Dye-sensitized solar cell for low light intensities

A solar cell and dye sensitization technology, which is applied in the field of dye-sensitized solar cells for low illumination, can solve the problems of current and voltage drop of dye-sensitized solar cells, reduction of photoelectric conversion efficiency, drop of open circuit voltage and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

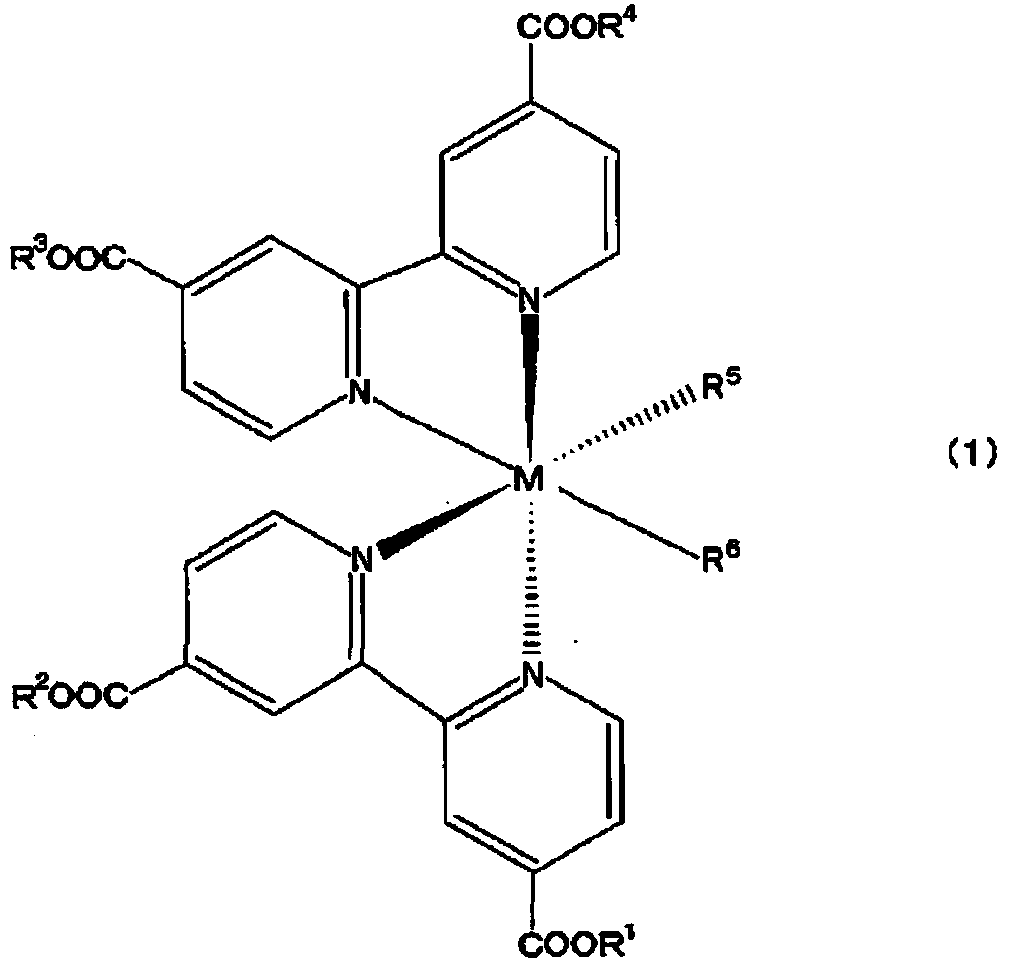

Method used

Image

Examples

Embodiment 1

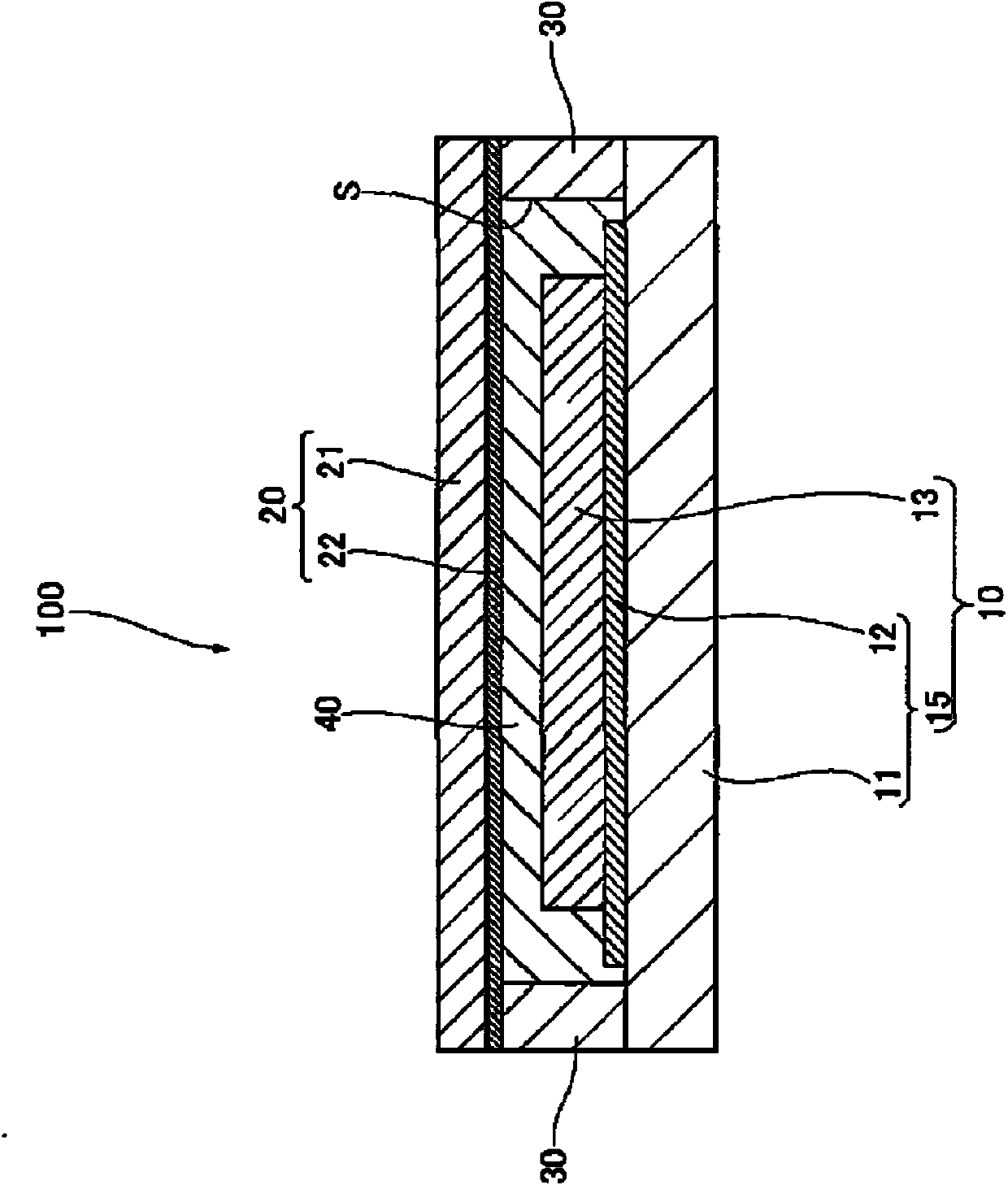

[0216] First, a transparent conductive substrate formed by forming a transparent conductive film made of FTO with a thickness of 1 μm on a transparent substrate made of glass with a thickness of 1 mm was prepared. Then, patterning was performed with a CO2 laser (V-460, a product of Universal System Co., Ltd.) to form four transparent conductive films arranged in a row. By patterning, each of the four transparent conductive films had a rectangular body part of 3 cm x 5 cm, and the interval between the body parts was 0.5 mm. In addition, for 3 transparent conductive films among the 4 transparent conductive films, two protruding parts are respectively formed from the two sides of the main body part, and from the two protruding parts are respectively formed to extend to the adjacent The DSC corresponds to the extension of the position on the side opposite to the side of the main body of the transparent conductive film. At this time, the length of the extending portion in the exte...

Embodiment 2~22 and comparative example 1~6

[0228] In addition to the photosensitizing dye, co-adsorbent 1, co-adsorbent 2 and I 3 - The DSC module was prepared in the same manner as in Example 1, except that the concentration (unit: μM) was changed as shown in Table 1 and Table 2.

Embodiment 23 and 24

[0230] In addition to the photosensitizing dye, co-adsorbent 1, co-adsorbent 2 and I 3 - The DSC module was prepared in the same manner as in Example 1, except that the concentration (unit: μM) was changed as shown in Table 2. At this time, the molar ratio of the co-adsorbent 2 to the co-adsorbent 1 was 3.

[0231] As shown in Table 1 and Table 2, the open voltage Voc at 100 lux and the photoelectric conversion efficiency were measured for the DSC modules obtained in Examples 1 to 24 and Comparative Examples 1 to 6. Here, the photoelectric conversion efficiency η was measured under the conditions of illuminance of 10 lux, 100 lux, 1000 lux, 10000 lux, and 20000 lux, respectively. The results are shown in Table 1 and Table 2.

[0232] As shown in Table 1 and Table 2, for the DSC modules obtained in Examples 1 to 24, under the illuminance of 100 lux (measurement light source is a fluorescent lamp), there is a lower open voltage than the DSC modules obtained in Comparative Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com