Ag-TiO2 composite fiber preparation method

A composite fiber and nanofiber technology, which is applied in fiber processing, spinning solution preparation, fiber chemical characteristics, etc., can solve the problems of lack of control methods, etc., and achieve the effect of simple preparation process, good photoelectric conversion characteristics, and improved photoelectric conversion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] a Ag-TiO 2 (10wt%Ag) the preparation method of composite fiber, comprises the following steps:

[0029] 1) Preparation of precursor solution

[0030] Solution 1: First, add 40 mg of silver nitrate solid into 8 mL of absolute ethanol to dissolve it with magnetic stirring, and prepare a silver nitrate absolute ethanol solution.

[0031] Solution 2: Dissolve 1 mL of tetrabutyl titanate in 1 mL of glacial acetic acid, and stir for 1 h with magnetic force.

[0032] Then solution 1 was added dropwise to solution 2, then 3g of polyvinylpyrrolidone (PVP) was added, stirred magnetically at room temperature for 6h, and then left to stand for a period of time until the bubbles completely disappeared to obtain a brownish-yellow, transparent, uniform electrospun Silk precursor solution.

[0033] 2) Preparation of precursor fibers

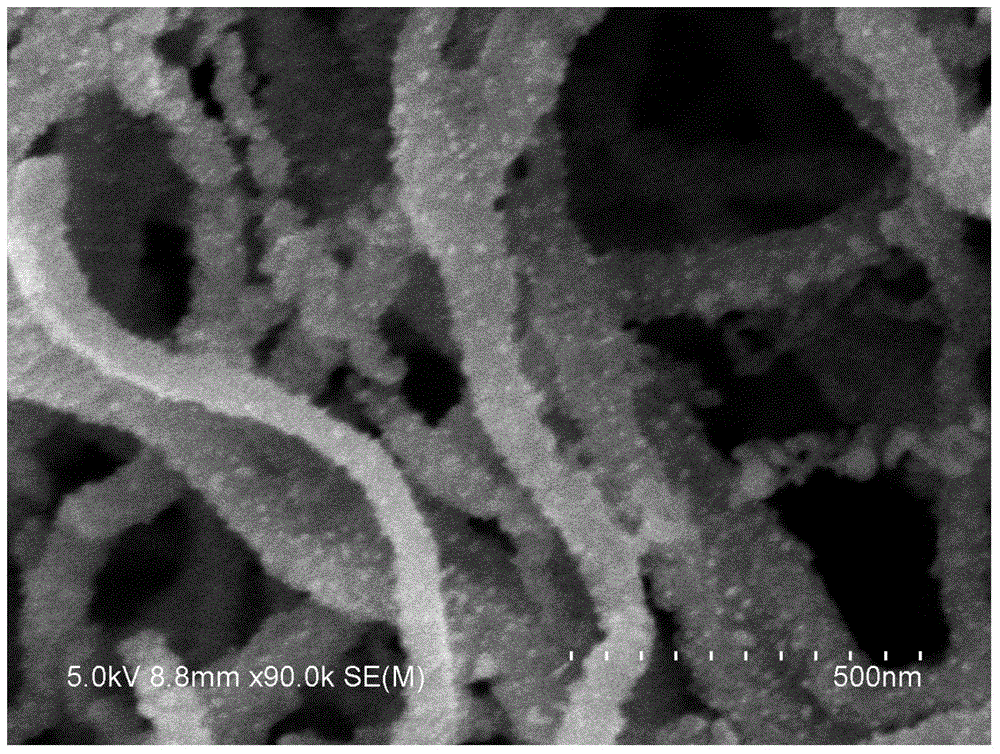

[0034] Prepare silver-doped titanium dioxide nanofibers based on electrospinning technology, transfer the prepared precursor solution into the syring...

Embodiment 2

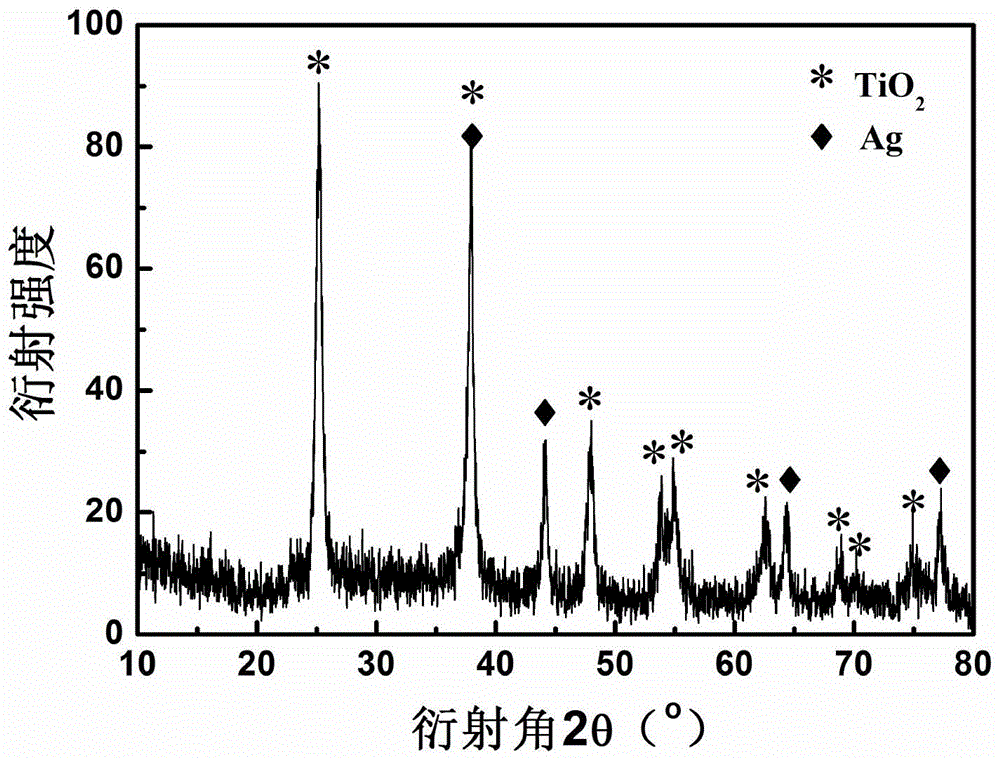

[0038] This embodiment is basically the same as Embodiment 1, the difference is that Ag-TiO 2 Ag deposition in composite fiber: Ag / TiO 2The mass percentages are 5wt% and 30wt%, respectively; the Ag localized surface plasmon resonance can be adjusted by changing the deposition amount of Ag in the composite fiber to enhance the TiO 2 Light absorption ability, and promote the effective separation of photogenerated electrons and holes, improve Ag-TiO 2 Photoelectric conversion efficiency of photovoltaic materials.

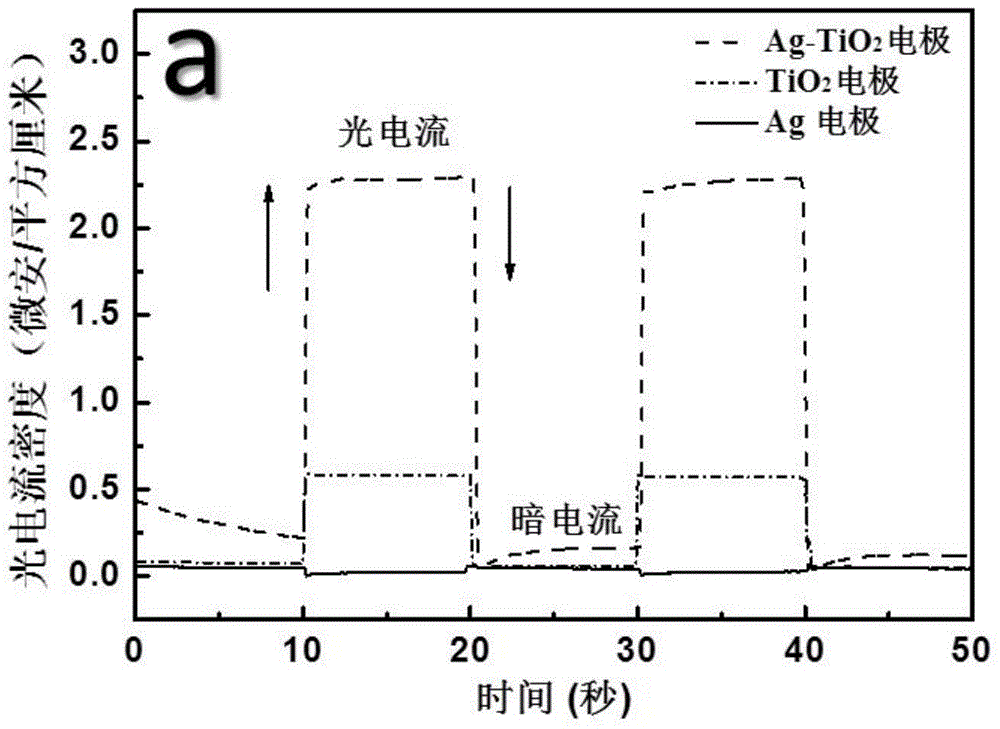

[0039] 4) Photoelectric test

[0040] First, in order to initially reveal the Ag deposition on Ag-TiO 2 The role of semiconductor photoelectric conversion materials, respectively, Ag nanoparticles, TiO 2 Nanofiber, Ag-TiO 2 The composite fiber was modified on the glassy carbon electrode, and the laser at λ=405nm (140mW / cm 2 ) Ag, TiO under irradiation 2 and Ag-TiO 2 The photocurrent response of the modified electrode, such as Figure 3a It can be seen that Ag ...

Embodiment 3

[0042] a Ag-TiO 2 The preparation method of composite fiber, comprises the following steps:

[0043] 1) Preparation of precursor solution

[0044] Solution 1: First, add 40 mg of silver nitrate solid into 10 mL of absolute ethanol with magnetic stirring to dissolve it, and prepare a silver nitrate absolute ethanol solution.

[0045] Solution 2: Dissolve 1 mL of tetrabutyl titanate in 1 mL of glacial acetic acid, and stir for 1 h with magnetic force.

[0046] Then solution 1 was added dropwise to solution 2, then 4g of polyvinylpyrrolidone (PVP) was added, stirred magnetically at room temperature for 8 hours, and then left to stand for a period of time until the bubbles completely disappeared to obtain a brownish yellow, transparent and uniform electrospun Silk precursor solution.

[0047] 2) Preparation of precursor fibers

[0048] Prepare silver-doped titanium dioxide nanofibers based on electrospinning technology, transfer the prepared precursor solution into the syringe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com