Foam concrete mixing method

A technology of bubble concrete and a method for making it, applied in the field of bubble concrete, can solve problems such as mixing a large amount of air, and achieve the effects of reducing bubble bursting, enhancing stability and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

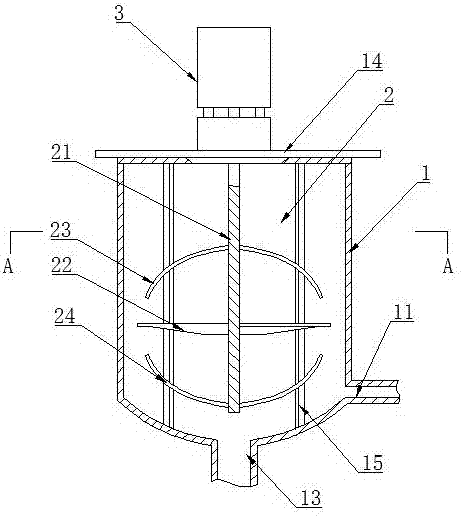

Image

Examples

Embodiment approach

[0029] Further, as a specific embodiment of the method for mixing cellular concrete provided by the present invention, the foaming agent includes a mixture of one or more of animal protein foaming agents and vegetable protein foaming agents .

[0030] Further, as a specific embodiment of the method for mixing air cell concrete provided by the present invention, in the concrete slurry mixed, the concrete slurry includes water, cement, aggregate and admixture, and the admixture is A quick-setting agent, the quick-setting agent is a mixture of sulfoaluminate slag cement and a shrinkage reducing agent, and the admixture accounts for 3% to 5% of the mass of the concrete slurry.

[0031] Furthermore, as a specific implementation of the method for mixing air cell concrete provided by the present invention, in the mixing concrete slurry, the stable gas includes one or more of nitrogen and inert gas. Gases such as nitrogen or inert gas do not chemically react with the substances in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com