Film deposition apparatus

A film-forming device and film-forming technology, applied in gaseous chemical plating, coating, metal material coating process, etc., can solve problems such as undocumented problems and their solutions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

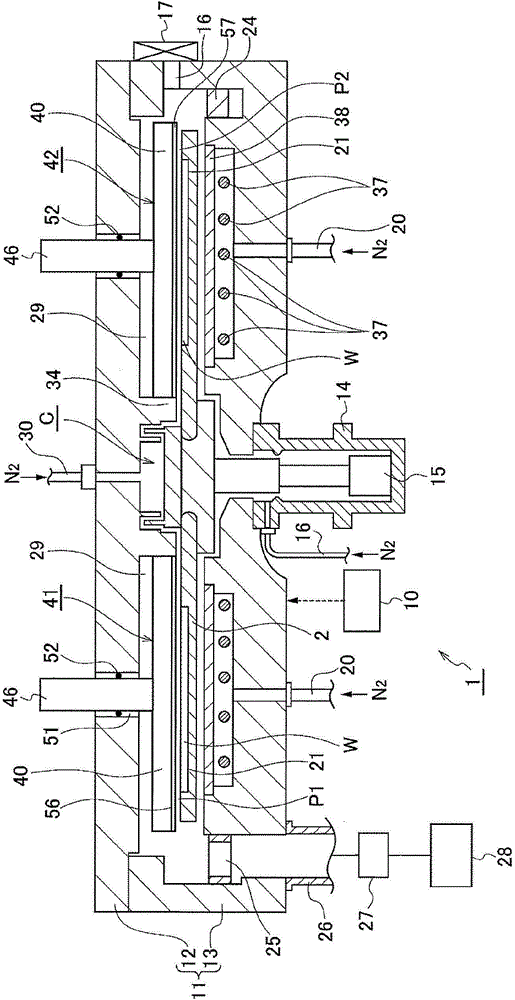

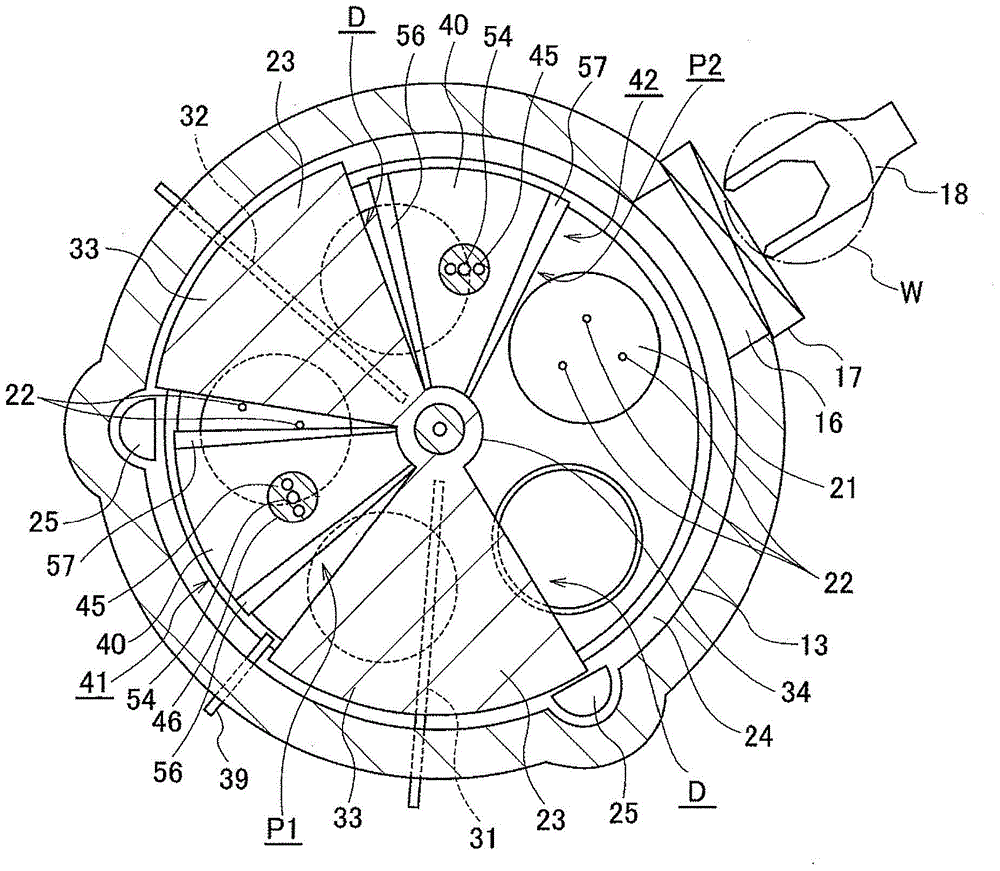

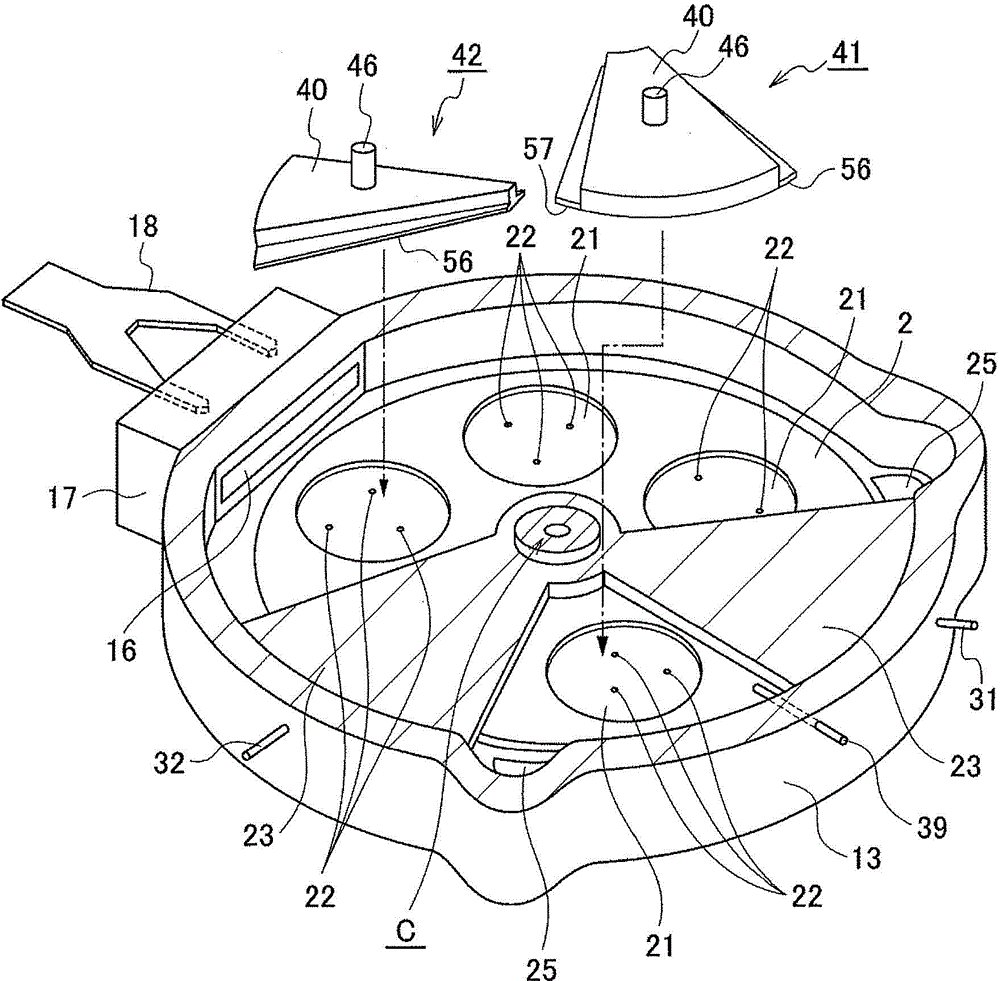

[0022] while referring to Figure 1 ~ Figure 3 A film forming apparatus 1 for performing an ALD process on a wafer W serving as a substrate, which is a film forming apparatus according to an embodiment of the present invention, will be described. figure 1 is a longitudinal sectional side view of the film forming apparatus 1, figure 2 is a schematic perspective view showing the inside of the film forming apparatus 1, image 3 It is a cross-sectional plan view of the film forming apparatus 1 . The film forming apparatus 1 includes a substantially circular flat vacuum container (processing container) 11 , and a disk-shaped horizontal turntable 2 installed in the vacuum container 11 . The vacuum vessel 11 is constituted by a top plate 12 and a vessel main body 13 which forms side walls and a bottom of the vacuum vessel 11 . like figure 1 As shown in , a cover 14 for closing the lower central portion of the container main body 13 is provided.

[0023] The turntable 2 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com