Concrete cast-in-place process for building construction

A technology for building construction and concrete, applied in construction, infrastructure engineering, sustainable waste treatment, etc., can solve the problems of large shrinkage deformation, low tensile strength, easy to produce cracks, etc., to achieve easy control and operation, high tensile strength. Powerful, easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

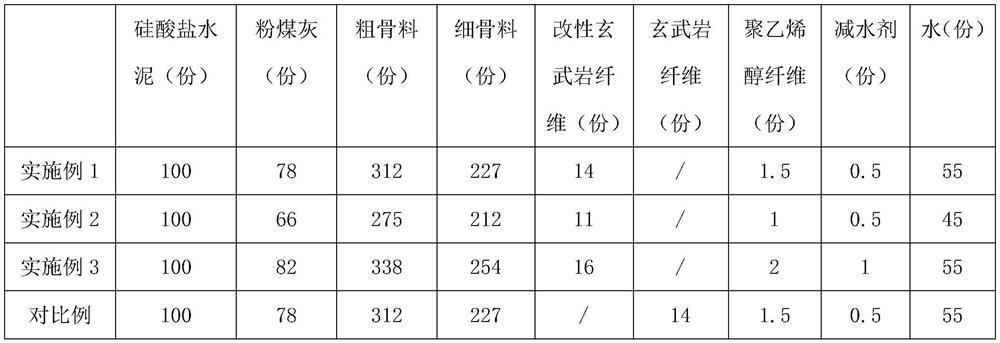

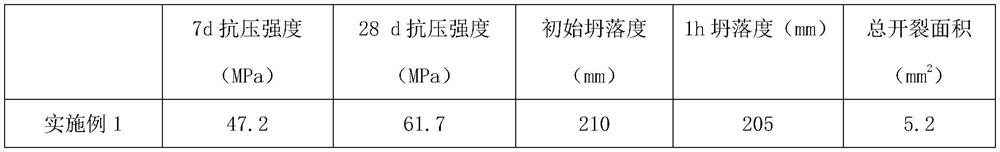

[0044] A concrete for building construction, calculated in parts by weight, comprising the following components:

[0045] 100 parts of ordinary Portland cement PO42.5, 78 parts of fly ash, 312 parts of coarse aggregate, 227 parts of fine aggregate, 14 parts of modified basalt fiber, 1.5 part of polyvinyl alcohol fiber, 0.5 part of polycarboxylate Aqua and 55 parts water.

[0046]The particle diameter of fly ash is 50-100μm; the source of coarse aggregate is mountain sand, river sand and lake sand, and the particle diameter is 0.15-4.75mm; the source of fine aggregate is crushed stone and pebbles, and the particle diameter is 4.75- 8mm; the length of the modified basalt fiber is 5-10mm, and the diameter is 10-15μm; the length of the polyvinyl alcohol fiber is 10-15mm, and the diameter is 30-45μm.

[0047] The preparation method of modified basalt fiber is:

[0048] S1. Pretreatment of Basalt Fiber:

[0049] Weigh sodium hydroxide and mix with deionized water, stir until comp...

Embodiment 2

[0063] A concrete for building construction, calculated in parts by weight, comprising the following components:

[0064] 100 parts of ordinary Portland cement PO42.5, 66 parts of fly ash, 275 parts of coarse aggregate, 212 parts of fine aggregate, 11 parts of modified basalt fiber, 1 part of polyvinyl alcohol fiber, 0.5 part of polyacrylate water reducing agent and 45 parts water.

[0065] The particle diameter of fly ash is 50-100μm; the source of coarse aggregate is mountain sand, river sand and lake sand, and the particle diameter is 0.15-4.75mm; the source of fine aggregate is crushed stone and pebbles, and the particle diameter is 4.75- 8mm; the length of the modified basalt fiber is 5-10mm, and the diameter is 10-15μm; the length of the polyvinyl alcohol fiber is 10-15mm, and the diameter is 30-45μm.

[0066] The preparation method of modified basalt fiber is:

[0067] S1. Pretreatment of Basalt Fiber:

[0068] Weigh sodium hydroxide and mix with deionized water, sti...

Embodiment 3

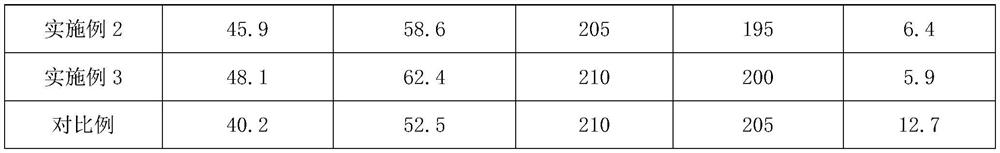

[0082] A concrete for building construction, calculated in parts by weight, comprising the following components:

[0083] 100 parts of ordinary Portland cement PO42.5, 82 parts of fly ash, 338 parts of coarse aggregate, 254 parts of fine aggregate, 16 parts of modified basalt fiber, 2 parts of polyvinyl alcohol fiber, 1 part of polycarboxylate Aqua and 55 parts water.

[0084] The particle diameter of fly ash is 50-100μm; the source of coarse aggregate is mountain sand, river sand and lake sand, and the particle diameter is 0.15-4.75mm; the source of fine aggregate is crushed stone and pebbles, and the particle diameter is 4.75- 8mm; the length of the modified basalt fiber is 5-10mm, and the diameter is 10-15μm; the length of the polyvinyl alcohol fiber is 10-15mm, and the diameter is 30-45μm.

[0085] The preparation method of modified basalt fiber is:

[0086] S1. Pretreatment of Basalt Fiber:

[0087] Weigh sodium hydroxide and mix with deionized water, stir until comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com