Concrete viscosity reducer and preparation method thereof

A viscosity reducer and concrete technology, applied in the field of viscosity reducer, can solve problems such as inability to guarantee concrete fluidity and slump, increase concrete viscosity, uneven mixing, etc., and achieve enhanced water reduction effect, good dispersion, and volatilization Sexually low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

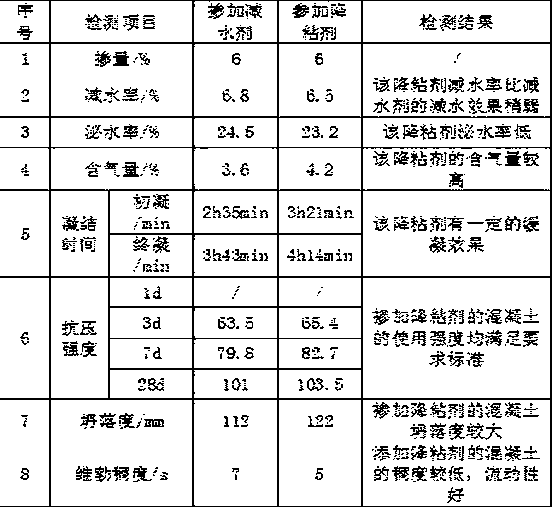

Examples

Embodiment 1

[0030] The concrete viscosity reducer of the present invention mainly consists of fly ash, co-forming microbeads, polycarboxylic acid, polysiloxane resin, sodium dodecylbenzenesulfonate, sodium phosphate, sodium sulfate, dihydrate gypsum, Composition of sodium gluconate, the components by weight of the components are: 200 parts of fly ash, 20 parts of Tongcheng microbeads, 10 parts of polycarboxylic acid, 0.001 part of polysiloxane resin, sodium dodecylbenzenesulfonate 0.001 parts, 0.3 parts of sodium phosphate, 5 parts of sodium sulfate, 3 parts of dihydrate gypsum, 20 parts of sodium gluconate.

Embodiment 2

[0032] The concrete viscosity reducer of the present invention mainly consists of fly ash, co-forming microbeads, polycarboxylic acid, polysiloxane resin, sodium dodecylbenzenesulfonate, sodium phosphate, sodium sulfate, dihydrate gypsum, Composition of sodium gluconate, its components by weight are: 180 parts of fly ash, 18 parts of Tongcheng microbeads, 8 parts of polycarboxylic acid, 0.001 part of polysiloxane resin, 0.001 part of sodium dodecylbenzenesulfonate, phosphoric acid 0.2 parts of sodium, 3 parts of sodium sulfate, 2 parts of dihydrate gypsum, 18 parts of sodium gluconate.

Embodiment 3

[0034] The concrete viscosity reducer of the present invention mainly consists of fly ash, co-forming microbeads, polycarboxylic acid, polysiloxane resin, sodium dodecylbenzenesulfonate, sodium phosphate, sodium sulfate, dihydrate gypsum, Composition of sodium gluconate, its components by weight are: 220 parts of fly ash, 22 parts of Tongcheng microbeads, 12 parts of polycarboxylic acid, 0.002 part of polysiloxane resin, 0.002 part of sodium dodecylbenzenesulfonate, phosphoric acid 0.4 parts of sodium, 7 parts of sodium sulfate, 4 parts of dihydrate gypsum, 22 parts of sodium gluconate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com