Aluminium nitride single crystal growth device dispensing with seed crystal bonding technology and method

A growth device, aluminum nitride technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problem of uneven temperature field distribution on the surface of the seed crystal, few types of non-carbon high-temperature adhesives, affecting the single crystal problems such as usable area, to achieve the effect of simple device and process method, increase usable area, and eliminate cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

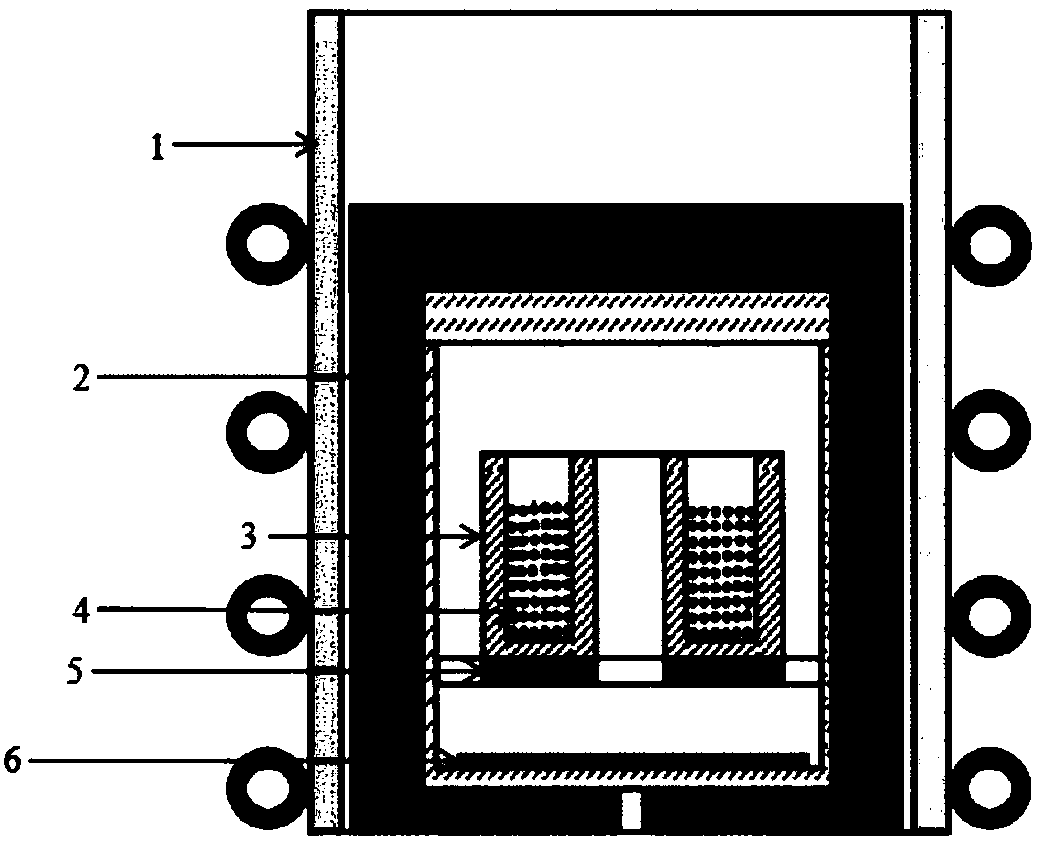

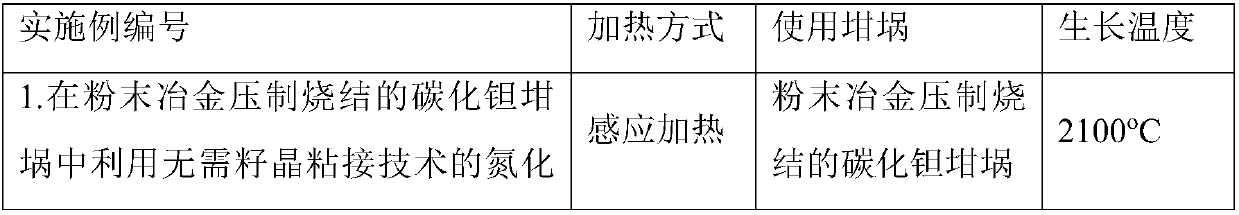

[0047] Embodiment 1: In a tantalum carbide crucible sintered by powder metallurgy, the growth of high-purity single crystal aluminum nitride is accomplished by using an aluminum nitride single crystal growth device that does not require seed crystal bonding technology.

[0048] The specific growth process is as follows:

[0049] (1) The induction coil feeds a current to heat the graphite.

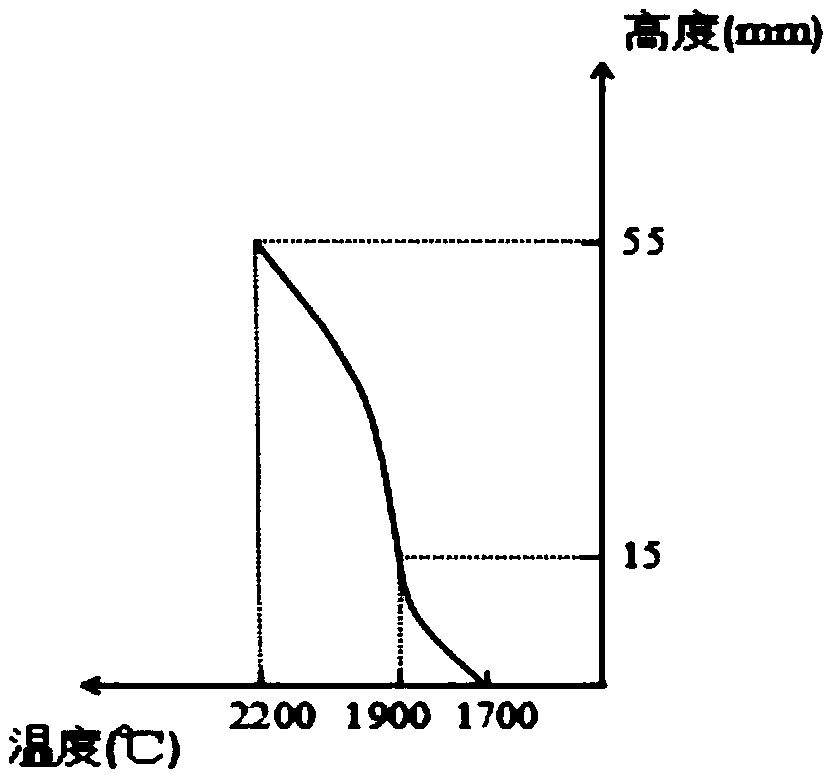

[0050] (2) Adjust the structure of the insulation layer so that the thickness of the top insulation material is greater than that of the bottom, so that the temperature at the top of the crucible is about 400°C higher than the temperature at the bottom. At the same time, an opening with a diameter of 9 mm is left directly below to ensure that the infrared temperature measurement system can perform non-contact infrared measurement of the thermal field conditions at the bottom of the crucible.

[0051] (3) The crucible is a tantalum carbide ceramic crucible sintered with tantalum carbide pow...

Embodiment 2

[0057] Embodiment 2: The growth of high-purity single-crystal aluminum nitride is completed in a carbonized metal tantalum crucible using an aluminum nitride single crystal growth device that does not require seed crystal bonding technology.

[0058] The specific growth process is as follows:

[0059] (1) The induction coil feeds a current to heat the graphite.

[0060] (2) Adjust the structure of the insulation layer so that the thickness of the top insulation material is greater than that of the bottom, so that the temperature at the top of the crucible is about 400°C higher than the temperature at the bottom. At the same time, an opening with a diameter of 9 mm is left directly below to ensure that the infrared temperature measurement system can perform non-contact infrared measurement of the thermal field conditions at the bottom of the crucible.

[0061] (3) The crucible is a tantalum crucible with a carbonized tantalum surface. The size of the carbonized tantalum crucib...

Embodiment 3

[0067] Embodiment 3: The growth of high-purity single-crystal aluminum nitride is completed in a tungsten crucible by using an aluminum nitride single crystal growth device that does not require seed crystal bonding technology.

[0068] The specific growth process is as follows:

[0069] (1) Pass current through the high-purity tungsten mesh (resistance heating) to heat it.

[0070] (2) Multi-section high-purity tungsten screens are used as the insulation layer, and the structure (shape and number of layers) of the insulation layer is adjusted so that the insulation effect of the top is greater than that of the bottom, and the temperature at the top of the crucible is about 400°C higher than that at the bottom. At the same time, an opening with a diameter of 9 mm is left directly below to ensure that the infrared temperature measurement system can perform non-contact infrared measurement of the thermal field conditions at the bottom of the crucible.

[0071] (3) The crucible ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com