Plasma treatment apparatus

A processing device and plasma technology, applied in the directions of plasma, gaseous chemical plating, coating, etc., can solve the problems of poor substrate processing uniformity, poor plasma density distribution uniformity, and film quality degradation, etc., and achieve uniformity. The effect of improving the uniformity of film thickness distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

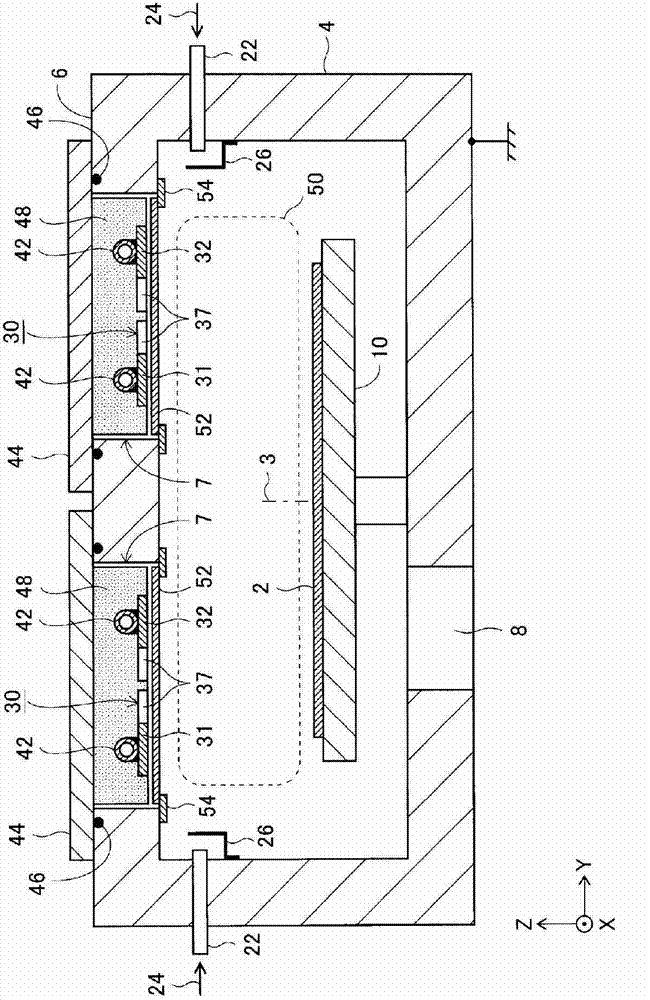

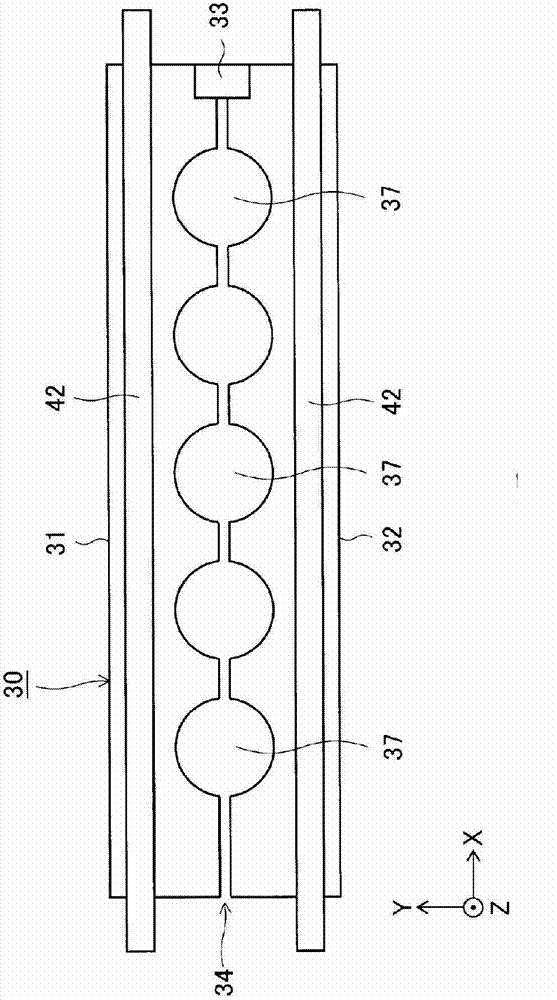

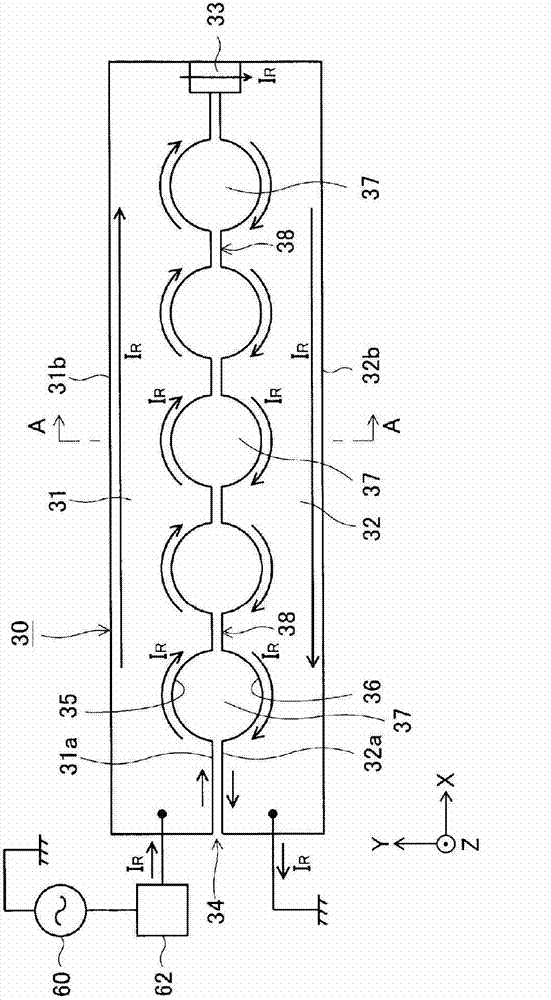

[0097] figure 1 One embodiment of the plasma processing apparatus of the present invention is shown, and one antenna 30 of the plasma processing apparatus is separated and shown in Figure 2 ~ Figure 4 . exist figure 1 , figure 2 In other figures, cooling pipes are omitted for simplification of illustration. The same applies to other embodiments described later.

[0098] In order to show the orientation of the antenna 30 and the like, the X direction, the Y direction, and the Z direction that are perpendicular to each other at one point are marked in each figure. The Z direction is a direction parallel to the vertical line 3 erected on the surface of the substrate 2, and the Y direction is a direction perpendicular to the vertical line 3. In order to simplify the expression, the directions are respectively referred to as the up-down direction Z and the left-right direction Y. . The X direction is a direction perpendicular to the vertical line 3 and is the longitudinal d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com