Conductive polymer composition, coated article, and patterning process

A conductive polymer and composition technology, applied in the direction of conductive materials, conductive materials, conductive coatings, etc., can solve the problems of uneven liquid quality and difficulty in changing, and achieve the effect of good film forming and excellent antistatic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0169] [Method for producing conductive polymer composition]

[0170] A composite (conductive polymer composite) of component (A) and component (B) can be obtained, for example, by adding a raw material as component (A) to an aqueous solution of component (B) or a water-organic solvent mixed solution Two or more aniline monomers, adding an oxidizing agent and, depending on the situation, an oxidation catalyst, are oxidatively polymerized.

[0171] As the oxidant and oxidation catalyst, peroxodisulfate (persulfate) such as ammonium peroxodisulfate (ammonium persulfate), sodium peroxodisulfate (sodium persulfate), potassium peroxodisulfate (potassium persulfate), etc. ), ferric chloride, ferric sulfate, copper chloride and other transition metal compounds, metal oxides such as silver oxide and cesium oxide, peroxides such as hydrogen peroxide and ozone, organic peroxides such as benzoyl peroxide, oxygen, etc. .

[0172] Water or a mixed solvent of water and a solvent can be us...

Embodiment

[0200] Hereinafter, the present invention will be specifically described using synthesis examples, examples, and comparative examples, but the present invention is not limited thereto.

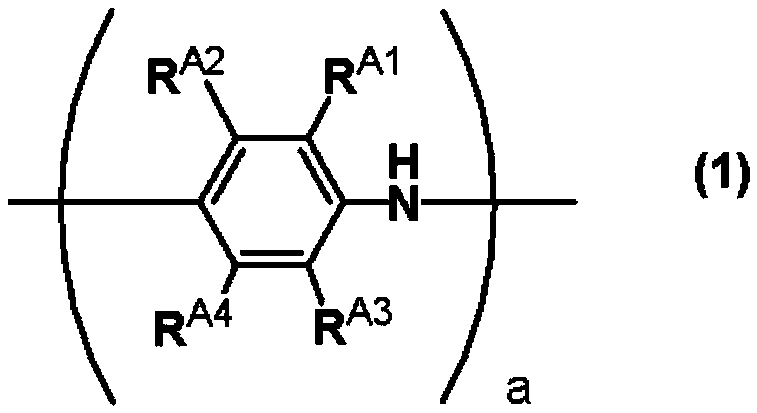

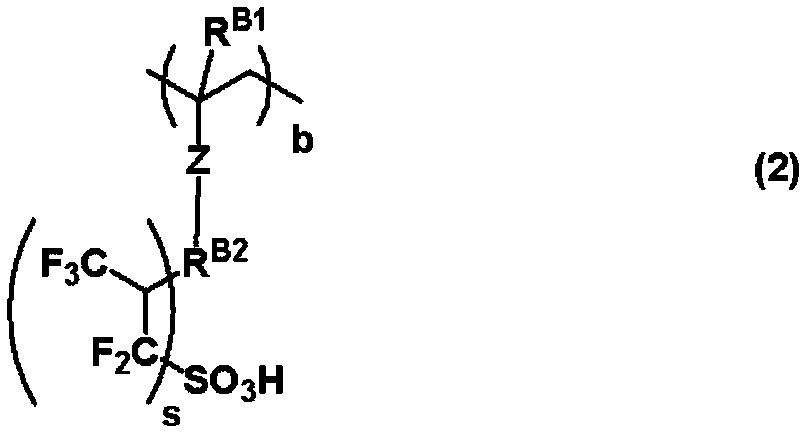

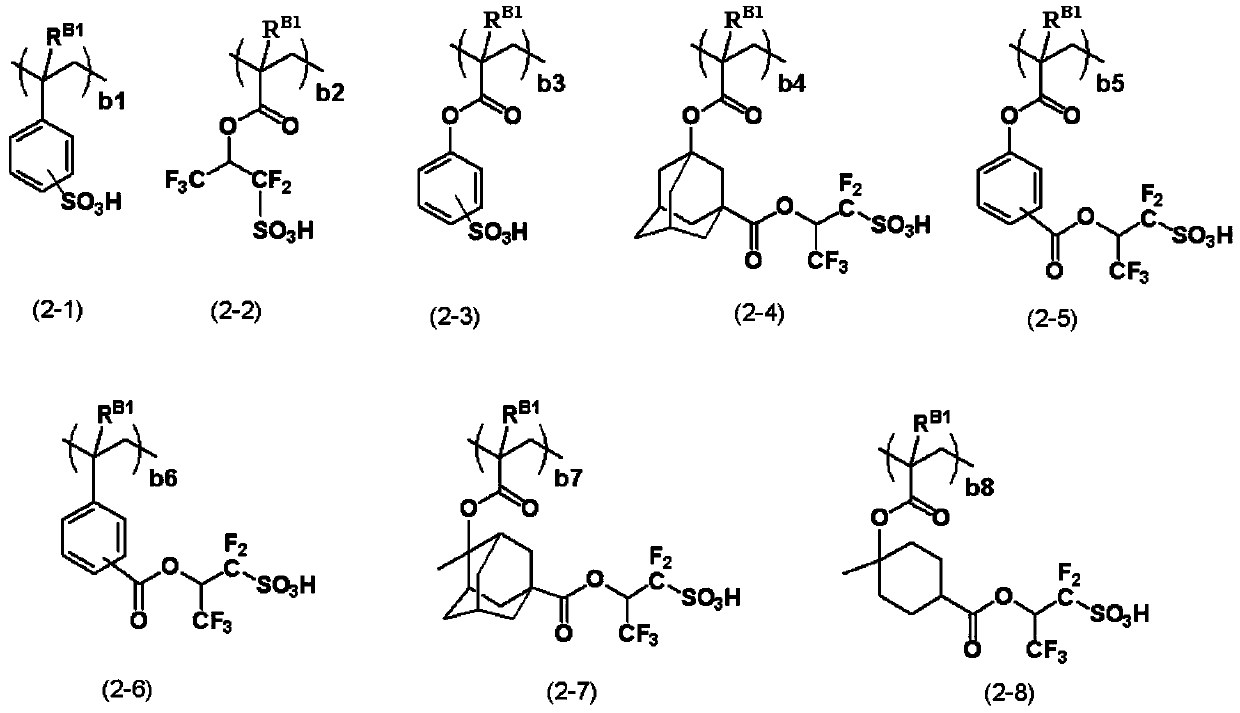

[0201] Hereinafter, monomers providing repeating units constituting the polyaniline-based conductive compound (A) and monomers providing repeating units constituting the dopant polymer component (B) used in Synthesis Examples, Examples, and Comparative Examples will be described. The structure is shown in Table 1 and the names are as follows.

[0202] [Table 1]

[0203]

[0204] A-1: Aniline

[0205] A-2: 2-Methoxyaniline

[0206] A-3: 2-Ethoxyaniline

[0207] B-1: Styrene-4-sulfonic acid

[0208] B-2: 1,1,3,3,3-pentafluoro-2-(4-vinylbenzoyloxy)-propane-1-sulfonate

[0209] B-3: 1,1,3,3,3-Pentafluoro-2-(3-methacryloyloxy-adamantane-1-carbonyloxy)-propane-1-sulfonate

[0210] B-4: 1,1,3,3,3-pentafluoro-2-(3-methacryloyloxy)-propane-1-sulfonate

[0211] B-5: 2-Methyl-acrylic acid-3-hyd...

Synthetic example 1

[0303] At 25°C, 213.8 mmol of (A-1) and 11.3 mmol of (A-2) were mixed in a solution in which 225.0 mmol of dopant polymer 1 was dissolved in 1,000 mL of ultrapure water The solution.

[0304] 202.5 mmol of ammonium persulfate dissolved in 200 mL of ultrapure water was slowly added with stirring while keeping the mixed solution obtained as described above at 0° C., and stirred for reaction.

[0305] The resulting reaction liquid was added dropwise to 4,000 mL of acetone after concentration to obtain a green powder. This green powder was again dispersed in 1,000 mL of ultrapure water, and was added dropwise to 4,000 mL of acetone to purify and recrystallize the green powder. This operation was repeated three times, and the obtained green powder was dispersed again in 2,000 mL of ultrapure water, and about 1,000 mL of water was removed by ultrafiltration. This operation was repeated 10 times to obtain a polyaniline conductive polymer composite 1 . The ultrafiltration condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com