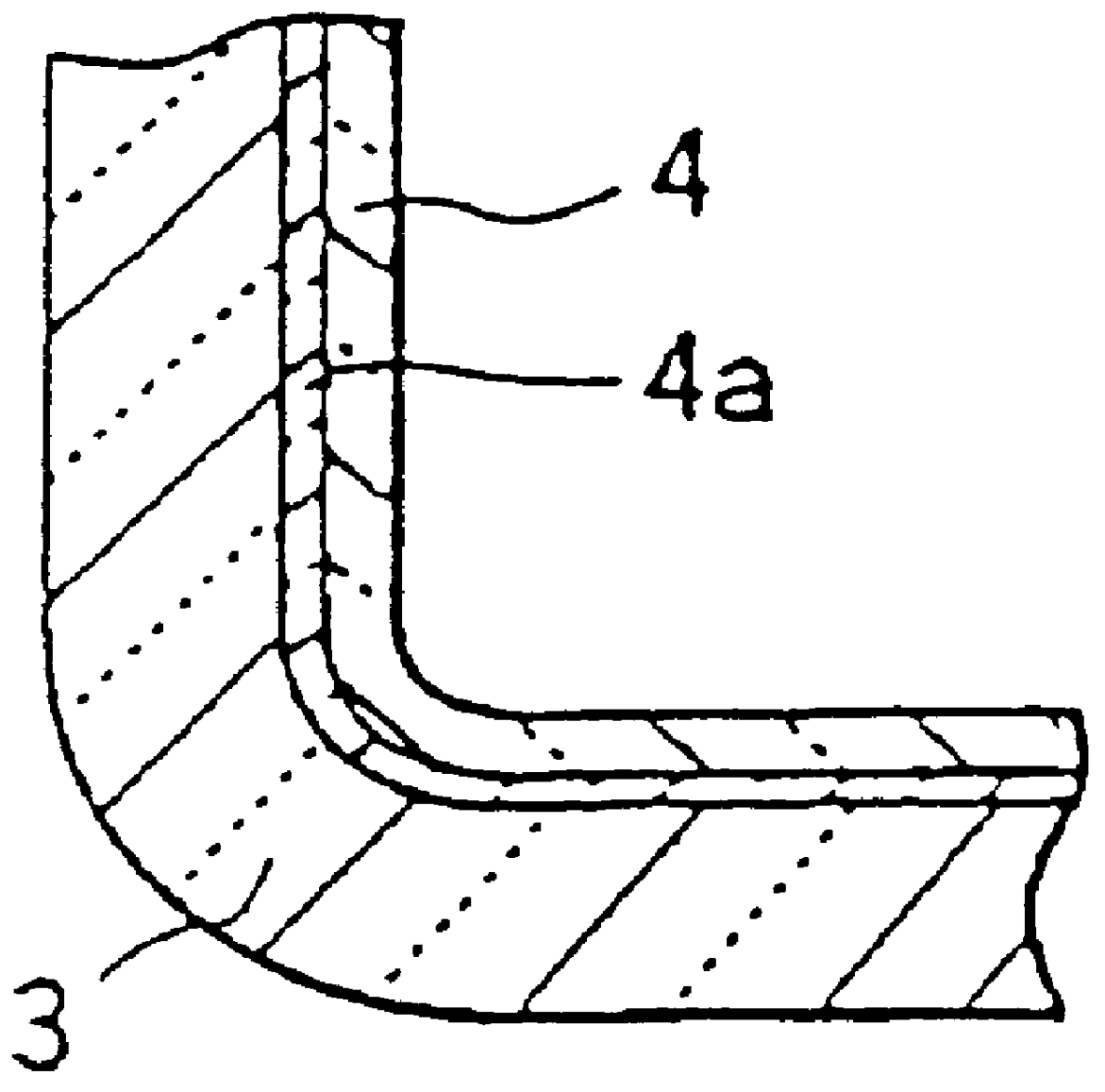

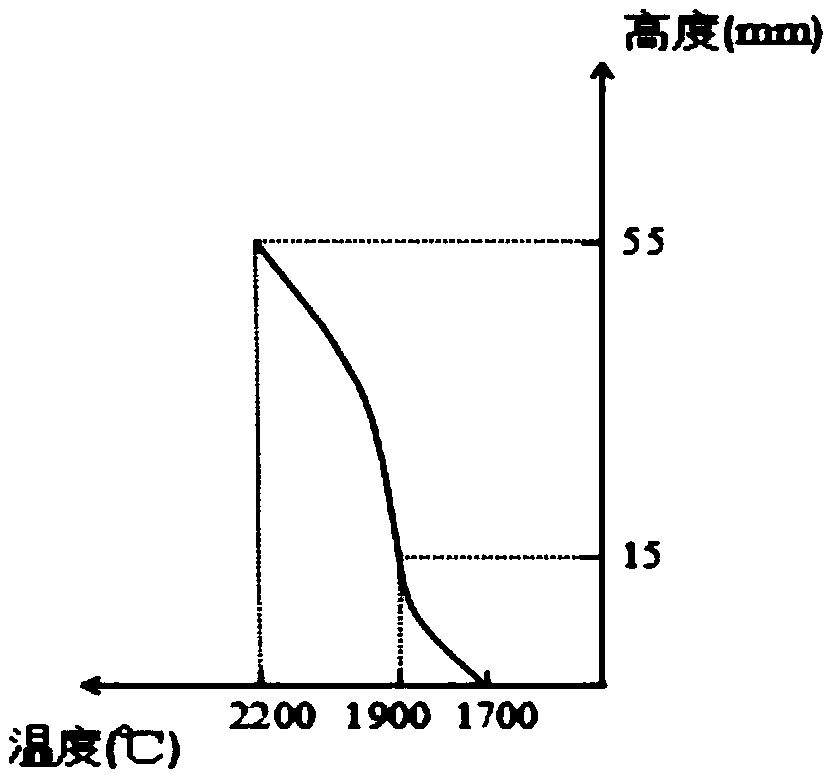

Quartz glass crucible for producing silicone single crystal and method for producing the crucible

InactiveUS6106610AQuality improvementRaise the ratioAfter-treatment apparatusPolycrystalline material growthCrucibleSingle crystal

A method for producing an improved quartz glass crucible for pulling up silicon single crystals comprises forming a premolding by feeding powdered silicon dioxide into the mold and by then forming it into a layer along the inner surface of the mold; forming a crucible base body of a translucent quartz layer by heating the premolding from the inner side, thereby partially melting the powdered silicon dioxide, followed by cooling and solidifying the melt; forming a crystallization-promoter containing layer along the internal wall surface of the crucible body by scattering the crystallization promoter on the surface of the internal wall of the crucible body during or after forming the crucible base body; and forming a synthetic quartz glass inner layer by scattering and fusing a powder of silicon dioxide on the crystallization promoter-containing layer that is formed along the internal wall surface of the crucible base body.

Owner:HERAEUS QUARZGLAS +1

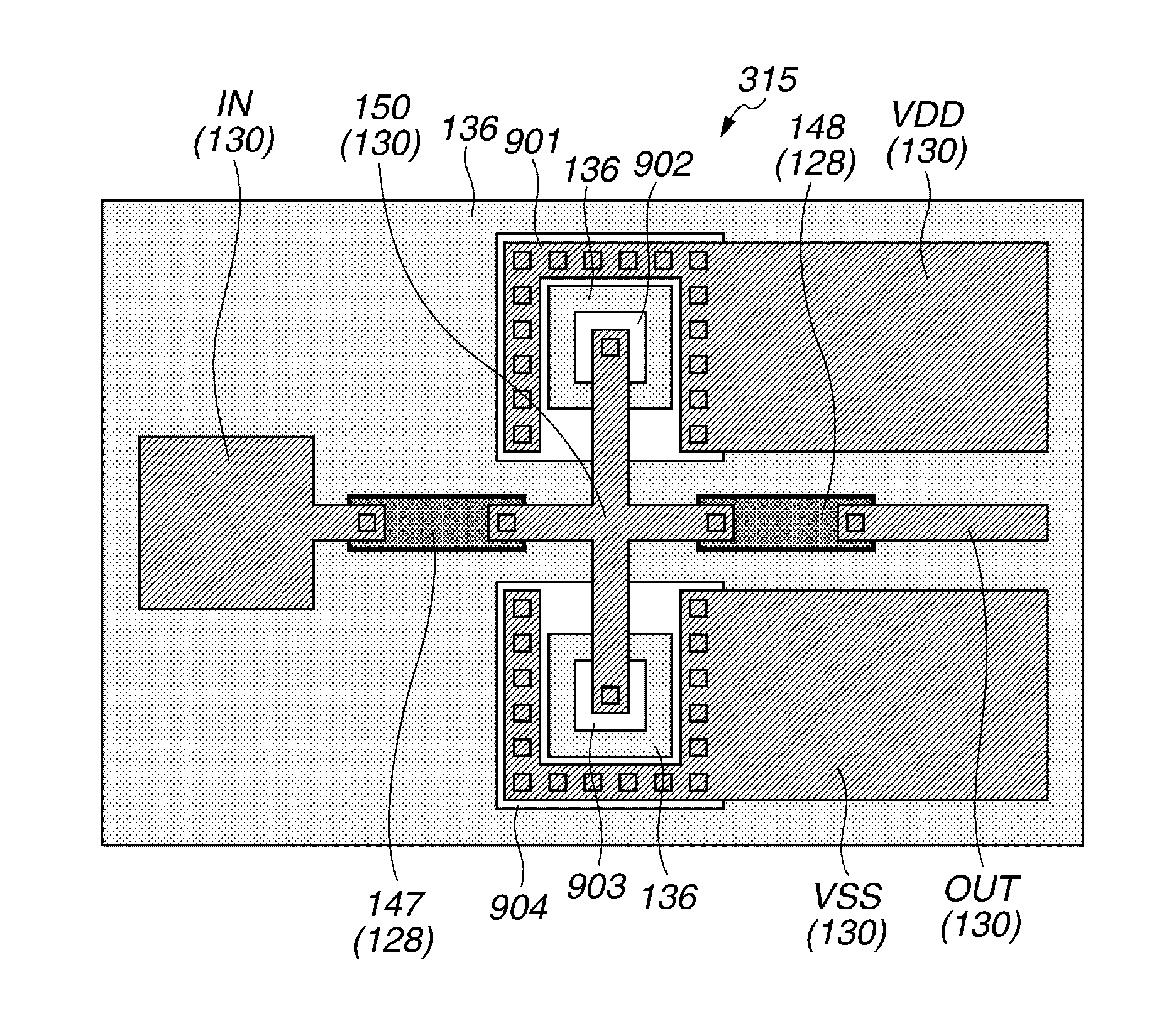

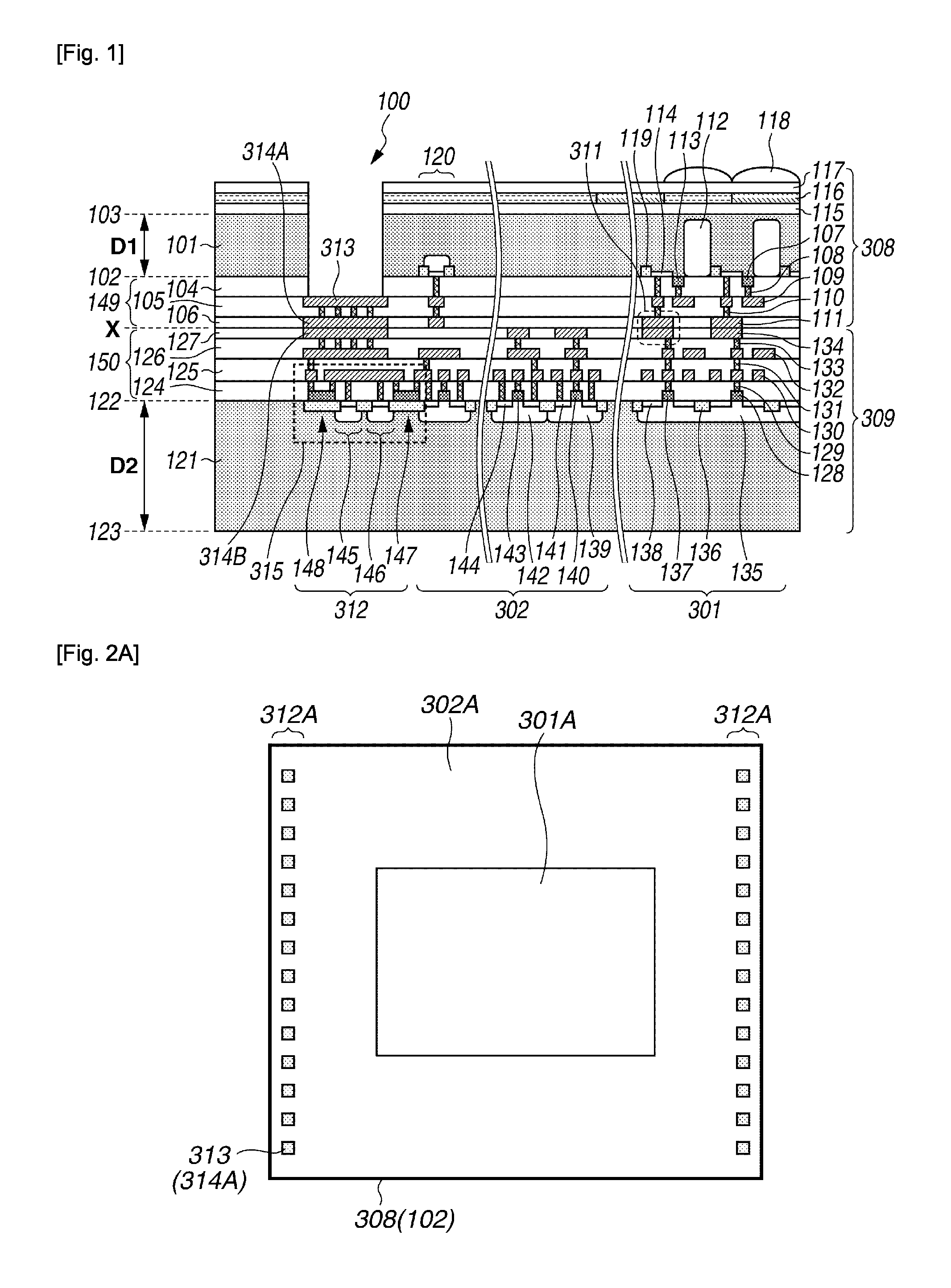

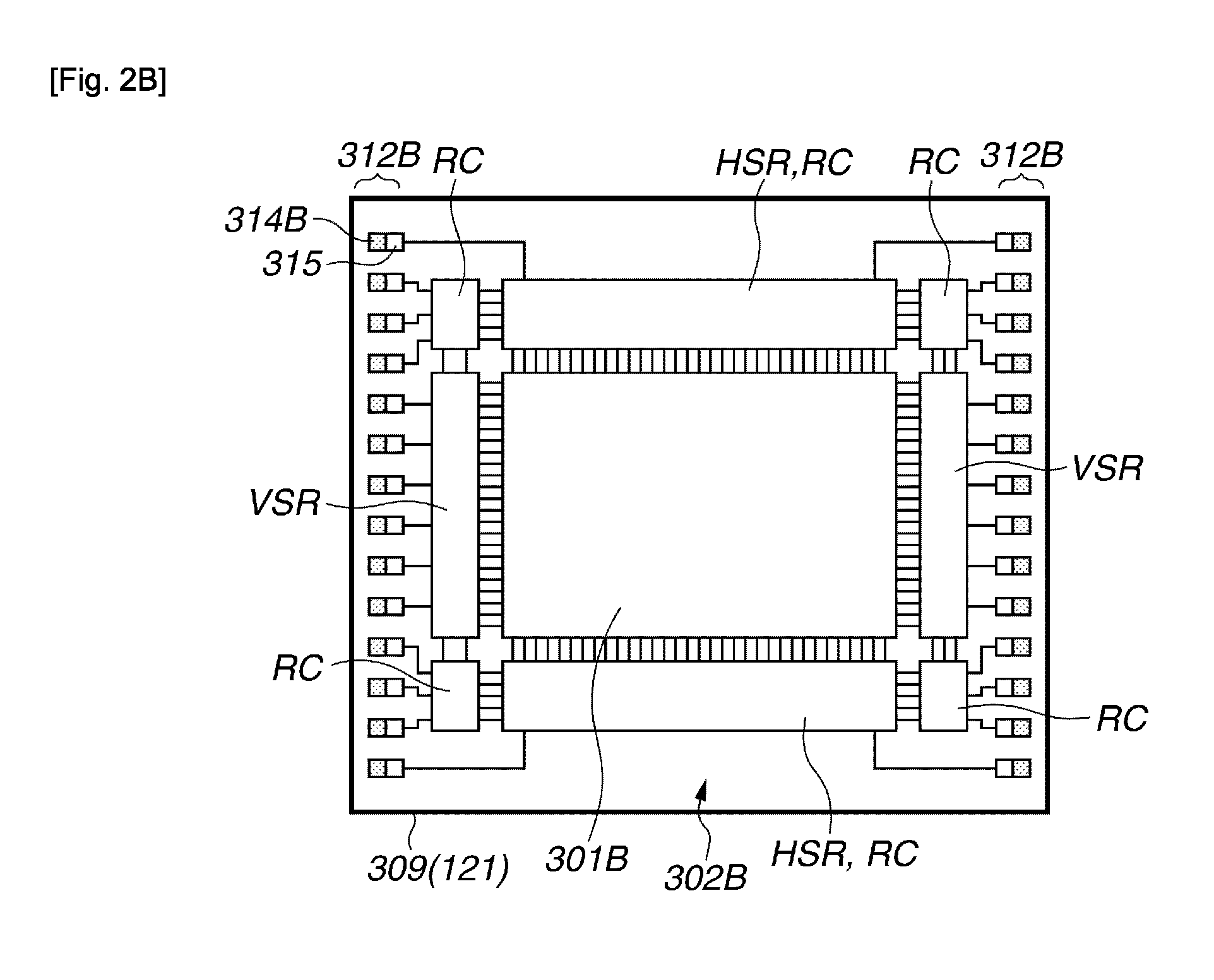

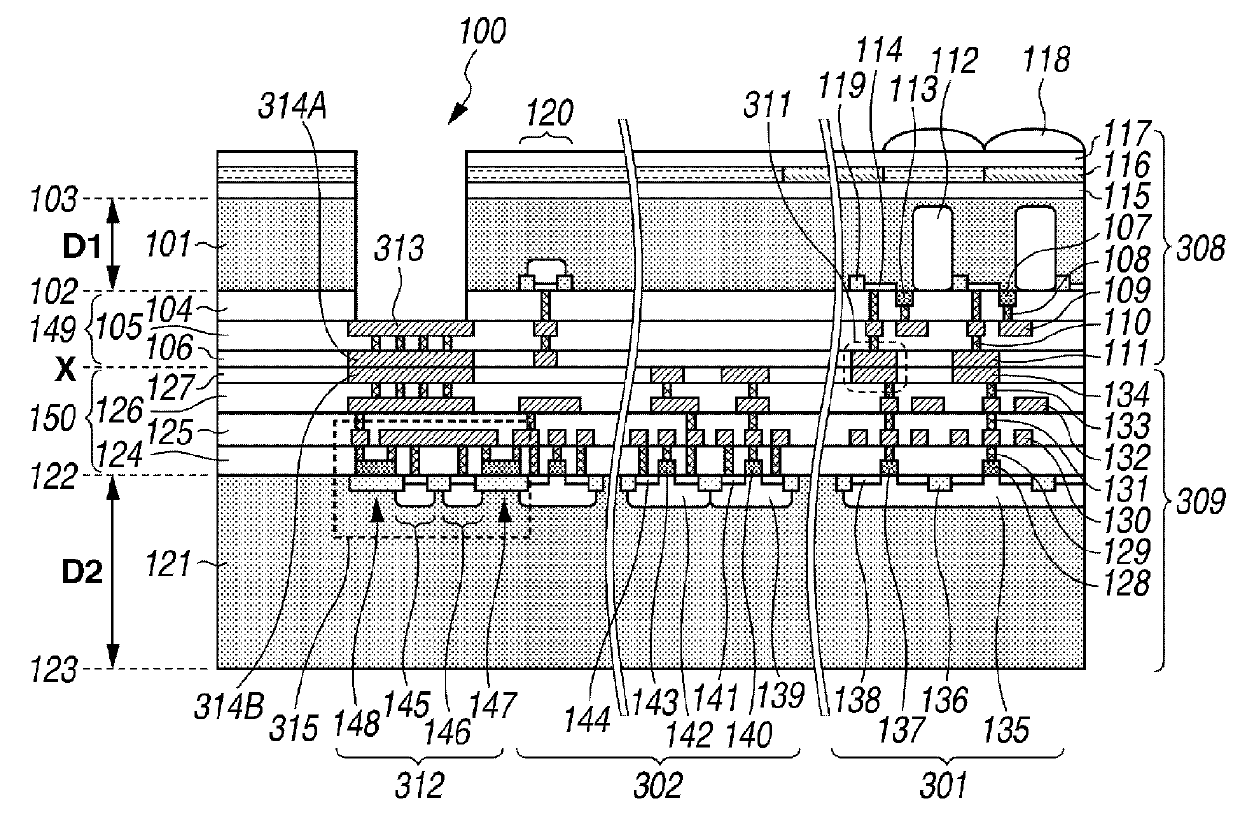

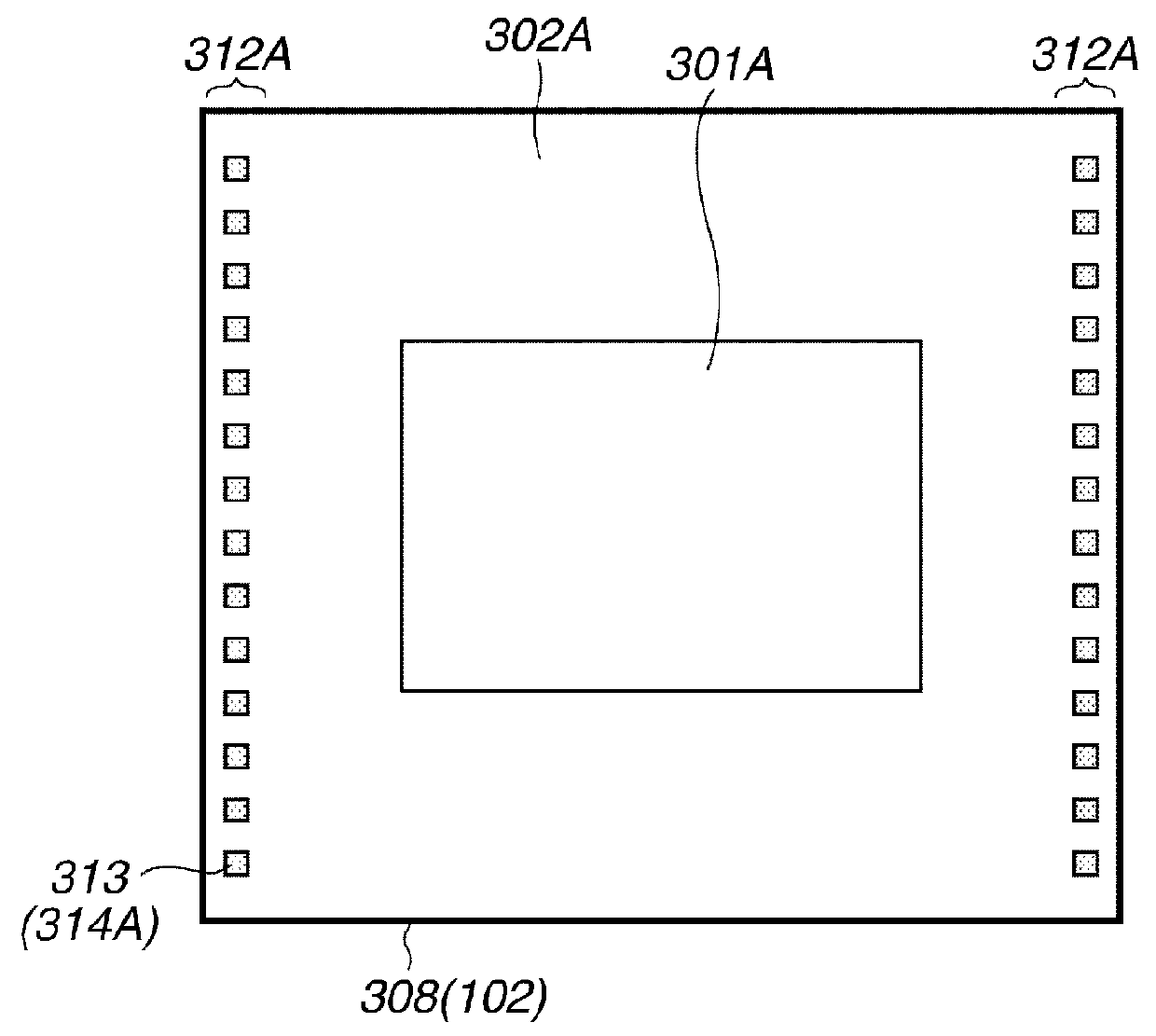

Solid-state imaging device and imaging system

ActiveUS20130107075A1Reduce incorporationTelevision system detailsSolid-state devicesSolid-statePeripheral

A solid-state imaging device includes: a first semiconductor substrate including a photoelectric conversion element; and a second semiconductor substrate including at least a part of a peripheral circuit arranged in a main face of the second semiconductor substrate, the peripheral circuit generating a signal based on the charge of the photoelectric conversion element, a main face of the first semiconductor substrate and the main face of the second semiconductor substrate being opposed to each other with sandwiching a wiring structure therebetween; a pad to be connected to an external terminal; and a protection circuit electrically connected to the pad and to the peripheral circuit, wherein the protection circuit is arranged in the main face of the second semiconductor substrate.

Owner:CANON KK

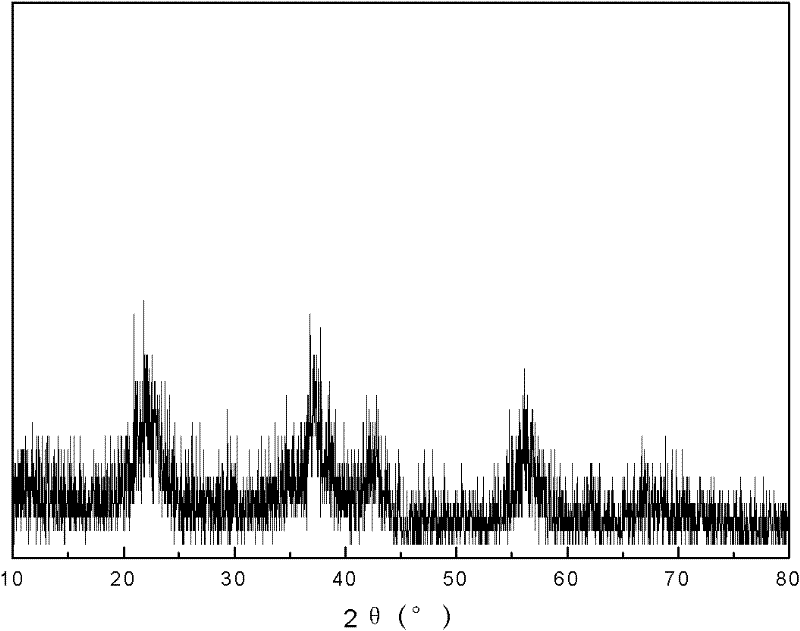

Co-precipitation method for preparing rare earth cerium ion-doped yttrium aluminum garnet fluorescent powder

InactiveCN101851510AReduce the chance of adulteration of impuritiesPrecise control of chemical calculations is easyLuminescent compositionsIonYttrium

The invention discloses a co-precipitation method for preparing rare earth cerium ion-doped yttrium aluminum garnet fluorescent powder and relates to fluorescent powder. The method comprises the following steps of: dissolving yttrium oxide powder in excessive concentrated sulfuric acid and mixing dissolved yttrium oxide with solution of cerous nitrate and solution of aluminum nitrate to prepare metal ion solution, wherein the ratio of Y<3+> to Ce<3+> to Al<3+> is 2.94:0.06:5; adding the metal ion solution into a precipitator to obtain a co-precipitate; cleaning, filtering and drying the co-precipitate to obtain a precursor; pre-sintering the precursor to obtain pre-sintered powder; and calcining the pre-sintered powder to obtain the rare earth cerium ion-doped yttrium aluminum garnet fluorescent powder. In the used co-precipitation method, mixing is performed under the ionic condition, so the mixing is more uniform compared with that of a mechanical mixing method, impurity doping possibility is reduced, accurate control of chemical calculation becomes easier and granularity can be controlled according to a reaction condition. The precipitator and the like are preferably selected and the co-precipitation method is implemented to form a pure YAG phase at the temperature of 1,100 DEG C, which is about 500 DEG C lower than that of a conventional high temperature solid phase reaction method.

Owner:XIAMEN UNIV

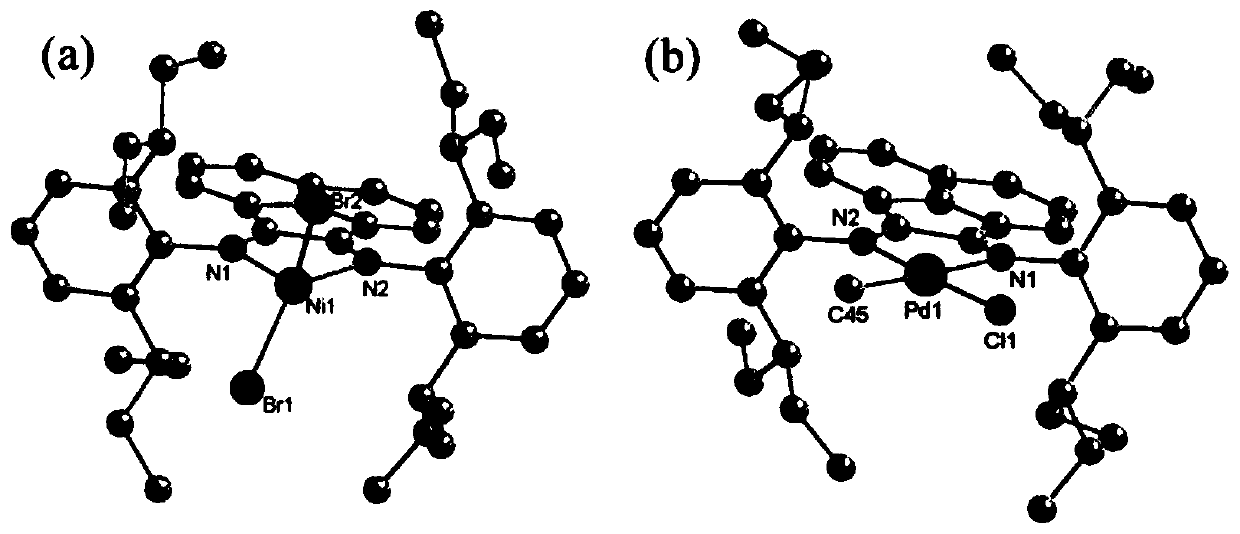

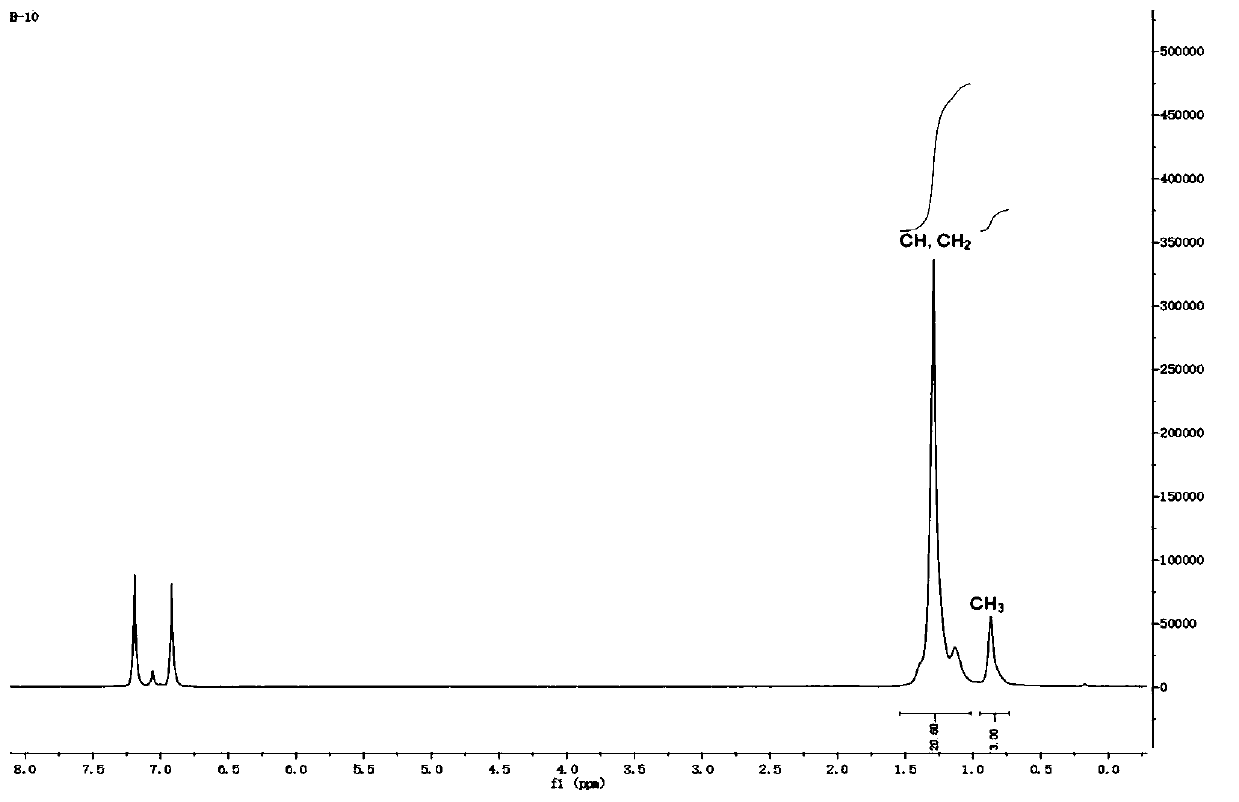

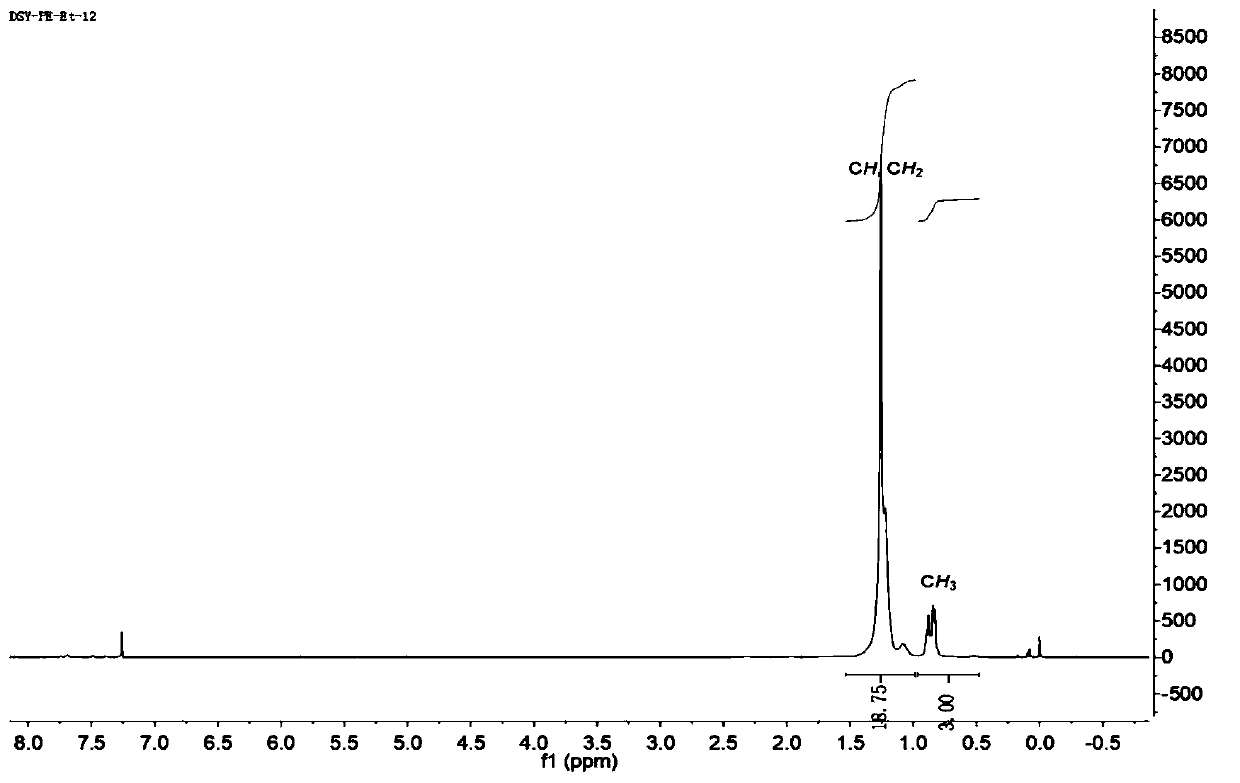

Large-steric-hindrance flexible diimine ligand, diimine nickel and palladium complexes based on large-steric-hindrance flexible diimine ligand and catalytic application of diimine nickel and palladium complexes

ActiveCN110317149AImprove thermal stabilityHigh molecular weightPalladium organic compoundsNickel organic compoundsPolyolefinDiimine

The invention discloses a large-steric-hindrance flexible diimine ligand, diimine nickel and palladium complexes based on the large-steric-hindrance flexible diimine ligand and catalytic application of the diimine nickel and palladium complexes. Flexible substituent groups of different structures are introduced to the diimine ligand, and a series of diimine nickel and palladium catalysts with thespace steric-hinerance effect are obtained. The obtained catalysts have high thermostability and high activity for olefinic polymerization catalysis and can regulate and control the molecular weight and branching density of polyolefin by adjusting the length of chains of the substituent groups.

Owner:ANHUI UNIVERSITY

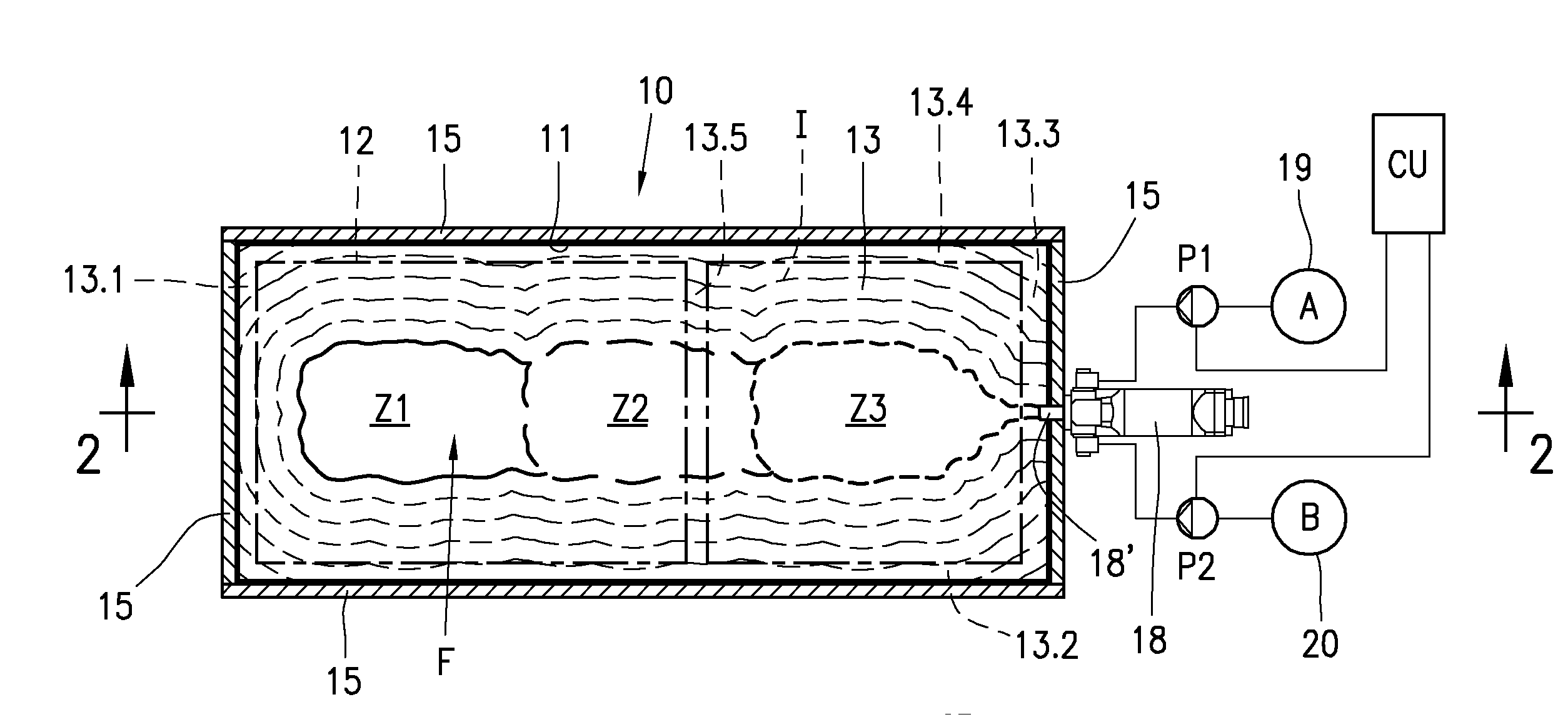

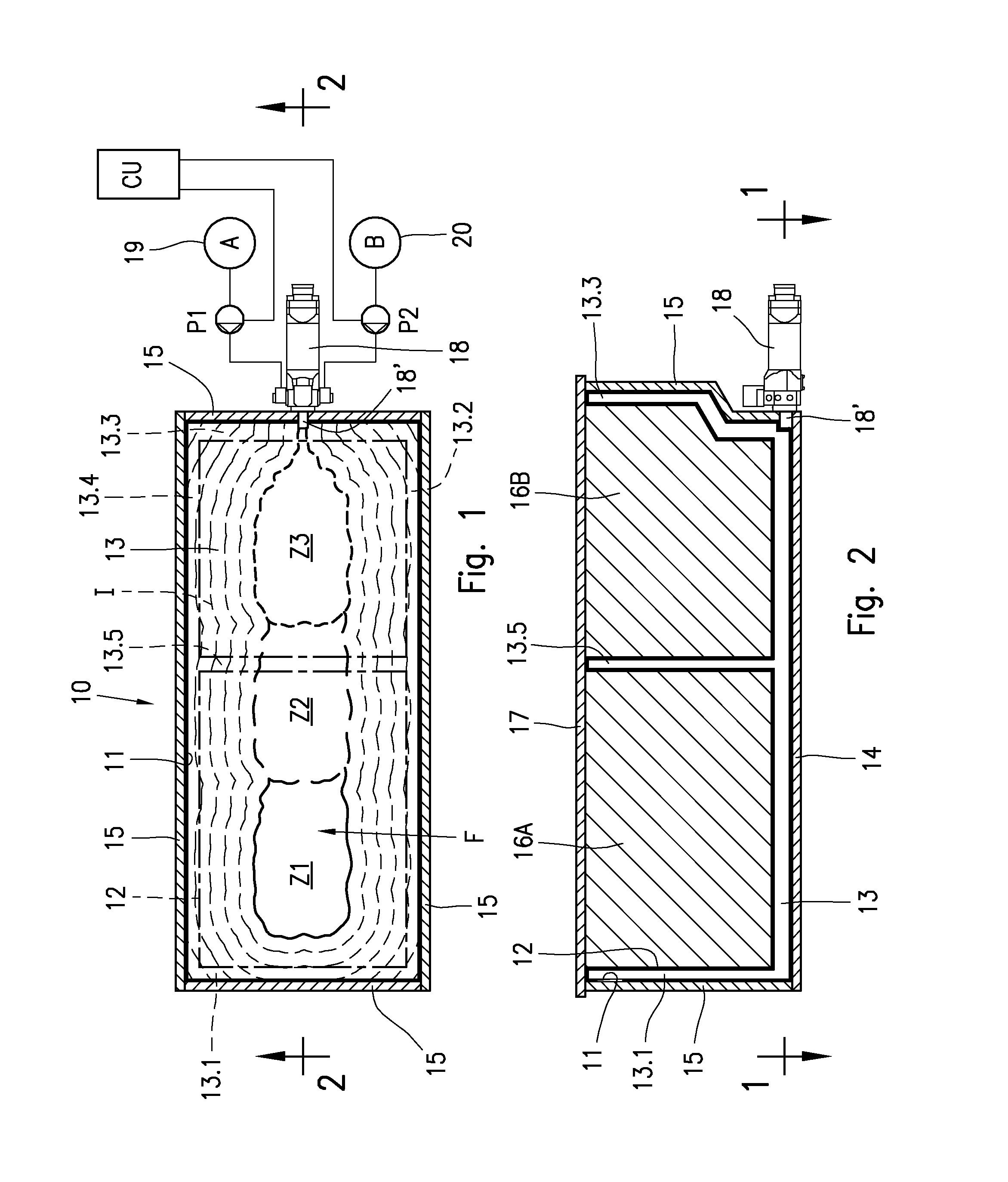

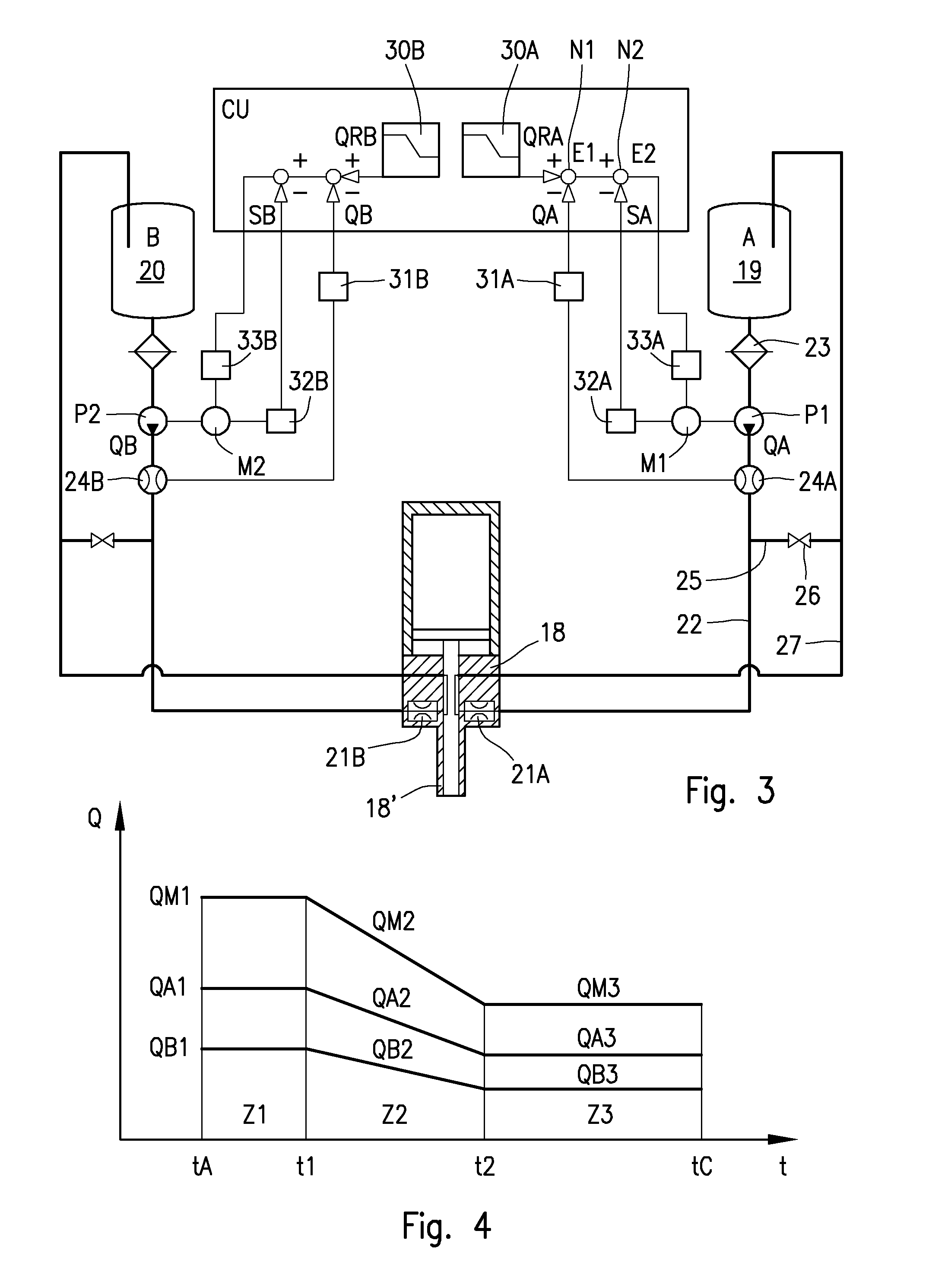

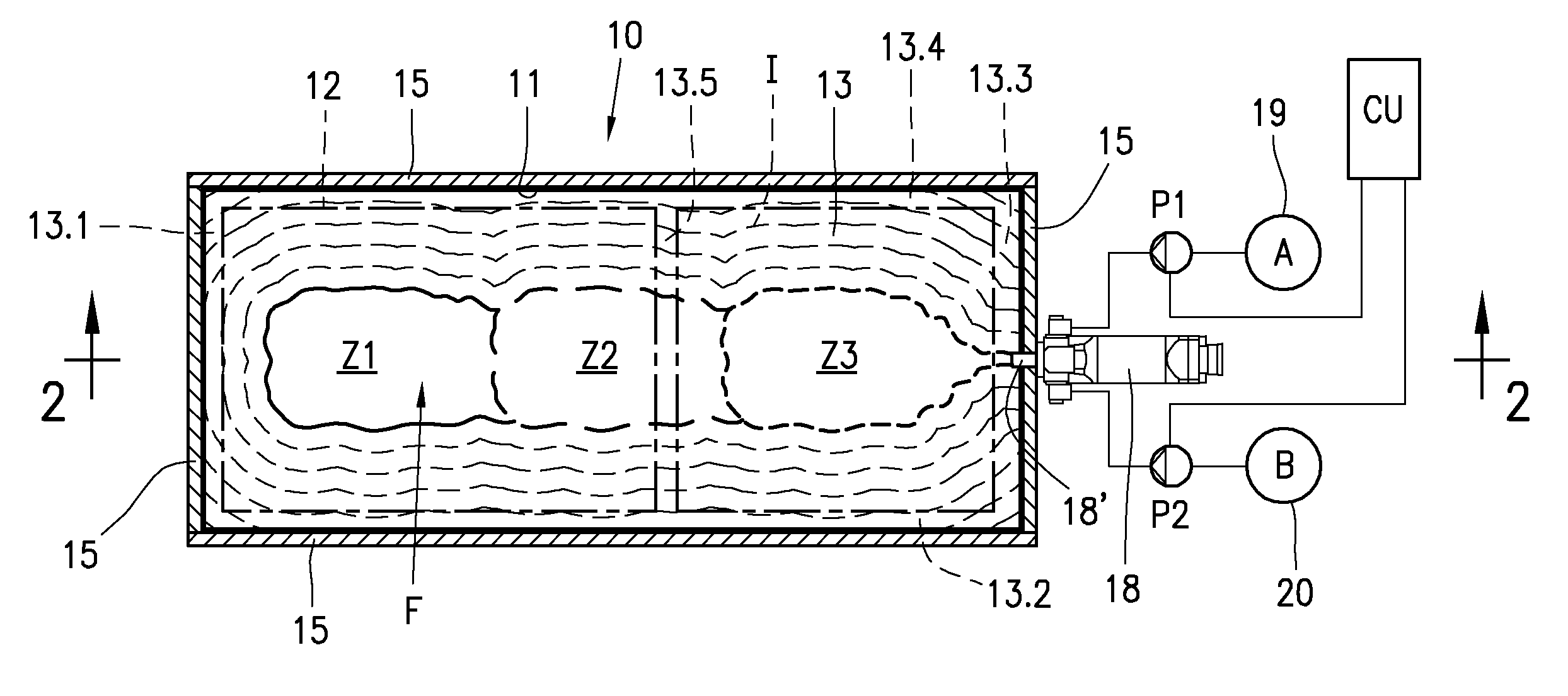

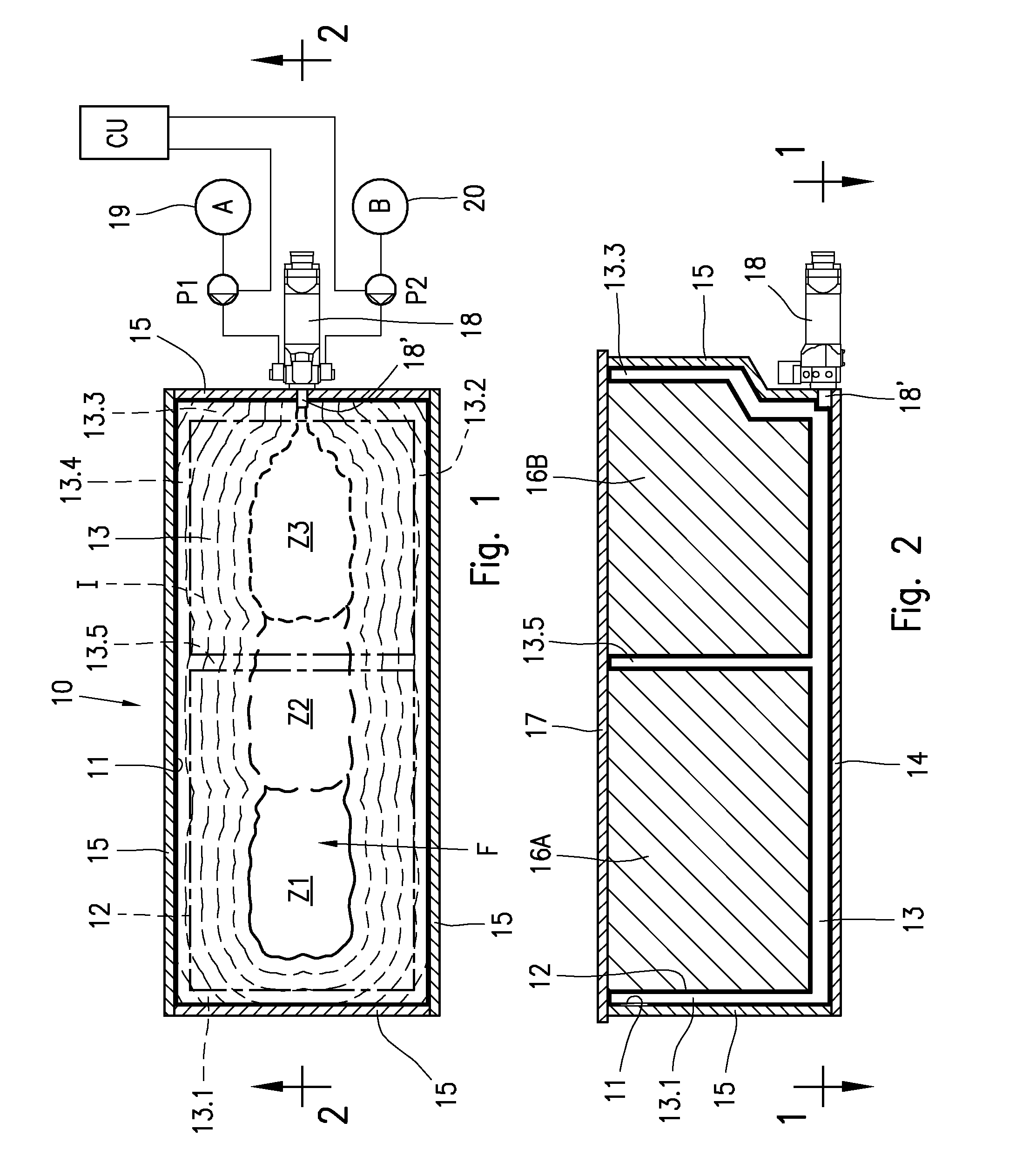

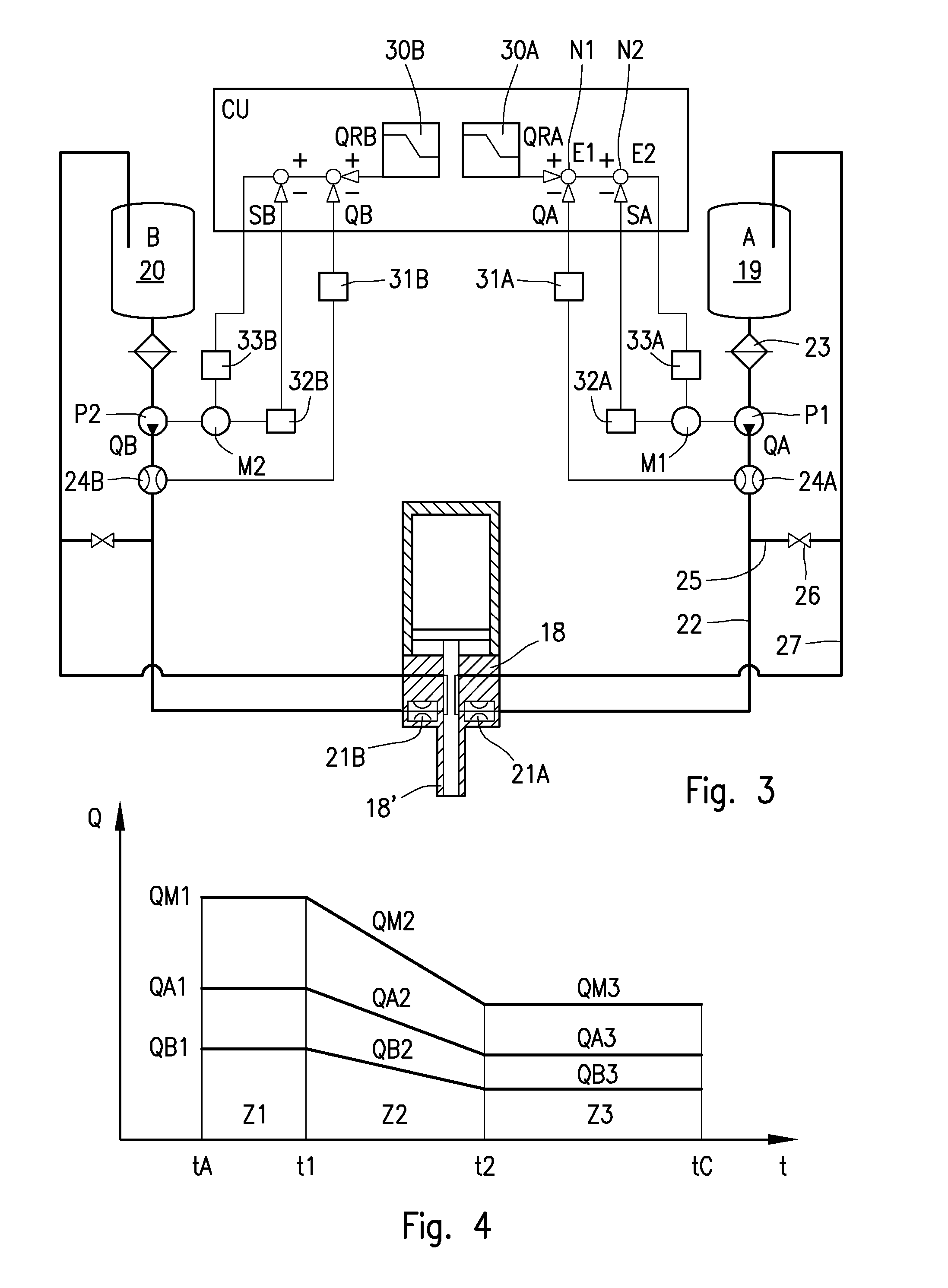

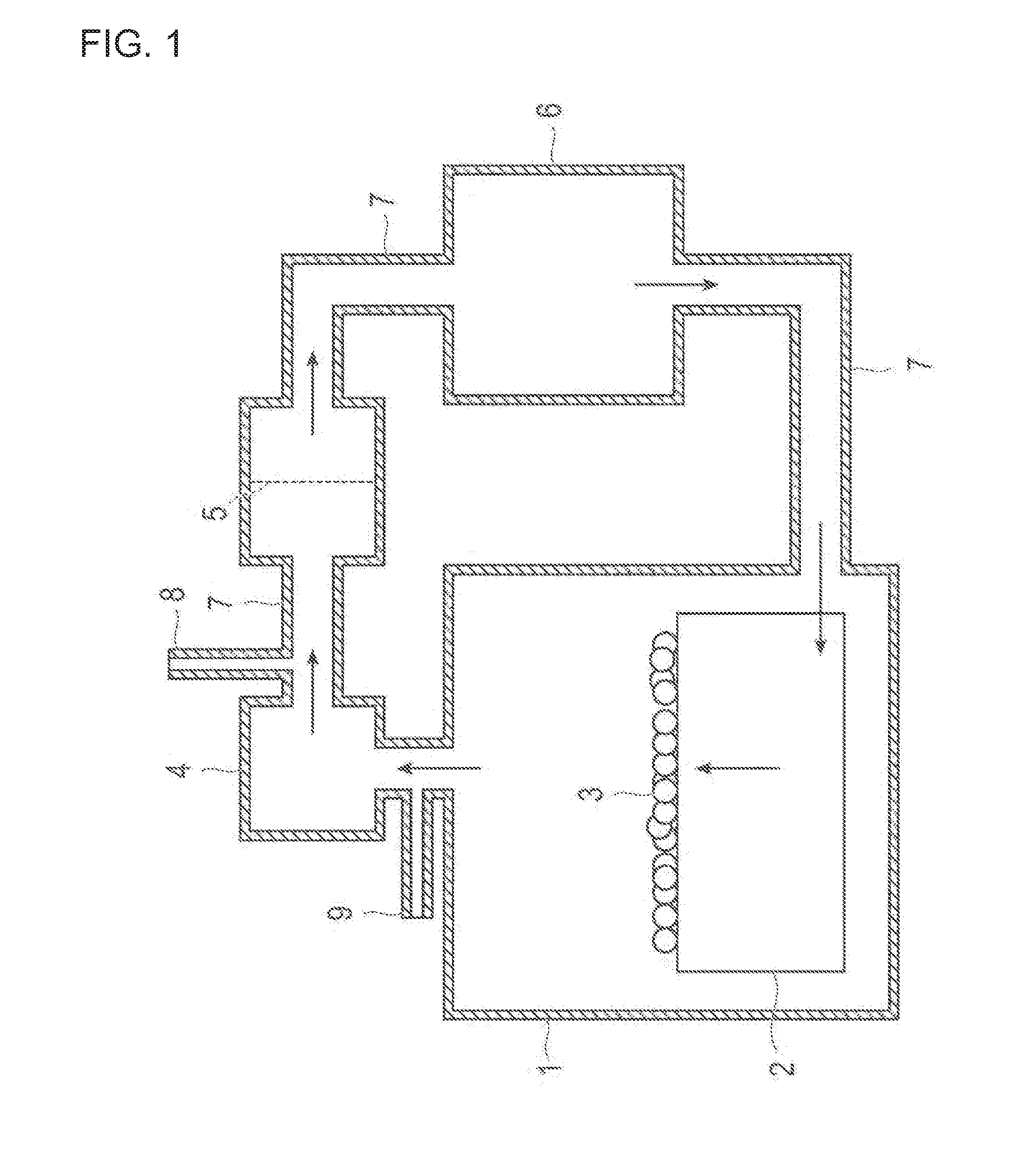

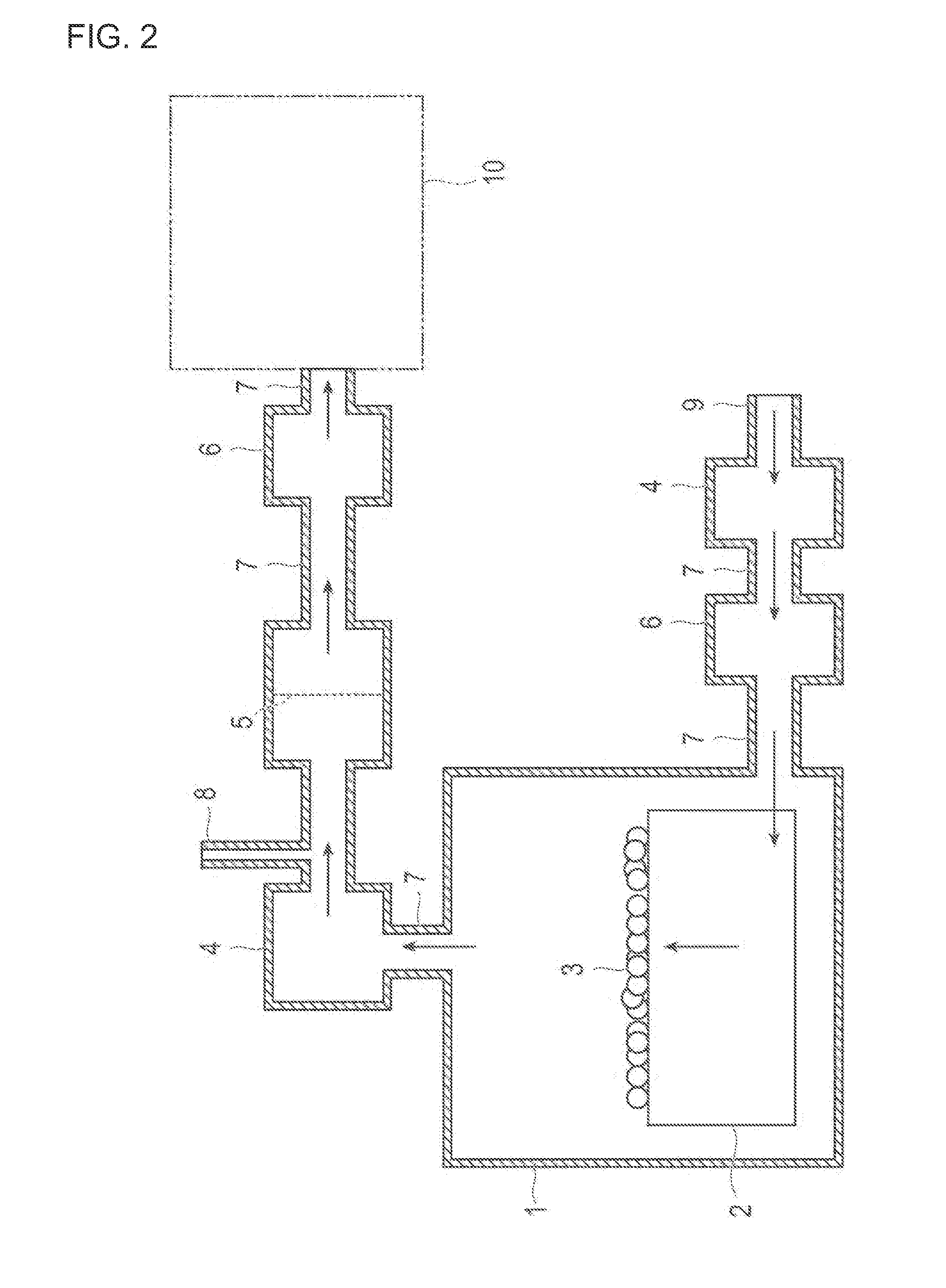

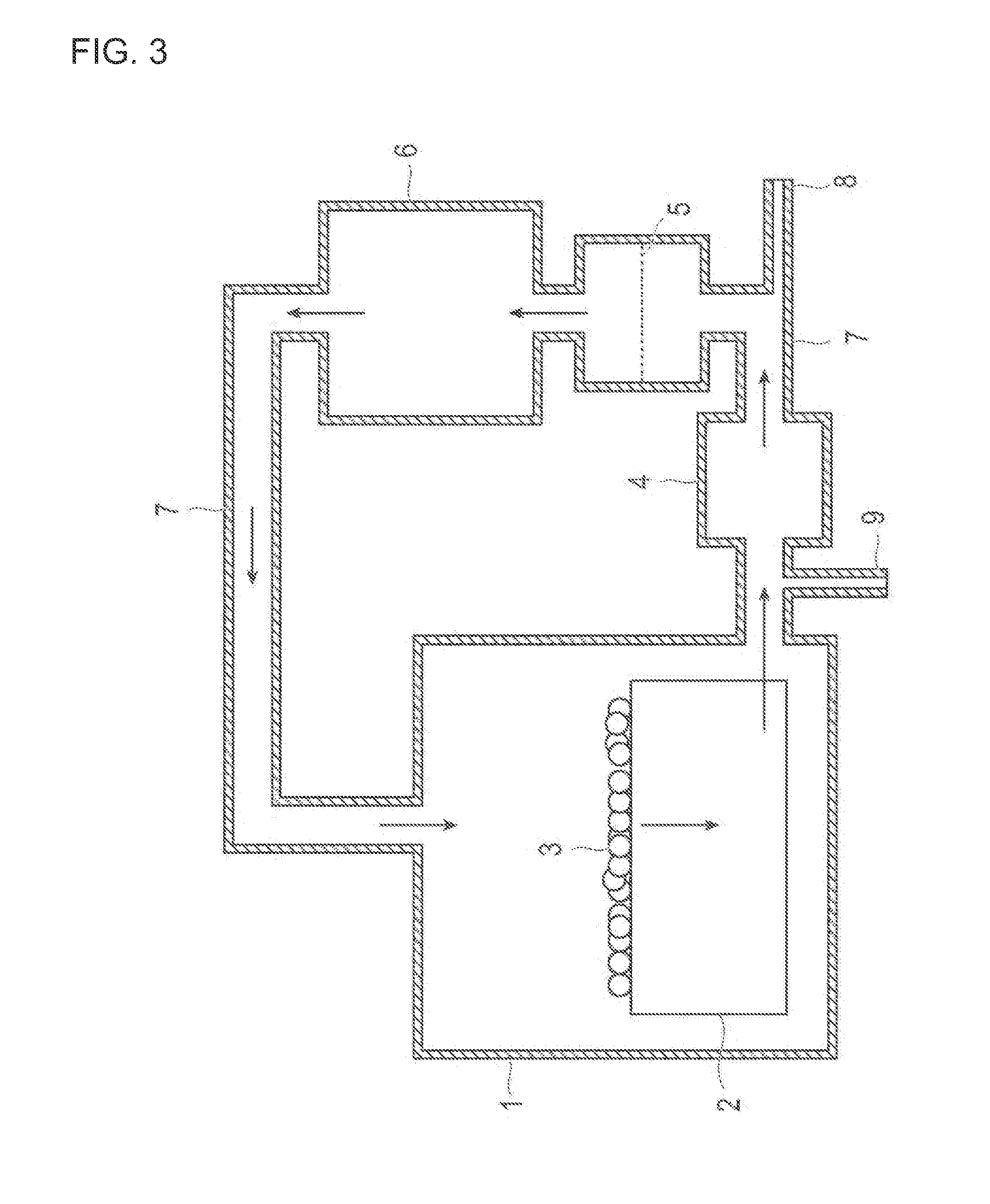

Method and apparatus for feeding a polyurethane mixture into hollow bodies

ActiveUS20110221085A1Short timeExpansion time can be acceleratedTailstocks/centresDomestic cooling apparatusChemical reactionControl manner

A method and apparatus for feeding a polyurethane mixture suitable to form a thermally insulating layer inside hollow bodies, such as hollow walls of a refrigerator cabinet, freezer, display counter or insulating panel. A polyurethane mixture resulting from chemically reactive components, supplied by a high-pressure mixing device, is injected into a cavity of a hollow body extending in a horizontal plain. The mixture is injected at a first flow-rate and a first injection speed, to be poured into a first deposition zone farthest from the injection point. Subsequently, the flow-rate and the injection speed of the polyurethane mixture are gradually reduced in a controlled manner, to be poured in successive deposition zones towards the injection point of the polyurethane mixture, along a distribution strip, allowing the injected mixture to spread out throughout the cavity of the hollow body along isometric expansion lines.

Owner:AFROS

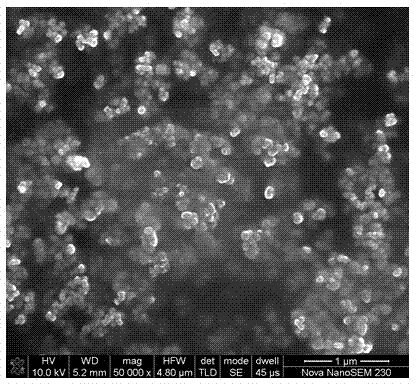

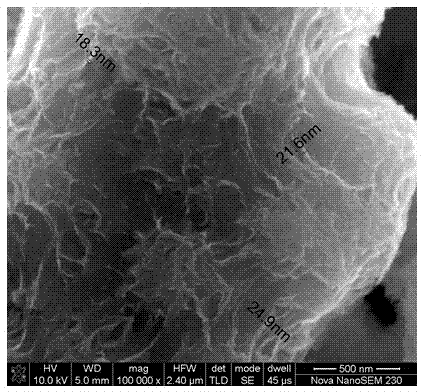

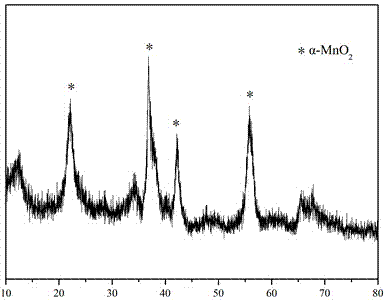

Preparation method and applications of nano-manganese oxide

ActiveCN104773760AUniform particlesReduce incorporationMaterial nanotechnologyManganese oxides/hydroxidesNanowireFluid phase

The invention provides a preparation method of nano-manganese oxide which is of a nanowire net structure. The preparation method comprises the following steps: dropwise adding an oxidant containing aqueous solution or feeding oxidizing gas into an active agent containing manganese salt aqueous solution, and uniformly dispersing; carrying out a liquid-phase co-precipitation reaction, so that nano-sized manganese dioxide is suspended in the solution; filtering the solution; and washing and drying the obtained precipitate subjected to filtering, so that the nano-manganese oxide is obtained. The nano-manganese oxide prepared by using the preparation method disclosed by the invention can be applied to the field of super capacitors and wastewater treatment. According to the invention, through elaborate design, the industrial process is maximally simplified, the quality of products is improved, and the production cycle is shortened, therefore, the method disclosed by the invention is a nano-manganese oxide preparation method which is simple in technological process, small in energy consumption, short in reaction period, good and stable in product quality and low in cost.

Owner:HUNAN RES INST FOR NONFERROUS METALS

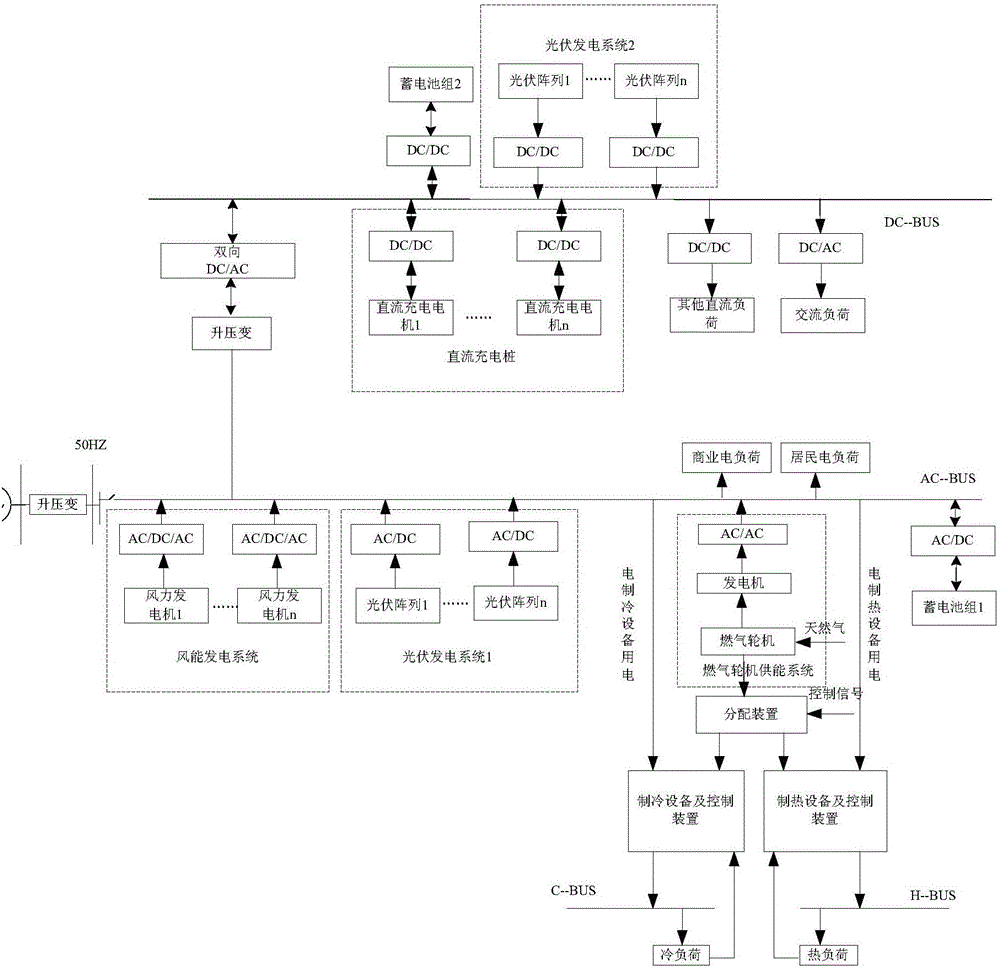

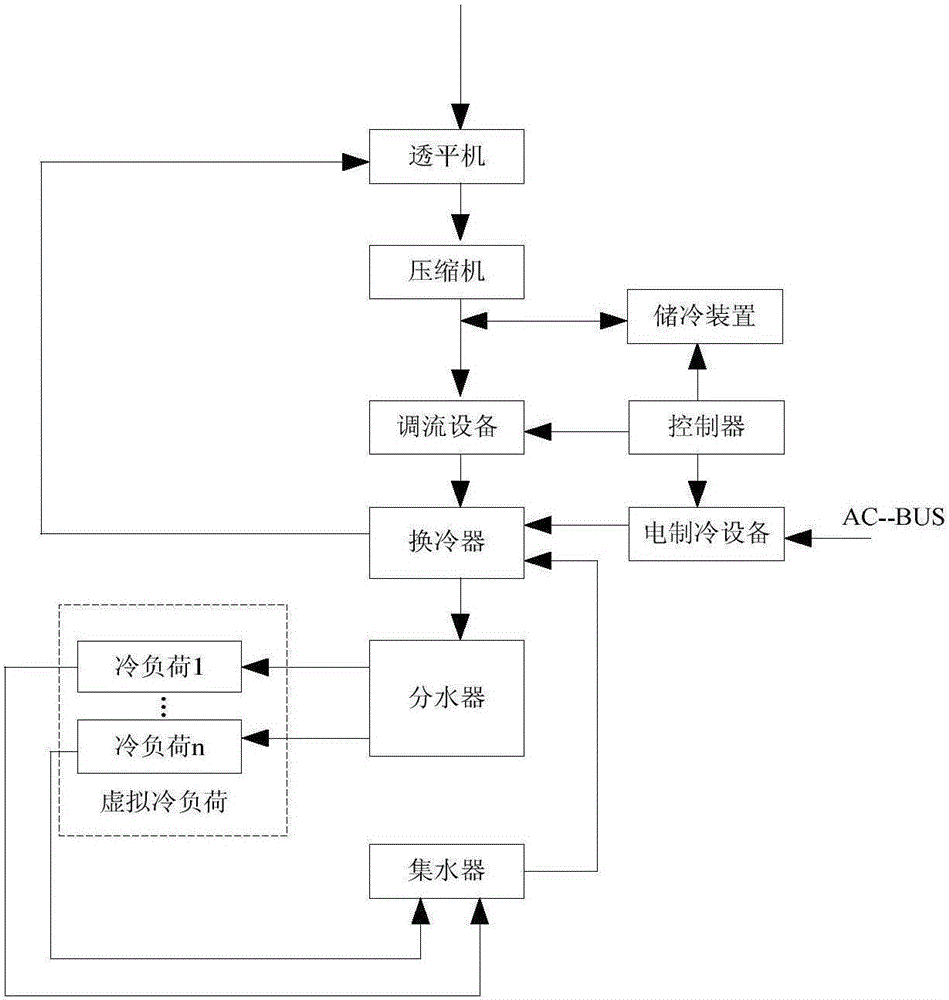

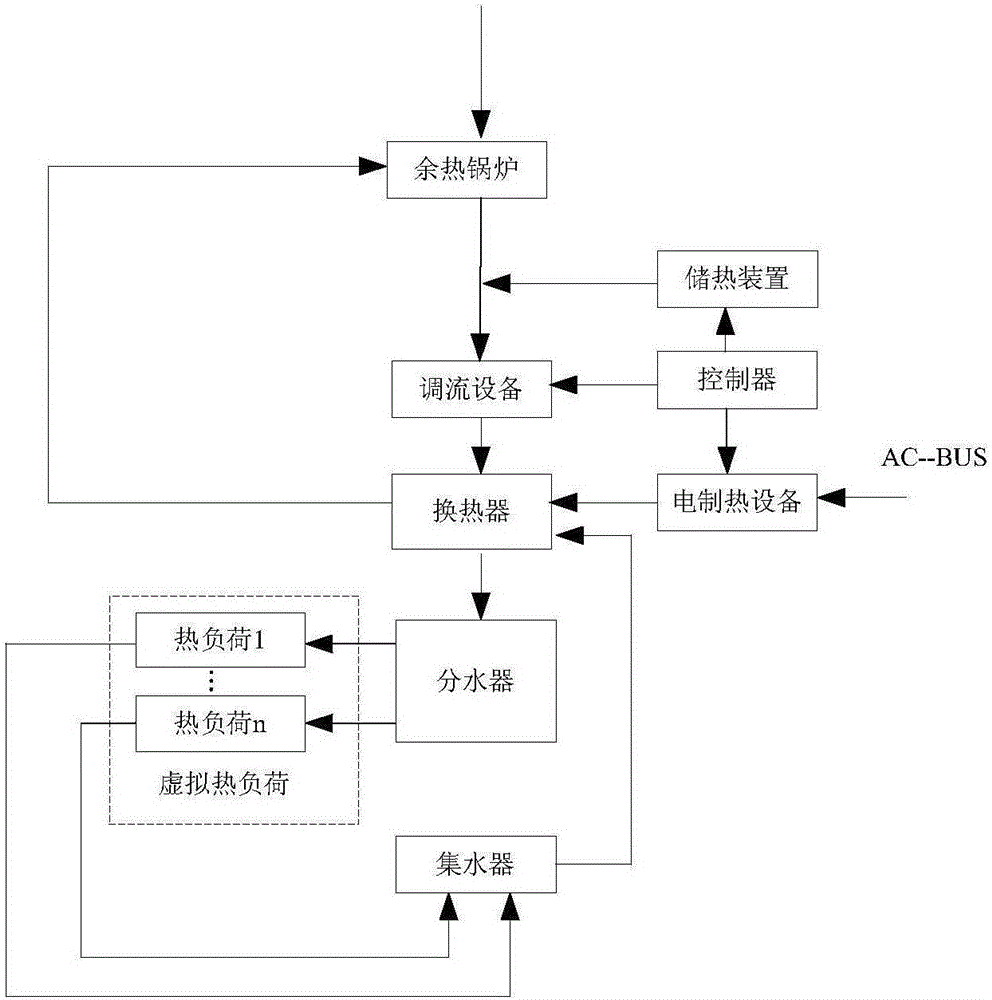

Pleuripotent interconnected AC/DC hybrid micro power grid system and optimal configuration method

The invention provides a pleuripotent interconnected AC / DC hybrid micro power grid system and optimal configuration method, and belongs to the field of micro power grid networking and optimal configuration. The capacity and the economy of the system are optimized; the isolated network operation is used as the majority, and the energy is sufficiently utilized by use of the pleuripotent interconnection method in triple generation of the cold, the hot and the electricity in the whole isolated network, the incorporation of multiple micro-source and the impact on the large power grid are reduced, and the energy can be utilized more reasonable; for solving the AC / DC switching problem, the AC / DC hybrid microgrid which is capable of satisfying the DC load and the AC load at the same time is constructed, and the system electric energy loss caused by repeated conversion is reduced; the pleuripotent interconnected AC / DC hybrid micro power grid is optimally configured, so that the whole system running is more reasonable, and the annual income of the micro power grid can achieve the maximum value.

Owner:SHENYANG POLYTECHNIC UNIV +2

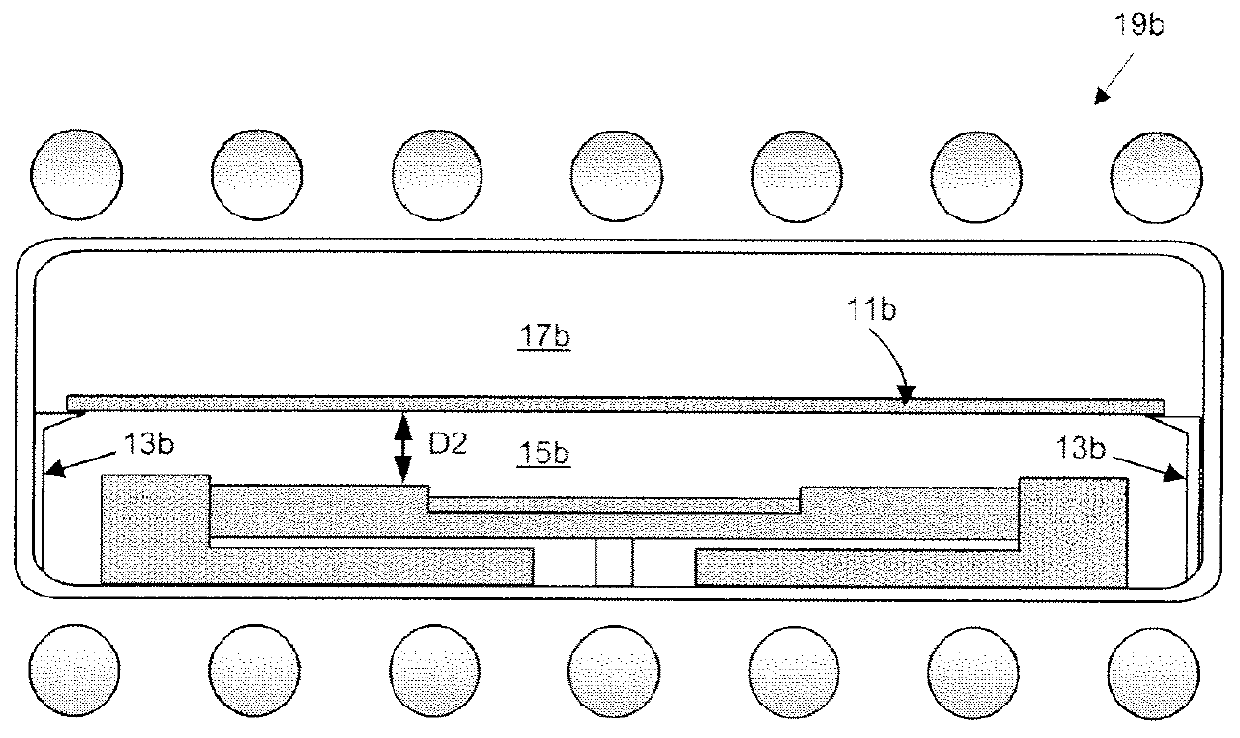

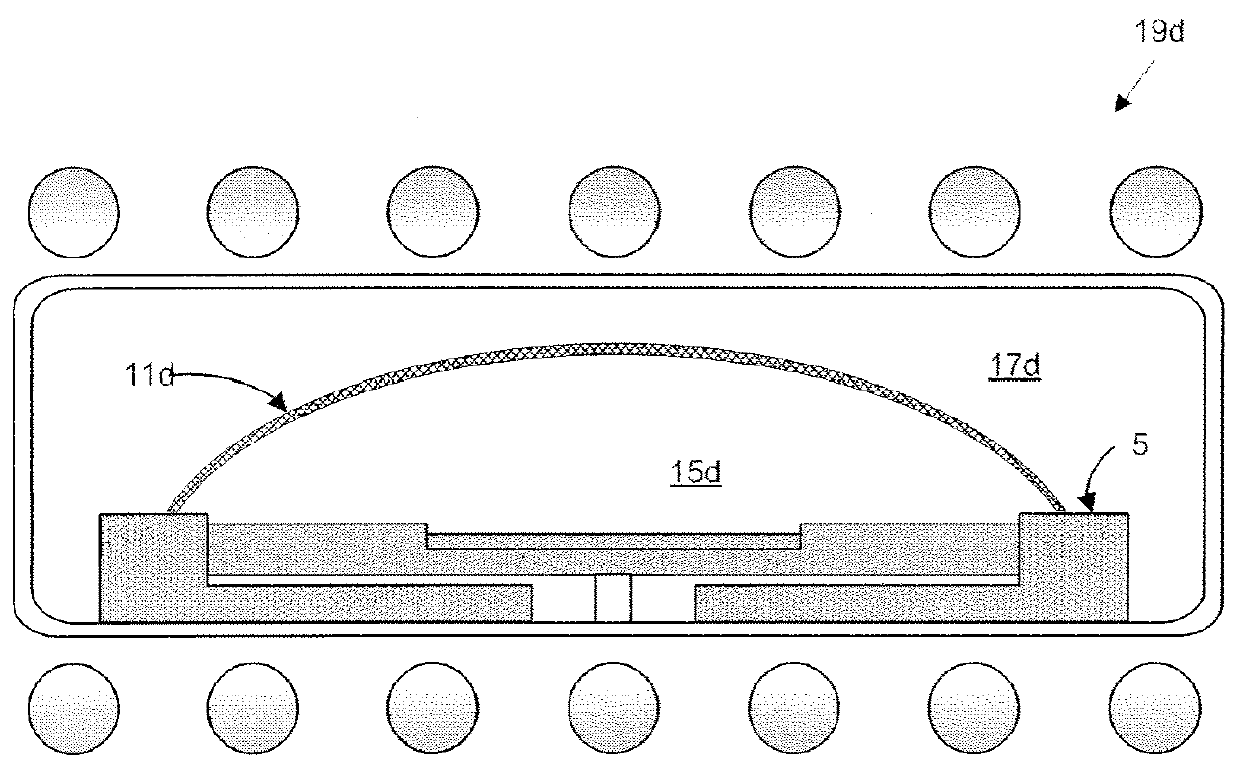

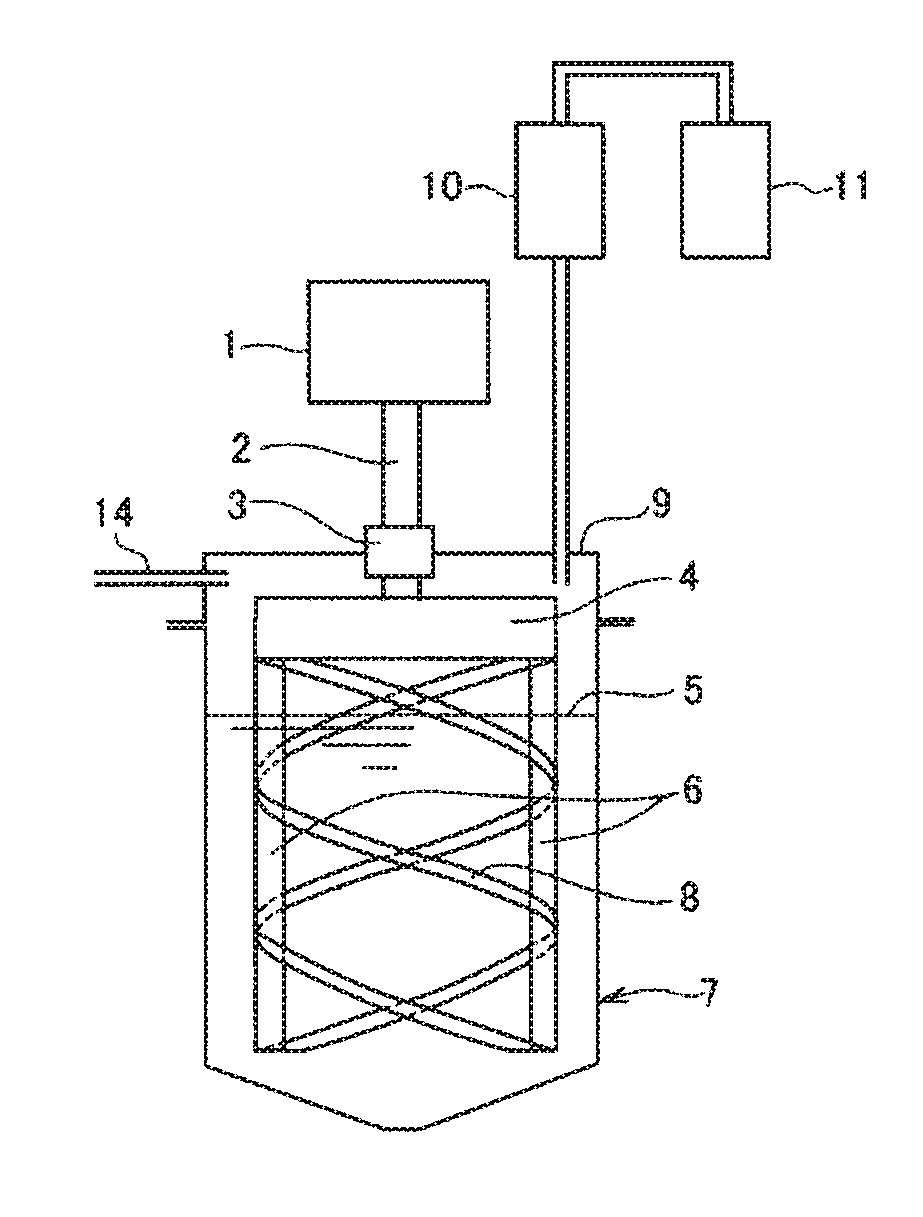

Thermalization of gaseous precursors in CVD reactors

InactiveUS8388755B2Improve efficiencyQuick upgradeSemiconductor/solid-state device manufacturingFrom chemically reactive gasesSemiconductor materialsEngineering

The present invention relates to the field of semiconductor processing and provides apparatus and methods that improve chemical vapor deposition (CVD) of semiconductor materials by promoting more efficient thermalization of precursor gases prior to their reaction. In preferred embodiments, the invention comprises heat transfer structures and their arrangement within a CVD reactor so as to promote heat transfer to flowing process gases. In certain preferred embodiments applicable to CVD reactors transparent to radiation from heat lamps, the invention comprises radiation-absorbent surfaces placed to intercept radiation from the heat lamps and to transfer it to flowing process gases.

Owner:SOITEC SA

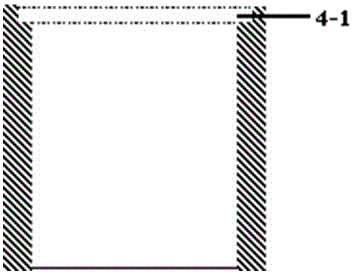

Aluminium nitride single crystal growth device dispensing with seed crystal bonding technology and method

ActiveCN107829134AGrowth impactIncrease the usable areaPolycrystalline material growthFrom condensed vaporsManufacturing technologyCrucible

The invention discloses an aluminium nitride single crystal growth device dispensing with a seed crystal bonding technology and a process and relates to the semiconductor manufacture technology. The aluminium nitride single crystal growth device comprises a heating system, an infrared temperature measurement system, seed crystals, a growth crucible, a crucible partition and a double-layered nestedcrucible, wherein the heating system is arranged on the outermost side; a temperature difference exists between the bottom and the top of the crucible; the crucible is arranged in a heat insulation material; the seed crystals are placed at the bottom of the crucible; the double-layered nested crucible is vertically placed on the upper side of the crucible partition and comprises an inner-layer crucible and an outer-layer crucible; the heights of the walls of the inner-layer crucible and the outer-layer crucible are kept the same; and a gap between the side walls of the inner-layer crucible and the outer-layer crucible is filled with high-purity aluminium nitride powder. Doping of aluminium nitride single-crystal impurity elements can be reduced, the crystal quality is improved, the single-crystal usable area is increased, the aluminium nitride single crystal growth device is simple and easy to use, facilitates low-cost preparation of aluminium nitride single crystals, and can preventgrowth of the aluminium nitride single crystals from being influenced by the seed crystal bonding technology.

Owner:PEKING UNIV

Solid-state imaging device and imaging system

A solid-state imaging device includes: a first semiconductor substrate including a photoelectric conversion element; and a second semiconductor substrate including at least a part of a peripheral circuit arranged in a main face of the second semiconductor substrate, the peripheral circuit generating a signal based on the charge of the photoelectric conversion element, a main face of the first semiconductor substrate and the main face of the second semiconductor substrate being opposed to each other with sandwiching a wiring structure therebetween; a pad to be connected to an external terminal; and a protection circuit electrically connected to the pad and to the peripheral circuit, wherein the protection circuit is arranged in the main face of the second semiconductor substrate.

Owner:CANON KK

Ultrasonic composite acidic water extraction method for cordyceps polysaccharide and cordycepin in cordyceps militaris

ActiveCN109810201AReduce incorporationIncreased structural damageSugar derivativesSolvent extractionFood additiveFreeze-drying

The invention provides an ultrasonic composite acidic water extraction method for cordyceps polysaccharide and cordycepin in cordyceps militaris, and belongs to the technical field of food processing.The ultrasonic composite acidic water extraction method comprises the steps that cordyceps militaris fruit bodies are picked, washed, dried, pulverized and degreased to obtain dry powder of the cordyceps militaris, then the dry powder of the cordyceps militaris is immersed in a prepared dilute hydrochloric acid solution, ultra-low temperature freezing and microwave defrosting are repeated for 3 times and low-frequency ultrasonic waves are used for assisted stirring and extraction at the same time, an extracting solution is subjected to evaporation concentration treatment, and finally, dry powder of a water extraction product is collected by freeze drying of the extracting solution. The dosage of an additive used in the ultrasonic composite acidic water extraction method meets the use requirements of food additives at home and abroad, the operation is simple and easy to perform, the combination of chemical and physical methods is adopted, and time saving and efficiency are achieved.

Owner:JIANGNAN UNIV

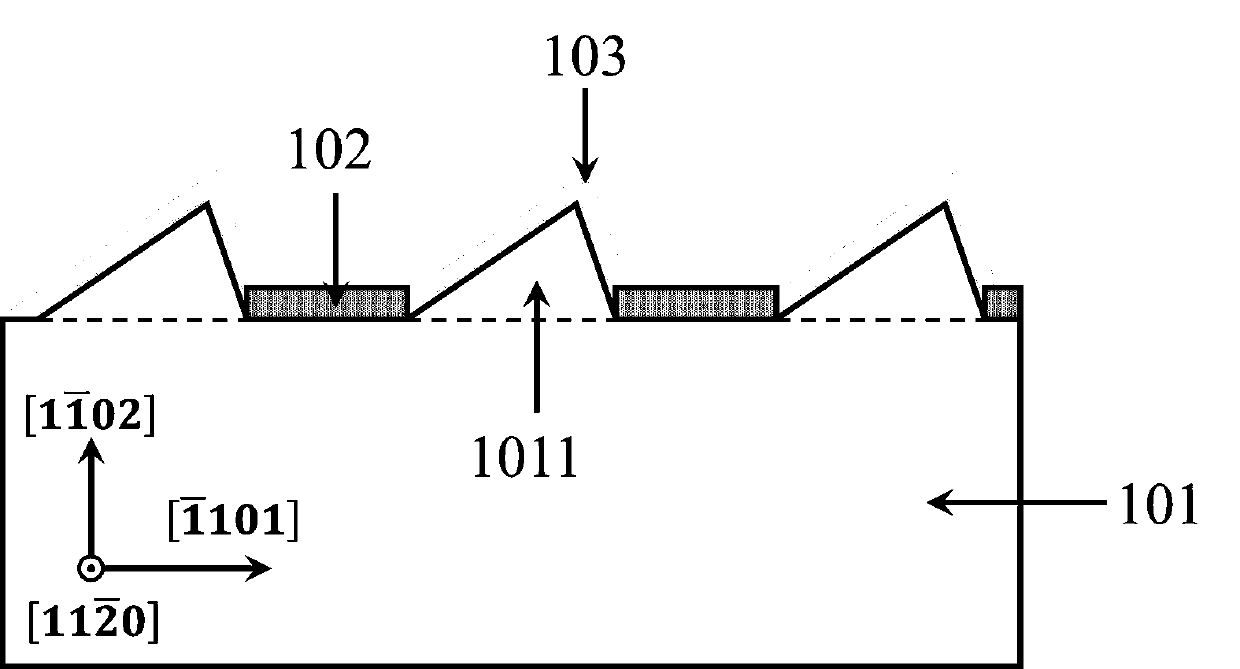

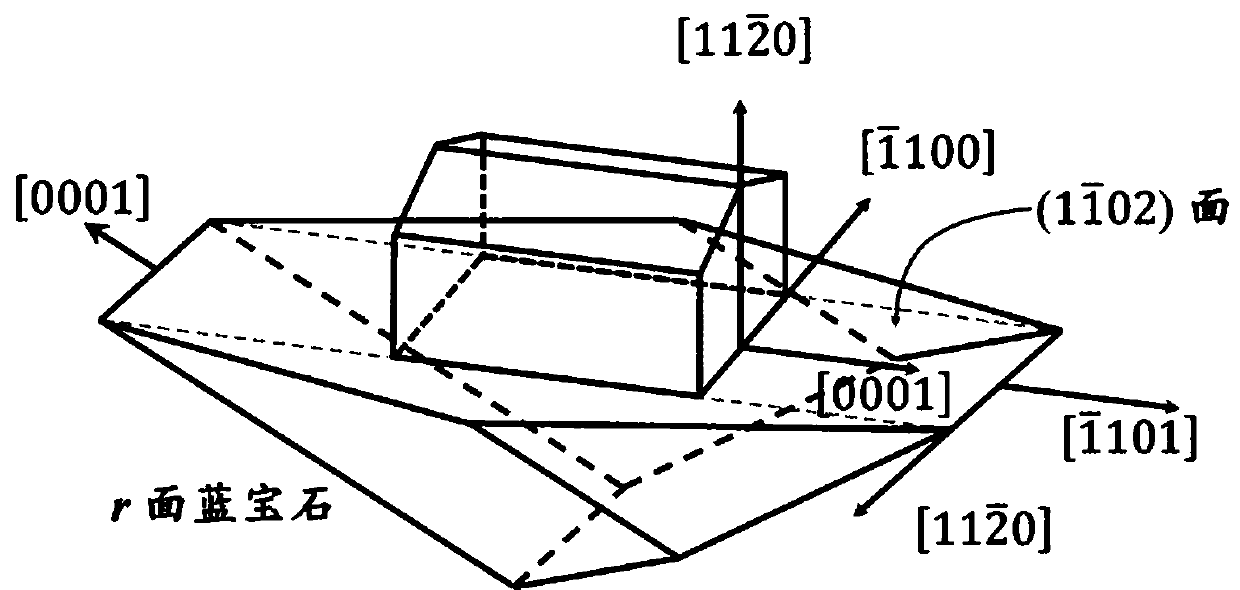

Non-polar patterned AlN/sapphire composite substrate and manufacturing method thereof

ActiveCN109545933AImprove crystal qualityReduce incorporationSemiconductor/solid-state device manufacturingSemiconductor devicesComposite substrateCrystal orientation

The invention discloses a non-polar patterned AlN / sapphire composite substrate and a manufacturing method thereof. The structure thereof comprises a r-plane patterned sapphire substrate, a sapphire pattern, a mask layer and an AlN covering layer. The sapphire pattern is a part of the r-plane patterned sapphire substrate, and is an asymmetric conical or pyramidal structure, that is, inclines towarda [1101] crystal orientation. The structure can effectively solve a problem that crystal quality is difficult to improve since growth rates along different directions are different during epitaxial growth of non-polar III-nitride. The AlN covering layer is formed by direct reaction with NH3 while the sapphire substrate is decomposed under high temperature in an NH3 atmosphere. The composite substrate provided by the invention can effectively reduce combination of O-containing impurities in an epitaxial growth process of the III-nitride, and can also obtain a dense high-quality non-polarity AlN covering layer on the surface of the sapphire substrate on the premise of not consuming an Al source, and has important significance on growing the high-quality non-polar III-nitrides and related devices on the substrate.

Owner:SOUTHEAST UNIV

Method for preparing powdery electrolytic manganese dioxide (EMD)

ActiveCN102242373ALow raw material requirementLow costElectrolysis componentsUltrasound - actionActive agent

The invention discloses a method for preparing powdery electrolytic manganese dioxide (EMD). In the method, the powdery EMD is directly obtained from solution by improving the electrolytic process and controlling the electrolytic condition; and during electrolysis, a diaphragm electrolytic cell is adopted, a lead silver alloy plate or a titanium manganese alloy plate subjected to acid treatment is taken as an anode, and a graphite plate or a stainless steel plate is taken as a cathode. The method comprises the following steps of: preparing electrolyte with 0.1 to 10.0mol / L sulfuric acid and 0.4 to 1.2mol / L manganese sulfate, adding an active agent into the electrolyte, electrolyzing at the temperature of between 20 and 100 DEG C under the action of ultrasonic waves, and filtering to obtain the powdery EMD; and washing the powdery EMD for multiple times, adding a dispersing agent into solution when the powdery EMD is washed for the last time, and drying to obtain the powdery EMD. The method has the characteristics that: the process flow is simple, energy consumption and cost are low, product particles are uniform and have good appearance, and the like.

Owner:CENT SOUTH UNIV

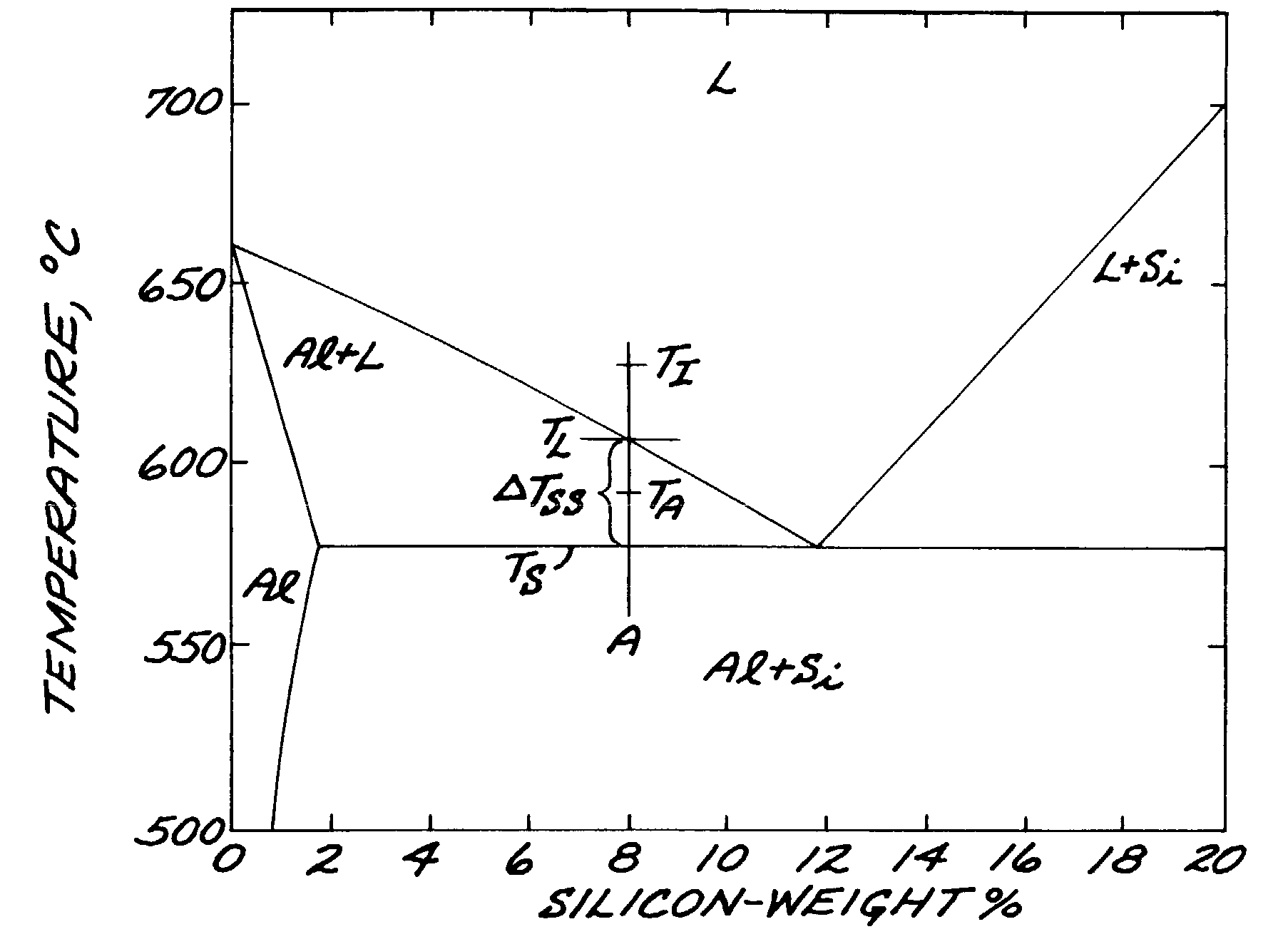

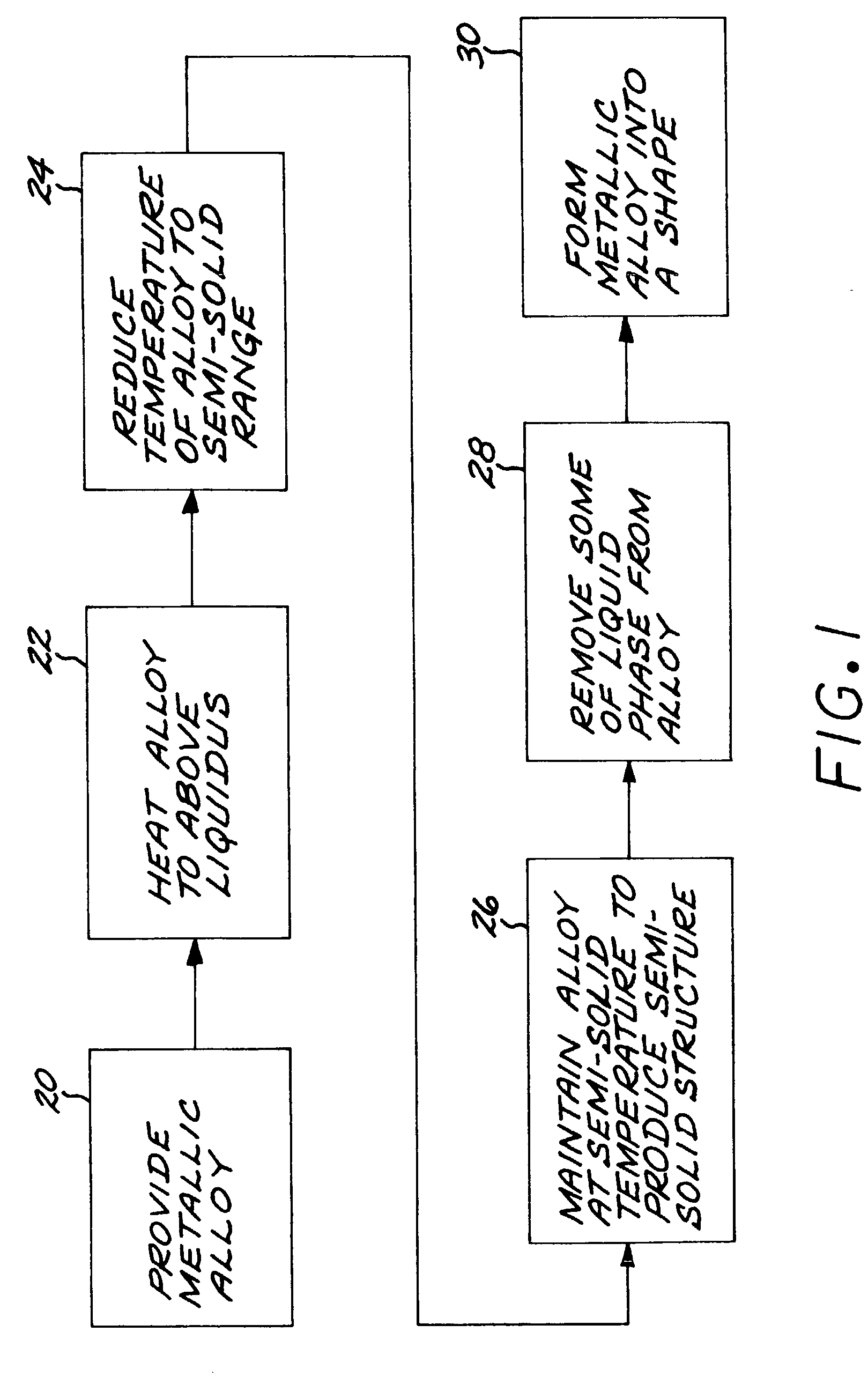

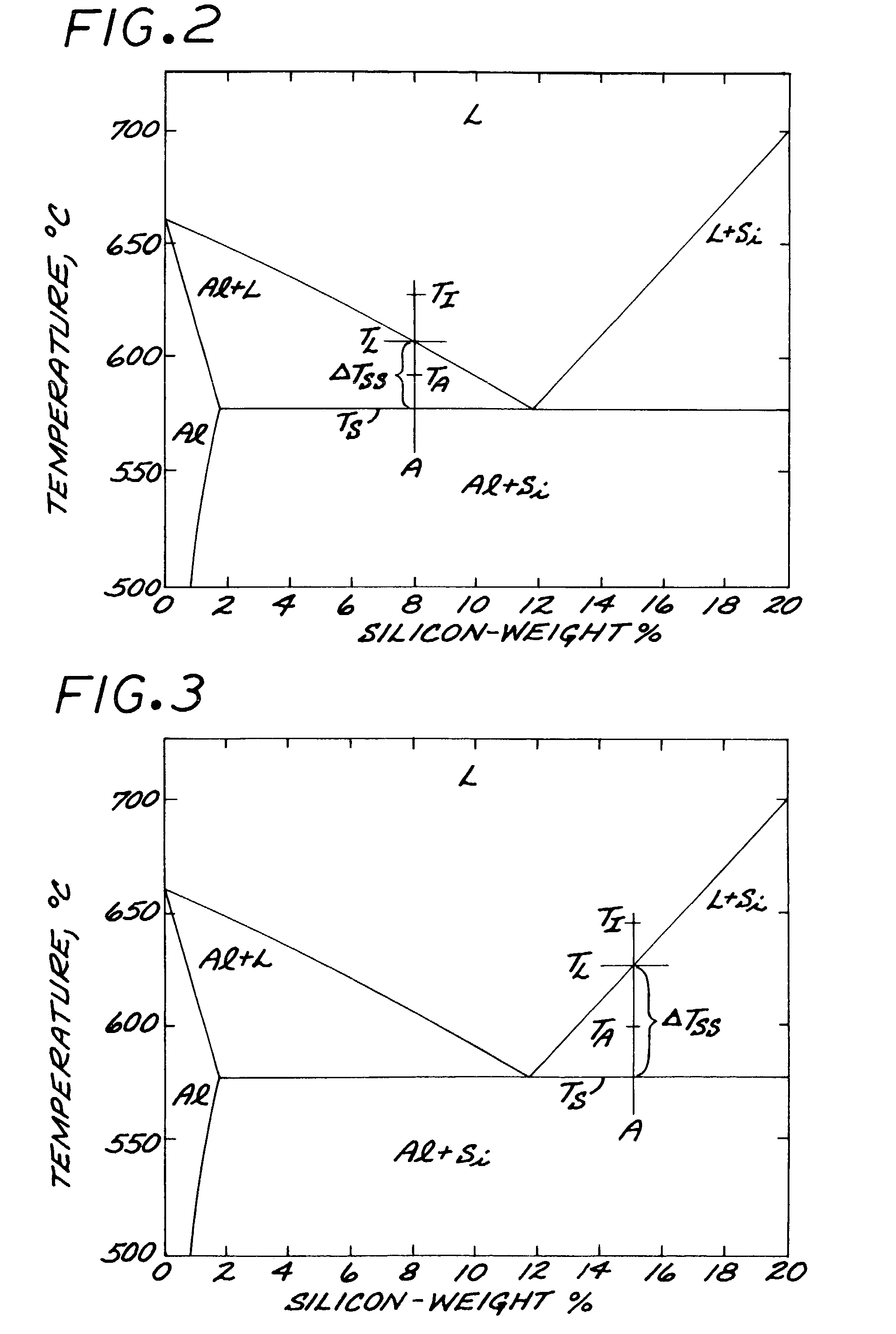

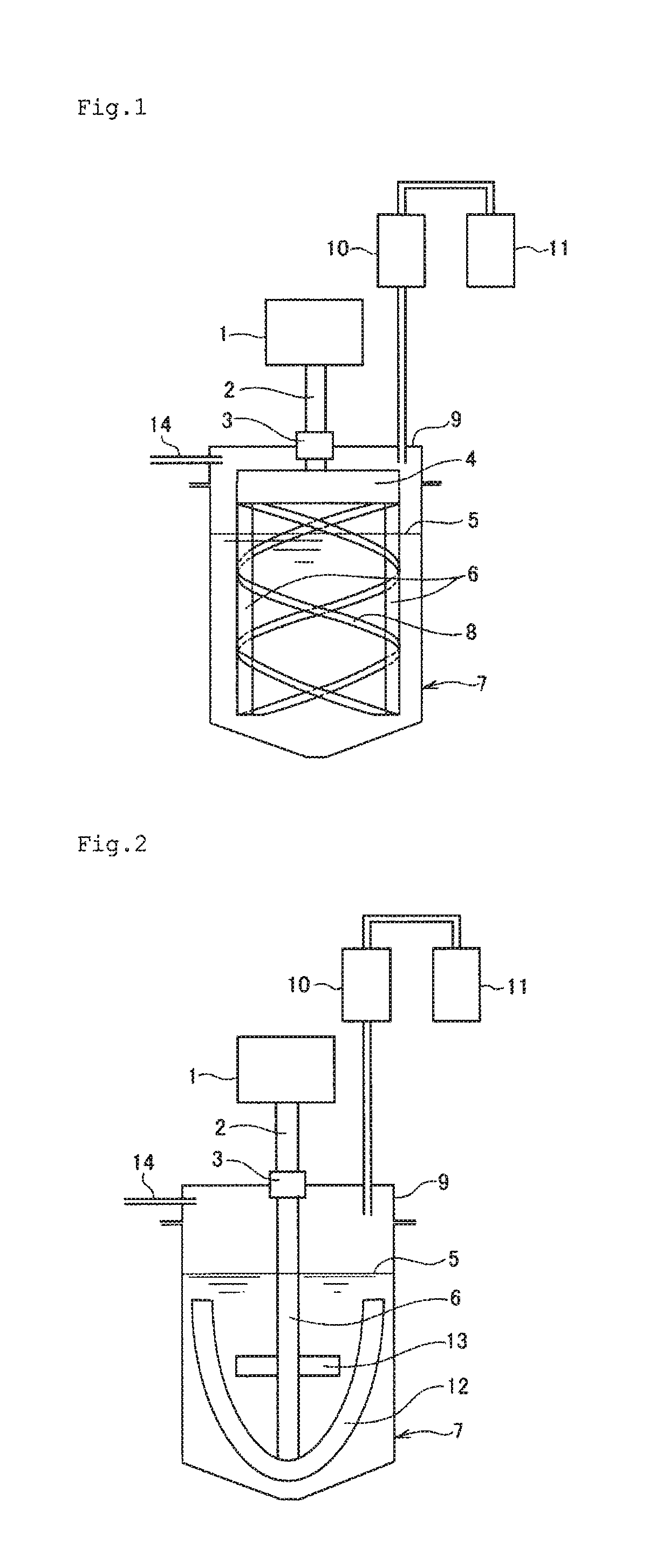

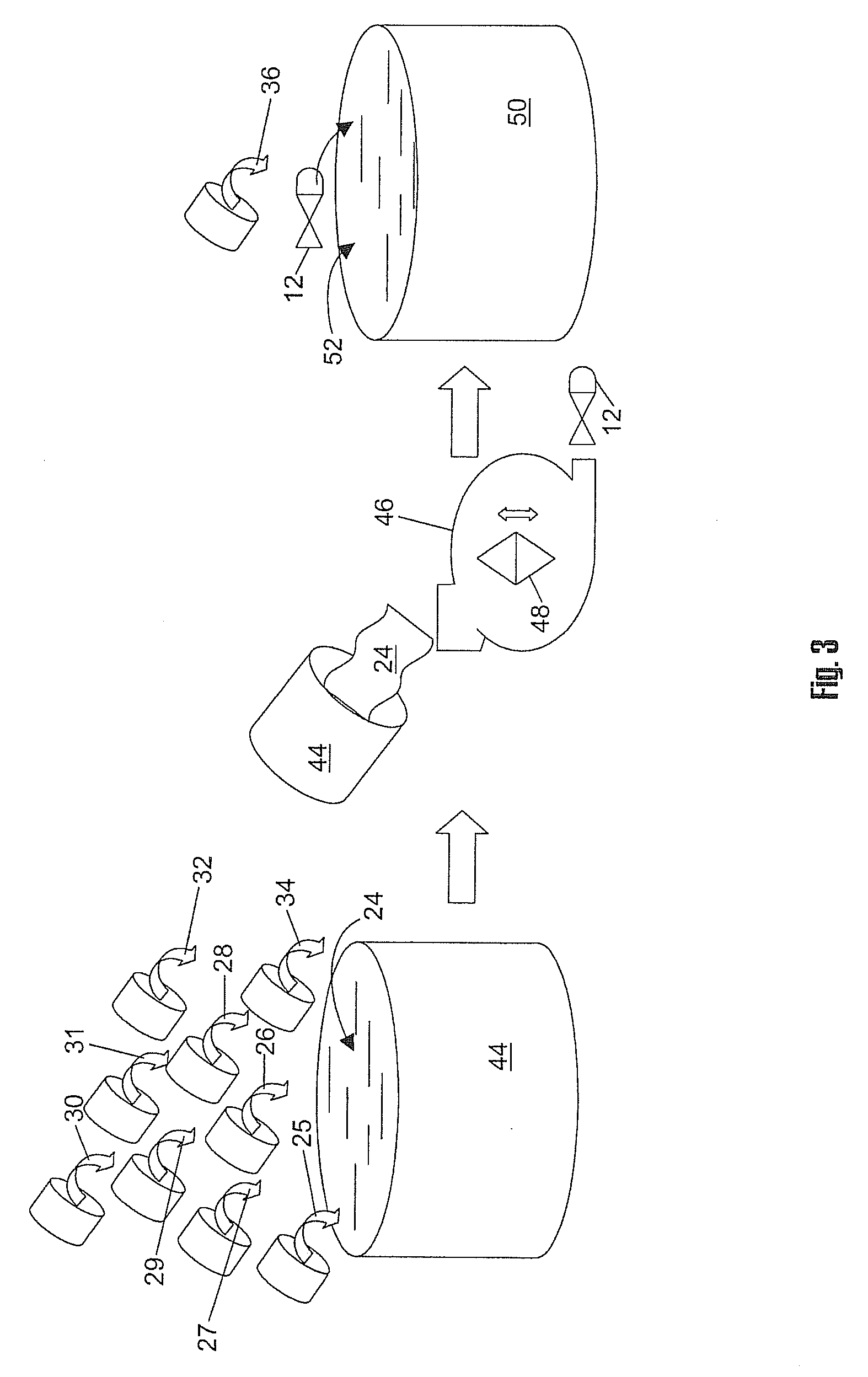

Semi-solid concentration processing of metallic alloys

InactiveUS7140419B2Quality improvementReduce incorporationSubstation equipmentMetal foundingSufficient timeCrucible

A metallic alloy having a semi-solid range between the liquidus temperature and the solidus temperature of the metallic alloy is processed by cooling the metallic alloy from an initial metallic alloy elevated temperature to a semi-solid temperature of less than the liquidus temperature and more than the solidus temperature, and maintaining the metallic alloy at the semi-solid temperature for a sufficient time to produce a semi-solid structure in the metallic alloy of a globular solid phase dispersed in a liquid phase. The cooling may be accomplished by providing a crucible at a crucible initial temperature below the solidus temperature, pouring the metallic alloy into the crucible, and allowing the metallic alloy and the crucible to reach a thermal equilibrium between the liquidus temperature and the solidus temperature of the metallic alloy. The method further includes removing at least some, but not all, of the liquid phase present in the semi-solid structure of the metallic alloy to form a solid-enriched semi-solid structure of the metallic alloy, and forming the metallic alloy having the solid-enriched semi-solid structure into a shape.

Owner:ALCAN INT LTD

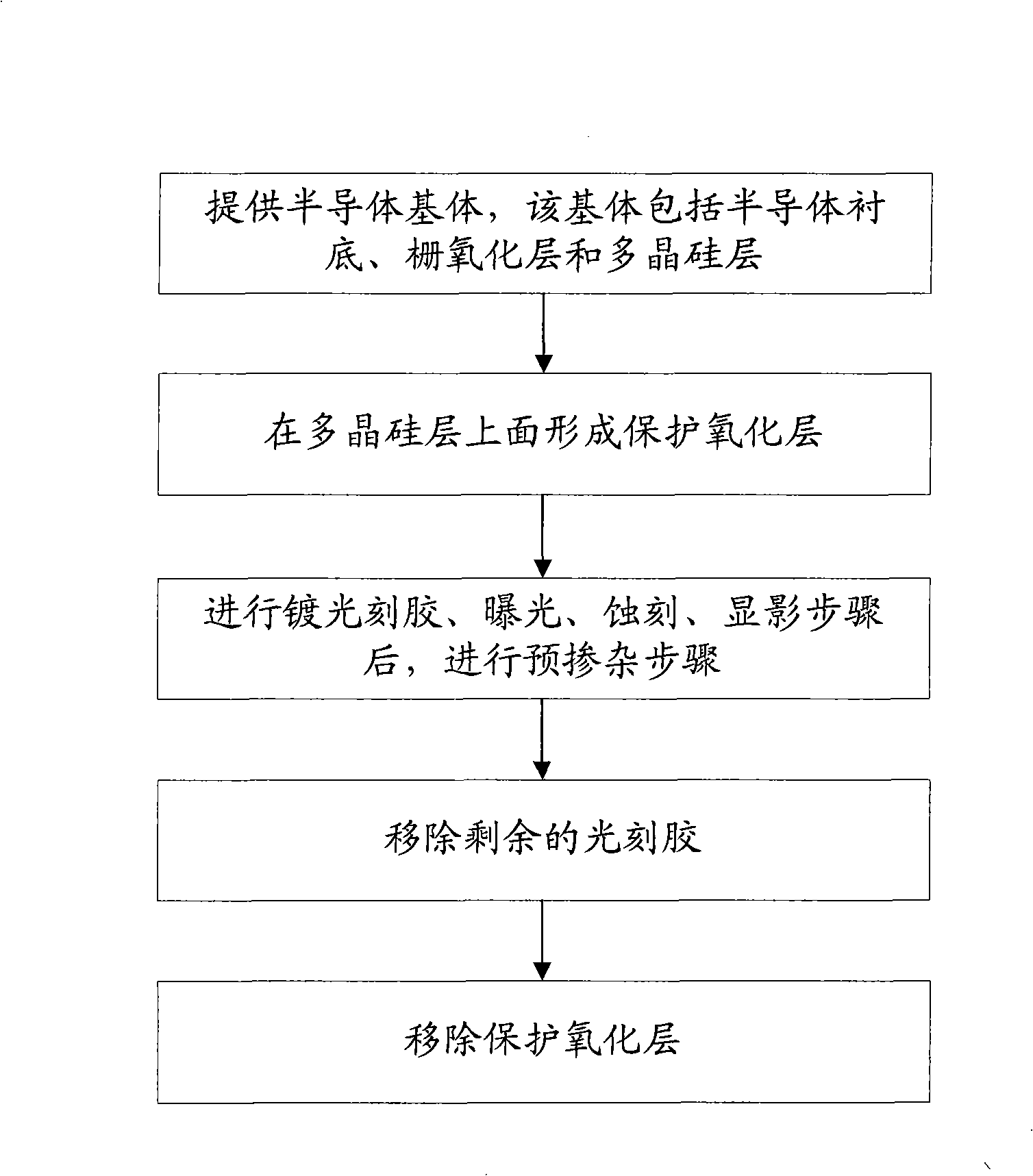

Ion injection method of semiconductor device

InactiveCN101308786AReduce performanceImprove yieldSemiconductor/solid-state device manufacturingState of artManufacturing technology

The invention discloses an ion injection method, relating to semiconductor manufacturing technical field. The ion injection method includes the following steps: a semiconductor basal body is provided, comprising a semiconductor substrate, a gate oxide layer deposited at the semiconductor substrate and a polycrystalline silicon layer arranged on the gate oxide layer; a protecting oxide layer is built on the polycrystalline silicon layer; the protecting oxide layer is plated with light-sensitive lacquer and then is exposed in light, etched and developed; pre-doping process is started and the injected ions penetrate the protecting oxide layer and reach the polycrystalline silicon layer; the light-sensitive lacquer is removed and then the protecting oxide layer is removed. Compared with prior art, the ion injection method of the invention avoids or at least reduces the injected ions that penetrate into the semiconductor substrate by adding a protecting oxide layer on the polycrystalline silicon layer, thus reducing the attenuation of the performance of the semiconductor.

Owner:SEMICON MFG INT (SHANGHAI) CORP

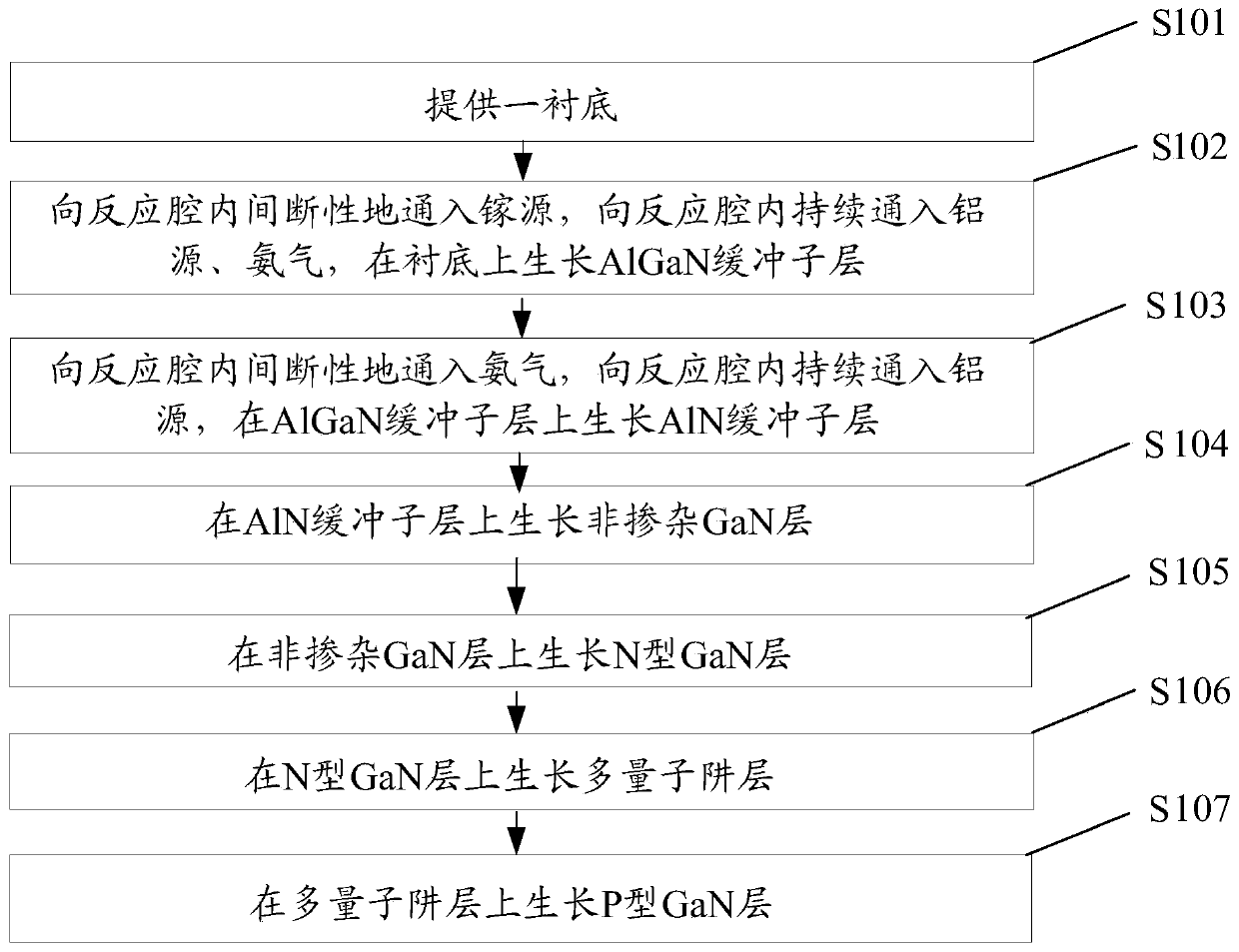

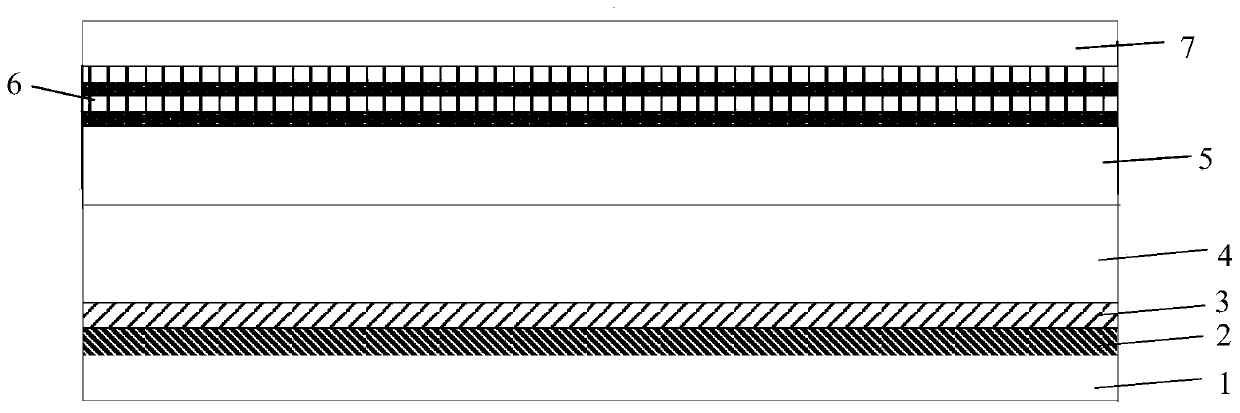

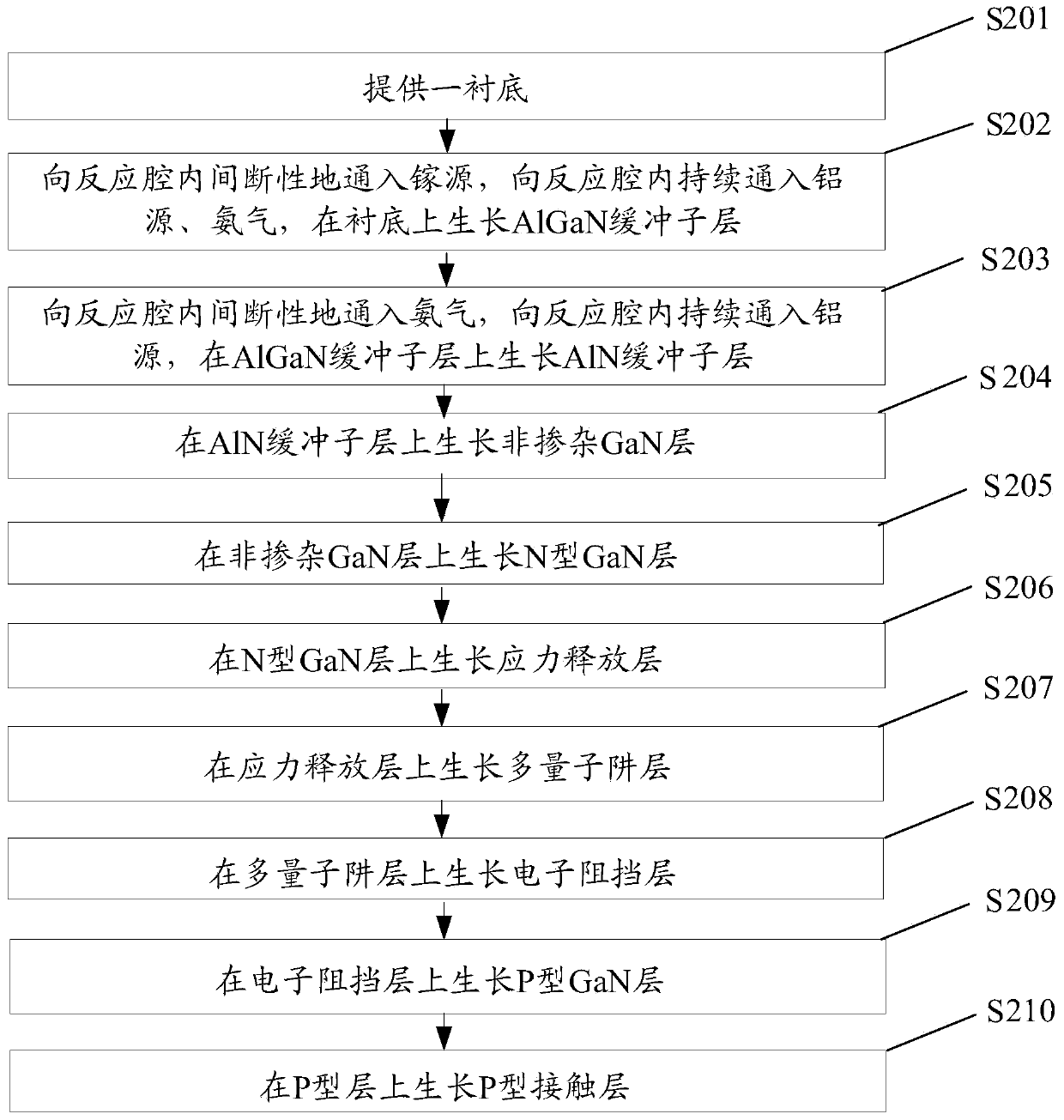

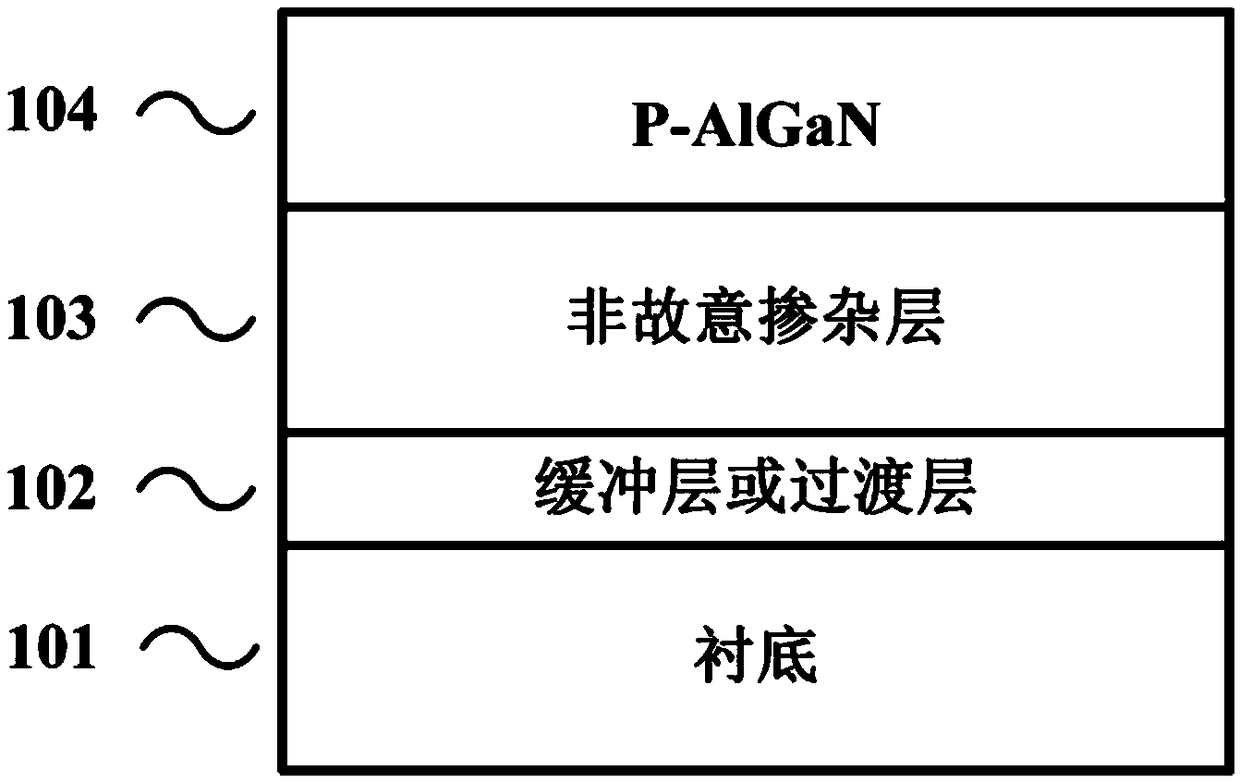

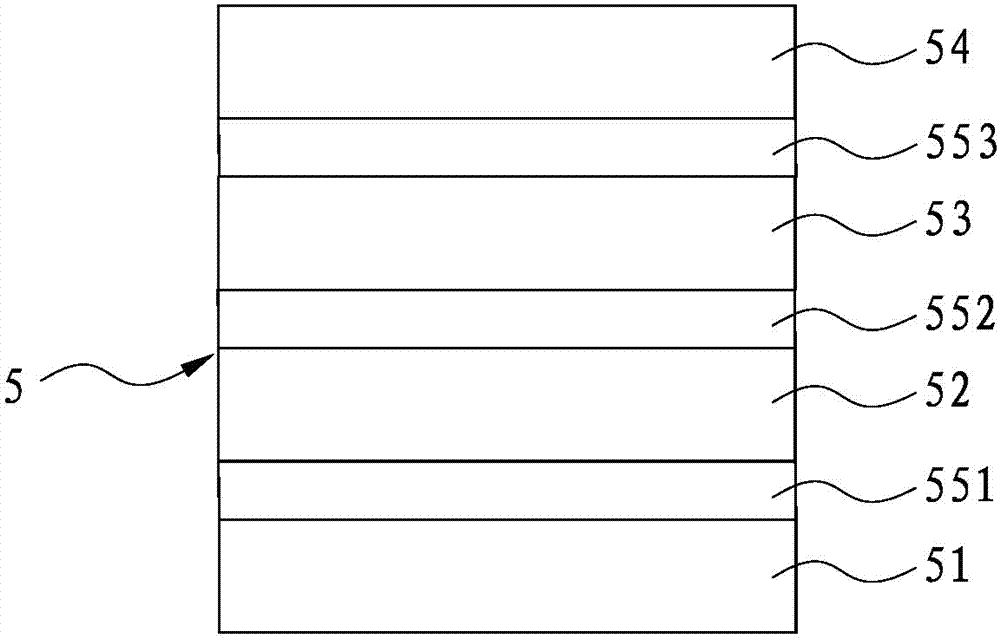

Method for preparing epitaxial wafer of light-emitting diode and epitaxial wafer

ActiveCN110148652AFacilitated DiffusionPromote migrationSemiconductor devicesGas phaseLight-emitting diode

The invention discloses a method for preparing an epitaxial wafer of a light-emitting diode and the epitaxial wafer and belongs to the field of light-emitting diode fabrication. A gallium source is intermittently introduced into a reaction chamber and an aluminum source is continuously introduced into the reaction chamber, the intermittent introduction of the gallium source allows an appropriate amount of gallium atoms to exist in the reaction chamber, the appropriate amount of gallium atoms act as an activator, the quality of an obtained AlGaN buffer sub layer is good, a AlN buffer sub layeris welled matched with the AlGaN buffer sub layer with appropriate amount of gallium atoms, and the quality of the AlN buffer sub layer grown on the AlGaN buffer sub layer is improved. When the AlN buffer sub layer is grown, due to the gas phase reaction between an ammonia gas and the aluminum source, a part of the reactants generated by the reaction are incorporated into the AlN buffer sub layer,and the quality of the AlN buffer sub layer is affected. The ammonia gas is intermittently introduced, the reduction of the ammonia gas can inhibit the gas phase reaction between aluminum and the ammonia gas, a reactant of the ammonia gas and aluminum source reaction growth is reduced and is combined into the AlN buffer sub layer, and finally the crystal quality of the epitaxial wafer is improved.

Owner:HC SEMITEK CORP

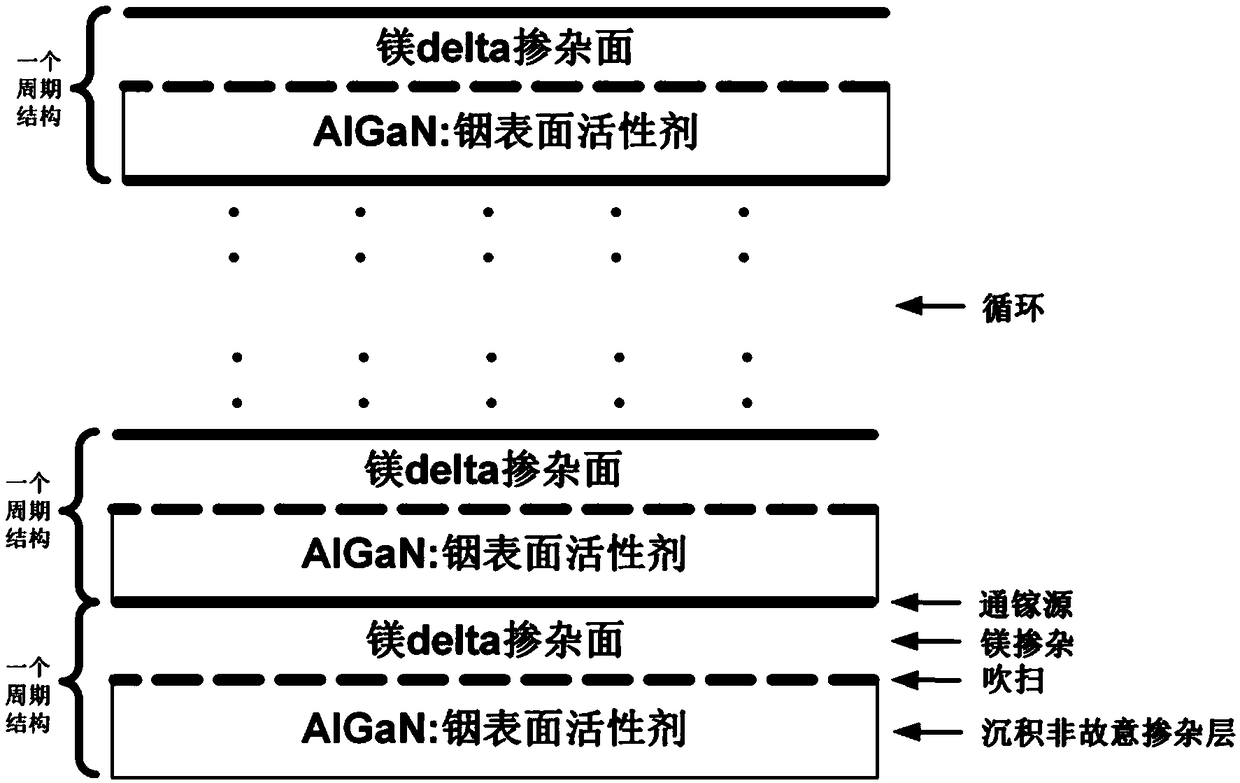

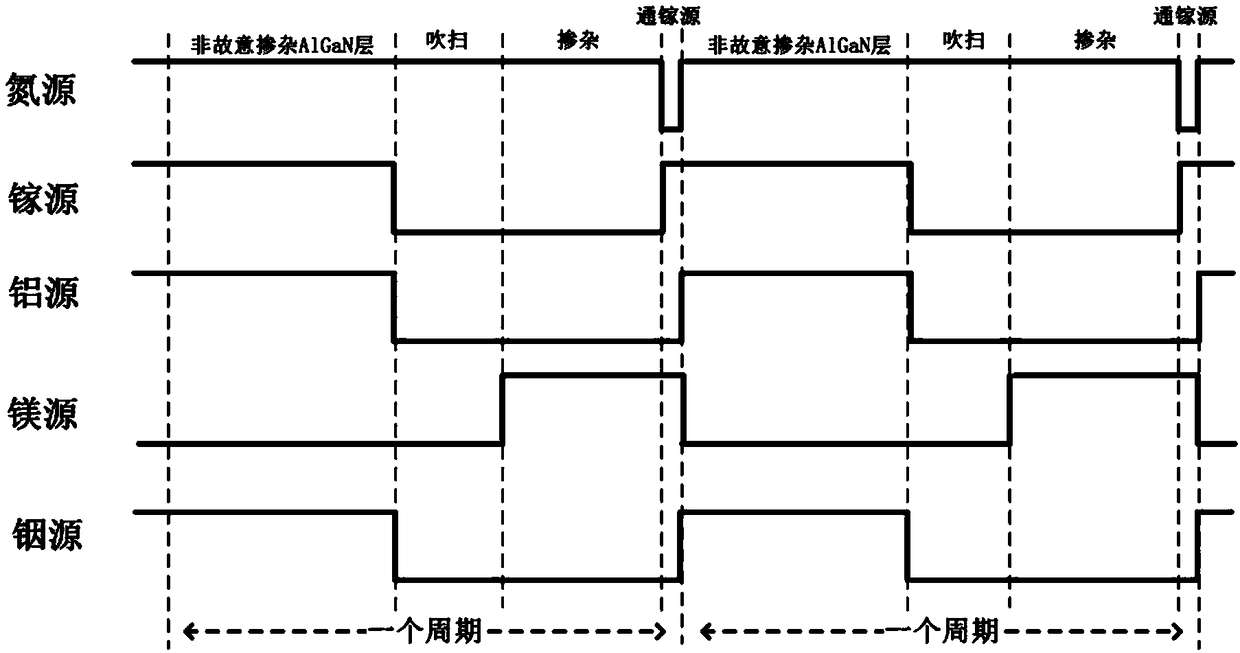

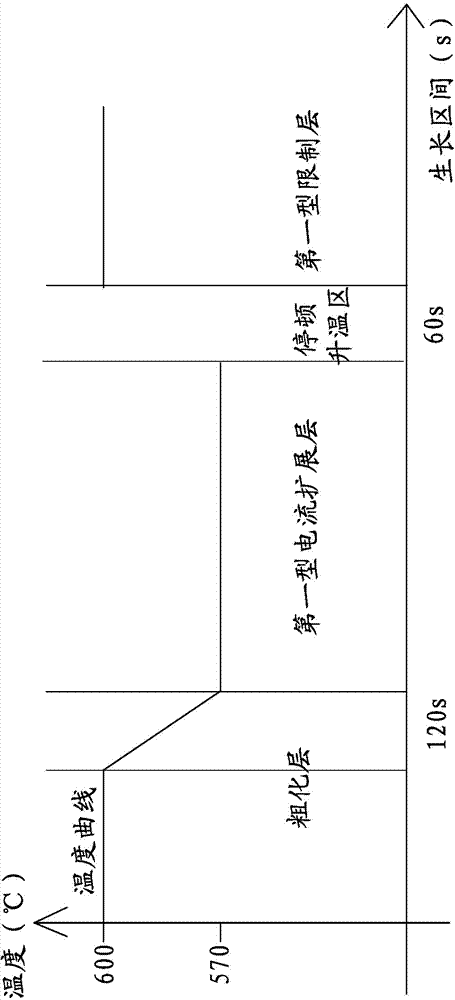

Growth method of p-type AlGaN semiconductor material

ActiveCN108987256AReduced Displacement Formation EnergyImprove retentionSemiconductor/solid-state device manufacturingDimethylhydrazineIndium

The invention discloses a growth method of p-type AlGaN semiconductor material, the semiconductor material is grown by a technical method of adding a gallium source through step into a surfactant-assisted magnesium delta doping, Ammonia gas or dimethylhydrazine nitrogen is used as group V nitrogen source in the growth of p-type AlGaN semiconductor material, Trimethylgallium or triethylgallium is used as a Group III gallium source, trimethylaluminum or triethylaluminum is used as a Group III aluminum source, trimethylindium or triethylindium is used as a Group III indium source, collectively referred to as a Group III metal source, and trimethylindium or triethylindium is also used as a surfactant in the acceptor doping layer. The method of the invention can improve crystal quality, increase doping concentration of acceptor doped magnesium atoms, reduce acceptor ionization energy by enhancing valence band modulation, and further suppress self-compensation effect, thereby obtaining p-type AlGaN semiconductor material with high crystal quality and high hole concentration.

Owner:SUN YAT SEN UNIV

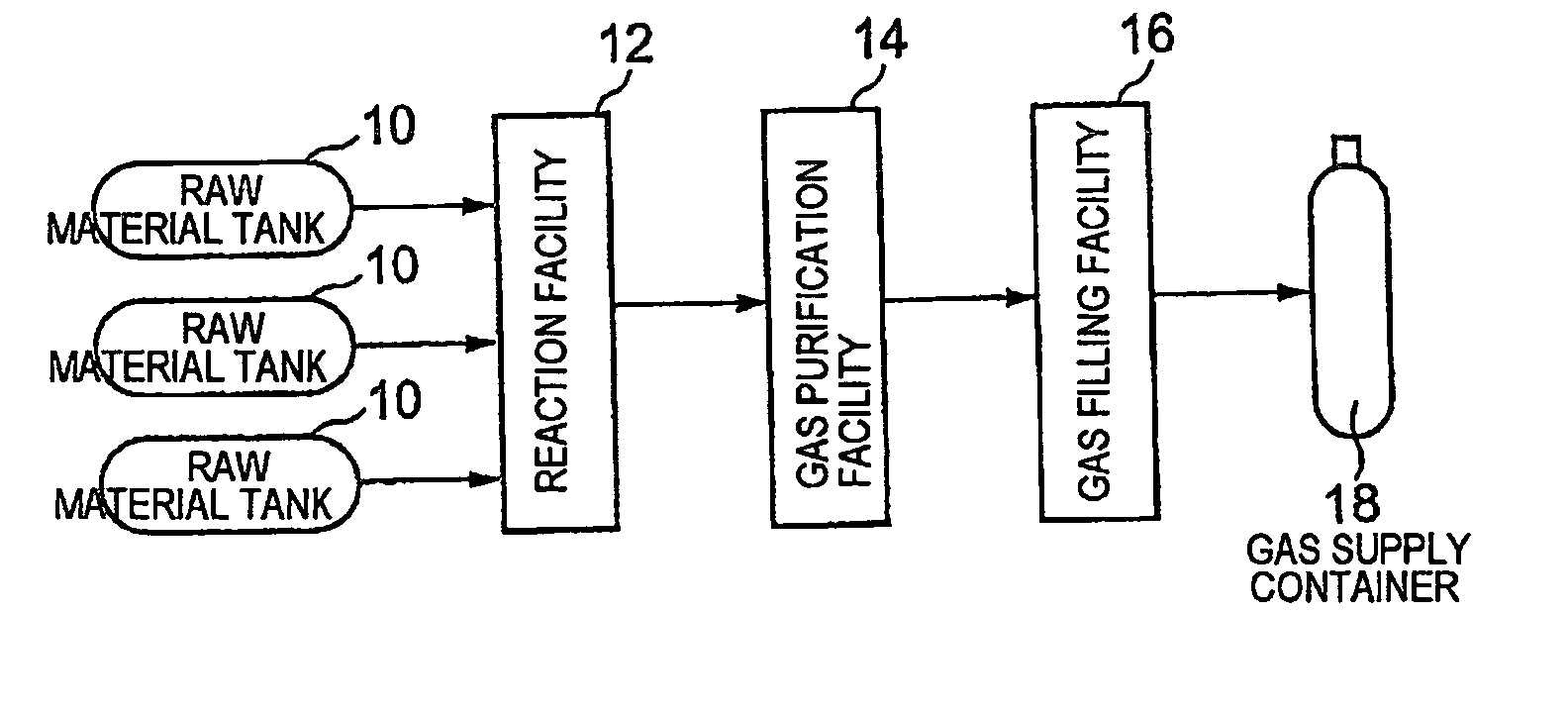

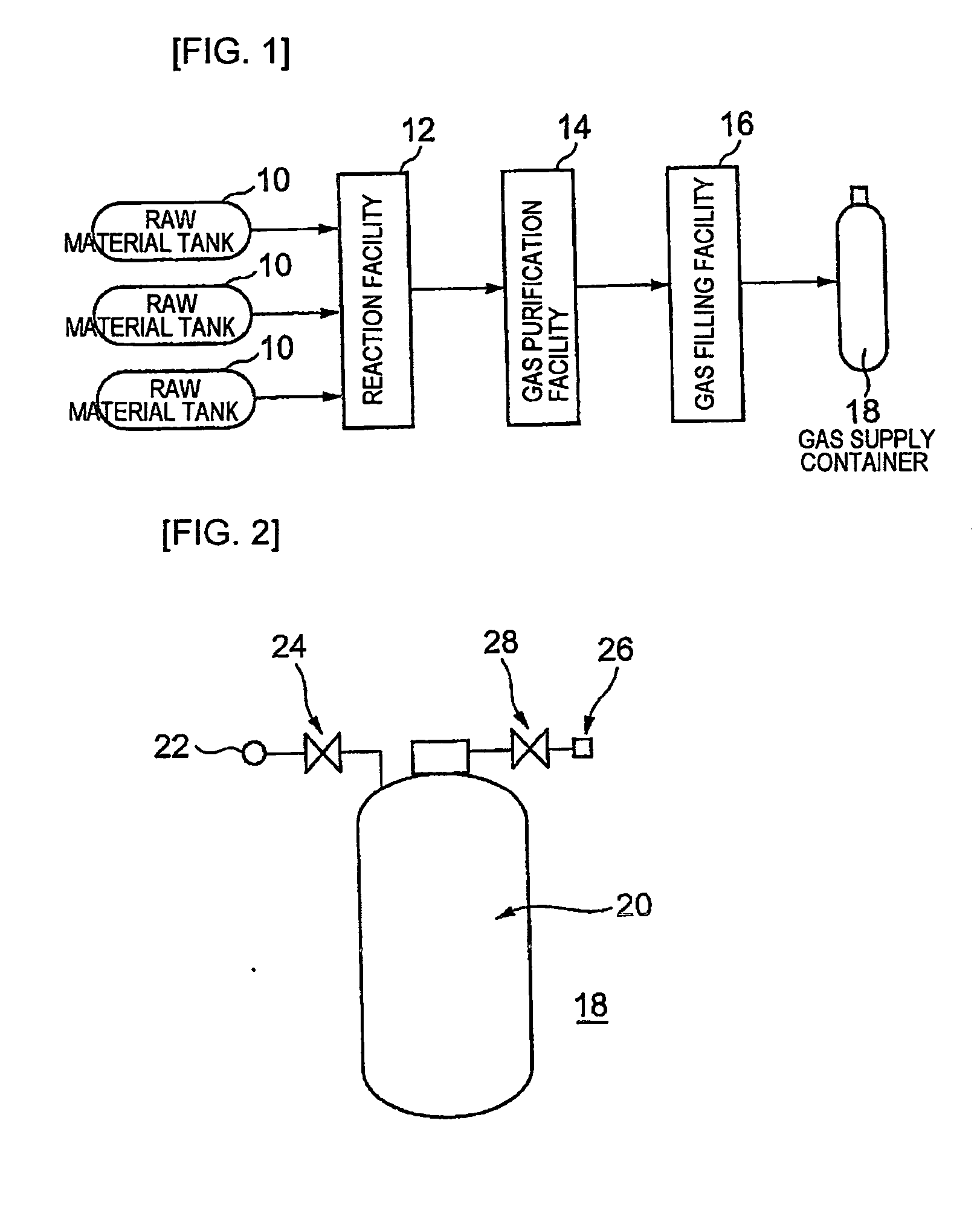

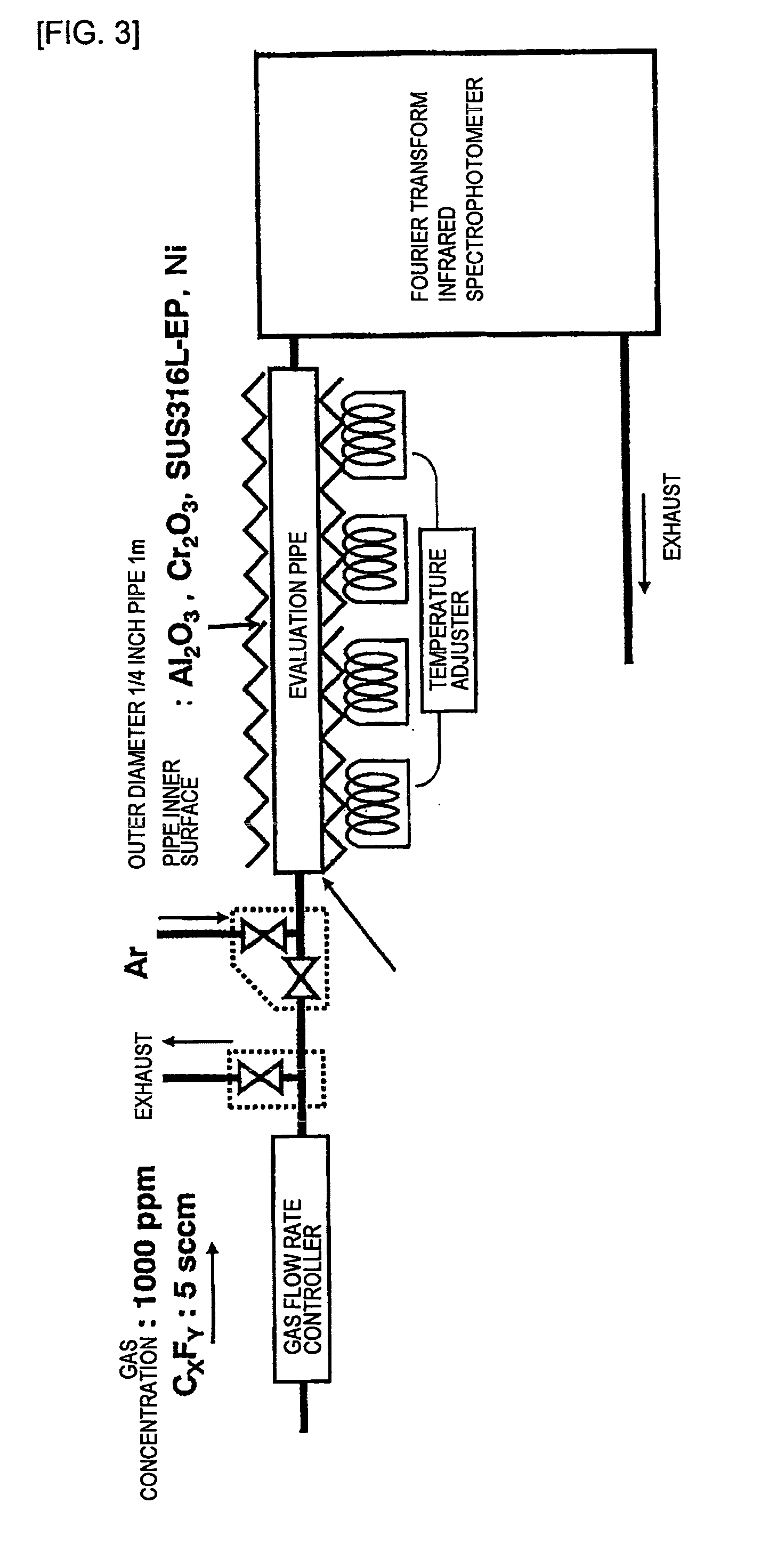

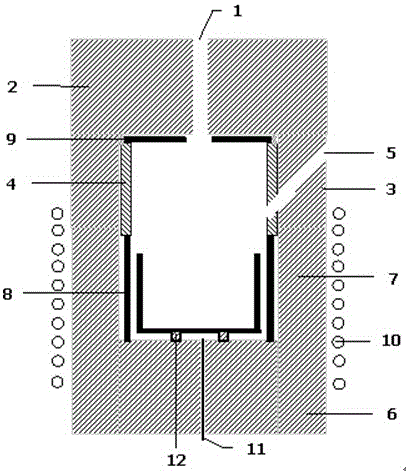

Gas Production Facility, Gas Supply Container, And Gas For Manufacture Of Electronic Devices

InactiveUS20070282142A1Easy to purifyReduce incorporationMolten spray coatingOrganic chemistryFilm baseYttrium

An apparatus for producing a gas using a raw material gas having high reactivity, in particular, a fluorinated hydrocarbon, or a vessel for supplying the gas, characterized in that the surface of a portion thereof contacting with the gas has an average roughness of 1 μm or less in terms of a center line average roughness Ra. It is preferred that an oxide-based passivated film such as a film based on chromium oxide, aluminum oxide, yttrium oxide, magnesium oxide or the like is formed on the surface having a roughness controlled as above. The above apparatus and vessel can be suitably used for preventing the contamination of a raw material gas originated from a gas production apparatus or a vessel for supplying the gas.

Owner:ZEON CORP

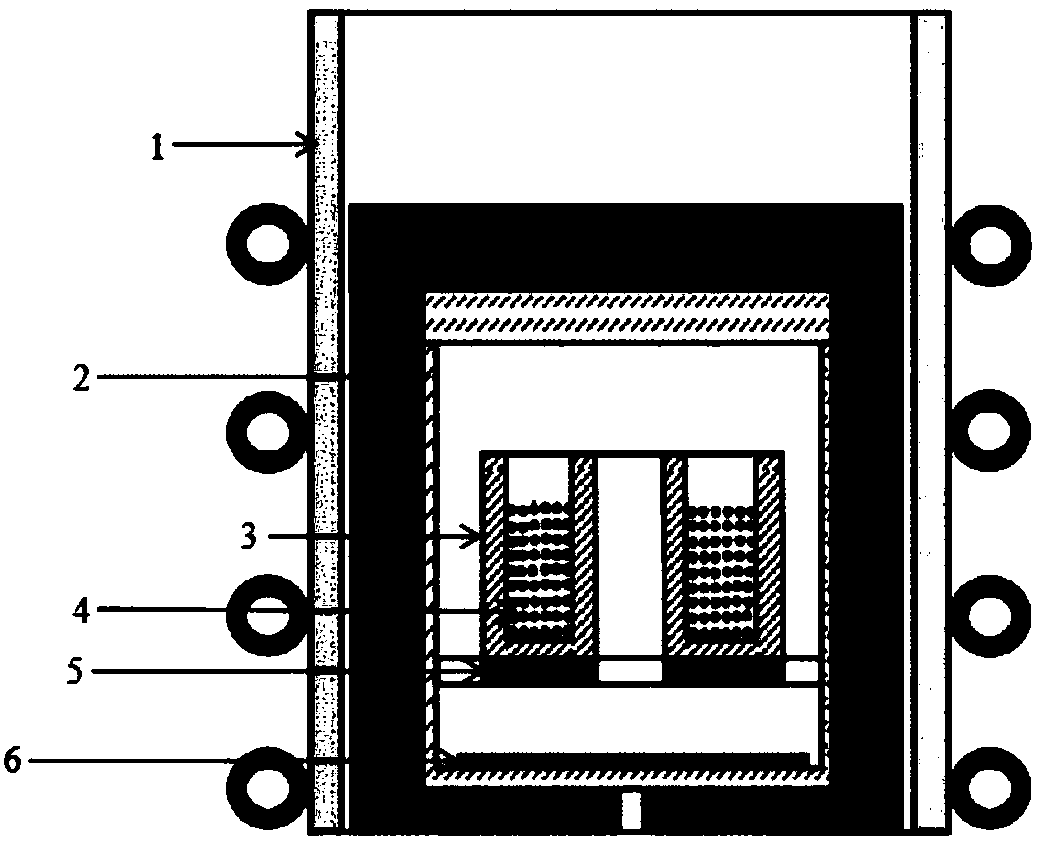

Grower for effectively restraining gallium oxide crystal defects

ActiveCN105970290AAvoid damageExtended service lifePolycrystalline material growthBy pulling from meltIridiumCrucible

The invention discloses a grower for effectively restraining gallium oxide crystal defects. The grower comprises a plurality of thermal field components in a formed single crystal furnace, and the thermal field components are horizontally and concentrically mounted. A heating body and an iridium crucible are embedded into the center of a thermal field and heated by round induction coils, the heating body and the iridium crucible are separated, and a clearance is reserved between the heating body and the iridium crucible. Each thermal field component comprises a zirconia inner heat preservation barrel for supporting an iridium reflecting screen, an upper heat preservation component covering the iridium reflecting screen, a middle heat preservation component surrounding the zirconia inner heat preservation barrel, and a lower heat preservation component surrounding the iridium crucible and the heating body, and seed rod inlets are reserved in the upper heat preservation component. According to design of the grower, losses of the iridium crucible can be reduced, the content of impurity elements in crystals can be effectively restrained, therefore, the defects in the crystals can be restrained well, the service life of the crucible can be prolonged, and a foundation is laid for achieving mass production of gallium oxide single crystals with high quality and low cost.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

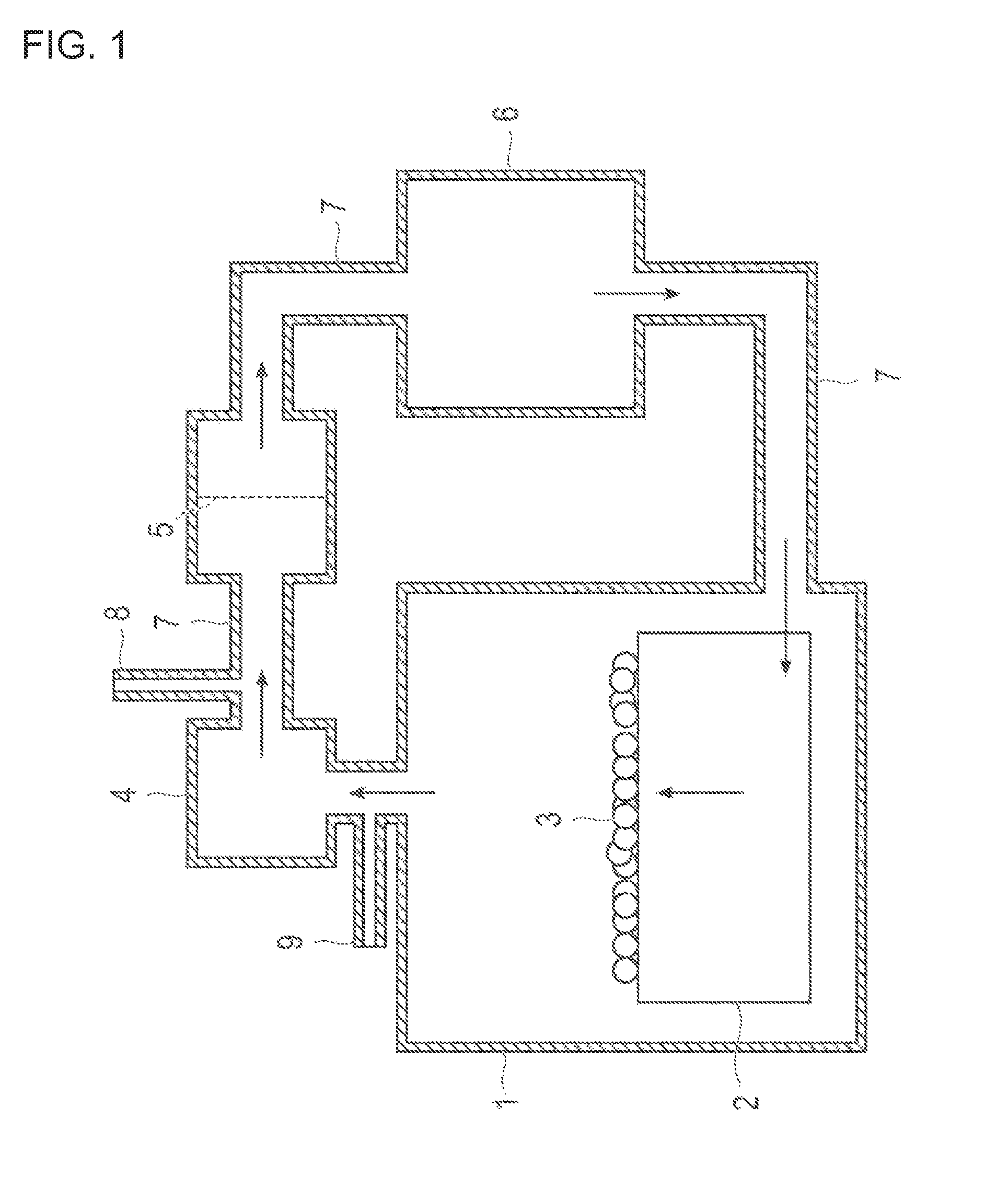

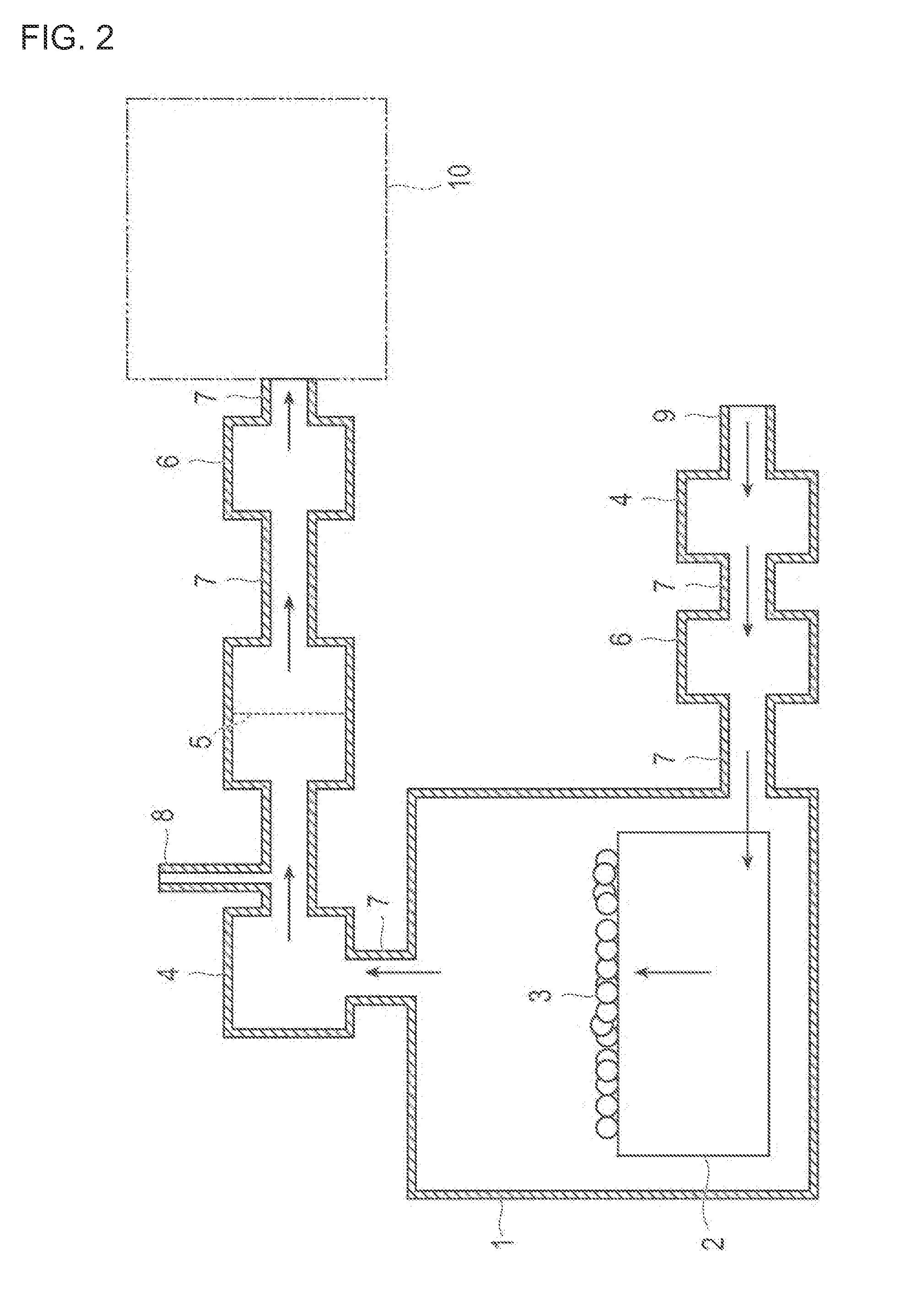

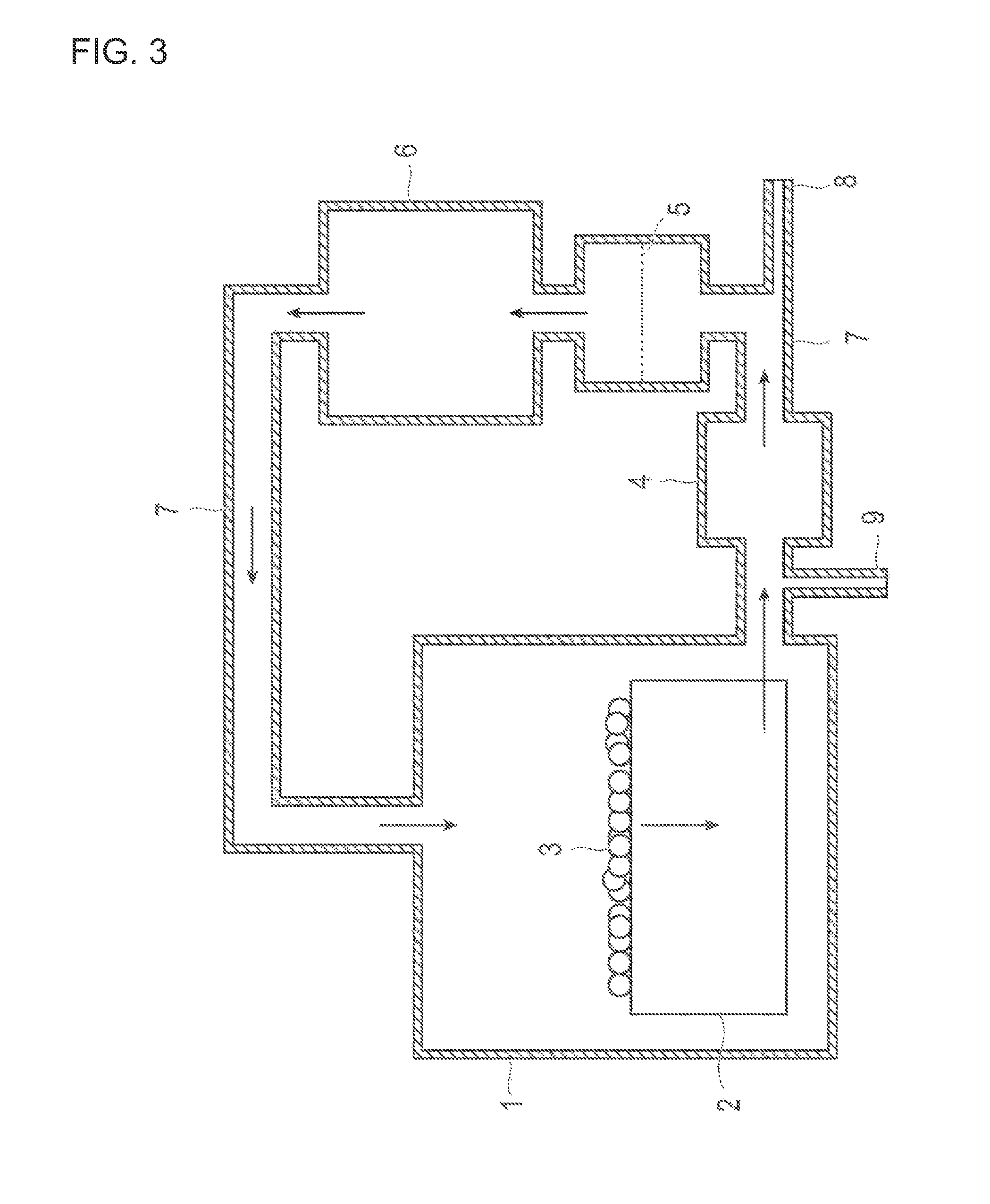

Method and apparatus for feeding a polyurethane mixture into hollow bodies

ActiveUS8709313B2Short and homogenous timeIncrease expansionDomestic cooling apparatusTailstocks/centresChemical reactionControl manner

A method and apparatus for feeding a polyurethane mixture suitable to form a thermally insulating layer inside hollow bodies, such as hollow walls of a refrigerator cabinet, freezer, display counter or insulating panel. A polyurethane mixture resulting from chemically reactive components, supplied by a high-pressure mixing device, is injected into a cavity of a hollow body extending in a horizontal plain. The mixture is injected at a first flow-rate and a first injection speed, to be poured into a first deposition zone farthest from the injection point. Subsequently, the flow-rate and the injection speed of the polyurethane mixture are gradually reduced in a controlled manner, to be poured in successive deposition zones towards the injection point of the polyurethane mixture, along a distribution strip, allowing the injected mixture to spread out throughout the cavity of the hollow body along isometric expansion lines.

Owner:AFROS

Method for producing particulate water absorbent resin

ActiveUS8791230B2Efficient productionGood physical propertiesDrying solid materials with heatHearth type furnacesCross-linkParticulates

A method for reducing colored foreign substances in a water absorbent resin by a convenient and simple technique in the production of a water absorbent resin, without requiring any modification of raw materials or high capital investment, is provided. The method for producing a particulate water absorbent resin includes a step of polymerizing an aqueous solution of an unsaturated monomer; and a step of drying a particulate water-containing gel-like cross-linked polymer having a solids concentration of 30% by weight or greater that is obtainable in a gel grain refining step during polymerization or after polymerization, with one or more apparatuses for aerating a water absorbent resin with a high temperature gas stream being installed in the drying step and / or in at least one of the subsequent steps, while in the aerating apparatus, the high temperature gas stream is passed through a filter and then is reused in the same step as the step where the aerating apparatus is installed, or in a different step.

Owner:NIPPON SHOKUBAI CO LTD

Production method for polyamide

ActiveUS20150073120A1Reduce frequencyImprove productivityTransportation and packagingRotary stirring mixersGas phasePolyamide

The present invention is directed to a process for producing a polyamide, which process includes directly melt-polymerizing a diamine component including 70 mol % or more of p-xylylenediamine and a dicarboxylic acid component including 70 mol % or more of a C6 to C18 aliphatic dicarboxylic acid, in the absence of solvent in a batch-type reactor equipped with a stirring blade, the process including: (1) reacting the diamine component with the dicarboxylic acid component under a pressure condition of 0.2 to 0.5 MPa (Abs); (2) maintaining a vapor phase section of a reaction tank of the reactor at 200° C. or higher during reaction; (3) stirring the contents of the reaction tank, from the start of adding the diamine component until after completion of the addition and before the start of pressure falling, such that the stirring-related Froude number represented by a specific formula is adjusted to 0.0002 to 0.15; and (4) employing a stirring blade having no structural body in the horizontal direction or having a structural body in the horizontal direction, which body does not come into contact with the interface between the reaction mixture and the vapor phase section during stirring. In the polyamide production process, deposition of solid matter in the reaction tank vapor section and in a vapor pipe is suppressed, and incorporation into the product of unmelted solid matter originating from the deposits is reduced.

Owner:MITSUBISHI GAS CHEM CO INC

Simple production process of peanut oil

InactiveCN107254352AAchieve oil yieldQuality improvementFatty-oils/fats productionWater contentArachis hypogaea

The invention discloses a simple peanut oil production process. The specific steps of the simple peanut oil production process are as follows: S1: Peanut material preparation, S2: Peanut screening treatment, S3: Water selection, S4: Drying treatment, S5: Shelling of peanuts, S6: manual screening of peanut kernels, S7: frying and peeling of peanuts, S8: crushing treatment, S9: compacting treatment, S10: oil pressing treatment of oil press, S11: purification and filtration of peanut oil . The invention strictly controls the water content in peanuts, realizes the oil yield of peanuts to the greatest extent, and at the same time, through multi-level screening, improves the quality of peanut raw materials for oil extraction to the greatest extent, reduces the incorporation of unqualified peanut kernels, and through water separation Double screening with artificial screening removes mildewed peanuts and shriveled peanuts, improves the oil yield of peanuts and the quality of peanut oil, making peanut oil healthier.

Owner:安陆市万众创新智能科技有限公司

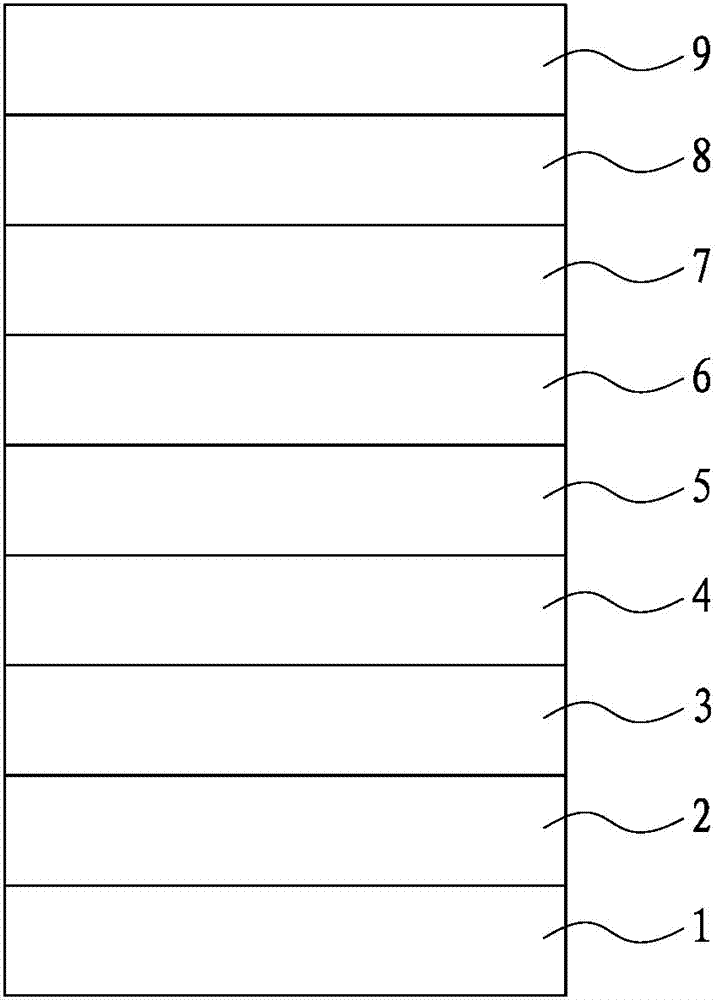

High concentration Te doped light emitting diode epitaxial structure

ActiveCN104332537AImprove merge efficiencyImprove luminous efficiencySemiconductor devicesHigh concentrationLength wave

The invention discloses a high concentration Te doped light emitting diode epitaxial structure. A buffer layer, a corrosion barrier layer, a coarsening layer, a first type current spreading layer, a first type limiting layer, an active layer, a second type limiting layer, and a second type current spreading layer. One side of the active layer is provided with the first type current spreading layer, and the other side of the active layer is provided with the second type current spreading layer. The active layer and the first type current spreading layer are provided with the first type limiting layer. The active layer and the second type current spreading layer are provided with the second type limiting layer. The first type current spreading layer is an n-layer structure, superlattice is arranged between layers, Te is doped in the first type current spreading layer. According to the high concentration Te doped light emitting diode epitaxial structure, the adsorption of short-wavelength light by impurities can be reduced, and the light emitting efficiency of a light emitting diode is effectively raised.

Owner:XIAMEN CHANGELIGHT CO LTD

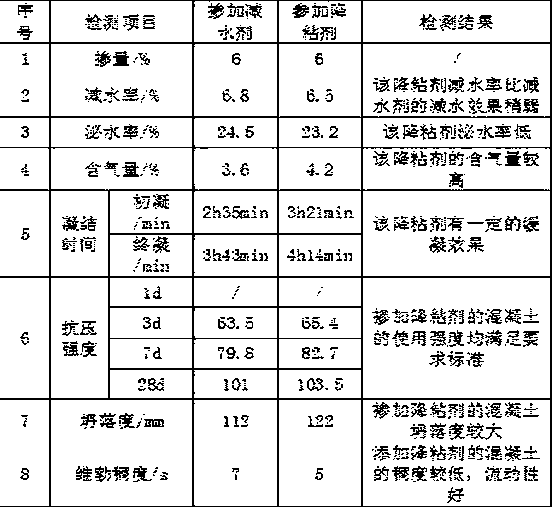

Concrete viscosity reducer and preparation method thereof

The invention provides a concrete viscosity reducer, relates to an external additive applied to ultrahigh-strength and ultra-large concrete, in particular to a viscosity reducer applied to the ultrahigh-strength and ultra-large concrete. The viscosity reducer is mainly prepared from coal ash, microbeads-POZZ, polycarboxylic acid, polysiloxane resin, sodium dodecyl benzene sulfonate, sodium phosphate, sodium sulfate, dihydrate gypsum and sodium gluconate. The viscosity reducer is designed by adding a lubricating component, a water reducer, an air entraining agent, a surfactant and a certain enhancing component, and the viscosity reducer can effectively reduce the viscosity of the concrete and avoid influence on various use properties of the concrete. The viscosity reducer is subjected to actual detection and is widely applied.

Owner:云南森博混凝土外加剂有限公司

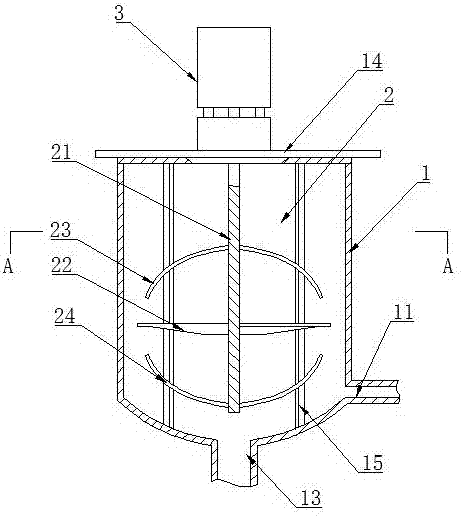

Foam concrete mixing method

The invention provides a foam concrete mixing method, belonging to the technical field of foam concrete. The method comprises the following steps: generating bubbles: filling foaming liquid with stabilized gas to make bubbles; mixing concrete grout; mixing the bubbles with the concrete grout: continuously pumping the bubbles from the lower part of the concrete grout, and stirring while pumping so as to enable the bubbles to be distributed in the concrete grout. According to the method, the bubbles are pumped from the lower part of the concrete grout, so that the bubbles have the trend of ascending under the action of buoyancy and can be evenly distributed in concrete in the processes of continuous replenishment and stirring; the method can be used for reducing the stirring strength while preventing the bubbles from being mixed with air, thus reducing the air incorporation into the concrete and bubble breakup, enabling the purity of the stabilized gas in the bubbles to be at a higher level, and guaranteeing the quality of the foam concrete.

Owner:HEBEI SANSHAN BUILDING MATERIALS TECH

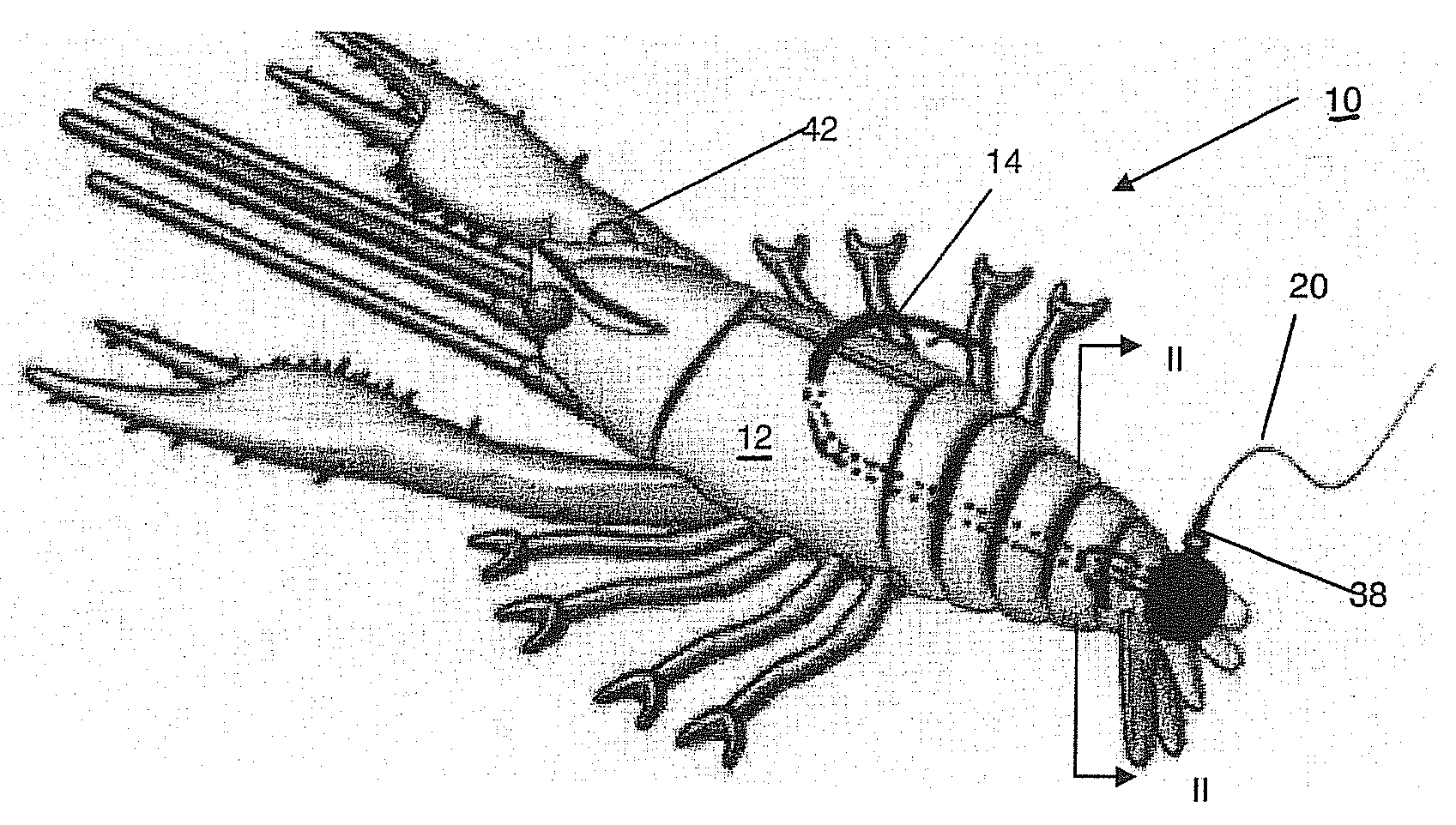

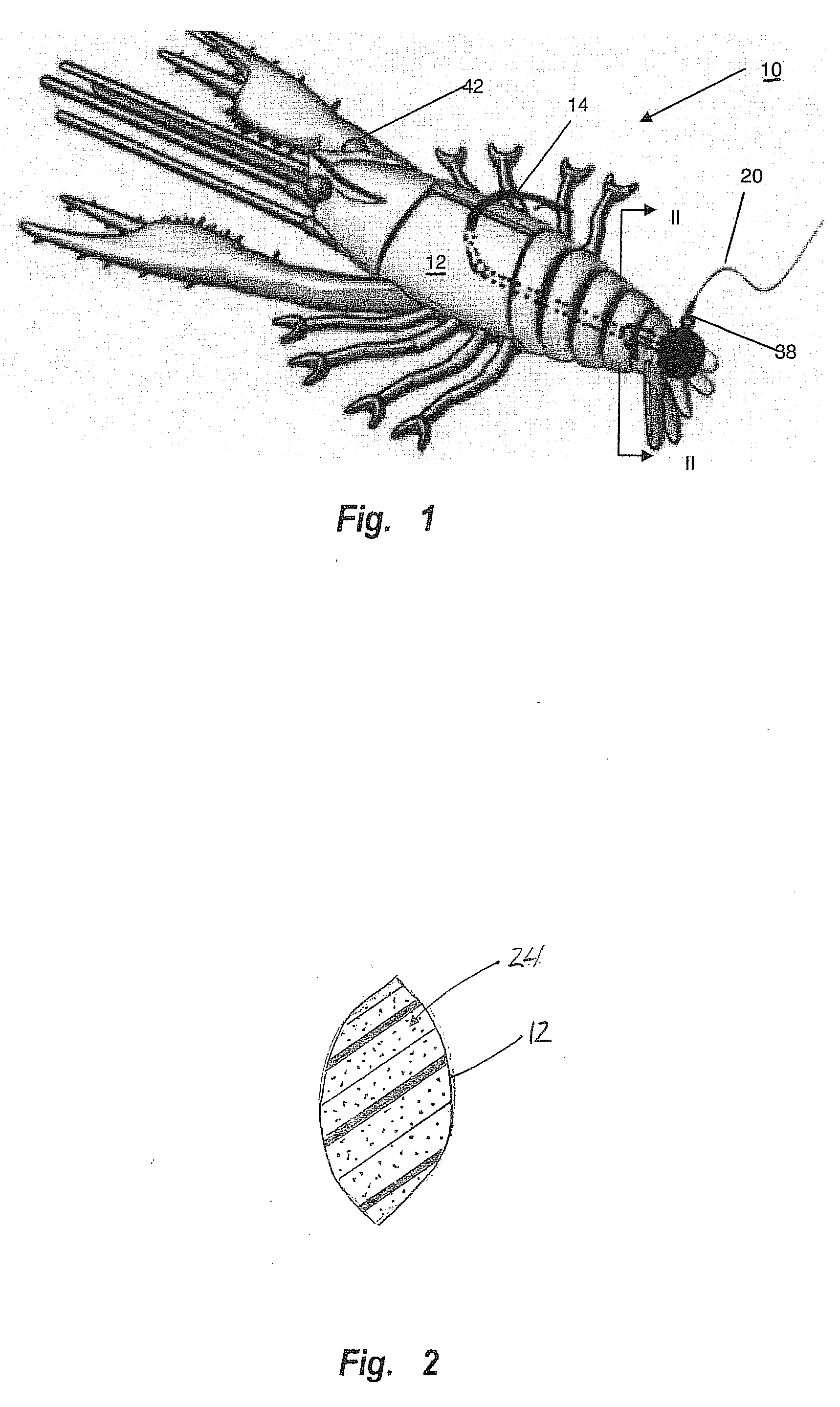

Biodegradable fishing lure and manufacturing methods

InactiveUS20080263936A1Easy to processSimple to useBaitAnimal feeding stuffMedicinePolyvinyl alcohol

A fishing lure is composed of polyvinyl alcohol in combination with urea, agar or both to be highly performing and biodegradeable without requiring a freeze / thaw cycle.

Owner:SU YUAN CHIEH

Method for producing particulate water absorbent resin

ActiveUS20130261276A1Efficient productionGood physical propertiesDrying solid materials with heatHearth type furnacesCross-linkParticulates

A method for reducing colored foreign substances in a water absorbent resin by a convenient and simple technique in the production of a water absorbent resin, without requiring any modification of raw materials or high capital investment, is provided. The method for producing a particulate water absorbent resin includes a step of polymerizing an aqueous solution of an unsaturated monomer; and a step of drying a particulate water-containing gel-like cross-linked polymer having a solids concentration of 30% by weight or greater that is obtainable in a gel grain refining step during polymerization or after polymerization, with one or more apparatuses for aerating a water absorbent resin with a high temperature gas stream being installed in the drying step and / or in at least one of the subsequent steps, while in the aerating apparatus, the high temperature gas stream is passed through a filter and then is reused in the same step as the step where the aerating apparatus is installed, or in a different step.

Owner:NIPPON SHOKUBAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com