Nitride semiconductor light emitting element

A technology of nitride semiconductors and light-emitting elements, which is applied in the direction of semiconductor devices, semiconductor lasers, and electrical components, and can solve problems such as complex manufacturing processes, reduced luminous output, and increased resistance of electrode connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

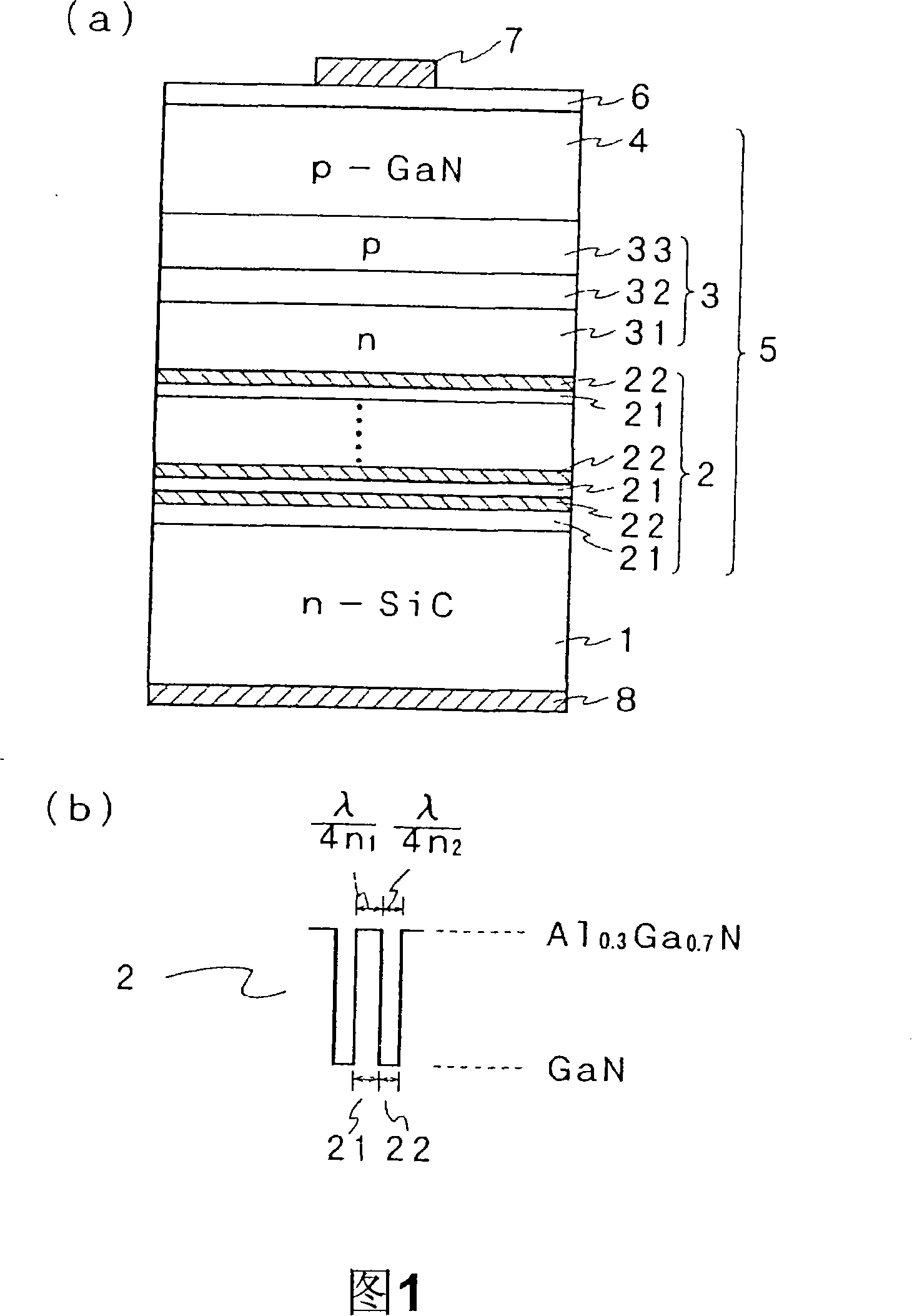

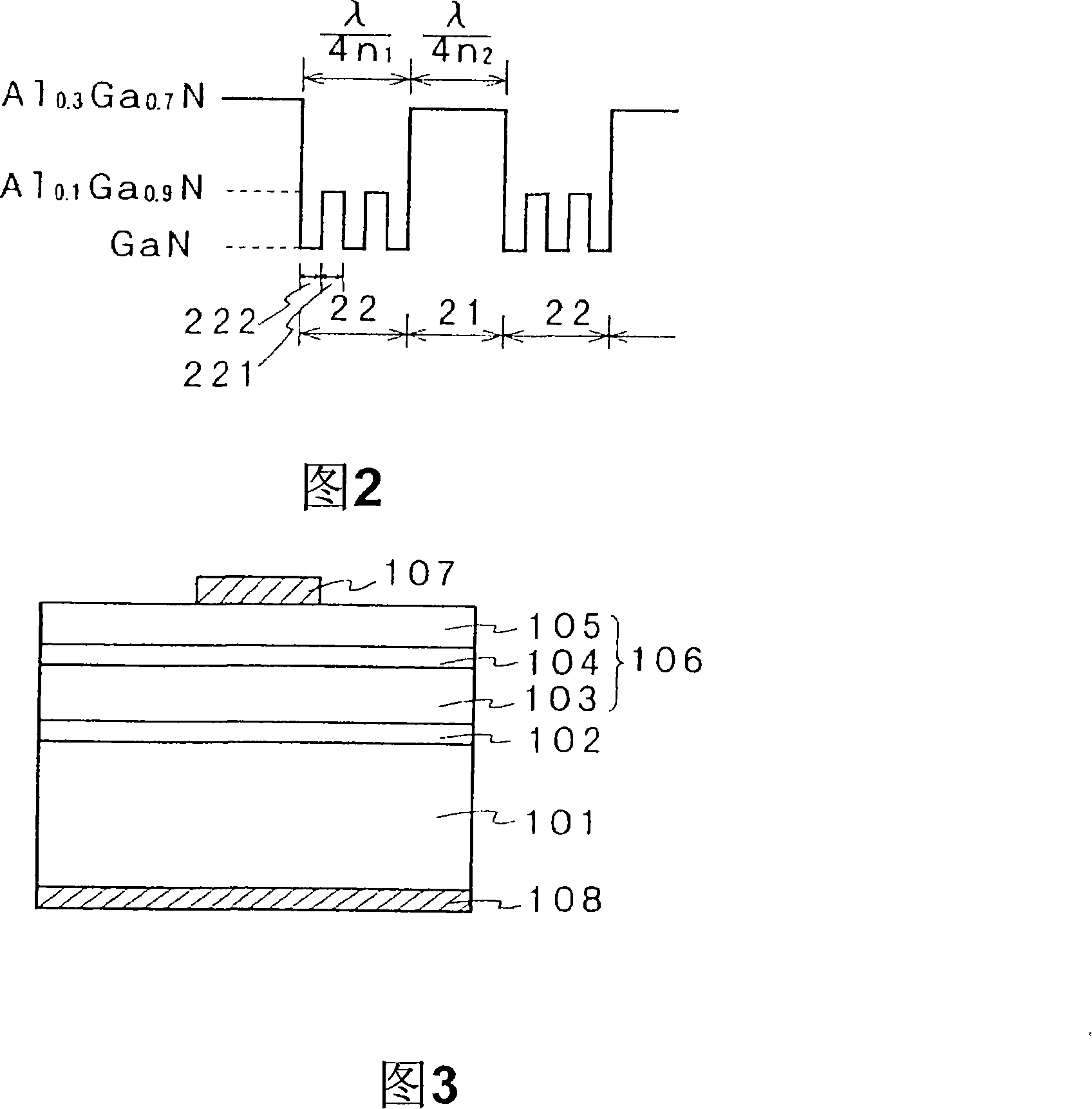

[0033] Next, the nitride semiconductor light-emitting device of the present invention will be described with reference to the drawings. The nitride semiconductor light-emitting element of the present invention, an explanatory cross-sectional view of one embodiment thereof and an energy band diagram of the light reflection layer are shown in FIG. The light reflection layers 2 are laminated alternately with the high refractive index layers 22 , and on the light reflection layers 2 are provided semiconductor lamination portions 5 in which nitride semiconductor layers are laminated so as to have at least the light emitting layer formation portion 3 . It is formed by providing the upper electrode 7 on the upper surface side of the semiconductor laminated portion 5 and the lower electrode 8 on the back surface of the SiC substrate 1 .

[0034] SiC substrate 1 uses a single crystal silicon carbide substrate, and is formed in n-type in the example shown in FIG. 1 . A light reflection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com