Preparation method and applications of nano-manganese oxide

A nano-manganese dioxide and oxidant technology, applied in the direction of manganese oxide/manganese hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of increasing the contact surface of chemical reactions, deteriorating surface smoothness, and incomplete coordination of surface atoms. Achieve the effect of saving the crushing and grinding process, reducing agglomeration and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

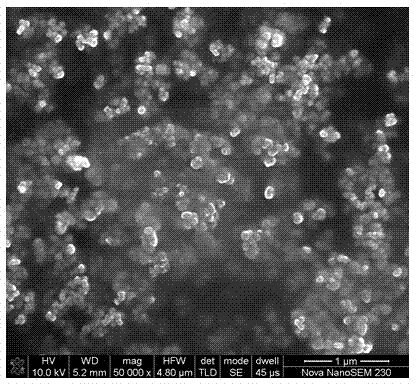

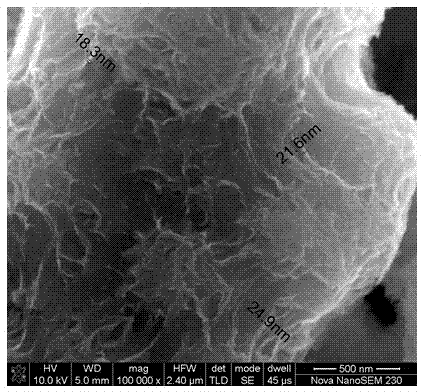

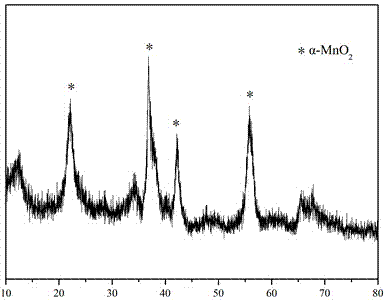

[0027] A kind of preparation method of nano-manganese dioxide of the present invention, comprises the following steps: take chemically pure manganese sulfate and potassium permanganate respectively by the proportioning ratio of the amount of substance of 1:10, and dissolve respectively in high-purity water, add to sulfuric acid Add polyethylene glycol-200 accounting for 0.01% of the mass of manganese sulfate into the manganese solution as an active agent; drop potassium permanganate solution into the manganese sulfate solution at a rate of 0.5 drops / min, ultrasonically disperse, and react at 25°C for 48 hours , nano-manganese dioxide is suspended in the solution, the solution is filtered, and the filtered precipitate is rinsed several times. During the washing process, polysorbate accounting for 0.01% of the product mass is added as a dispersant, filtered, and heated at 30 ± 5 and drying at ℃, so as to obtain nano-manganese dioxide with uniform nanowire network structure.

[0...

Embodiment 2

[0031] A kind of preparation method of nano-manganese dioxide of the present invention, comprises the following steps: take chemically pure manganese carbonate and potassium permanganate respectively by the proportioning ratio of the amount of substance of 1:10, and dissolve respectively in high-purity water, add to sulfuric acid Add polyethylene glycol-400 accounting for 0.01% of the mass of manganese carbonate to the manganese solution as an active agent; drop potassium permanganate solution into the manganese carbonate solution at a rate of 60 drops / min, stir mechanically to disperse, and react at 30°C For 48 hours, nano-manganese dioxide was suspended in the solution, the solution was filtered, and the filtered precipitate was washed several times. During the washing process, 0.01% ethanol was added to the product mass as a dispersant, filtered, and dried at 30 ± 5 and drying at ℃, so as to obtain nano-manganese dioxide with uniform nanowire network structure.

[0032] An ...

Embodiment 3

[0034] A kind of preparation method of nano manganese dioxide of the present invention, comprises the following steps: take chemically pure manganese sulfate and potassium permanganate respectively by the proportioning ratio of the amount of substance of 10:1, and dissolve respectively in high-purity water, add to sulfuric acid Add oleic acid accounting for 10% of the mass of manganese sulfate as an active agent in the manganese solution; drop potassium permanganate solution into the manganese sulfate solution at a rate of 60 drops / minute, stir mechanically to disperse, and react at 30°C for 48 hours. High-grade manganese dioxide is suspended in the solution, the solution is filtered, and the filtered precipitate is washed several times. During the washing process, polysorbate accounting for 10% of the product mass is added as a dispersant, filtered, and heated at 30±5°C and drying to obtain nano-manganese dioxide with uniform nanowire network structure.

[0035] An applicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com