Manufacturing method of shallow trench isolation structure

A technology of isolation structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., and can solve the problem of ineffective removal of exhaustable gases, adverse effects on the performance of active regions, leakage and local area breakdown To achieve the effect of improving the oxygen and nitrogen replacement effect, good filling, and reducing the thermal process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

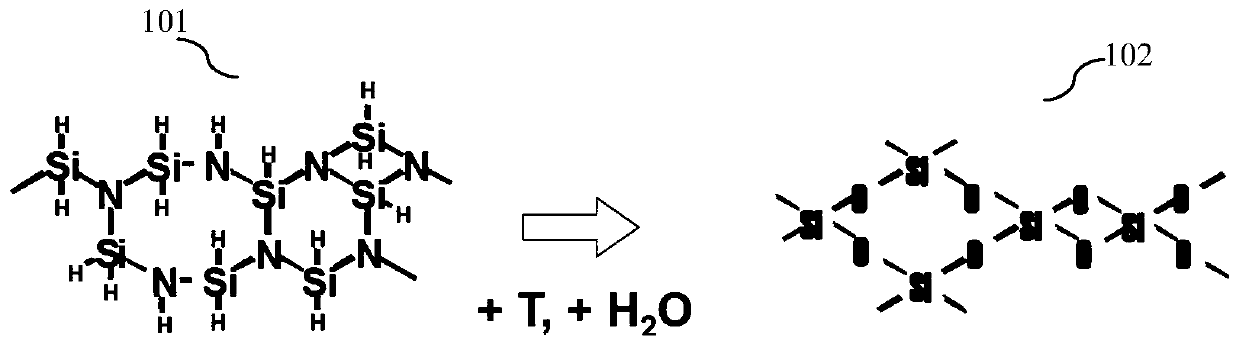

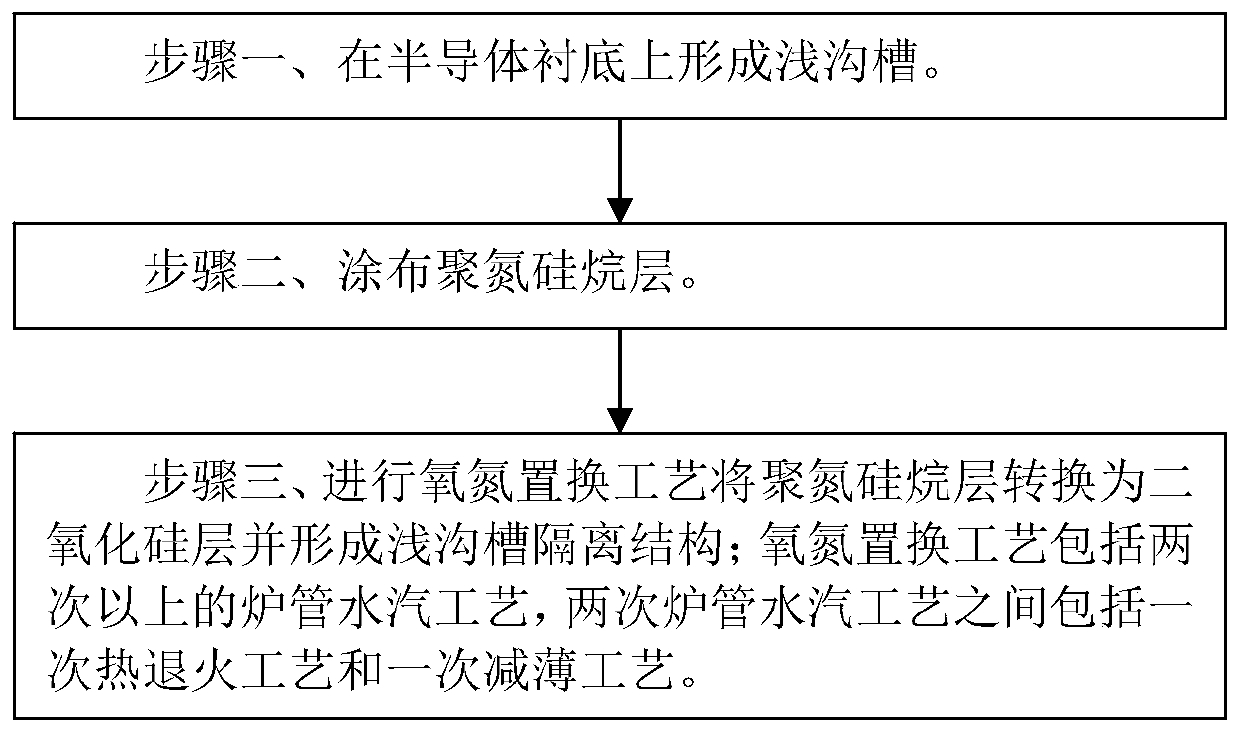

[0038] like figure 2 As shown, it is a flow chart of the manufacturing method of the shallow trench isolation structure according to the embodiment of the present invention. The manufacturing method of the shallow trench isolation structure according to the embodiment of the present invention includes the following steps:

[0039] Step 1, forming a shallow trench on the semiconductor substrate, and the active region is isolated by the shallow trench.

[0040] In an embodiment of the present invention, the semiconductor substrate is a silicon substrate.

[0041] The aspect ratio of the shallow trench is greater than 13. Preferably, the depth of the shallow trench is

[0042] The active area is used to form a NAND flash memory process with a process node below 20nm.

[0043] Step 2, coating a polynitrosilane layer, the polynitrosilane layer completely fills the shallow trench and extends to the surface of the semiconductor substrate outside the shallow trench, the polynitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com