Film-forming apparatus and film-forming method for forming passivation film, and manufacturing method of solar cell element

一种成膜方法、钝化膜的技术,应用在电气元件、最终产品制造、可持续制造/加工等方向,能够解决无法充分抑制、损失等问题,达到抑制再结合、抑制损失、膜质好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

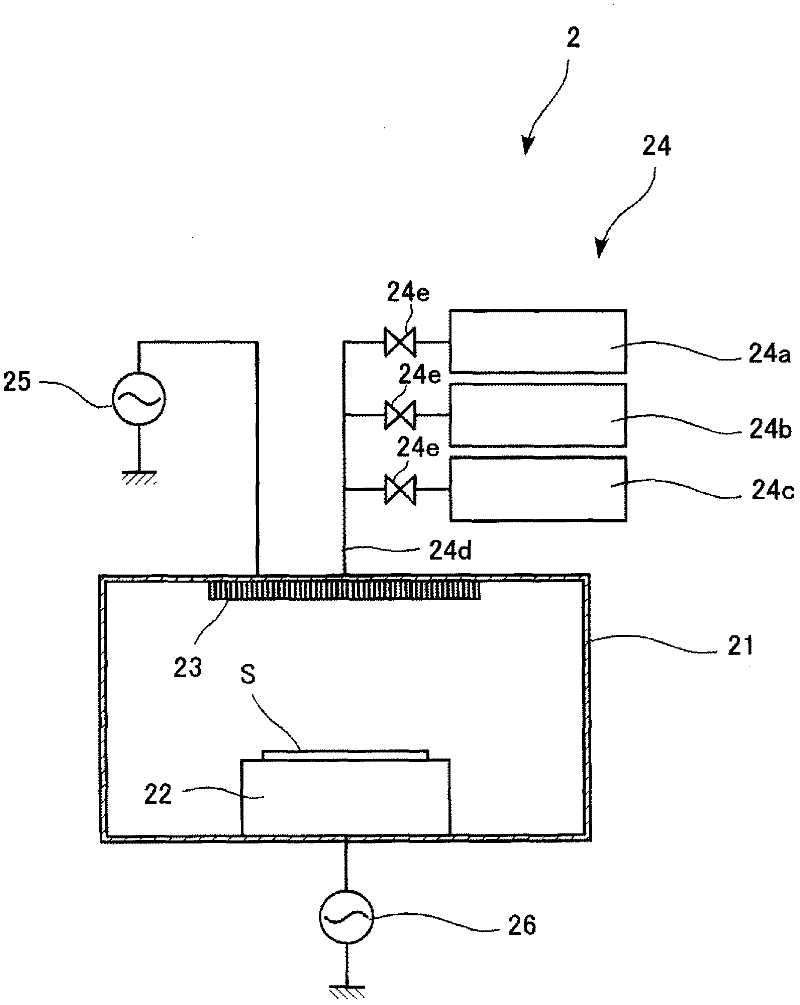

[0047] In this example, use figure 2 The shown film forming apparatus 2 forms a passivation film to fabricate a solar cell element.

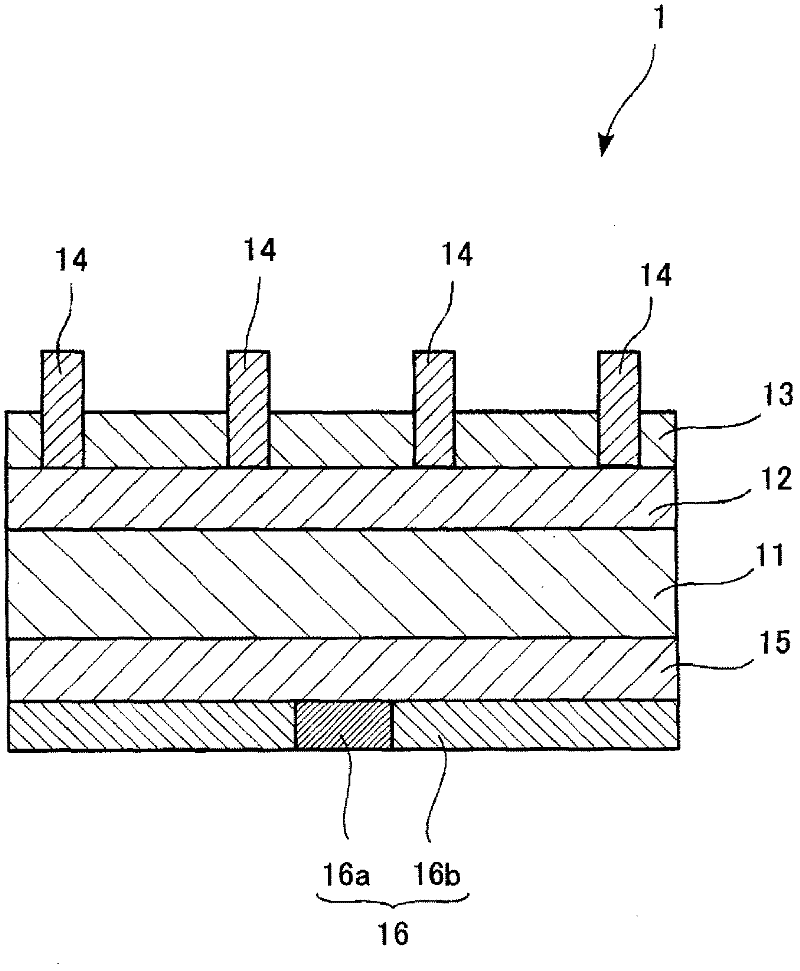

[0048] First, an n-type diffusion layer 12 was formed on the surface of a p-type semiconductor substrate 11 (156 mm×156 mm) made of single-crystal silicon with a thickness of 220 μm in which unevenness was provided on the surface by texture etching. A plurality of these sheets are arranged on a tray to be a film-forming object S.

[0049] Next, at figure 2 The film formation device 2 shown is loaded with the film formation object S, and the following settings are made: substrate temperature: 350°C, SiH 4 Flow: 1500sccm, NH 3 Flow: 5000sccm, N 2 Flow rate: 6000sccm, frequency of high-frequency power supply 25: 13.56MHz, input power of high-frequency power supply 25: 1500W, pressure in vacuum chamber: 100Pa, E / S: 14mm, frequency of low-frequency power supply: 300kHz, input power of low-frequency power supply 26: 500W, and a passivation film...

Embodiment 2

[0053] In this example, the solar cell element 1 was produced under the same conditions as in Example 1 except that the input power of the low-frequency power supply 26 was 1000W.

Embodiment 3

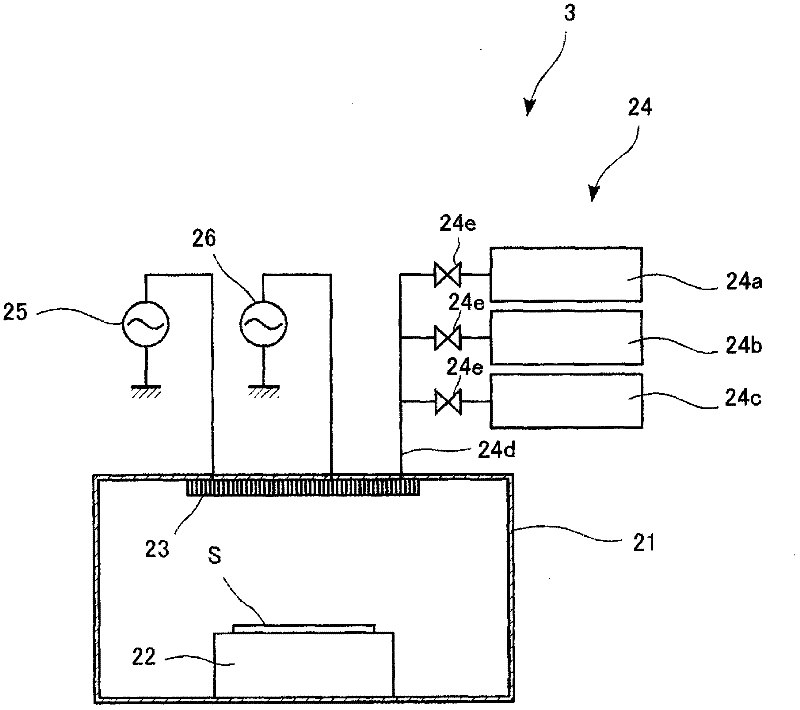

[0055] In this example, in addition to using image 3 The solar cell element 1 was produced under the same conditions as in Example 1 except that the passivation film was formed using the film forming apparatus 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com