Structure of semiconductor metal capacitor and etching method

A metal capacitor and semiconductor technology, which is applied to the etching of semiconductor metal capacitors and the structure of semiconductor metal capacitors, can solve the problems of inability to achieve large-capacity capacitors, large dielectric coefficient of nitride films, and many pinholes in nitride films. Achieve the effect of simple and easy etching method, large dielectric coefficient and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

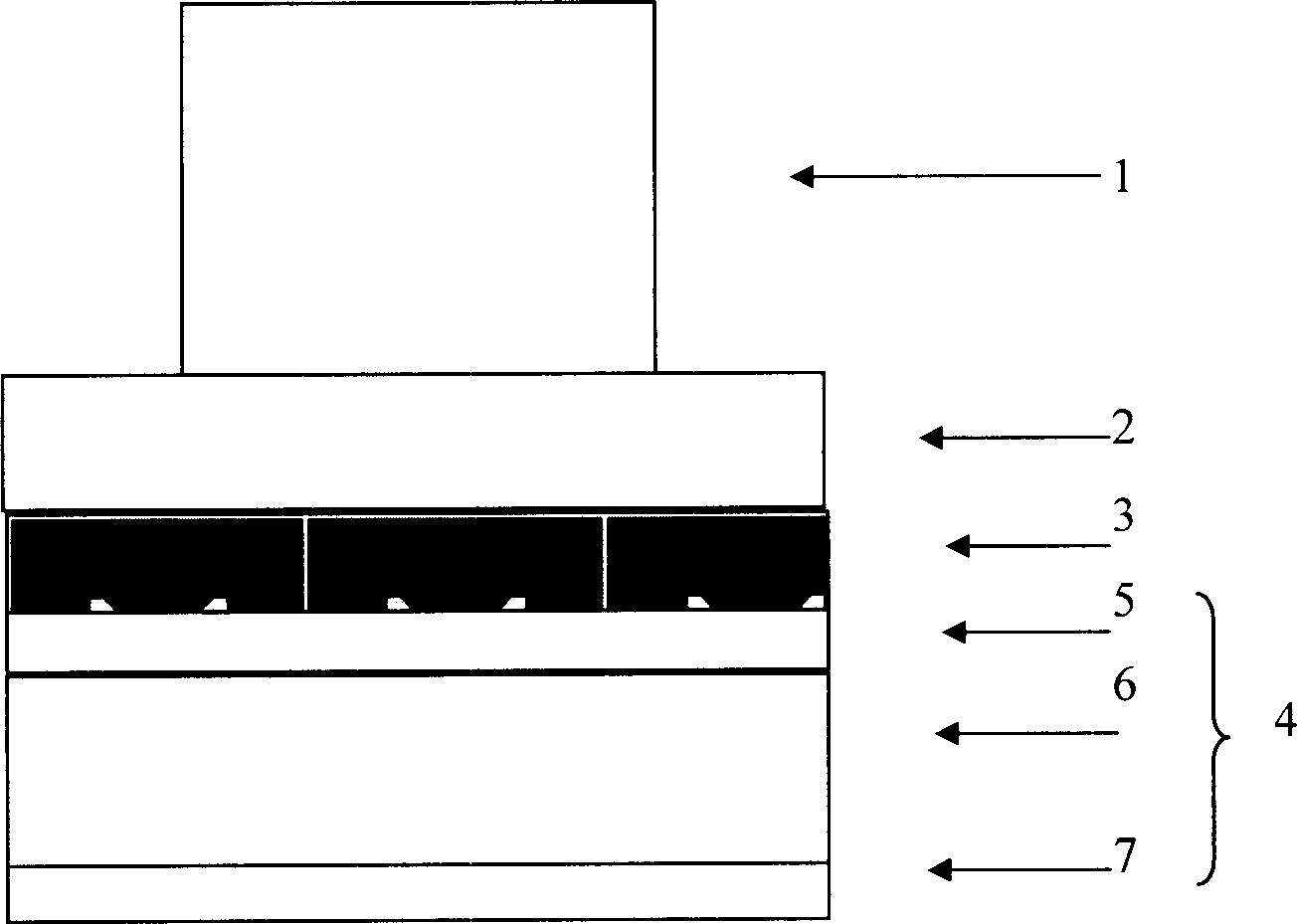

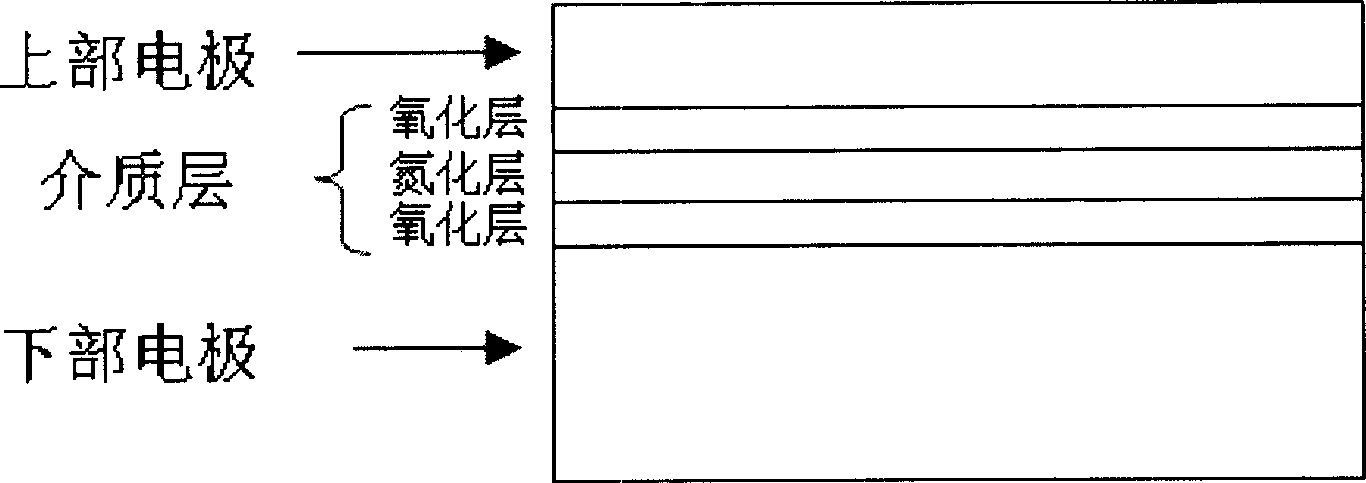

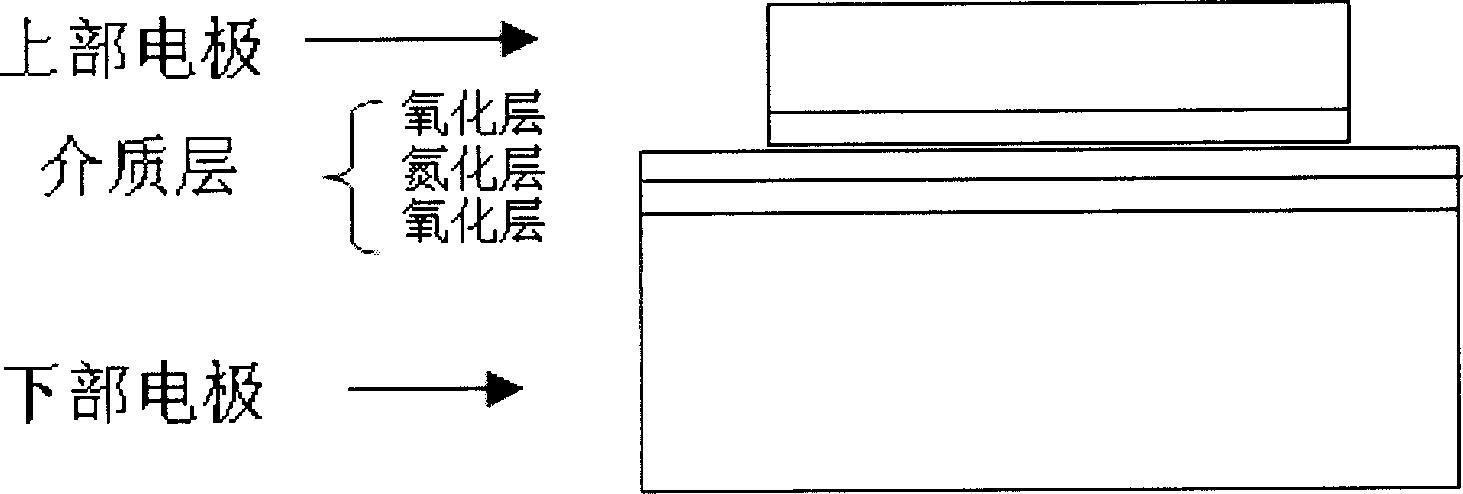

[0013] Such as figure 2 Therefore, a semiconductor metal capacitor of the present invention includes a lower electrode, a dielectric layer and an upper electrode from bottom to top, and the dielectric layer includes an oxide film layer, a nitride film layer and another oxide film layer from bottom to top. film layer. The capacitor structure uses a composite layer composed of oxide film and nitride film as the dielectric layer, so that the semiconductor metal capacitor not only retains the advantages of good oxide film quality, less pinholes, and large dielectric coefficient of the nitride film, but also overcomes the advantages of the oxide film. Small dielectric coefficient and many pinholes in the nitride film can easily cause leakage.

[0014] The present invention also includes an etching method for realizing the above-mentioned semiconductor metal capacitor structure, the steps of which include firstly etching off the upper electrode, and then using the condition of an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com