Asymmetrically porous ion exchange membranes and their method of manufacture

An ion-exchange membrane, asymmetric technology, applied in the direction of chemical instruments and methods, membrane, membrane technology, etc., can solve the problems of limited improvement and achieve the effect of low effective thickness, simple and effective method, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

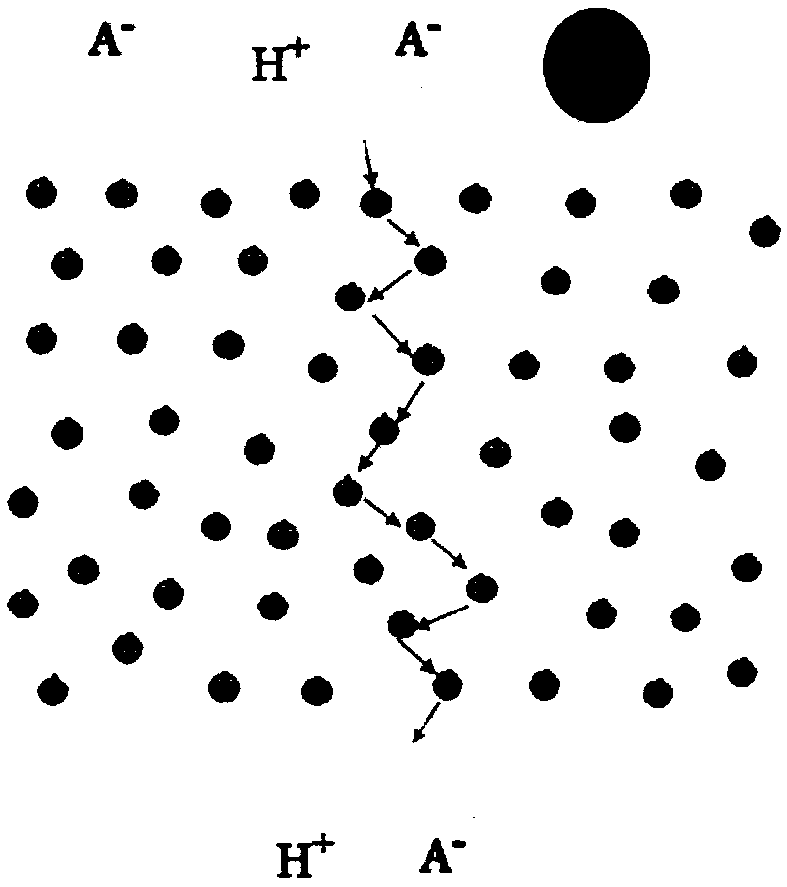

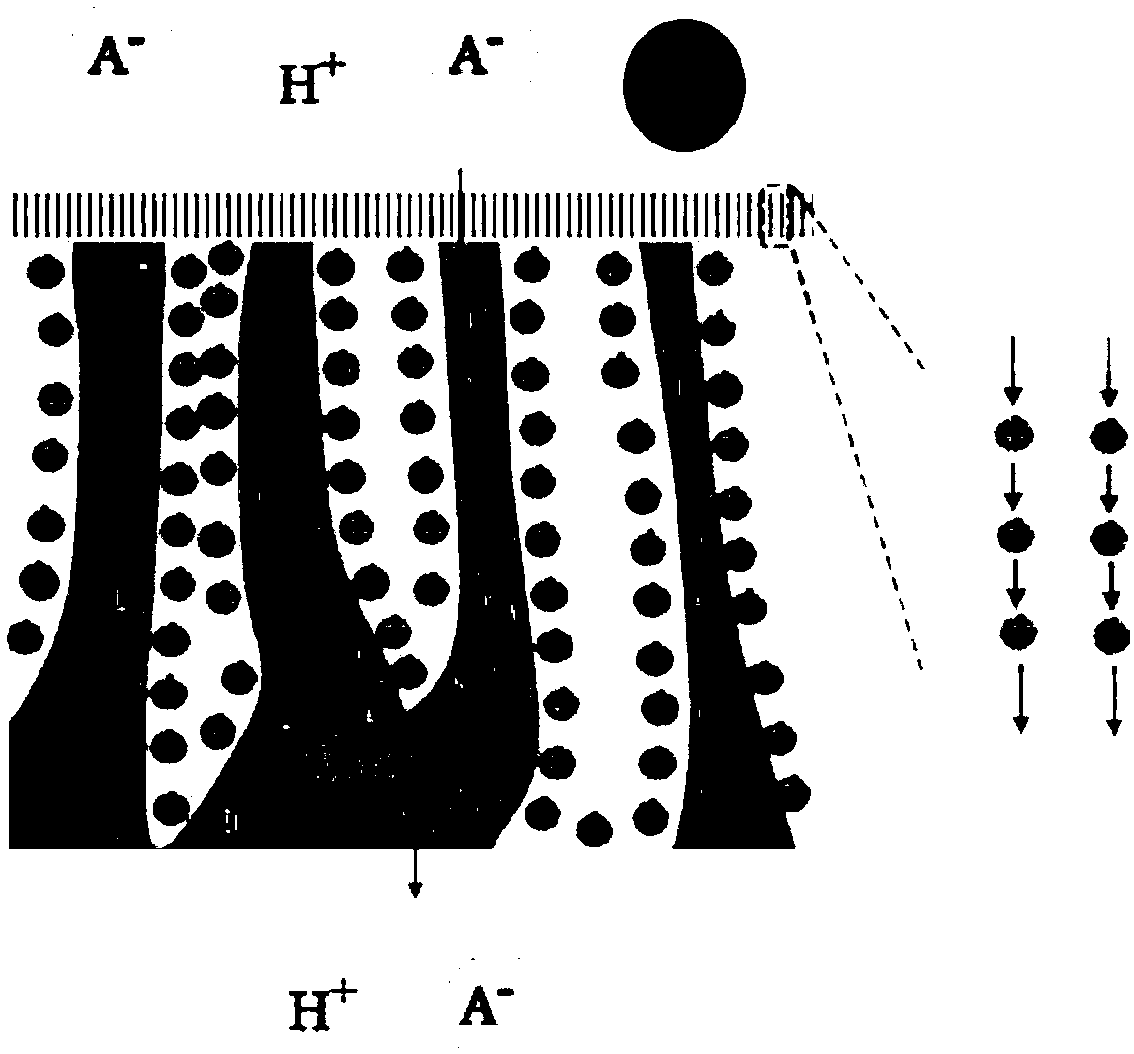

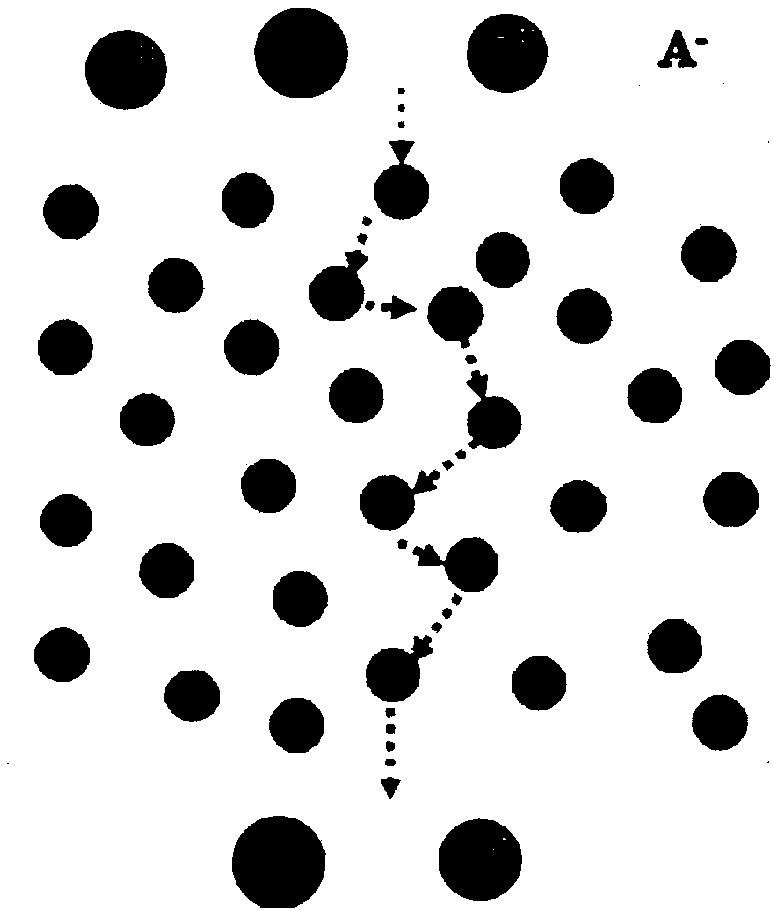

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Example 1 - Fabrication for Anion Exchange Membrane Preparation Using a Single Modification Step

[0074] Commercially available bromomethylated poly(phenylene oxide) (BPPO) was used to prepare the ultrafiltration membranes of the present invention. BPPO is dissolved in N-methyl-2-pyrrolidone to form a casting solution, which is cast on glass through a micron film applicator, and then soaked in distilled water as a coagulation bath to obtain a solution with benzyl bromide Group (-CH 2 Br) ultrafiltration membrane. Then, the ultrafiltration membrane is modified by soaking in N,N,N',N'-tetramethylethylenediamine (TEMED) aqueous solution through a one-step method to obtain the final porous TPPO anion exchange membrane.

[0075] The concentration and thickness of the casting solution, the concentration of TEMED as a bifunctional reagent, the soaking temperature and time of the ultrafiltration membrane in the TEMED solution can be changed to produce asymmetric porous anion...

Embodiment 2

[0079] Example 2 - Fabrication for Anion Exchange Membrane Preparation Using Two-Step Modification

[0080] Commercial bromomethylated poly(phenylene oxide) (BPPO) was used as the starting material for ultrafiltration membrane preparation. It was dissolved in N-methyl-2-pyrrolidone to form a casting solution with a concentration of 30% by weight, which was cast on glass through a micron film applicator whose gap was set to 250 μm, and then soaked in distilled water In order to obtain a benzyl bromide group (-CH 2 Br) ultrafiltration membrane. The ultrafiltration membrane was then modified via a two-step process by immersing in an aqueous solution of butanediamine (BTDA) to obtain a cross-linked BBPPO membrane, which was then further immersed in an aqueous solution of trimethylamine (TMA) to obtain the final Porous BTPPO anion exchange membrane.

[0081] The concentrations of BTDA and TMA aqueous solutions as the first and second functional reagents, respectively, and the im...

Embodiment 3

[0086] Example 3 - Fabrication for Cation Exchange Membrane Preparation Using Two-Step Modification

[0087] Commercial bromomethylated poly(phenylene oxide) (BPPO) was used as the starting material for ultrafiltration membrane preparation. It was dissolved in N-methyl-2-pyrrolidone to form a casting solution with a concentration of 30% by weight, which was cast on glass through a micron film applicator whose gap was set to 250 μm, and then soaked in distilled water In order to obtain a benzyl bromide group (-CH 2 Br) ultrafiltration membrane. The ultrafiltration membrane was then modified via a two-step process by immersing in an aqueous solution of butanediamine (BTDA) to obtain a cross-linked BBPPO membrane, which was further immersed in an aqueous solution of chlorosulfonic acid to obtain the final porous cation exchange membrane.

[0088] The concentrations of BTDA and chlorosulfonic acid aqueous solutions as the first and second functional reagents, respectively, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com