Production method for semiconductor device, production device for semiconductor device, and storage medium

A manufacturing method and manufacturing device technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., to achieve the effect of improving film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

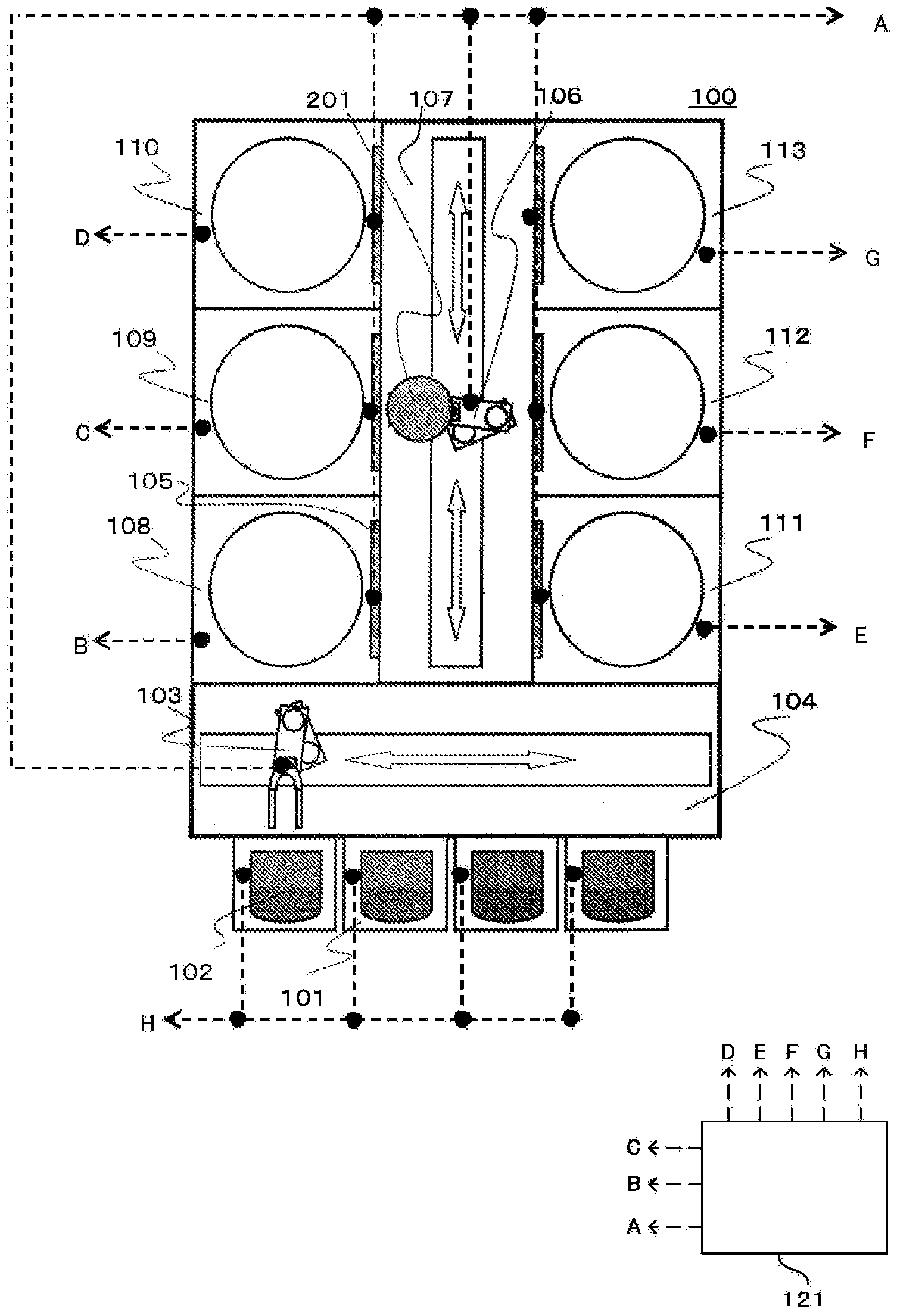

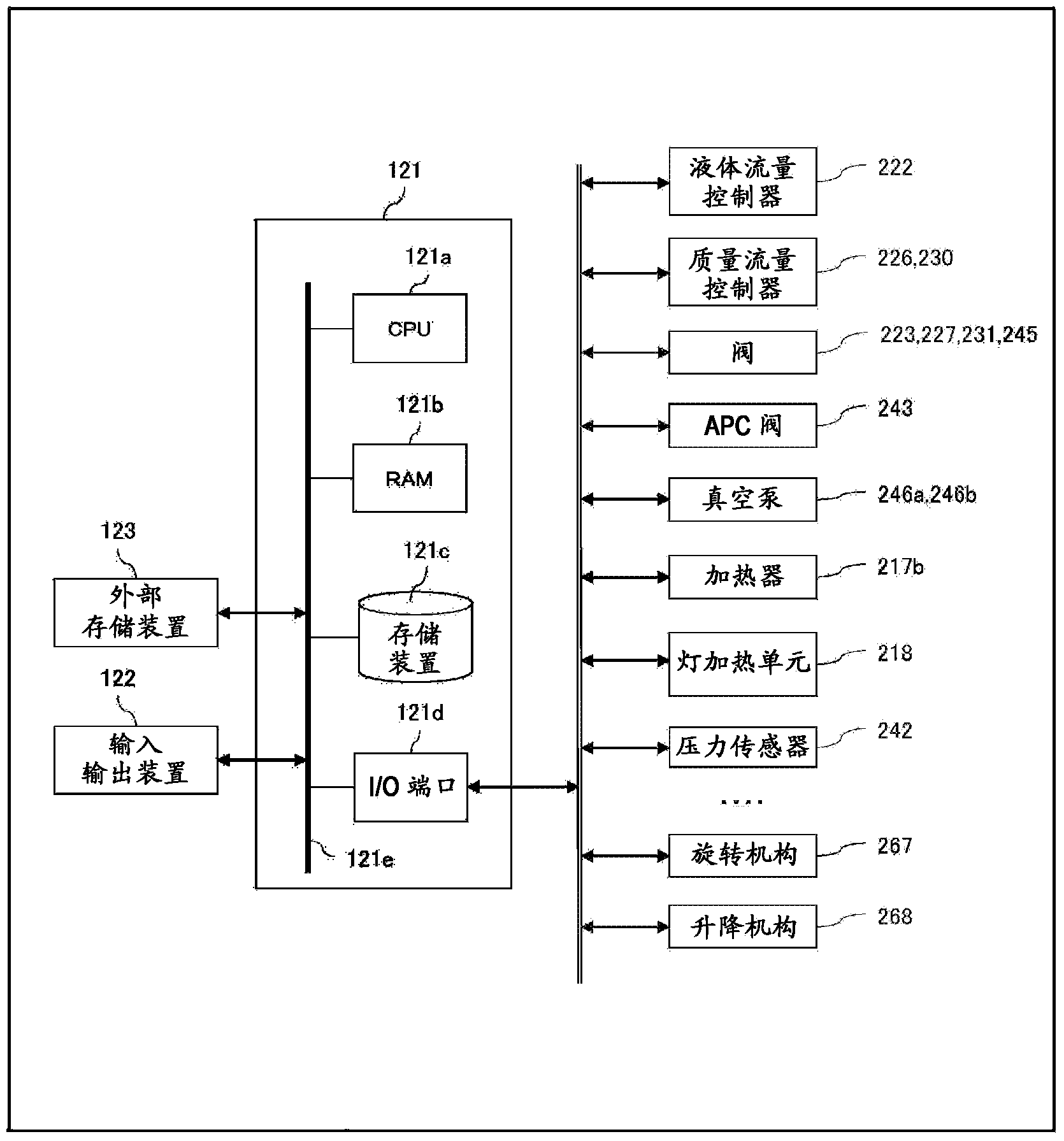

[0195] Next, while referring to Figure 14 ~ Figure 16 Embodiments of the present invention will be described.

[0196] In this embodiment, a wafer 201 having a silicon-containing film containing polysilazane is used. The film thickness of the silicon-containing film was 600 nm. First, a curing treatment (pre-baking treatment) is performed on a wafer 201 having a silicon-containing film (Example 1).

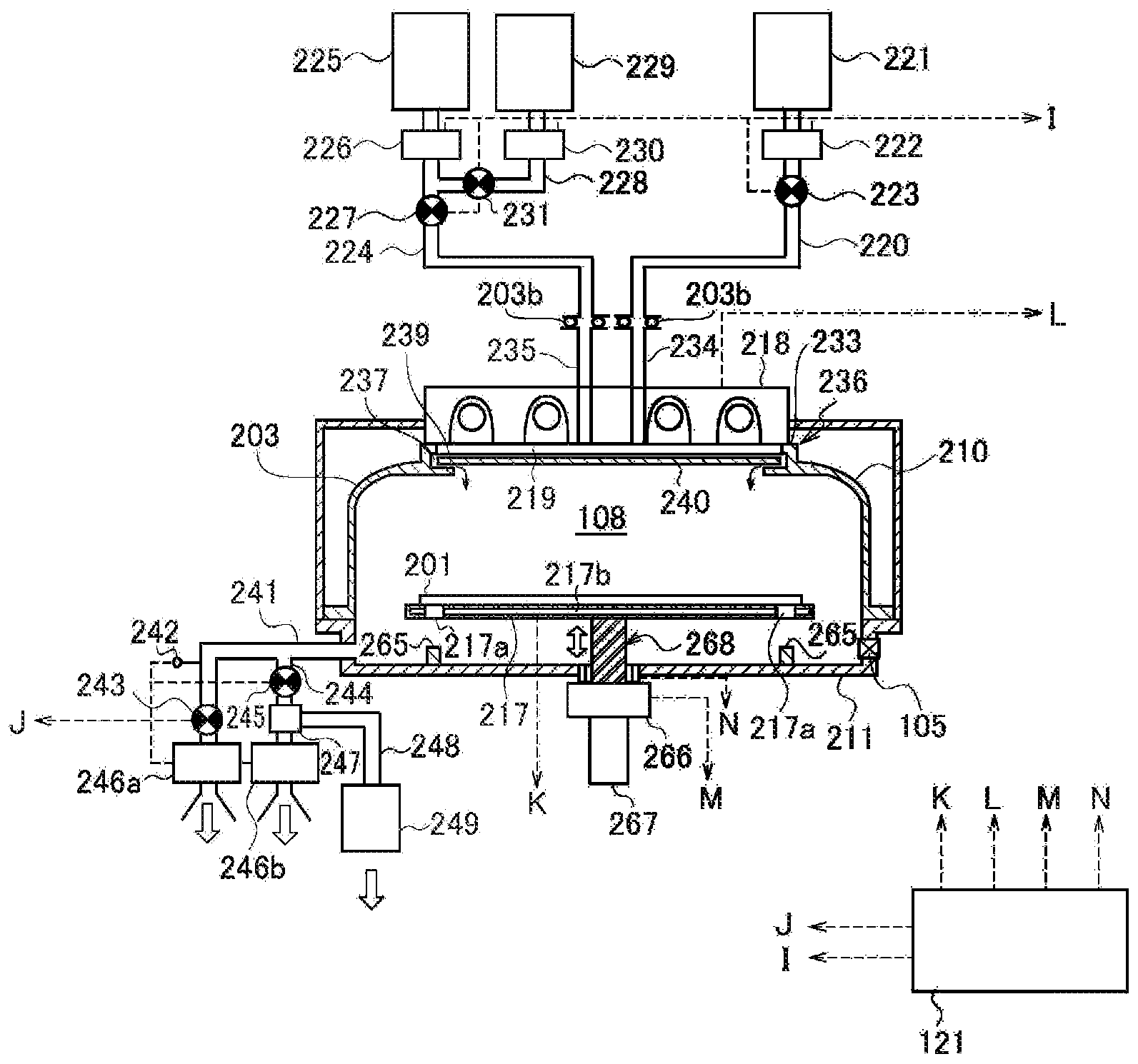

[0197] In addition, the cured wafer 201 (wafer 201 of Example 1) having a silicon-containing film was subjected to oxidation treatment (hydrogen peroxide treatment, atmospheric pressure peroxidation treatment) in the treatment chamber 108 at 50° C. and atmospheric pressure. hydrogen water treatment) (embodiment 2). In addition, in the oxidation treatment, hydrogen peroxide water having a hydrogen peroxide concentration of 30 wt % was used as an oxidizing agent solution, and was performed for 30 minutes.

[0198] In addition, pure water treatment was performed by supplying pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com