Patents

Literature

75 results about "Plasma density distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

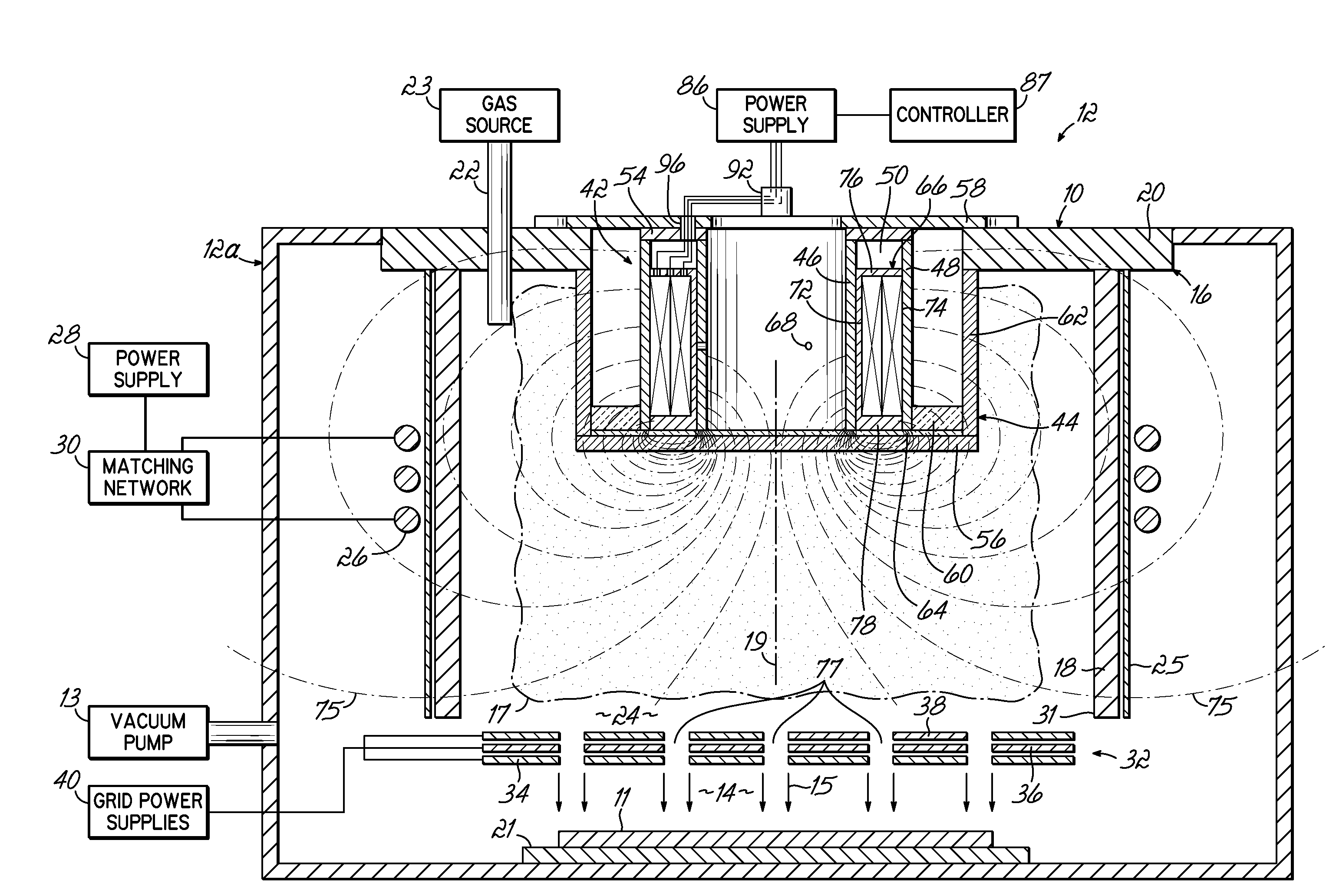

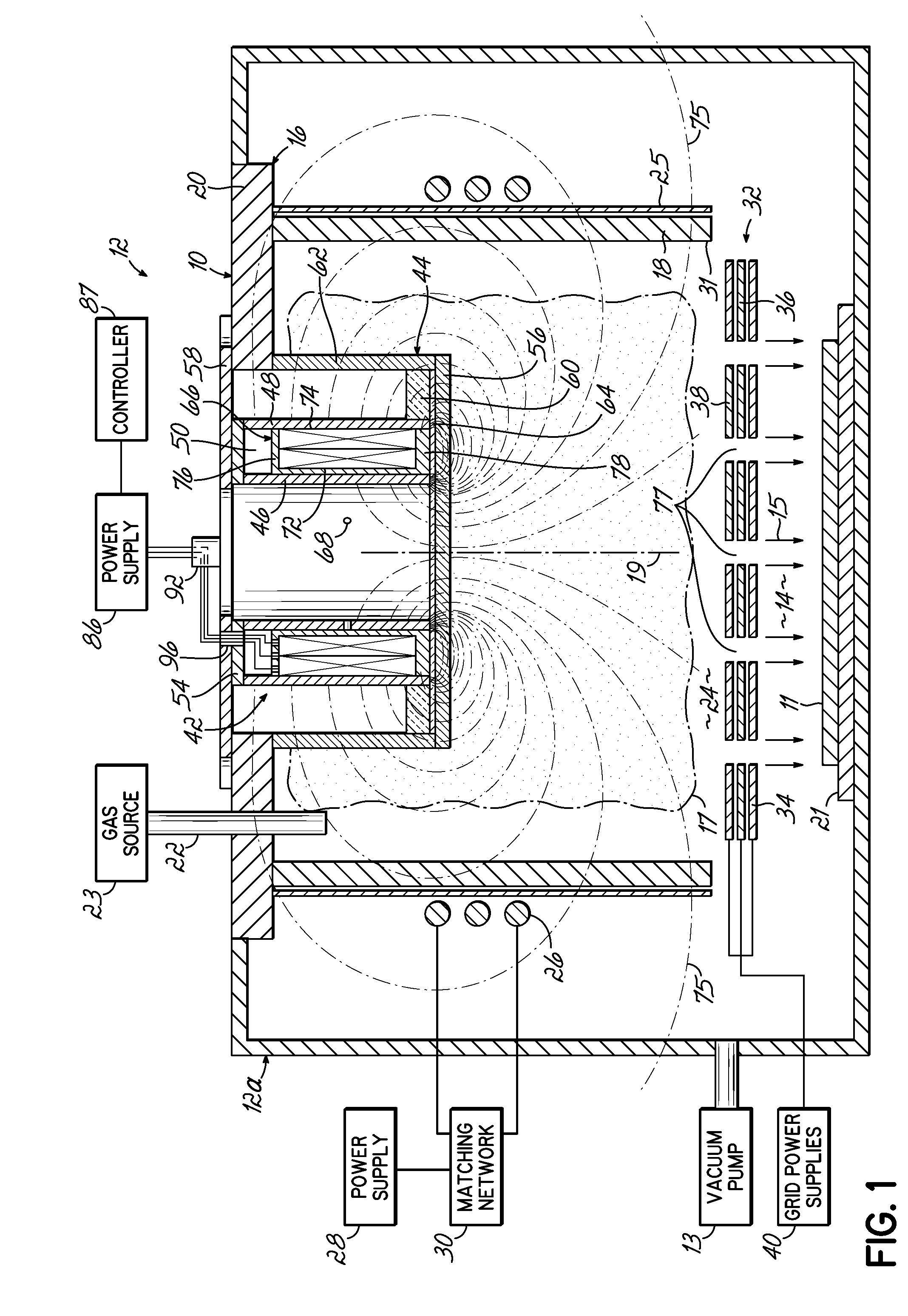

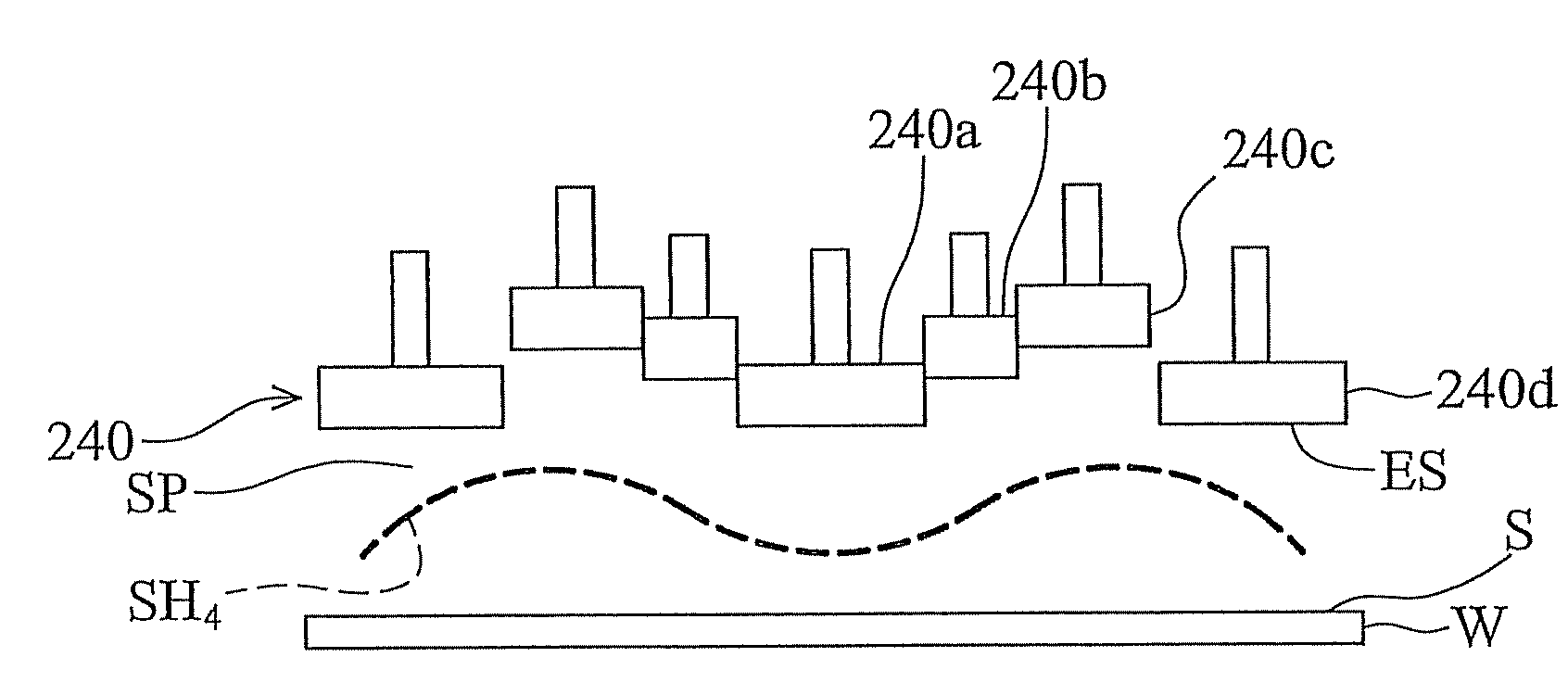

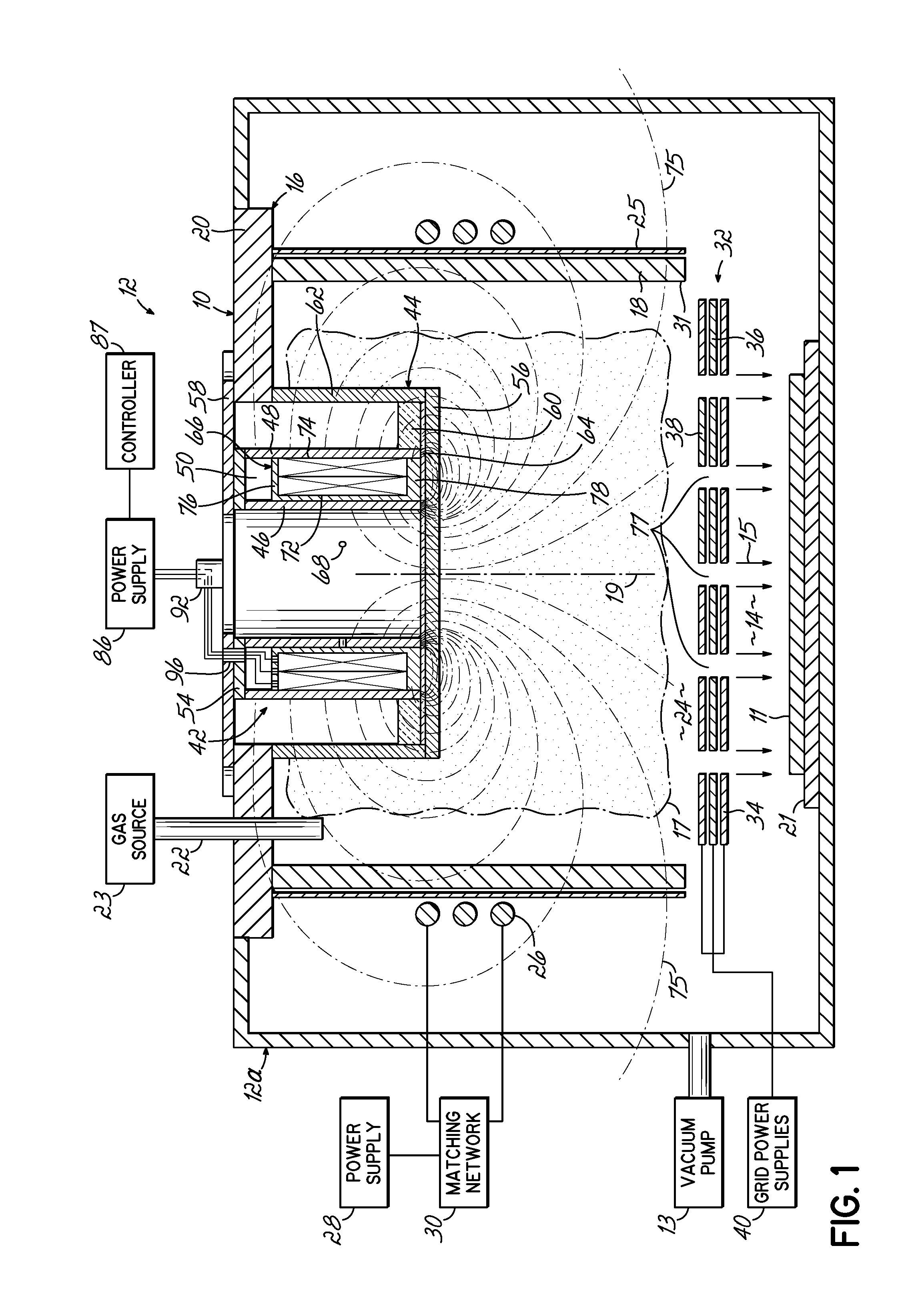

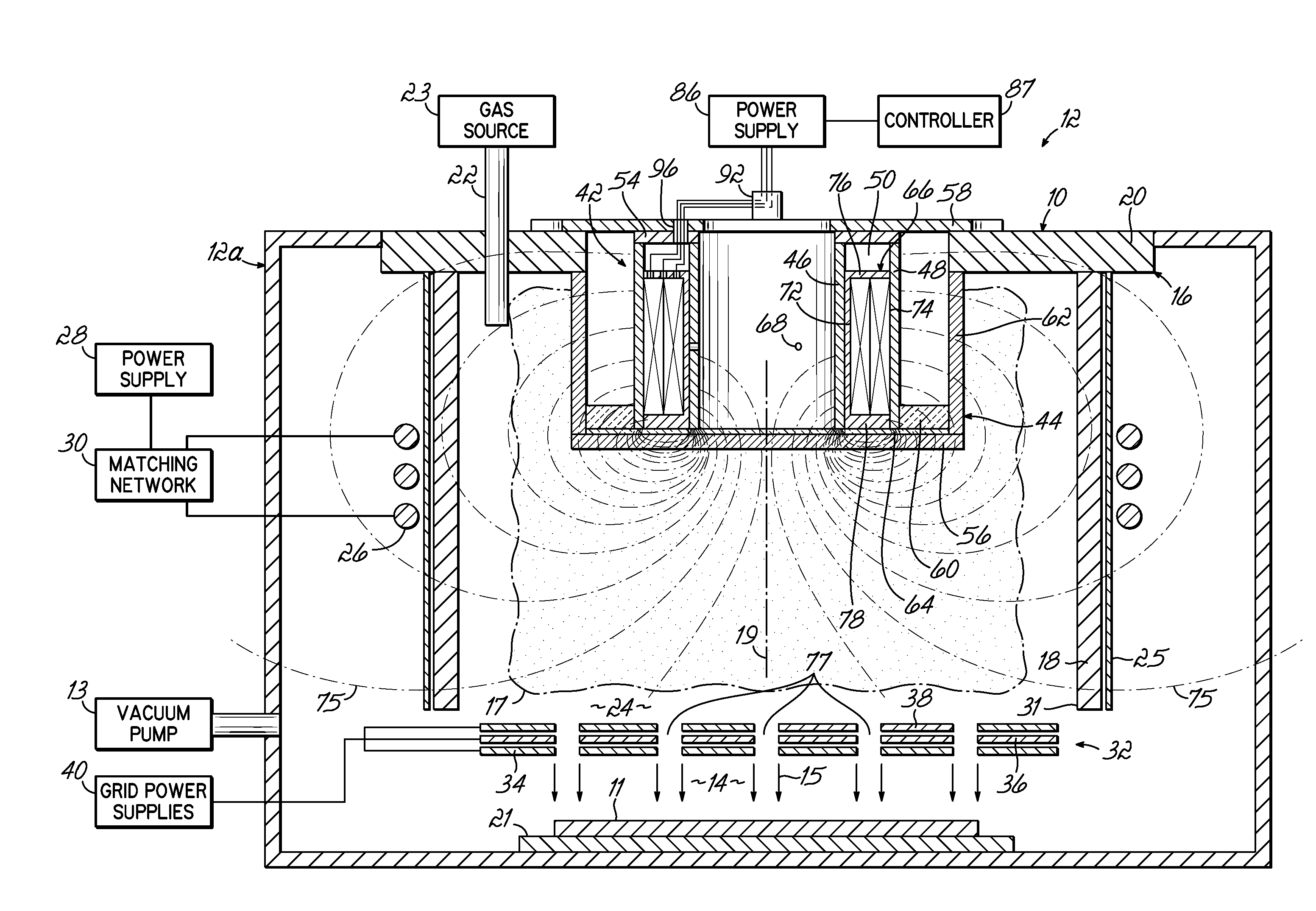

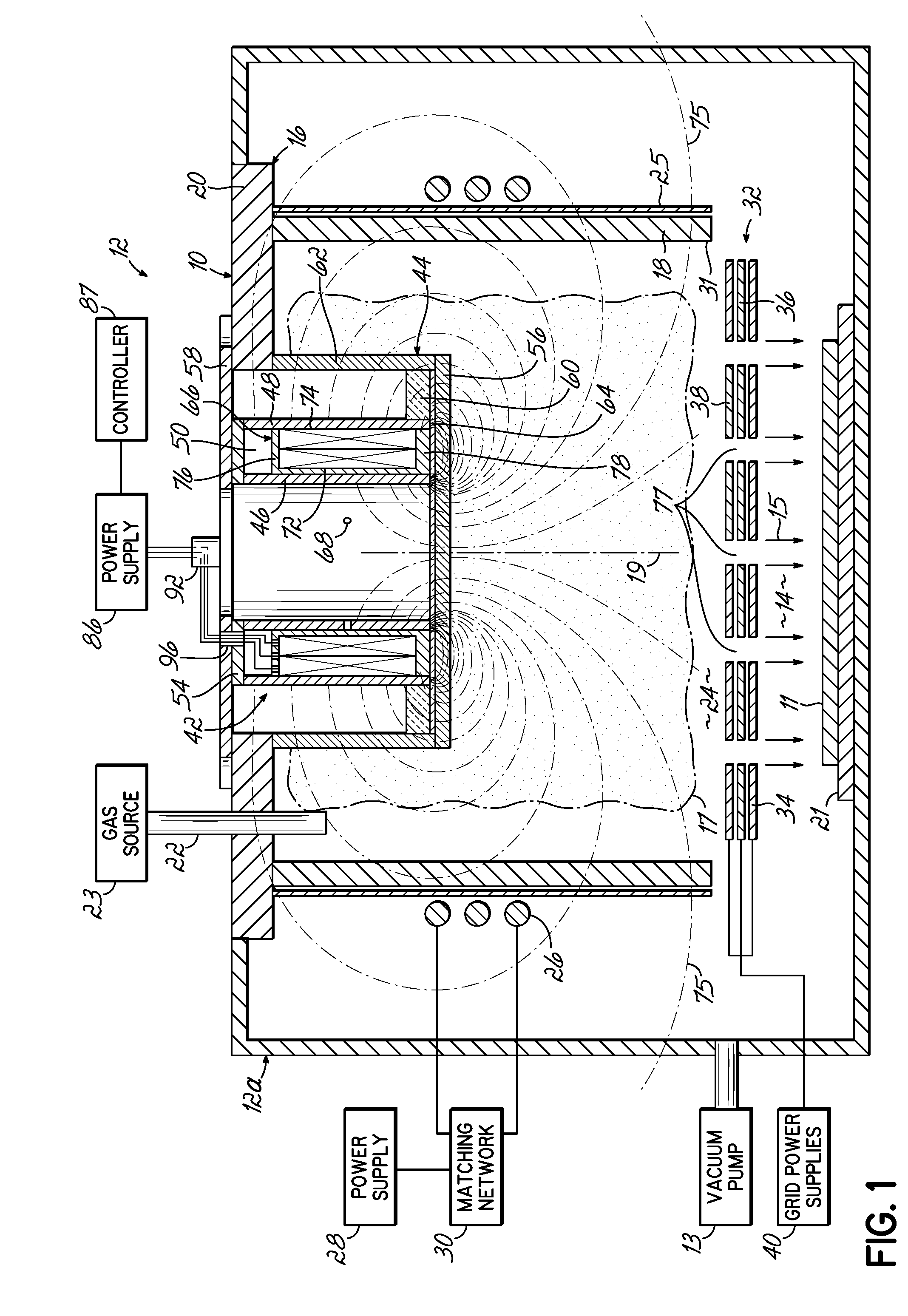

Adjustable electrodes and coils for plasma density distribution control

InactiveUS20080083710A1Electric discharge tubesSemiconductor/solid-state device manufacturingSemiconductorPlasma density distribution

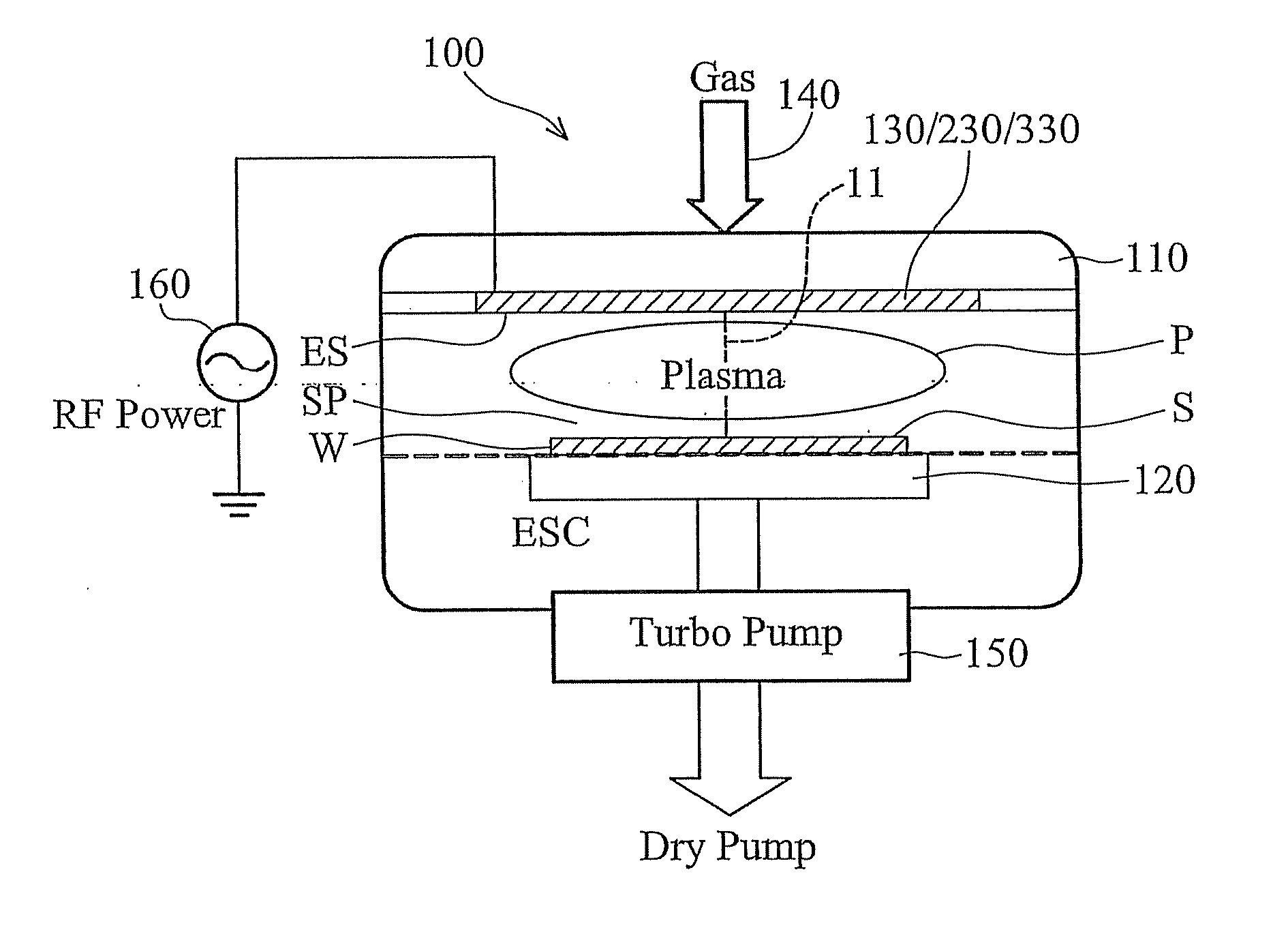

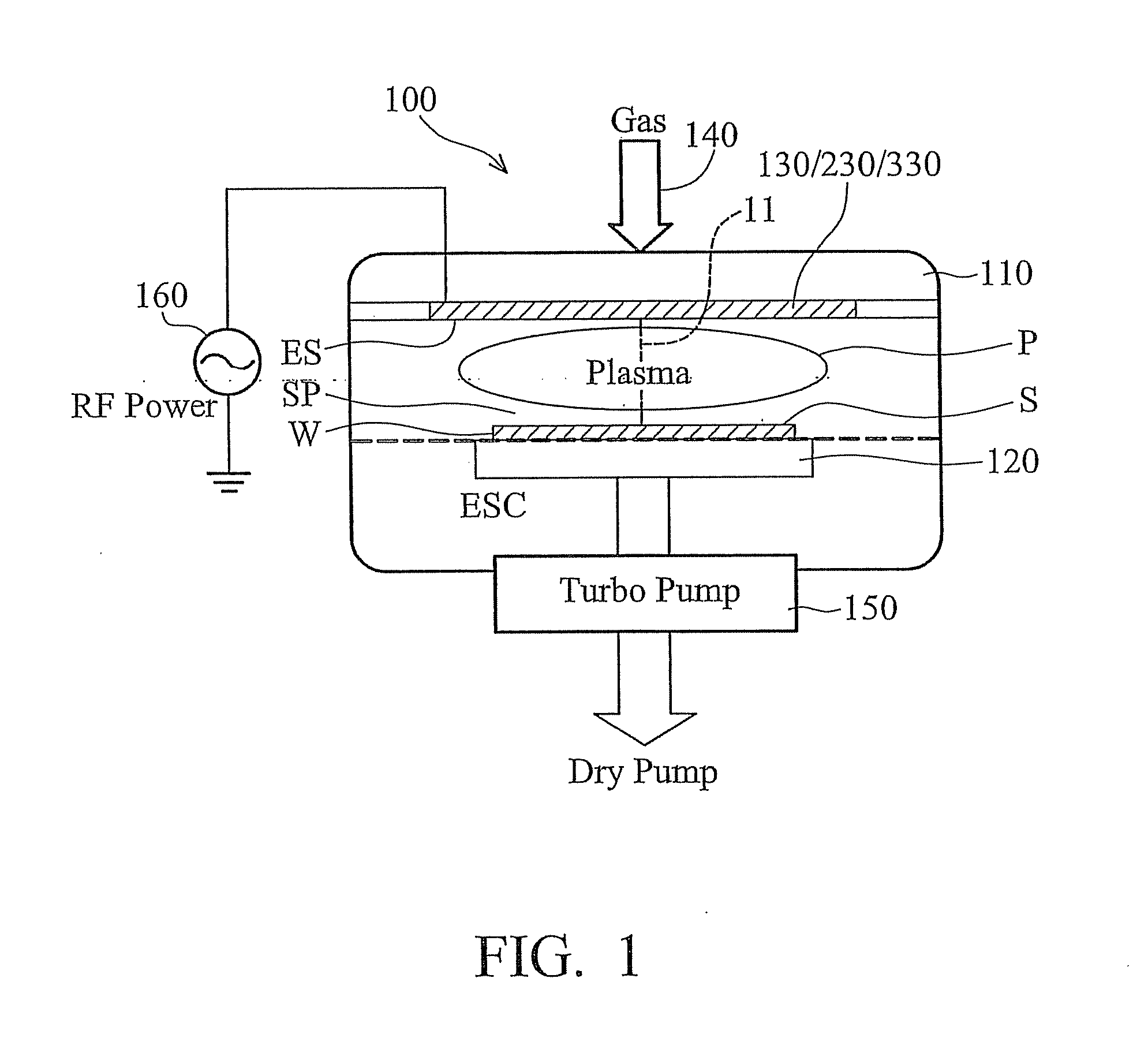

A adjustable upper coil or electrode for a reaction chamber apparatus useable in semiconductor processing, is constructed so that its shape may be selectively changed or so at least two portions thereof may be selectively driven at different power and / or frequencies. The adjustable upper coil or electrode, therefore, enables the plasma density distribution in the reaction chamber apparatus to be selectively controlled.

Owner:TAIWAN SEMICON MFG CO LTD

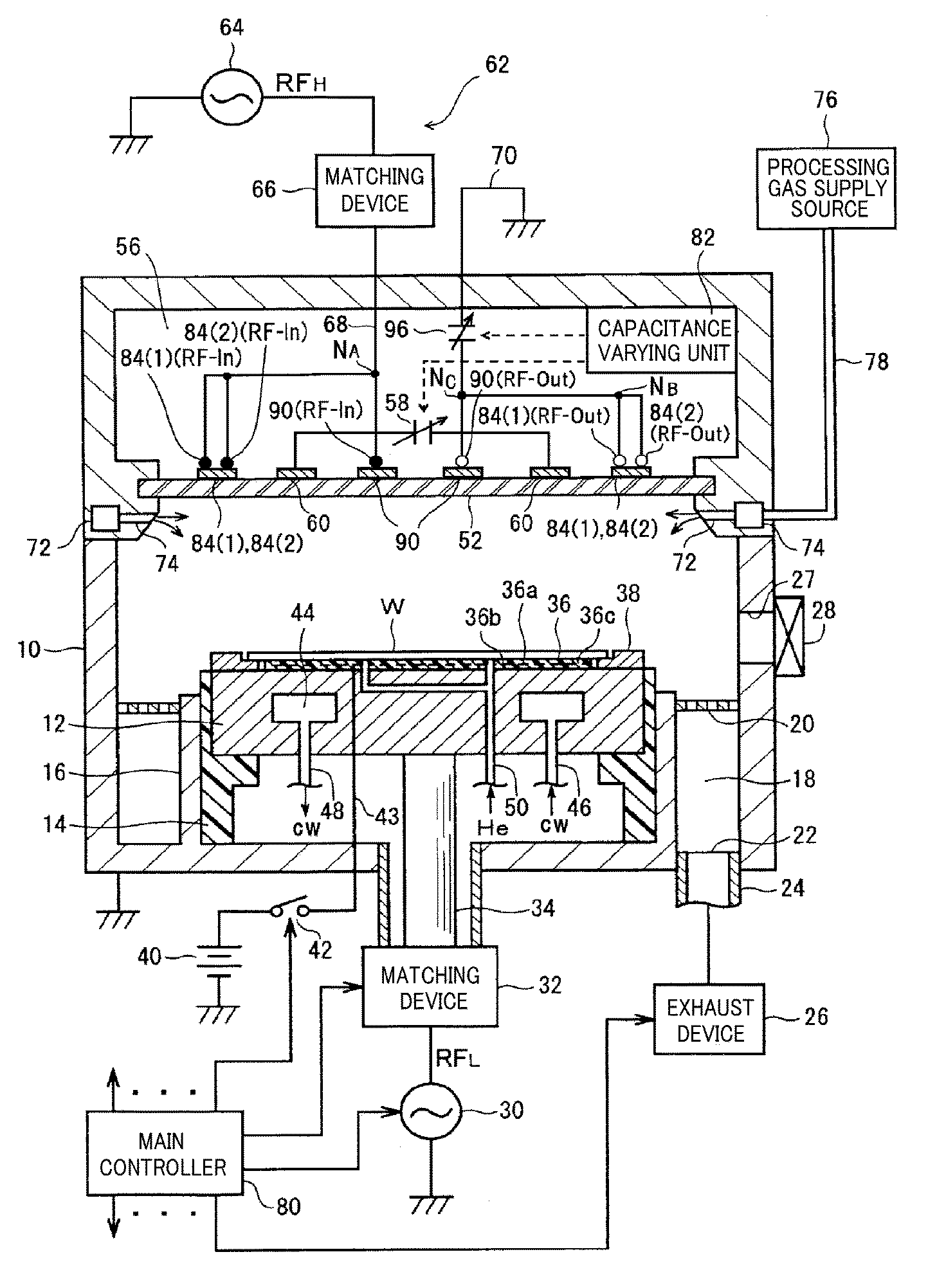

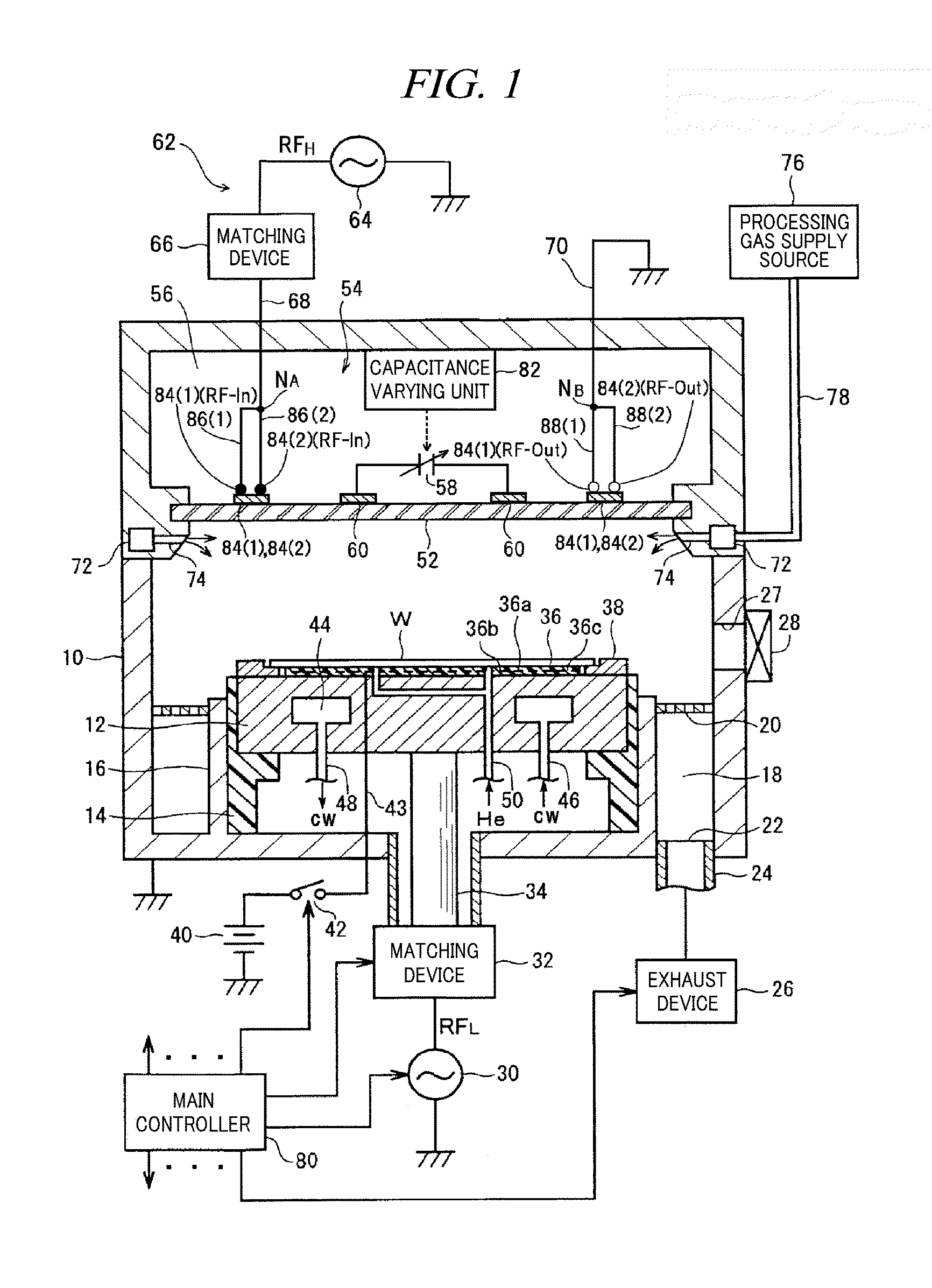

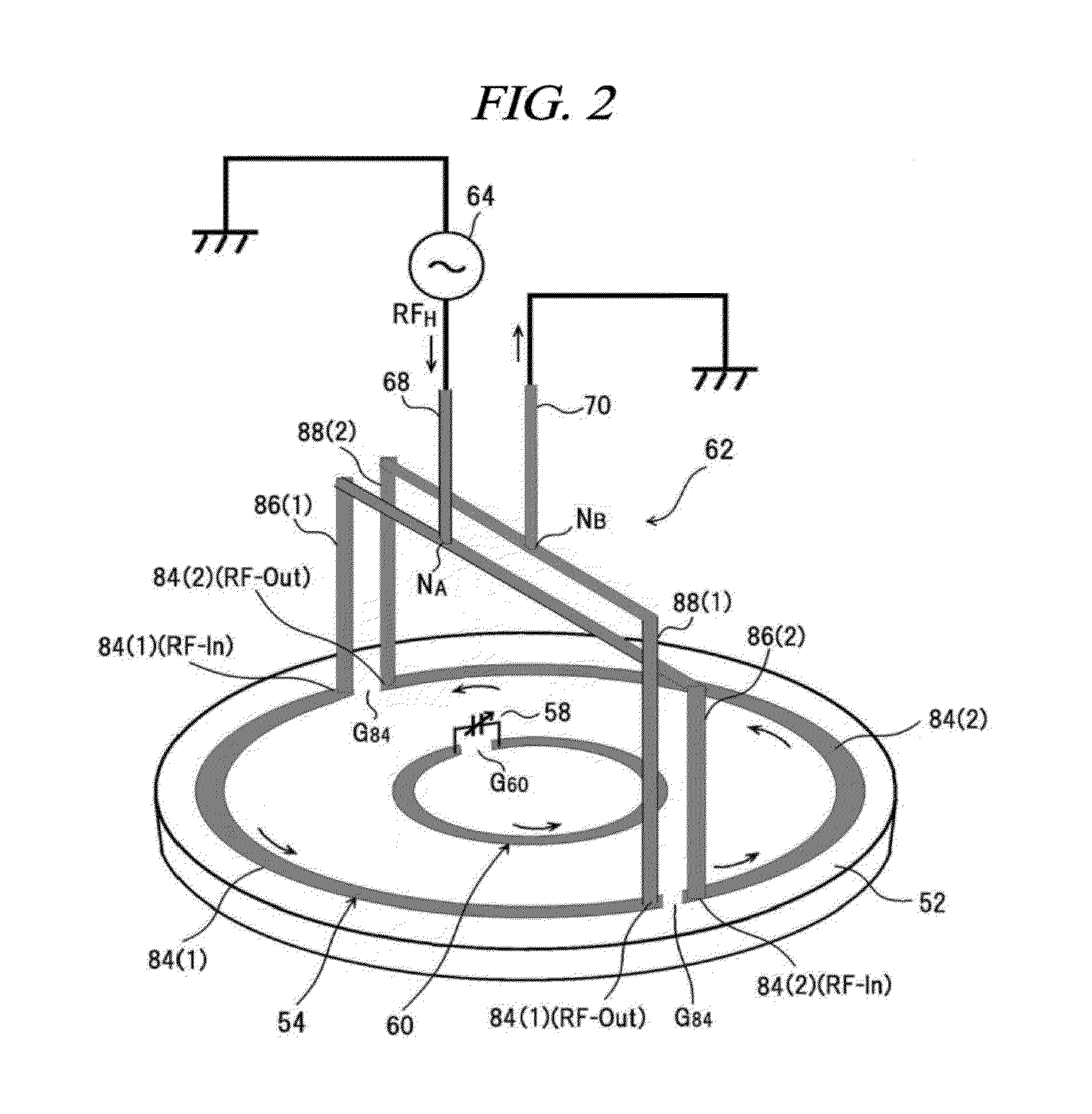

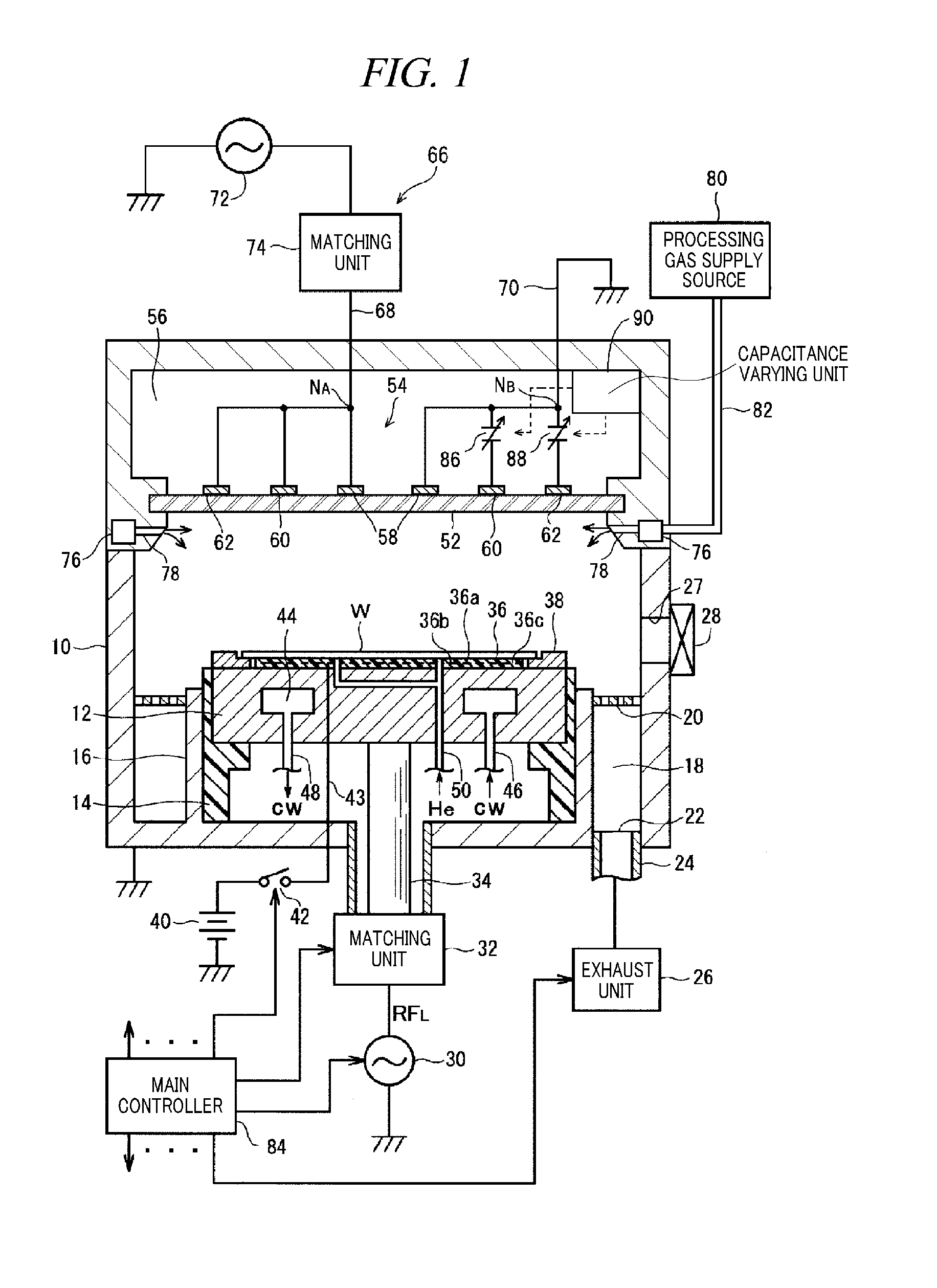

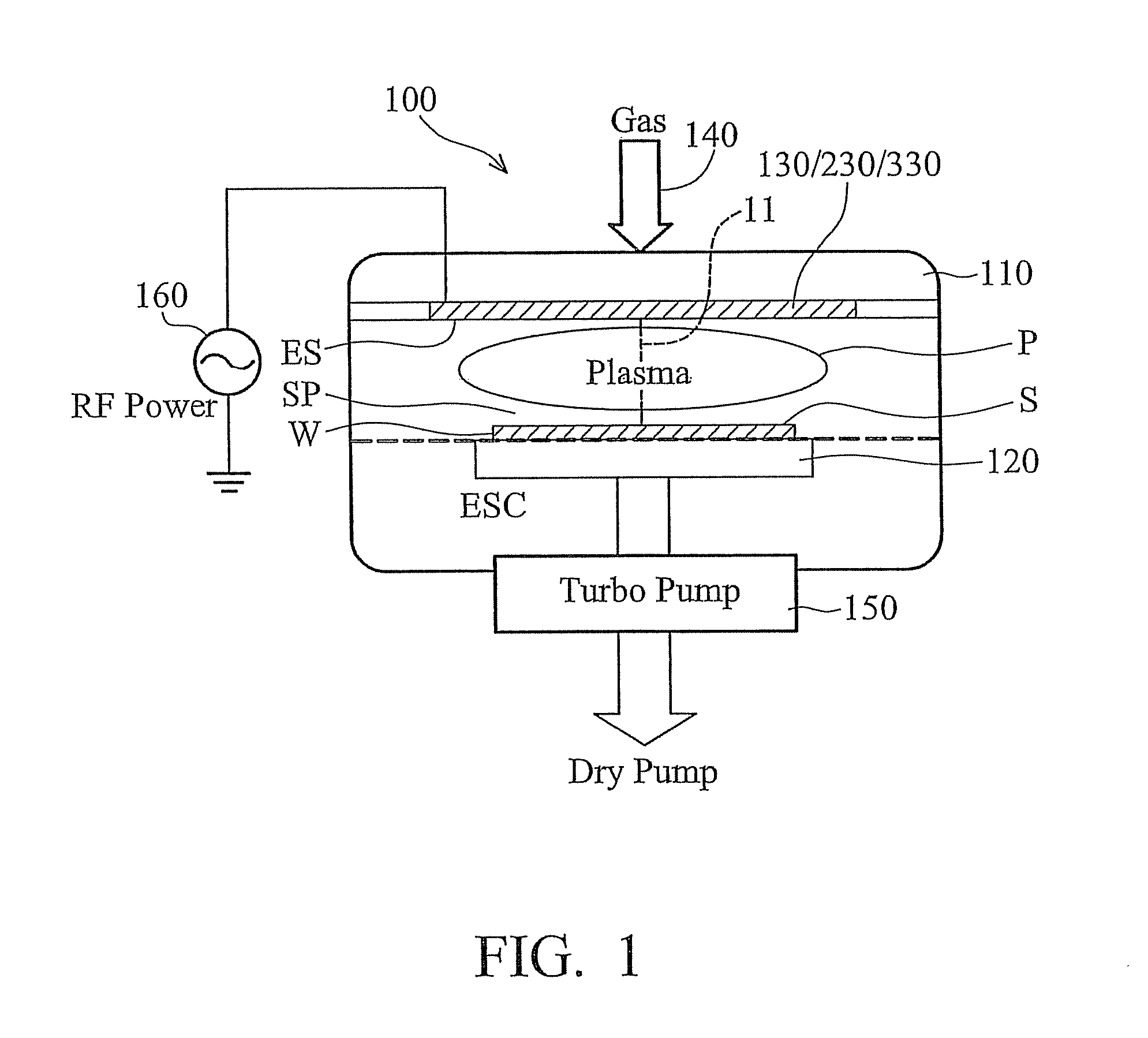

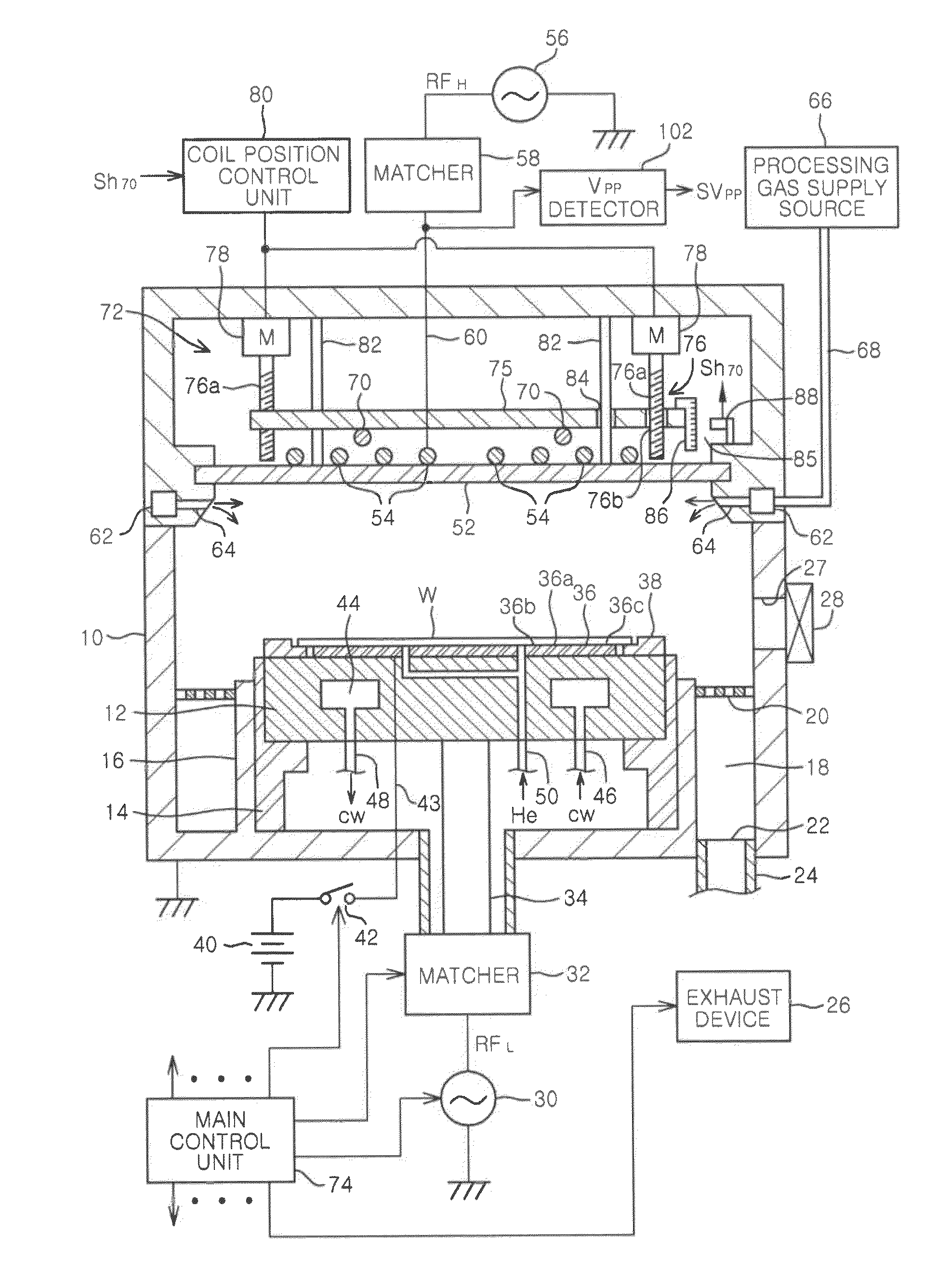

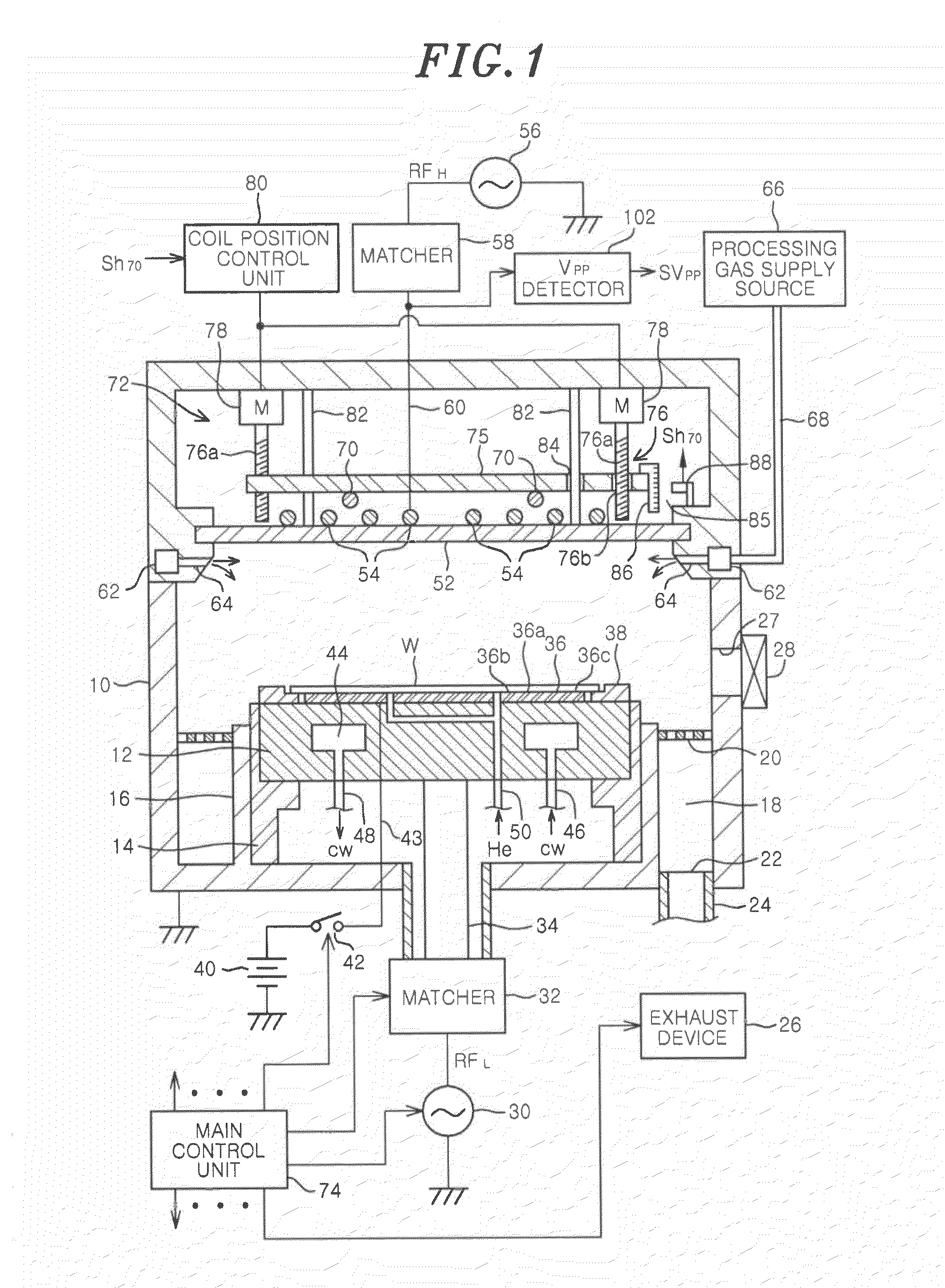

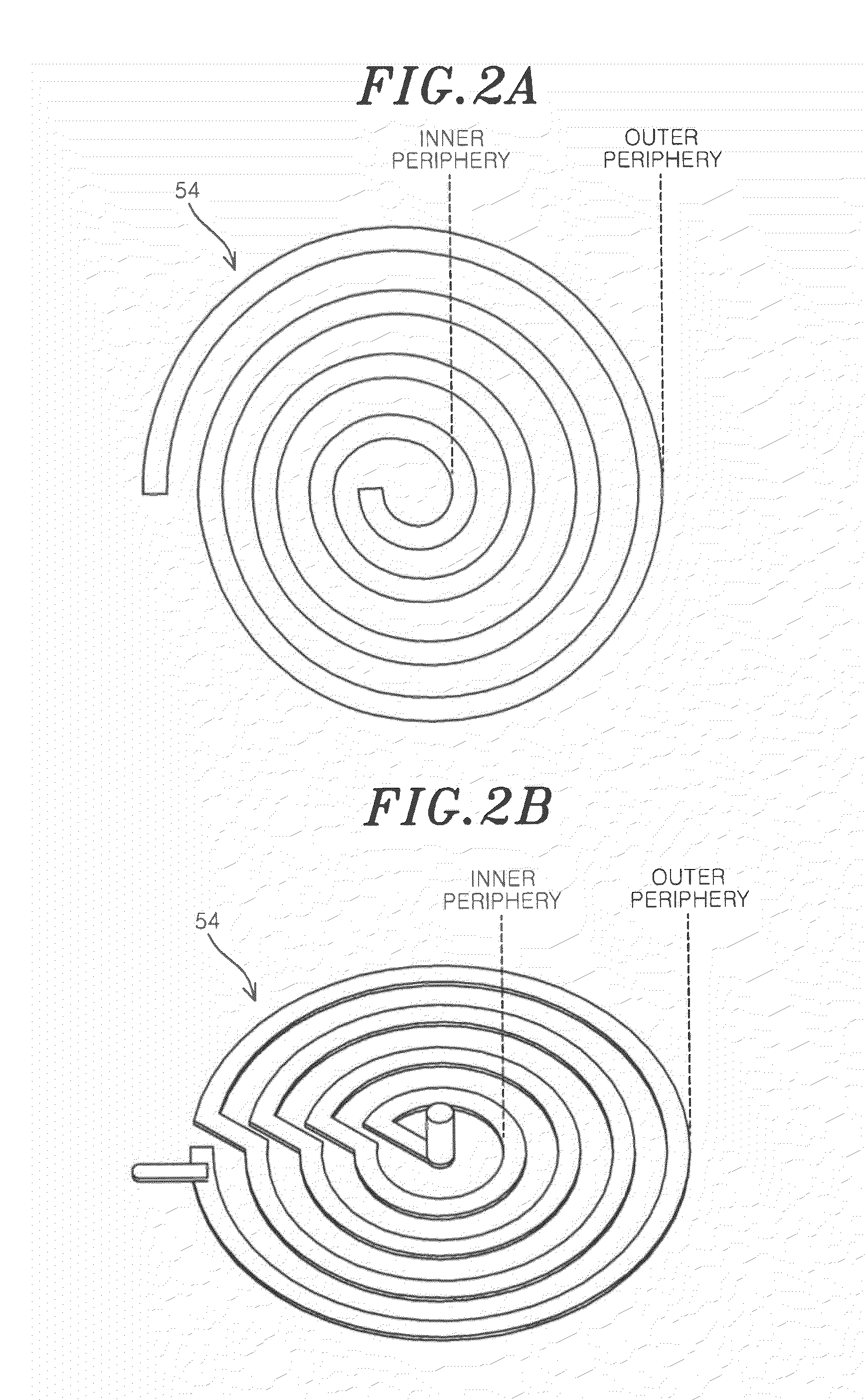

Plasma processing apparatus

ActiveUS20120247679A1Easy to controlSuppression of wavelength effectsLiquid surface applicatorsElectric discharge tubesCapacitanceHigh frequency power

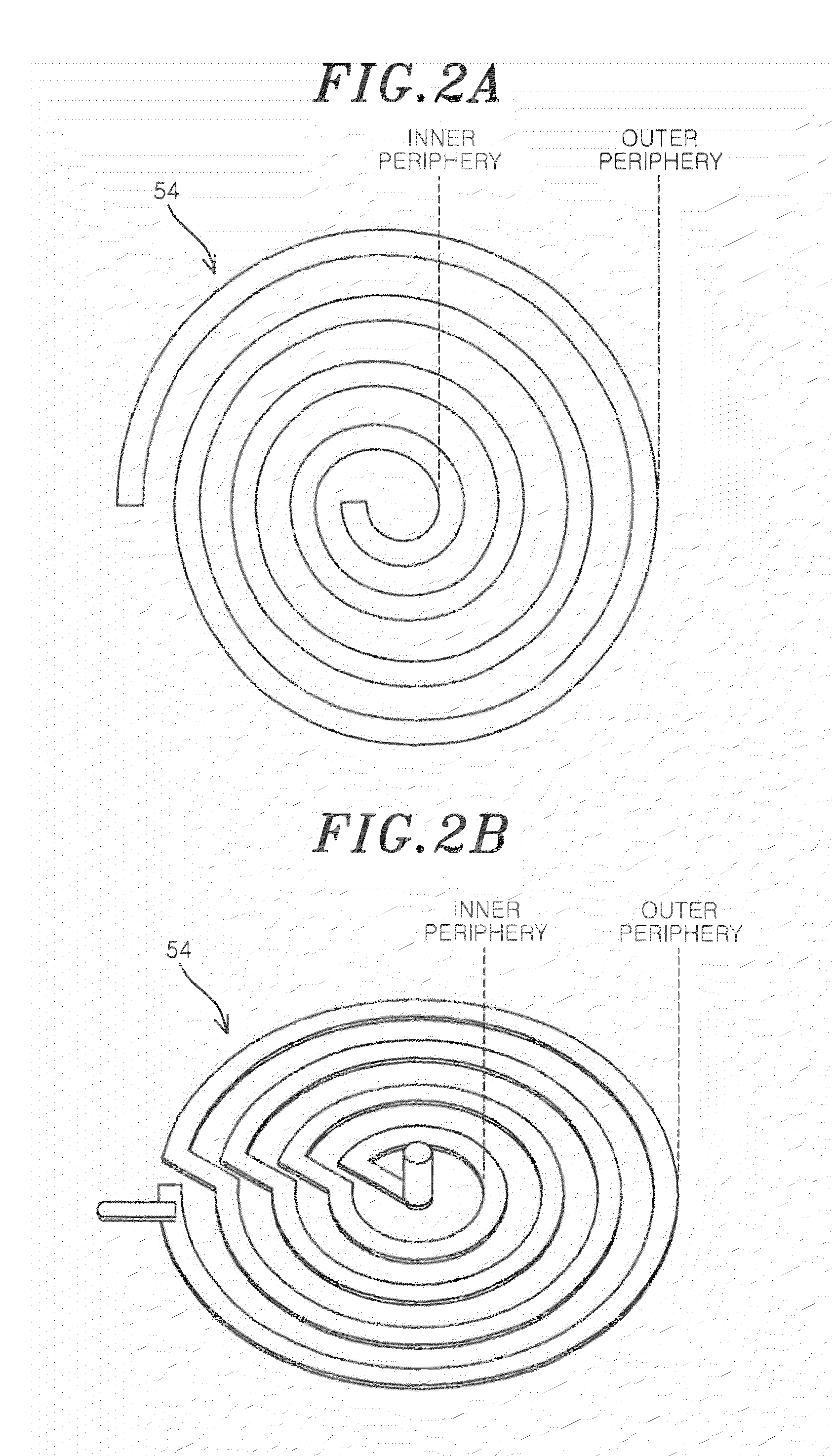

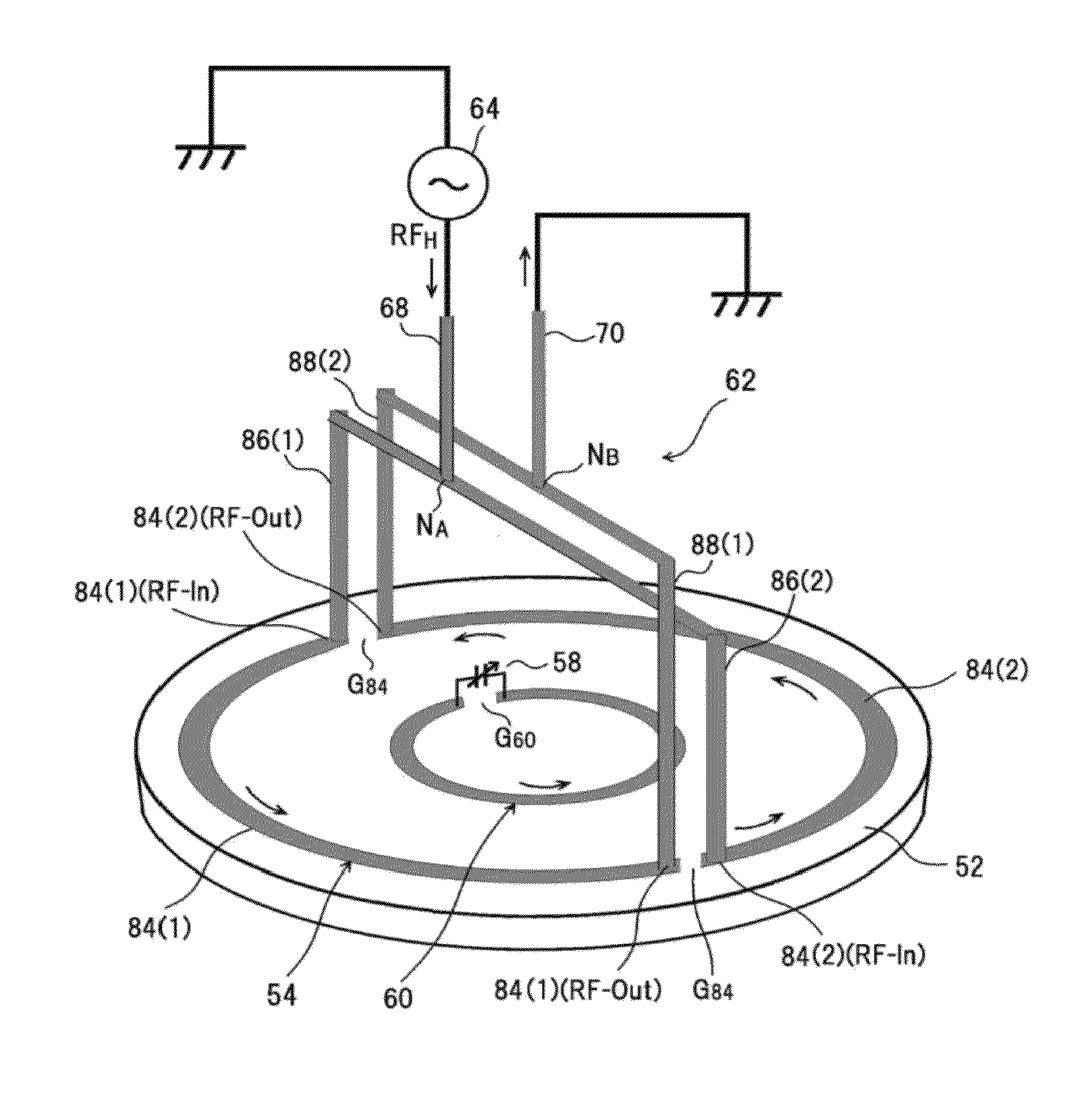

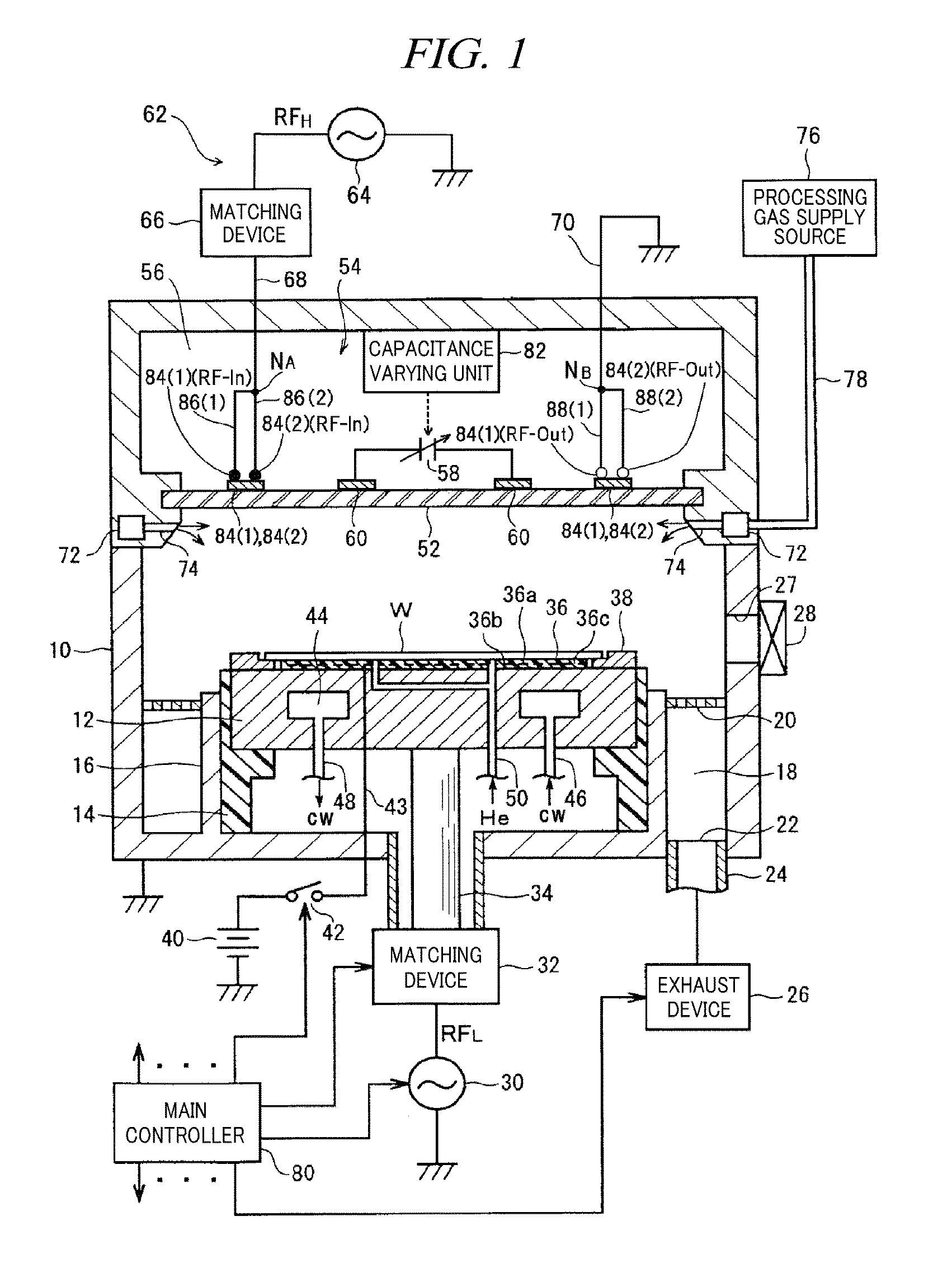

In an inductively coupled plasma processing apparatus, it is possible to control a plasma density distribution while suppressing a wavelength effect within a RF antenna. Provided at a ceiling of a chamber 10 or above a dielectric window 52 is a circular ring-shaped RF antenna 54 for generating inductively coupled plasma within the chamber 10. This RF antenna 54 includes two coil segments 84(1) and 84(2) each having a semicircular arc shape. The coil segments 84(1) and 84(2) are electrically connected to each other in parallel with respect to a high frequency power supply unit 62. On the dielectric window 52, a circular ring-shaped floating coil 60 having a variable capacitor 58 coupled to the RF antenna 54 by an electromagnetic induction is provided. The variable capacitor 58 is varied in a certain range by a capacitance varying unit 82 under the control of a main controller 80.

Owner:TOKYO ELECTRON LTD

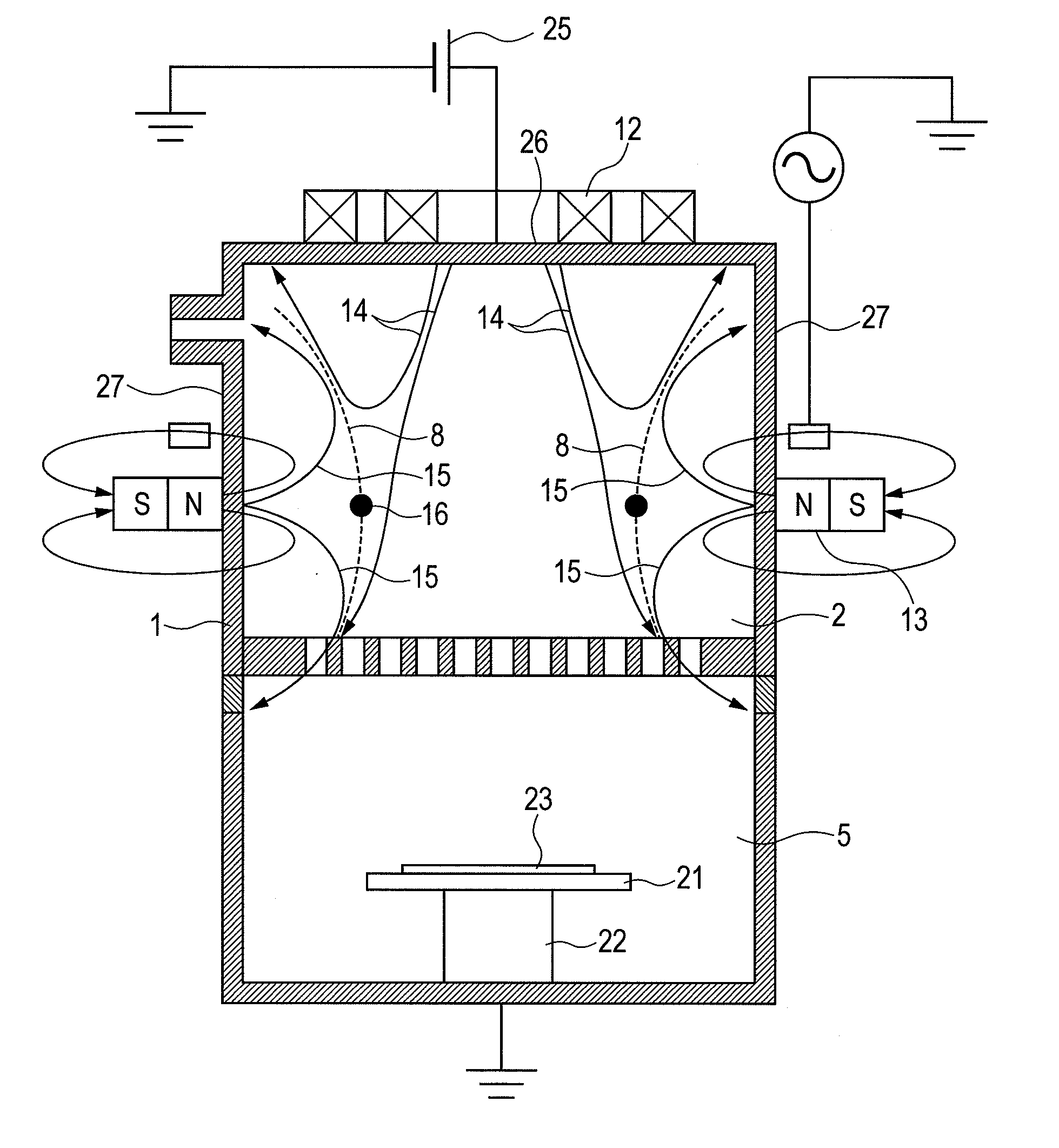

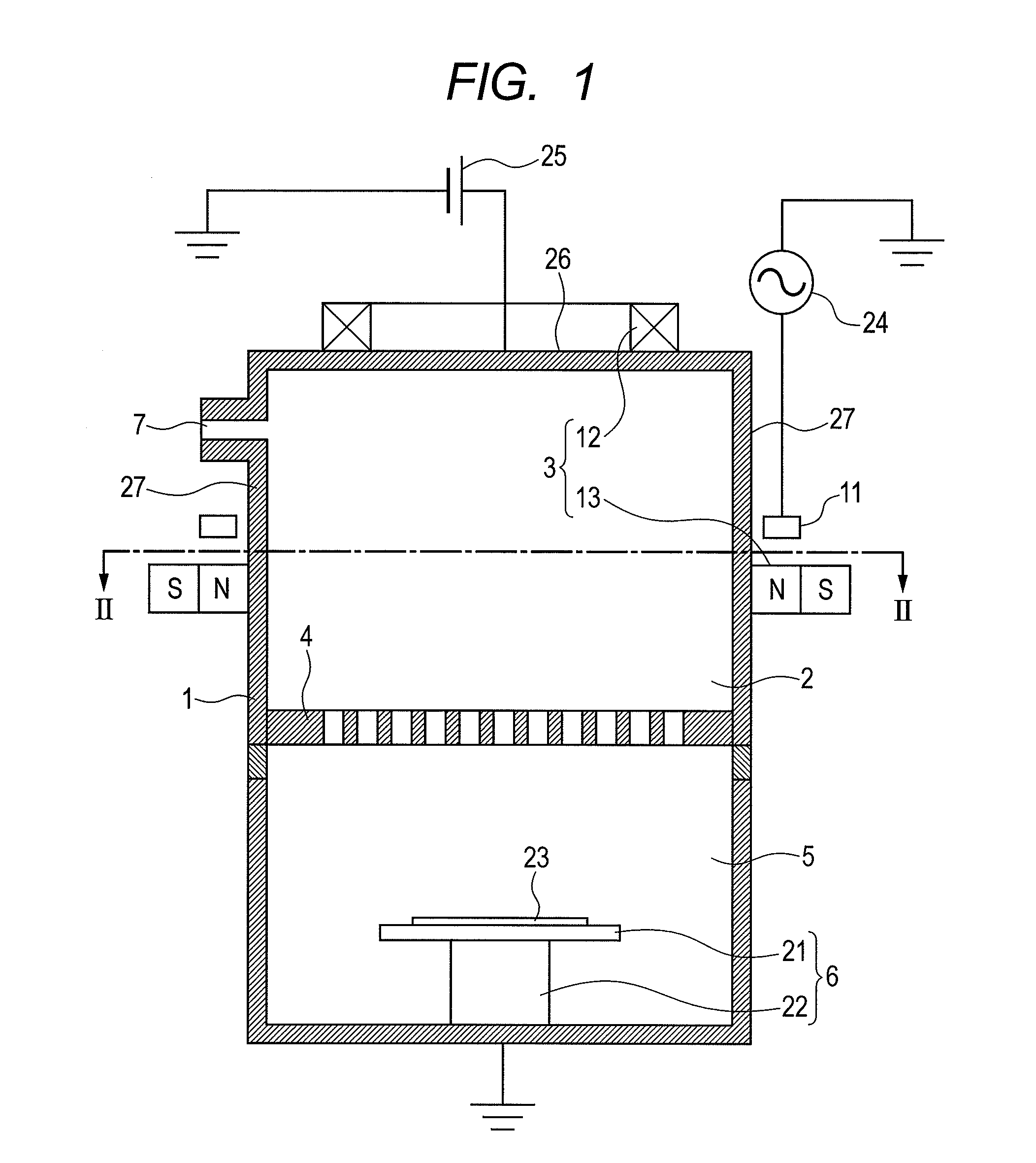

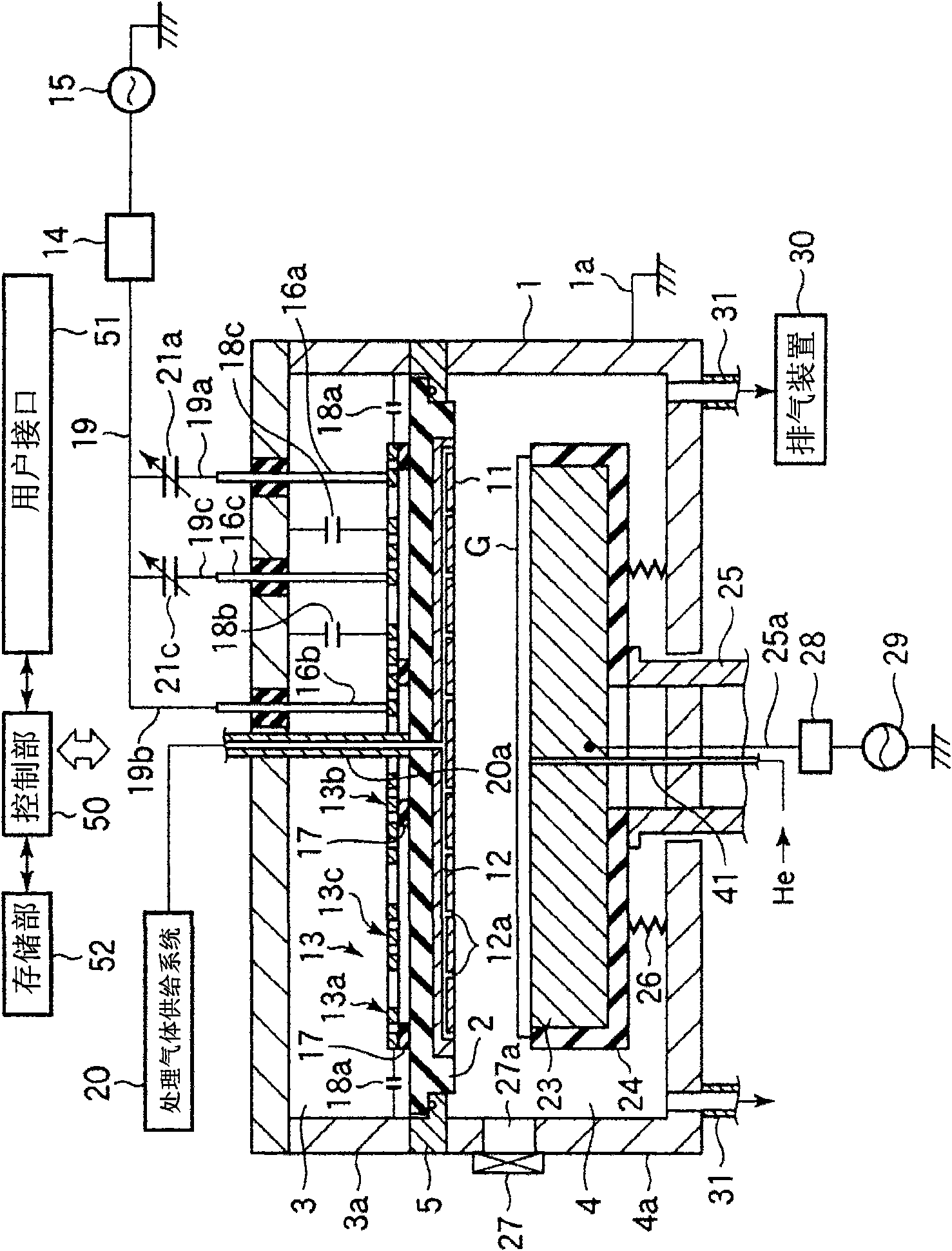

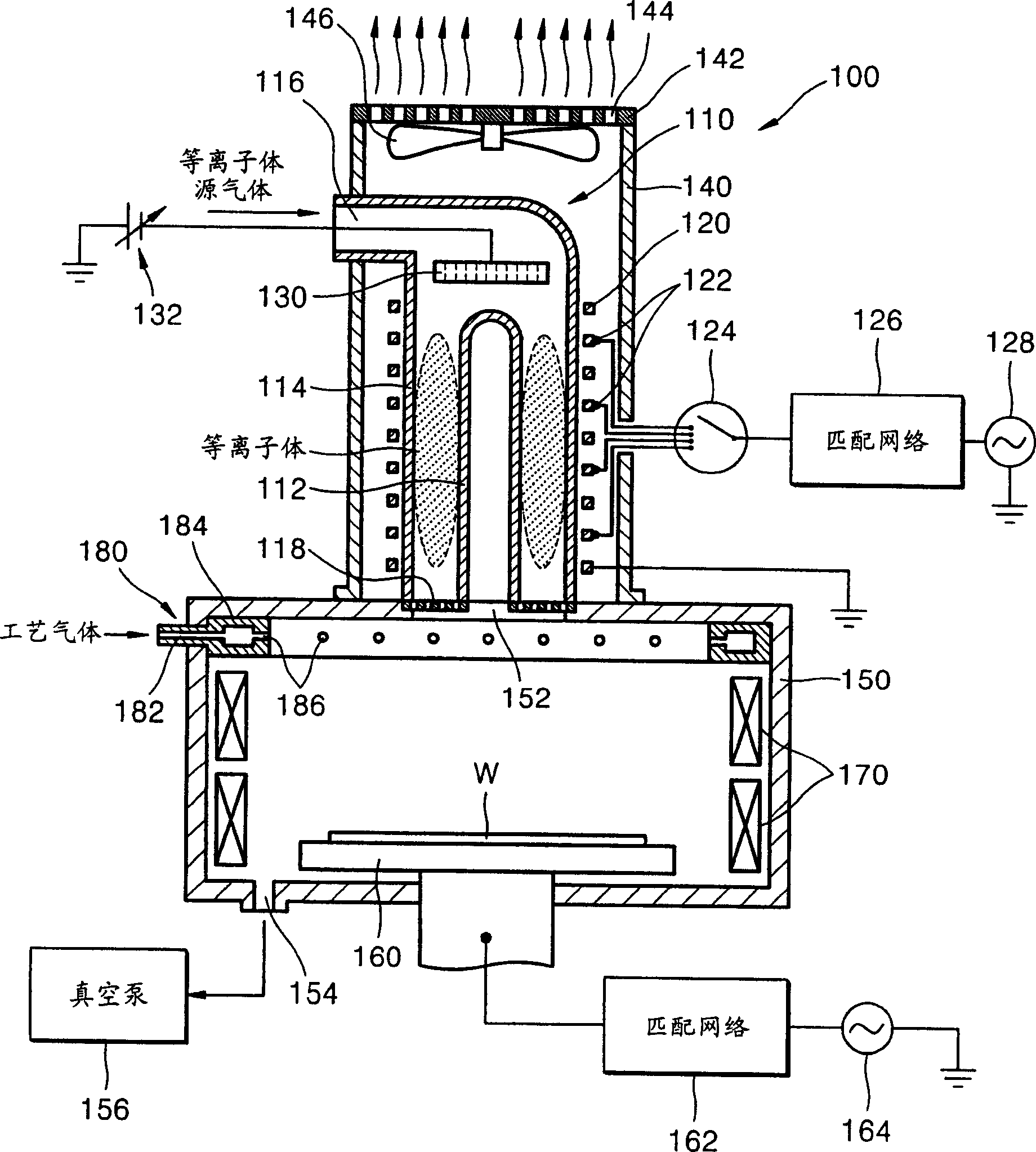

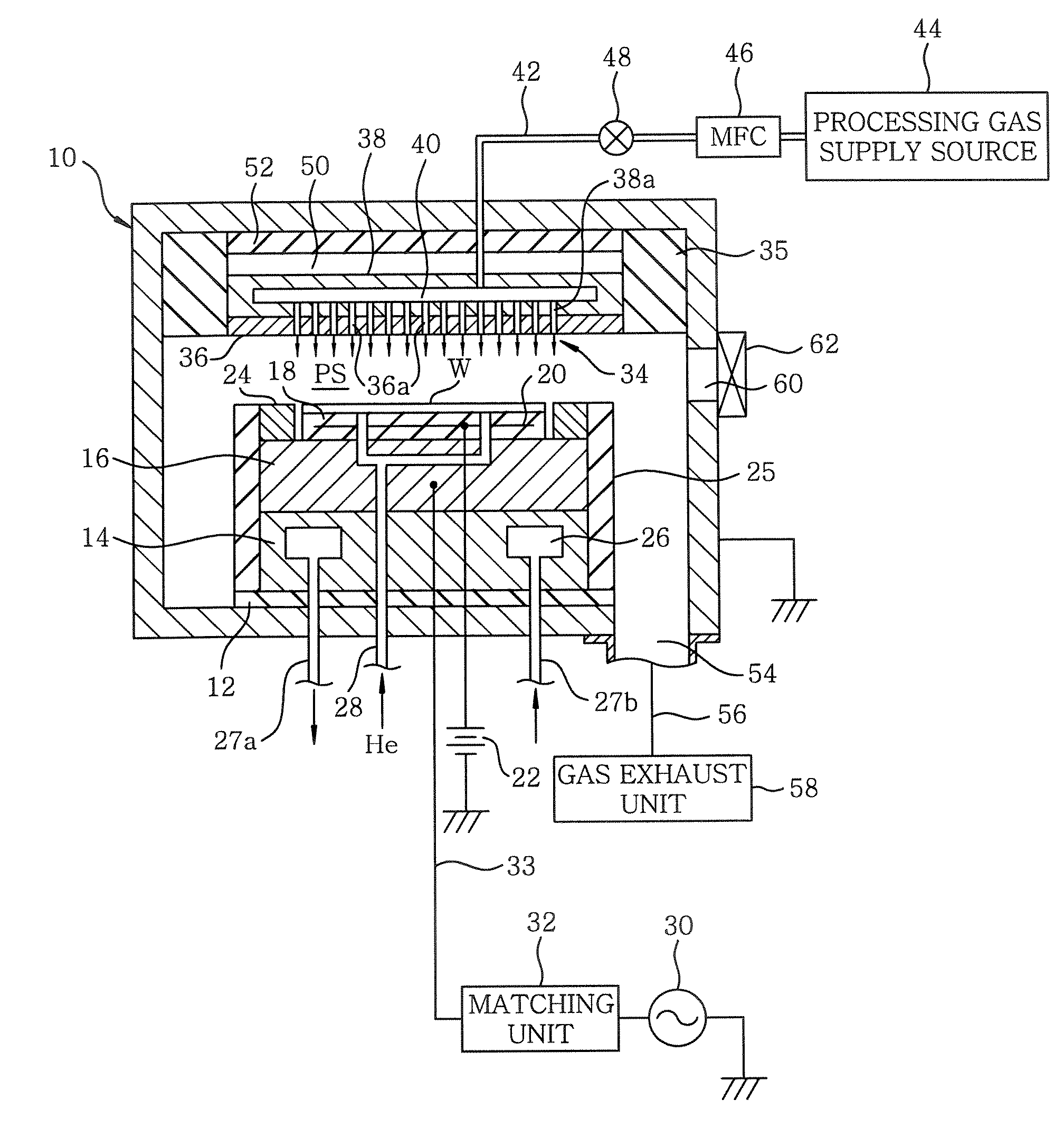

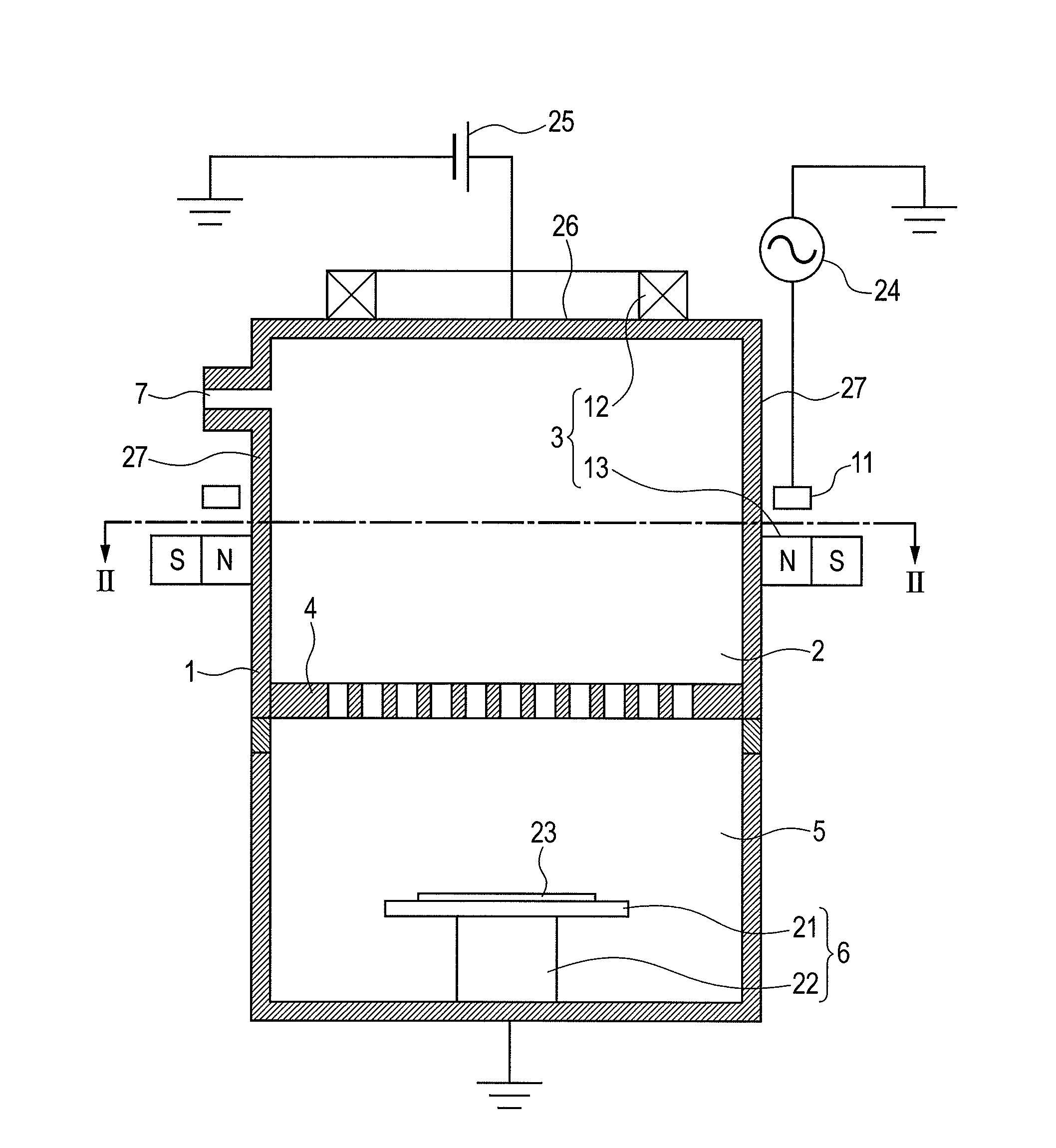

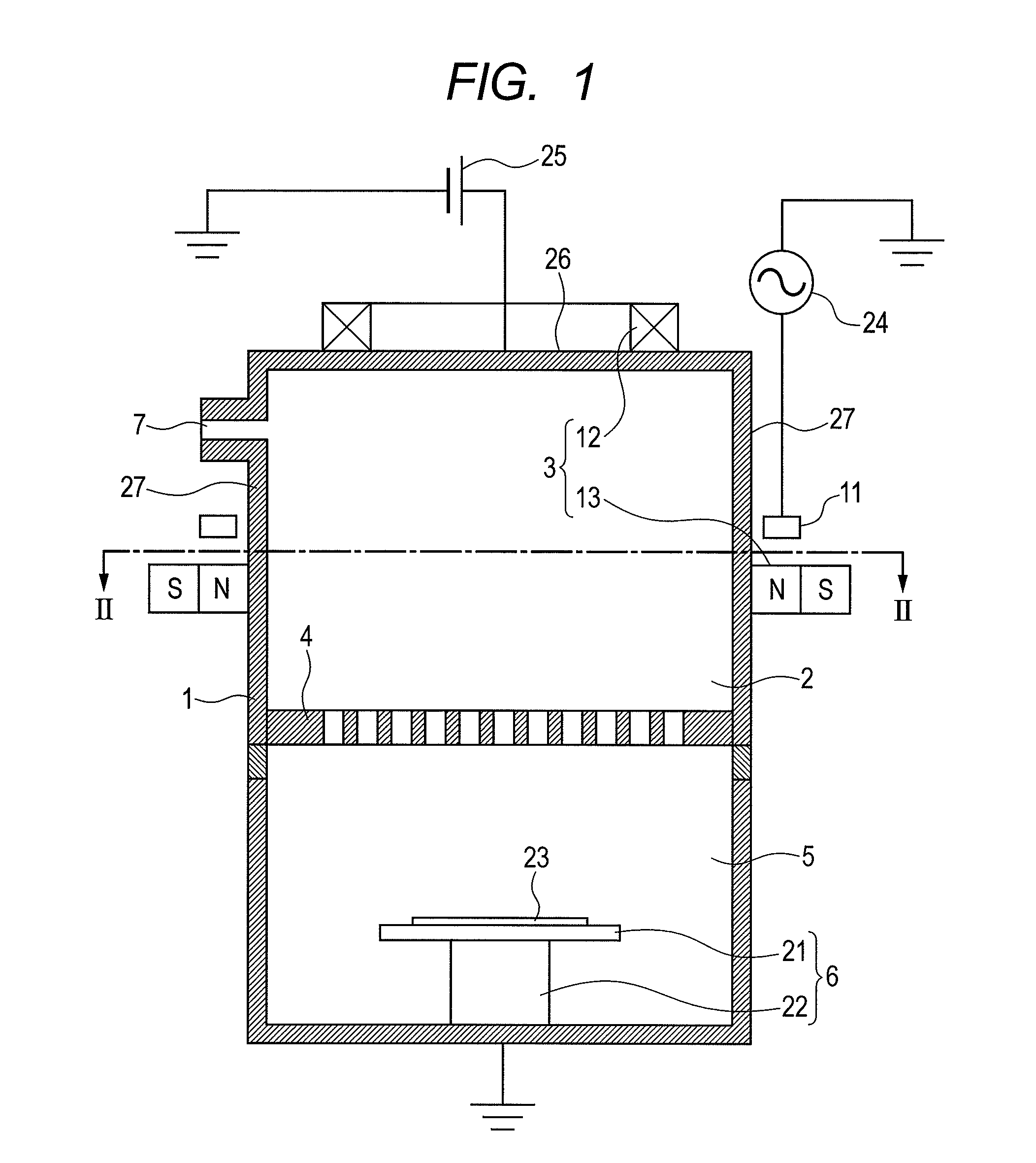

Plasma processing device, plasma processing method and method of manufacturing element including substrate to be processed

ActiveUS20110309050A1Fast processingOptimizationElectric discharge tubesDecorative surface effectsElectrical polarityEngineering

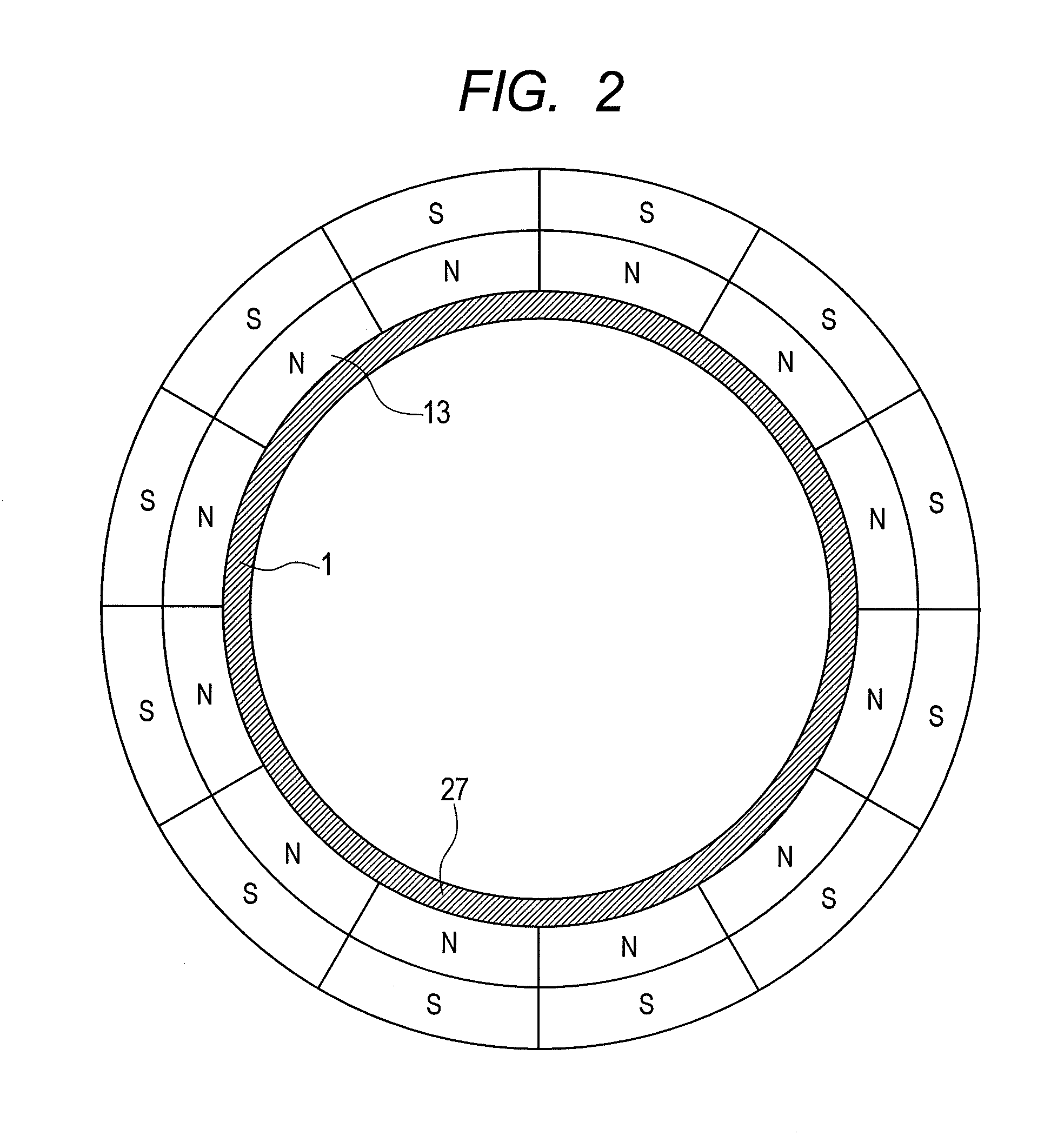

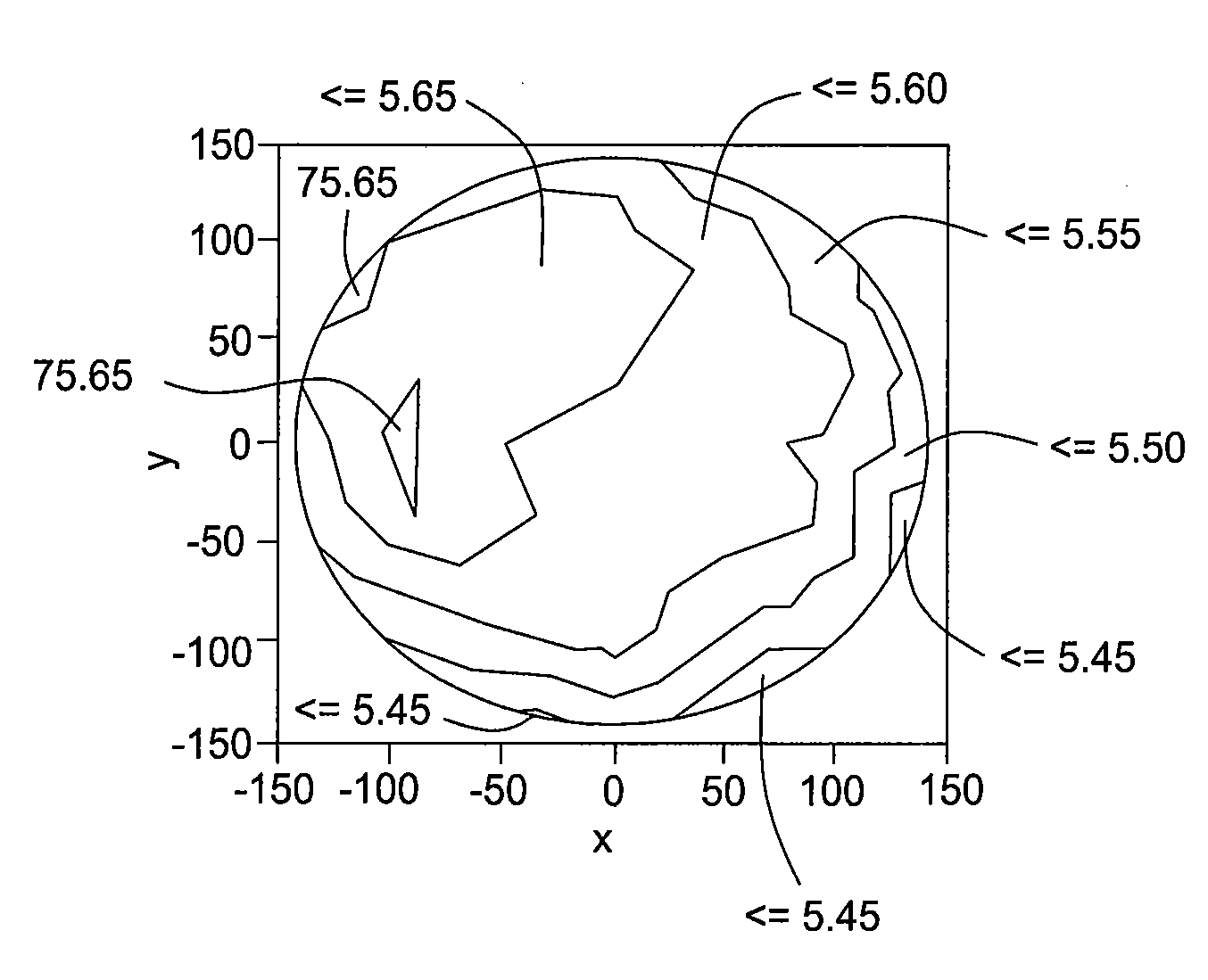

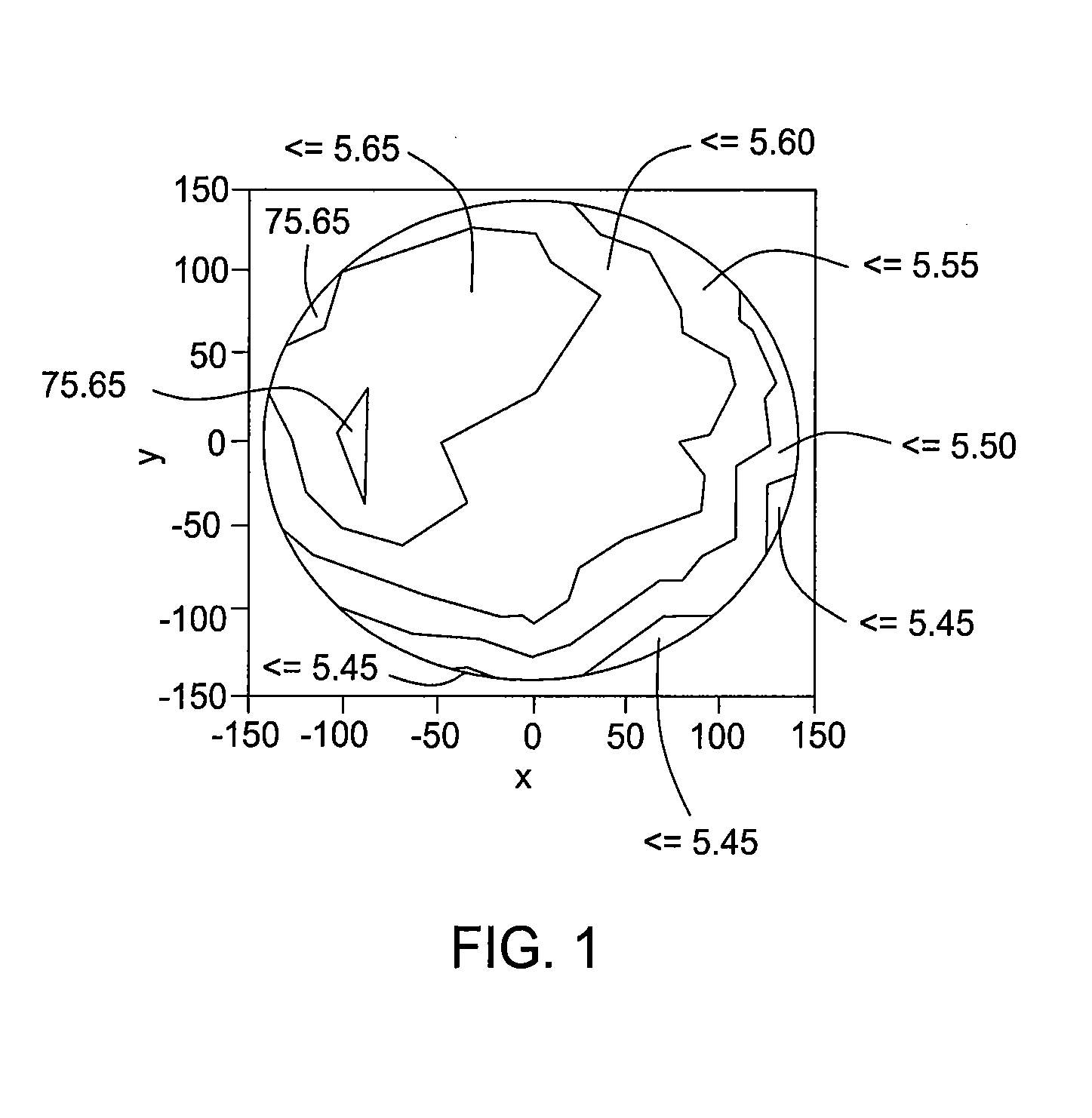

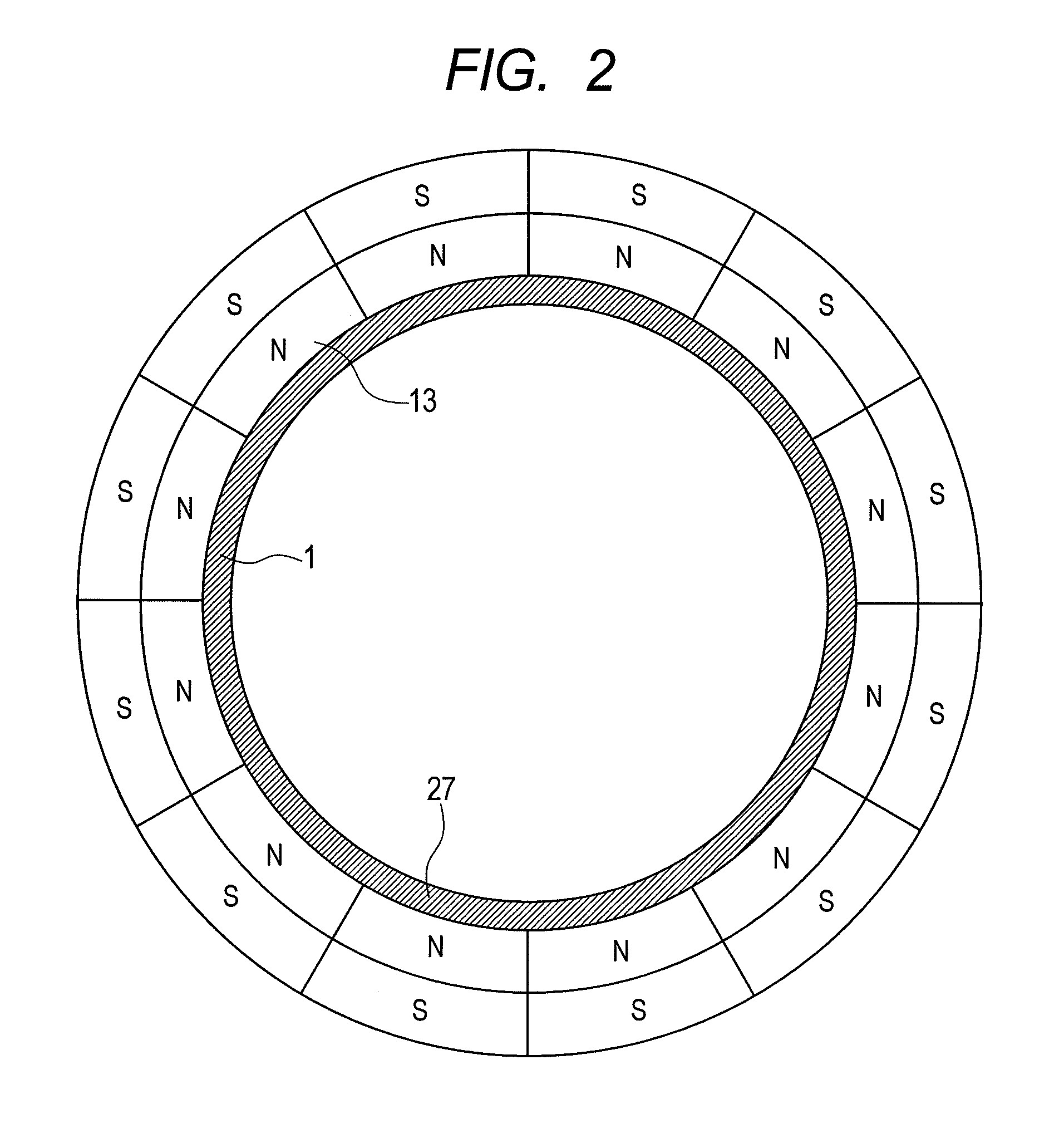

The present invention provides a plasma processing device and a plasma processing method that can easily adjust plasma density distribution while making the plasma density uniform, and a method of manufacturing an element including a substrate to be processed. In an embodiment of the present invention, the inside of a vacuum vessel (1) is divided by a grid (4) having communication holes into a plasma generation chamber (2) and a plasma processing chamber (5). On the upper wall (26) of the plasma generation chamber (2), magnetic coils (12) are arranged such that magnetic field lines within the vacuum vessel (1) point from the center of the vacuum vessel (1) to a side wall (27), and, outside the side wall (27) of the plasma generation chamber (2), ring-shaped permanent magnets (13) are arranged such that a polarity pointing to the inside of the vacuum vessel (1) is a north pole and a polarity pointing to the outside of the vacuum vessel (1) is a south pole.

Owner:CANON ANELVA CORP

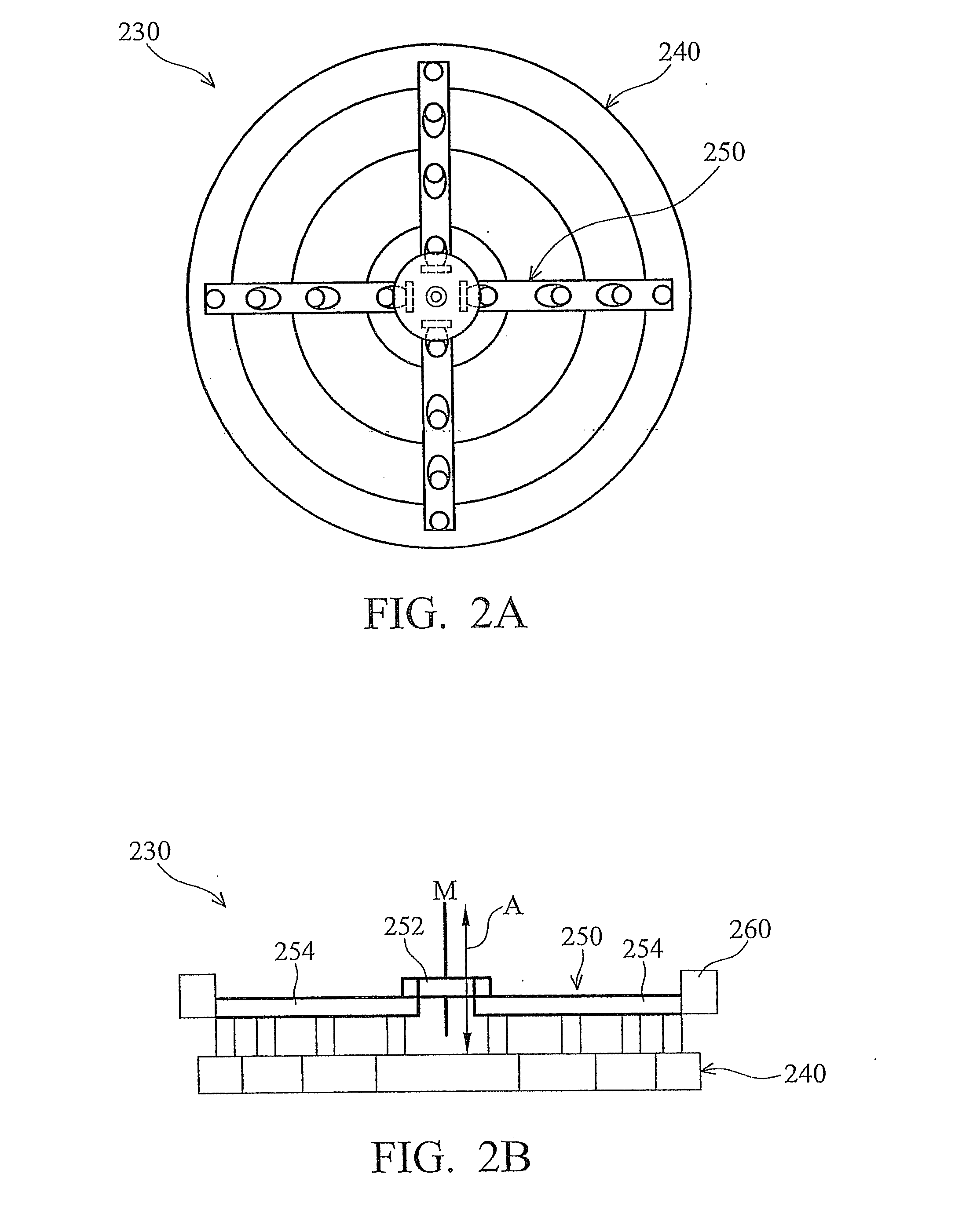

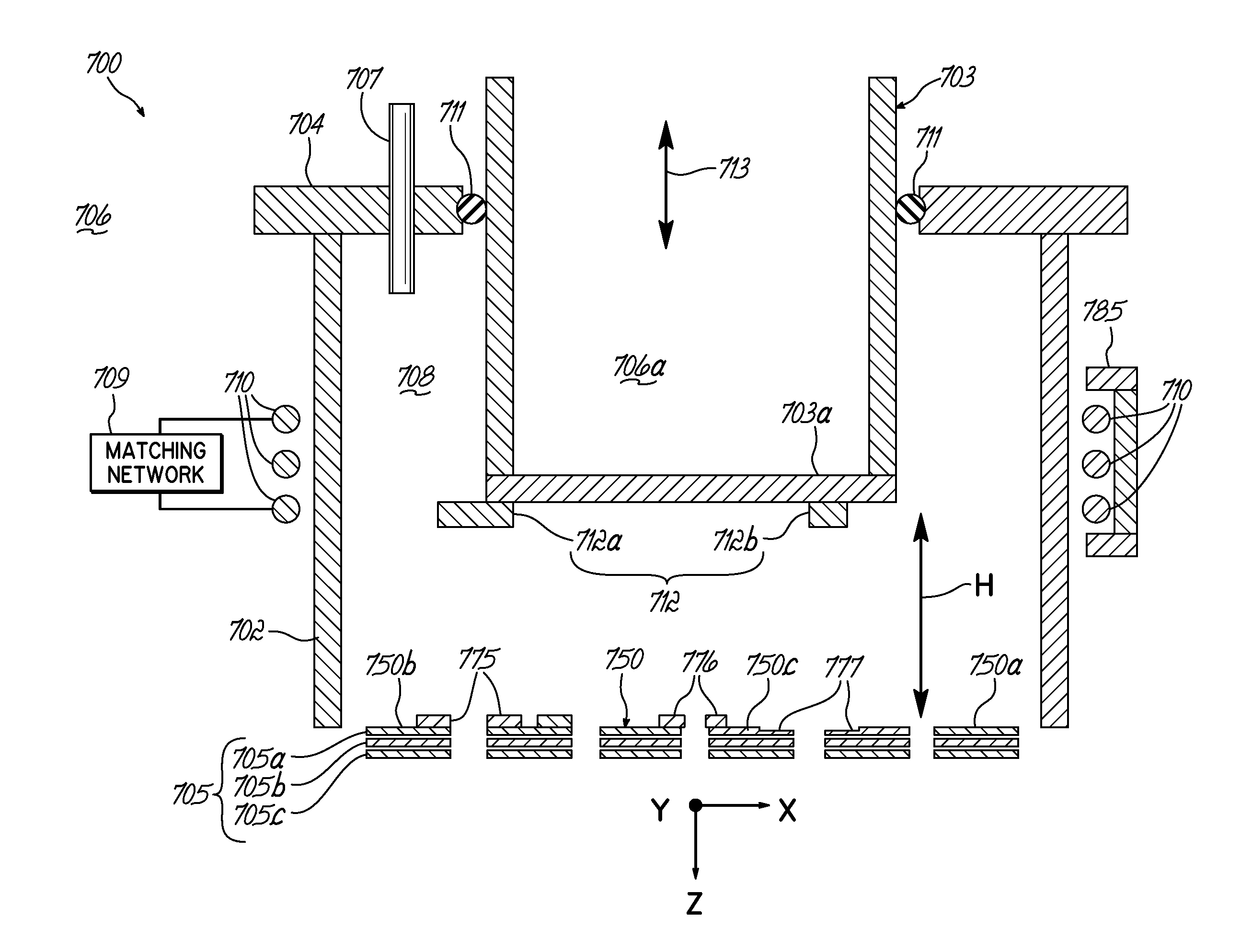

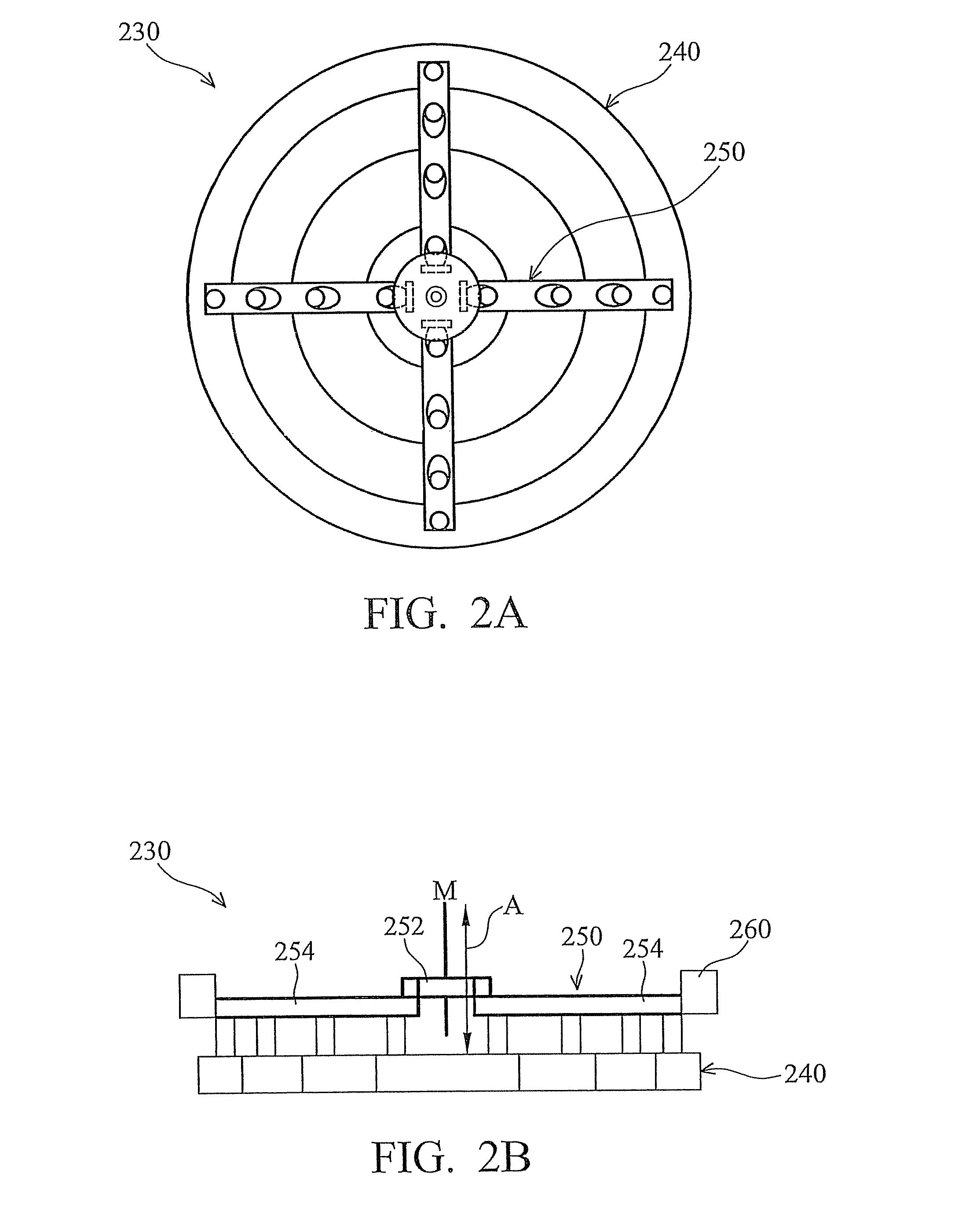

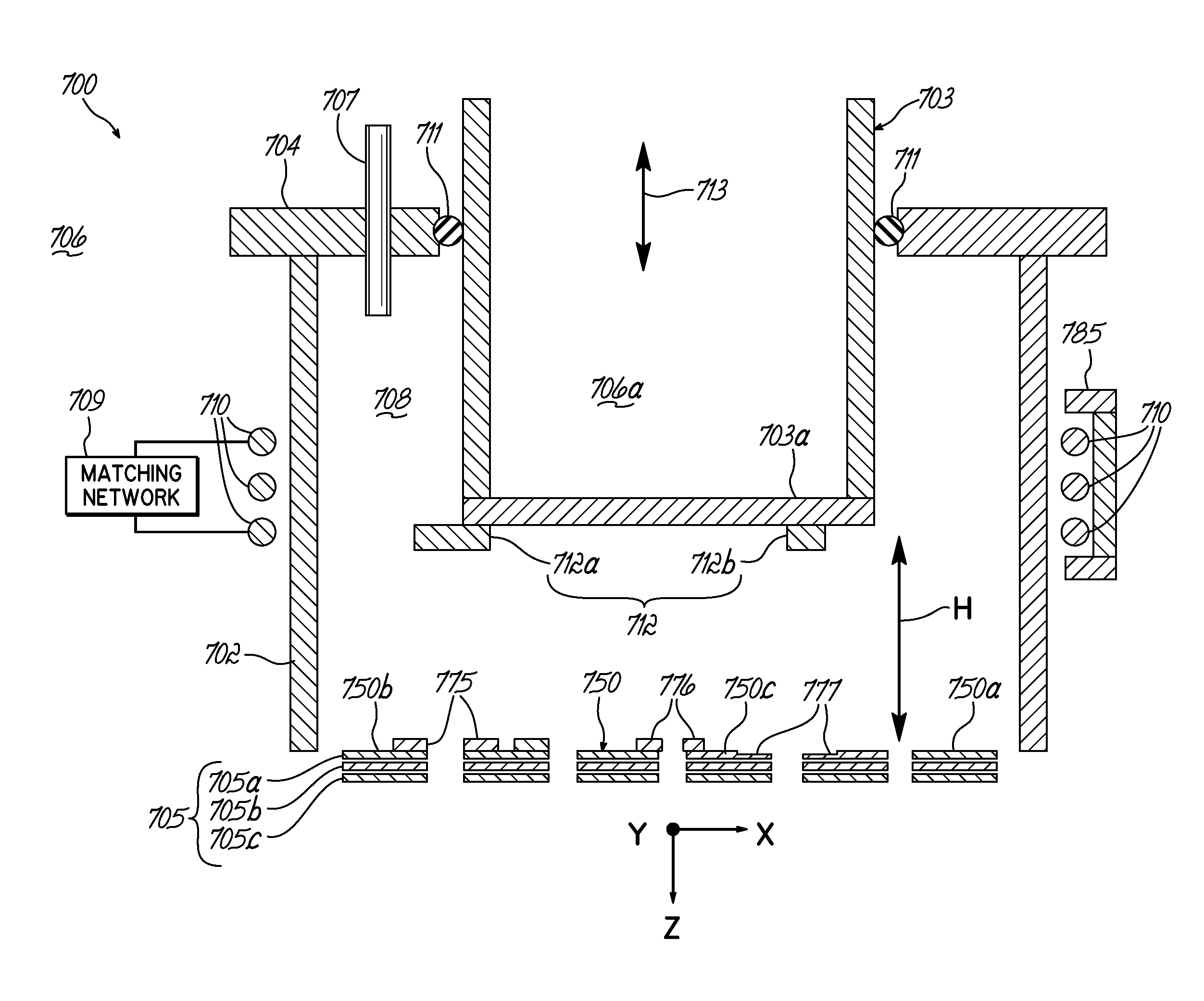

Method of correcting baseline skew by a novel motorized source coil assembly

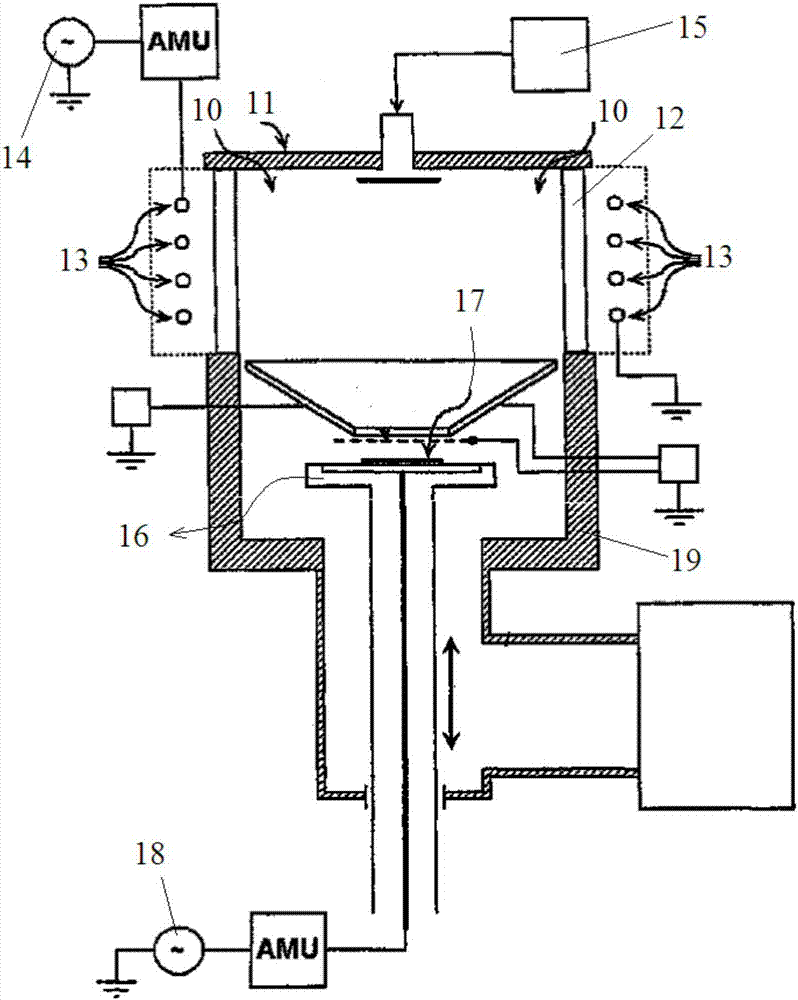

ActiveUS20090159425A1Electric discharge tubesSemiconductor/solid-state device manufacturingEngineeringInductively coupled plasma

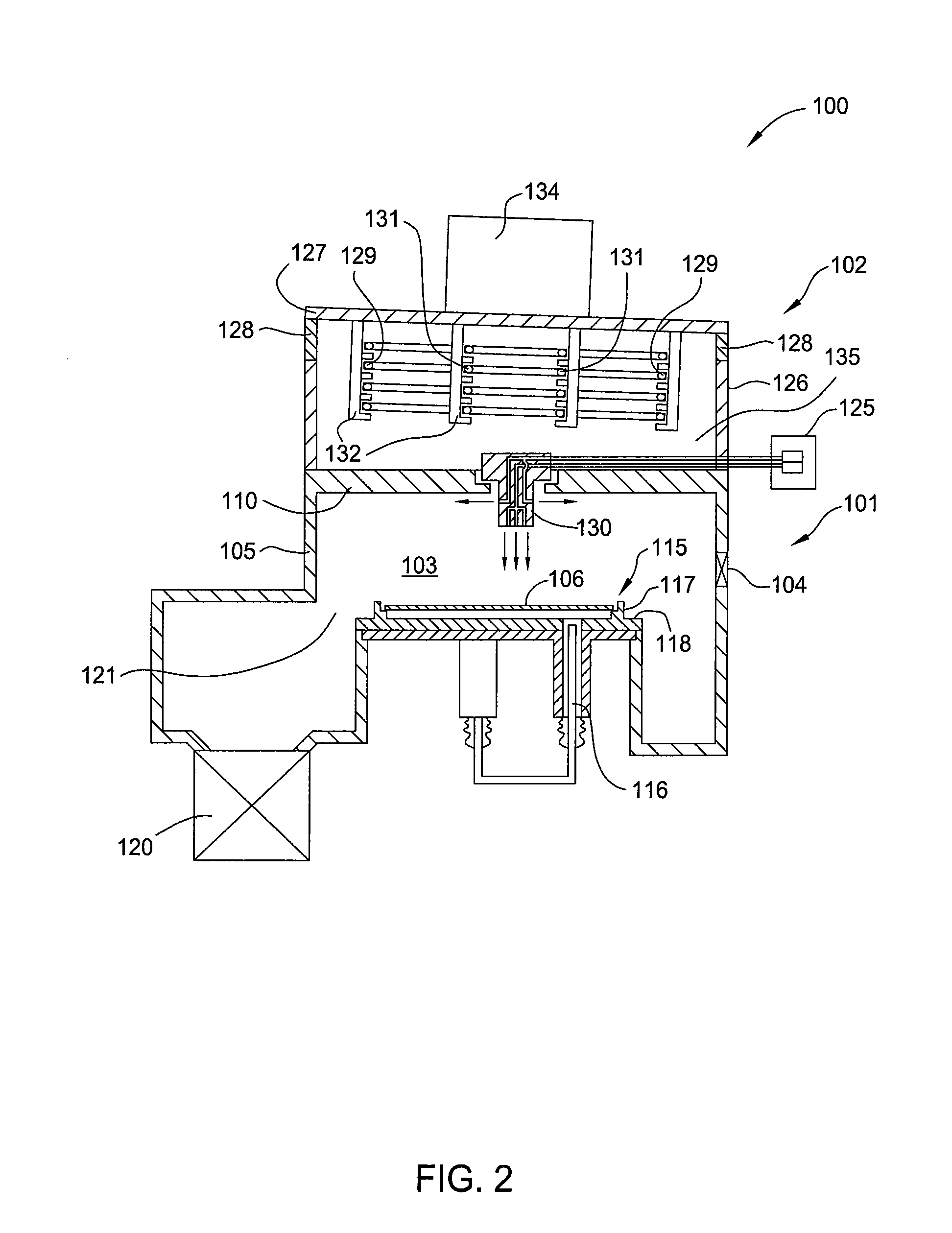

The present invention generally provides apparatus and method for adjusting plasma density distribution in an inductively coupled plasma chamber. One embodiment of the present invention provides an apparatus configured for processing a substrate. The apparatus comprises a chamber body defining a process volume configured to process the substrate therein, and a coil assembly coupled to the chamber body outside the process volume, wherein the coil assembly comprises a coil mounting plate, a first coil antenna mounted on the coil mounting plate, and a coil adjusting mechanism configured to adjust the alignment of the first coil antenna relative to the process volume.

Owner:APPLIED MATERIALS INC

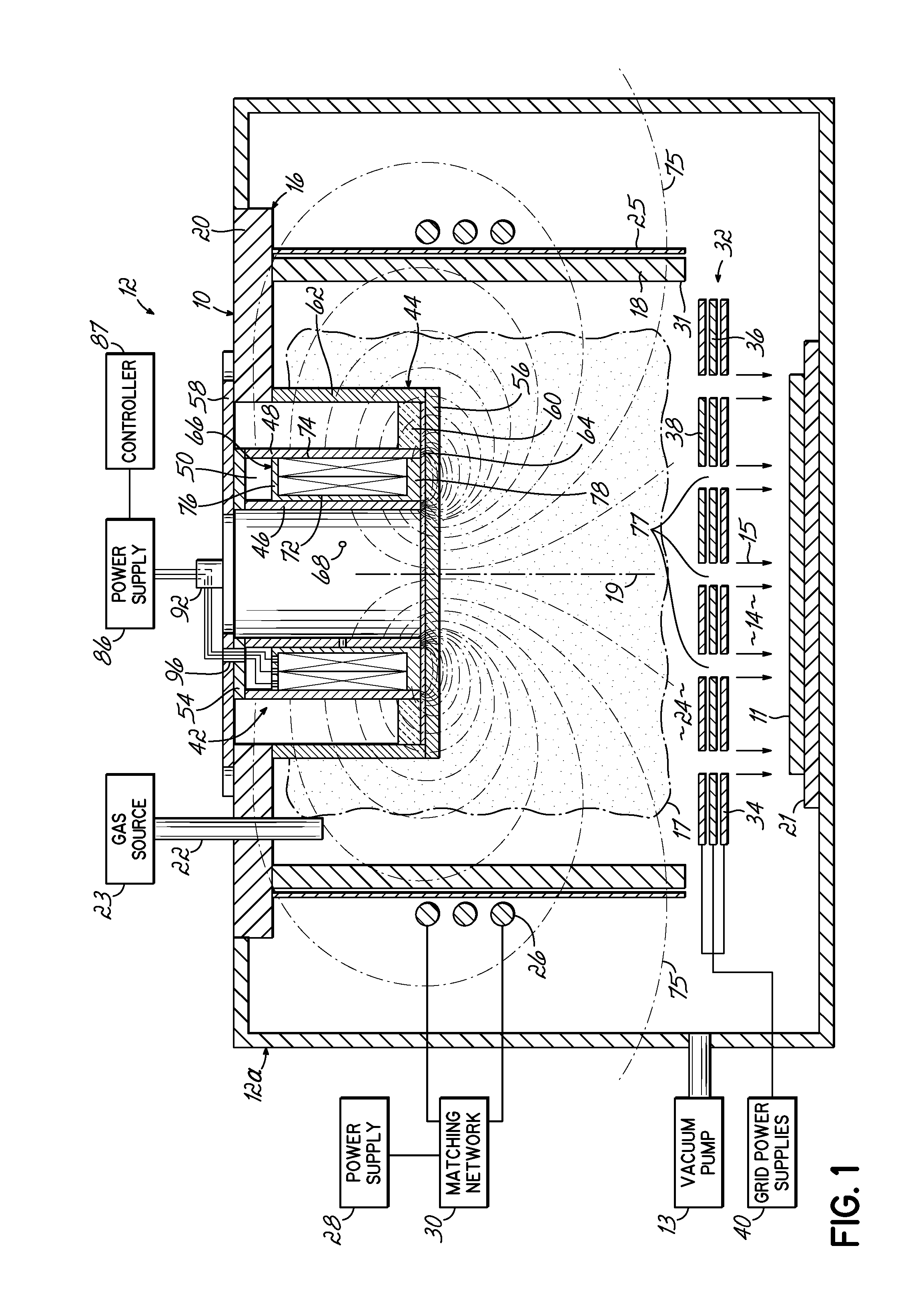

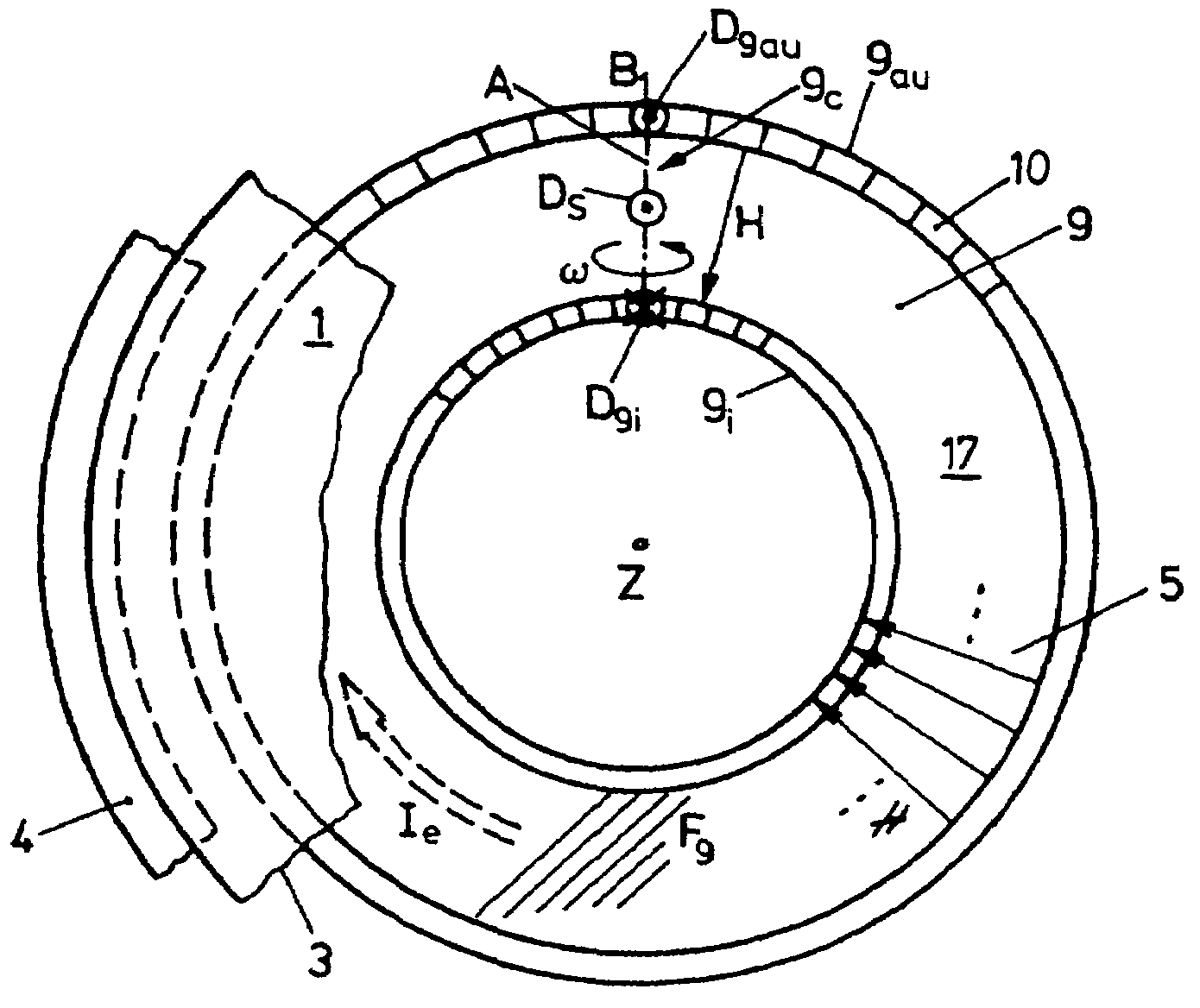

Methods of operating an electromagnet of an ion source

ActiveUS20080179284A1Modify performanceVacuum gauge using ionisation effectsDecorative surface effectsAuto regulationIon beam

Methods of operating an electromagnet of an ion source for generating an ion beam with a controllable ion current density distribution. The methods may include generating plasma in a discharge space of the ion source, generating and shaping a magnetic field in the discharge space by applying a current to an electromagnet that is effective to define a plasma density distribution, extracting an ion beam from the plasma, measuring a distribution profile for the ion beam density, and comparing the actual distribution profile with a desired distribution profile for the ion beam density. Based upon the comparison, the current applied to the electromagnet may be adjusted either manually or automatically to modify the magnetic field in the discharge space and, thereby, alter the plasma density distribution.

Owner:VEECO INSTR

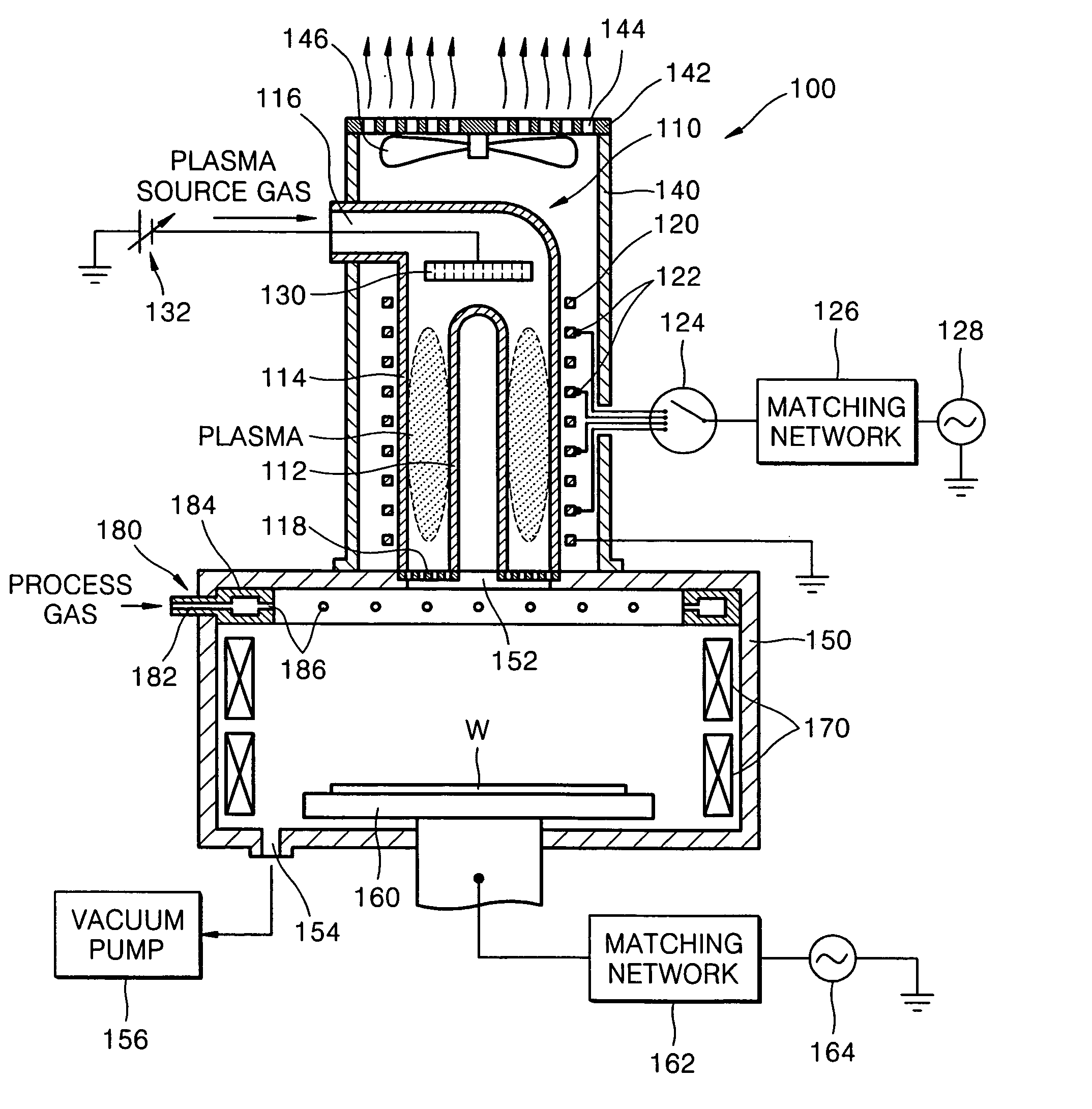

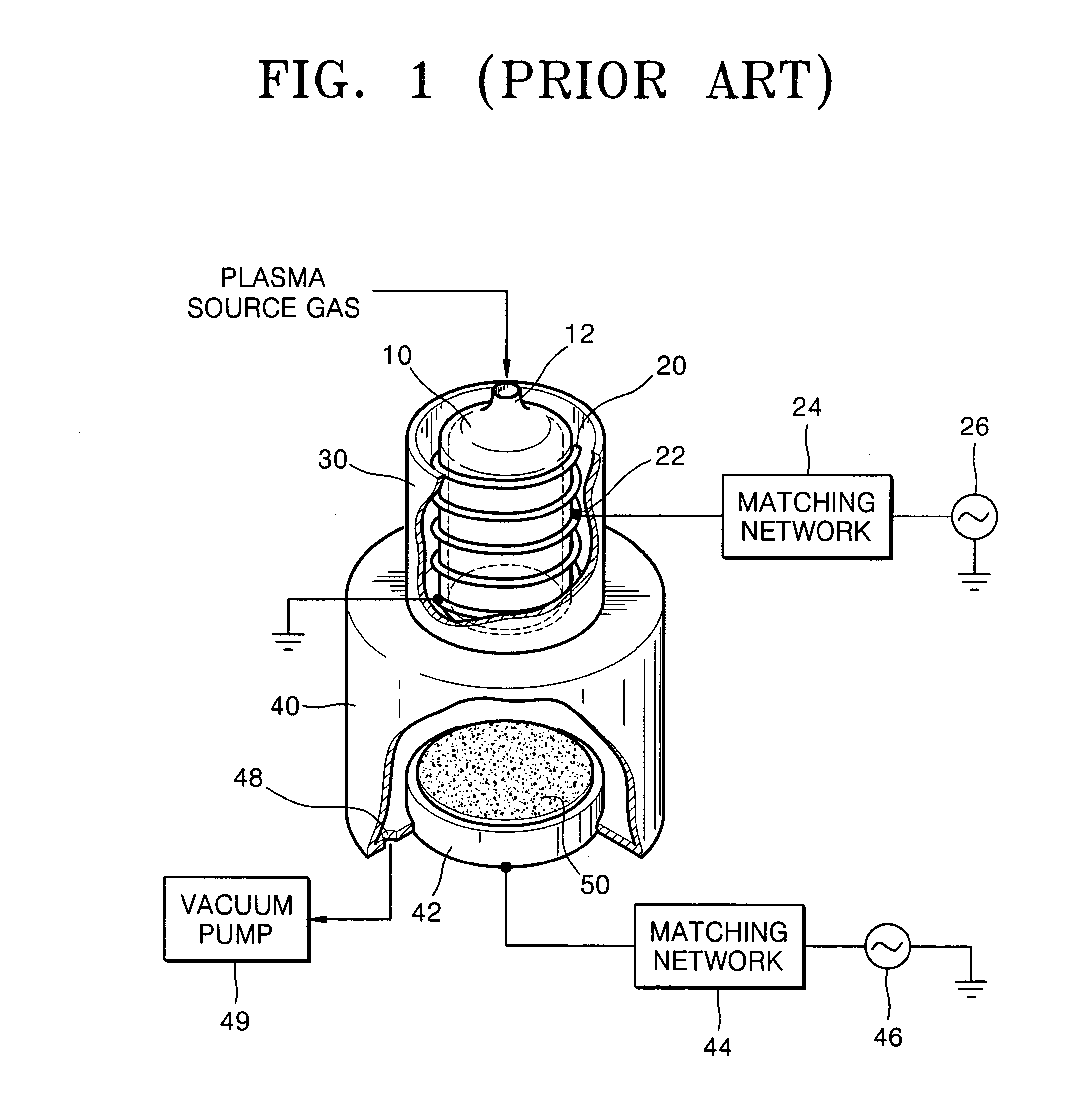

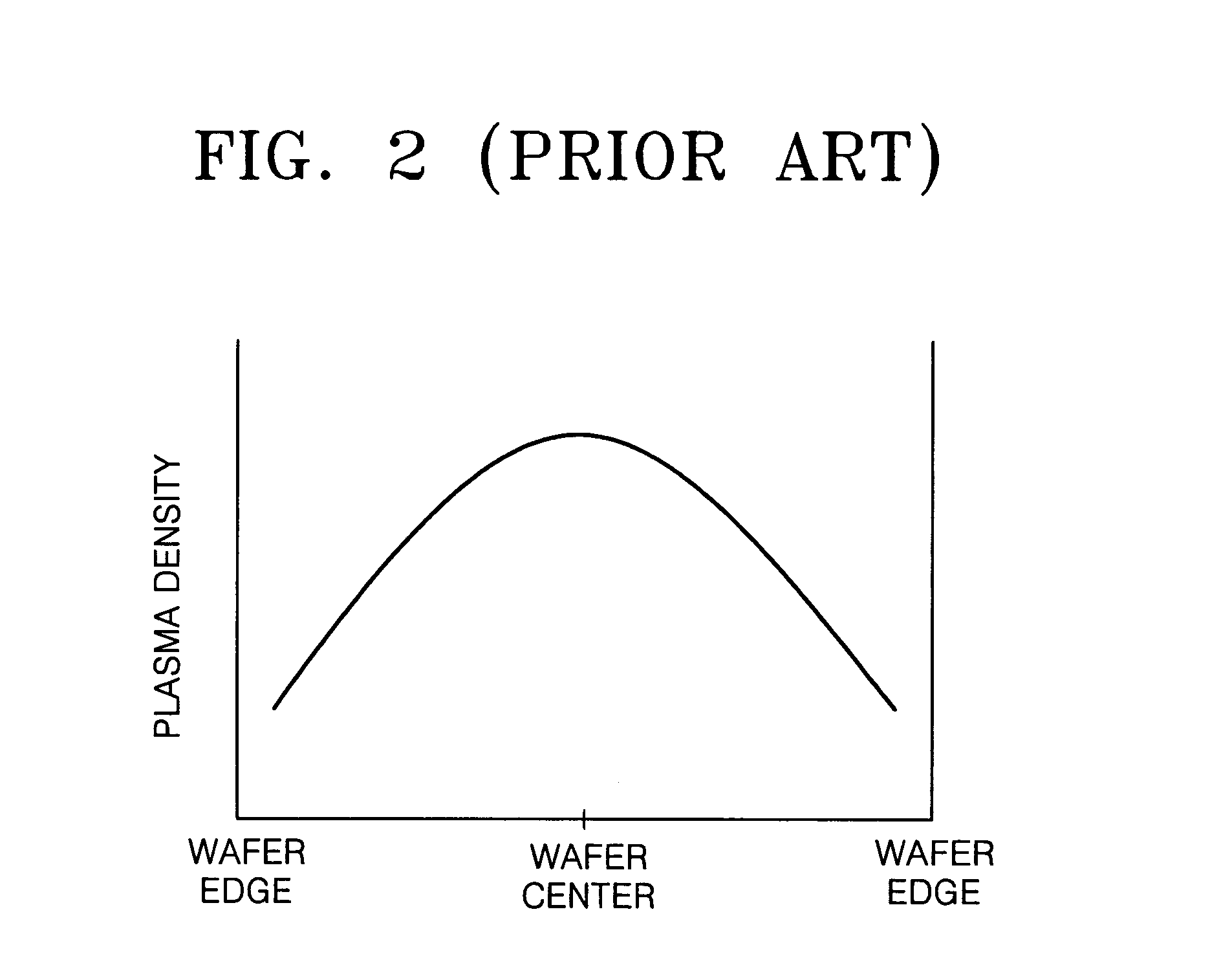

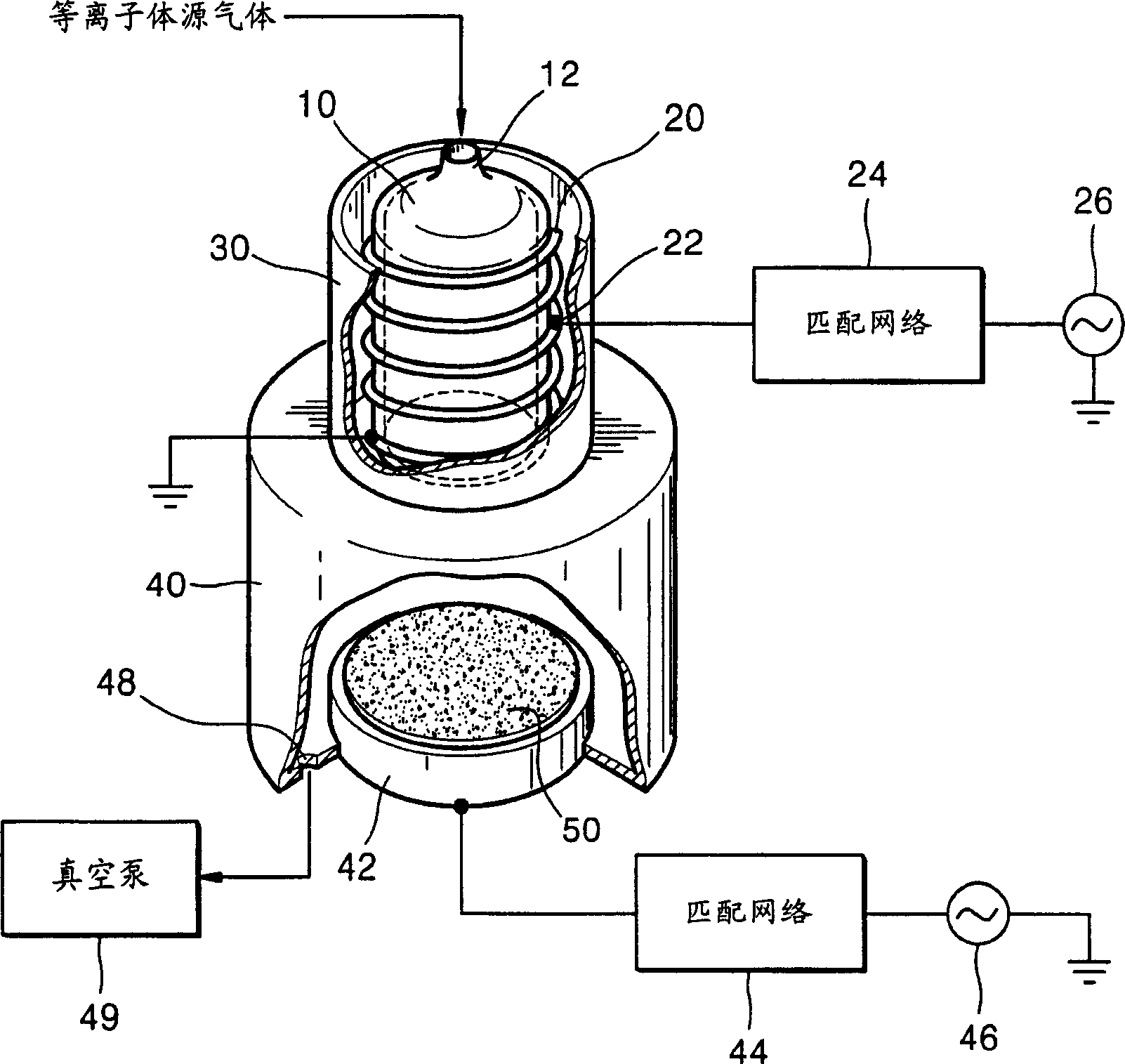

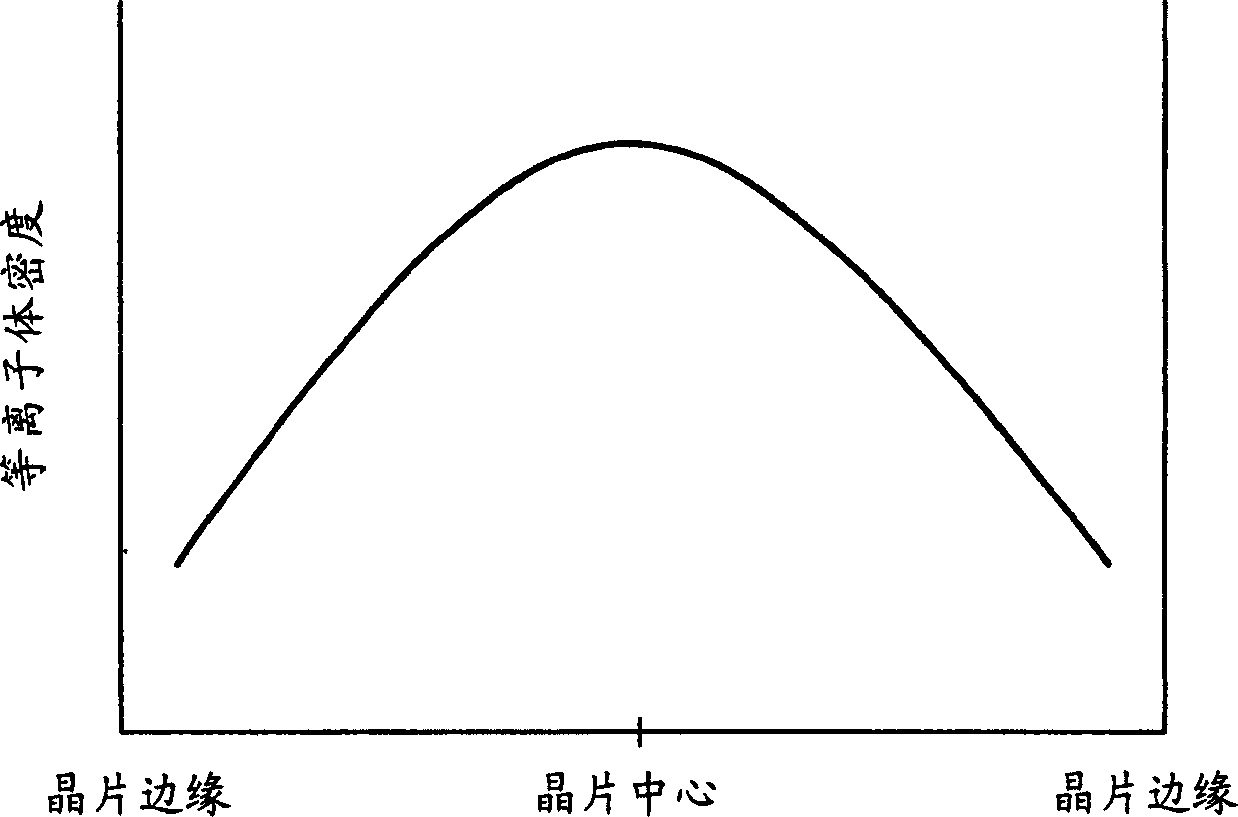

Helical resonator type plasma processing apparatus

InactiveUS20050093460A1Improve density uniformityEasy to controlElectric discharge tubesElectric arc lampsDouble tubeHelical resonator

Provided is helical resonator plasma processing apparatus. The plasma processing apparatus comprises a process chamber having a substrate holder for supporting a substrate, a dielectric tube disposed on the process chamber to communicate with the process chamber, a helix coil wounded around the dielectric tube, and an RF power source to supply RF power to the helix coil. The dielectric tube has a double tube shape and comprises an inner tube and an outer tube, and a plasma source gas inlet port to supply plasma source gas into a space between the inner tube and the outer tube is disposed in the outer tube. A control electrode to control plasma potential is disposed in the dielectric tube. This plasma processing apparatus provides a uniform plasma density distribution along a radial direction of a wafer, and easy control of the plasma potential in the process chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

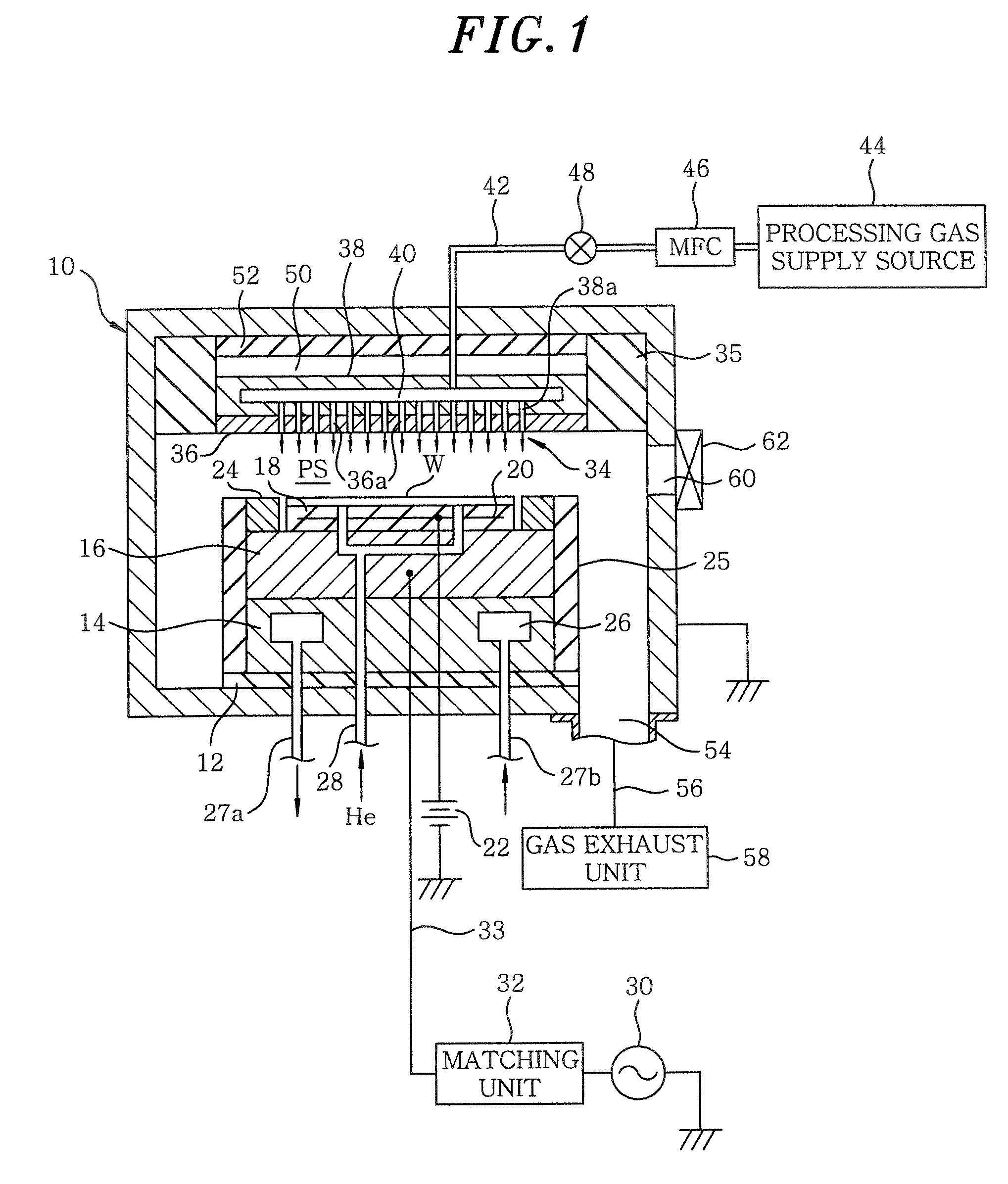

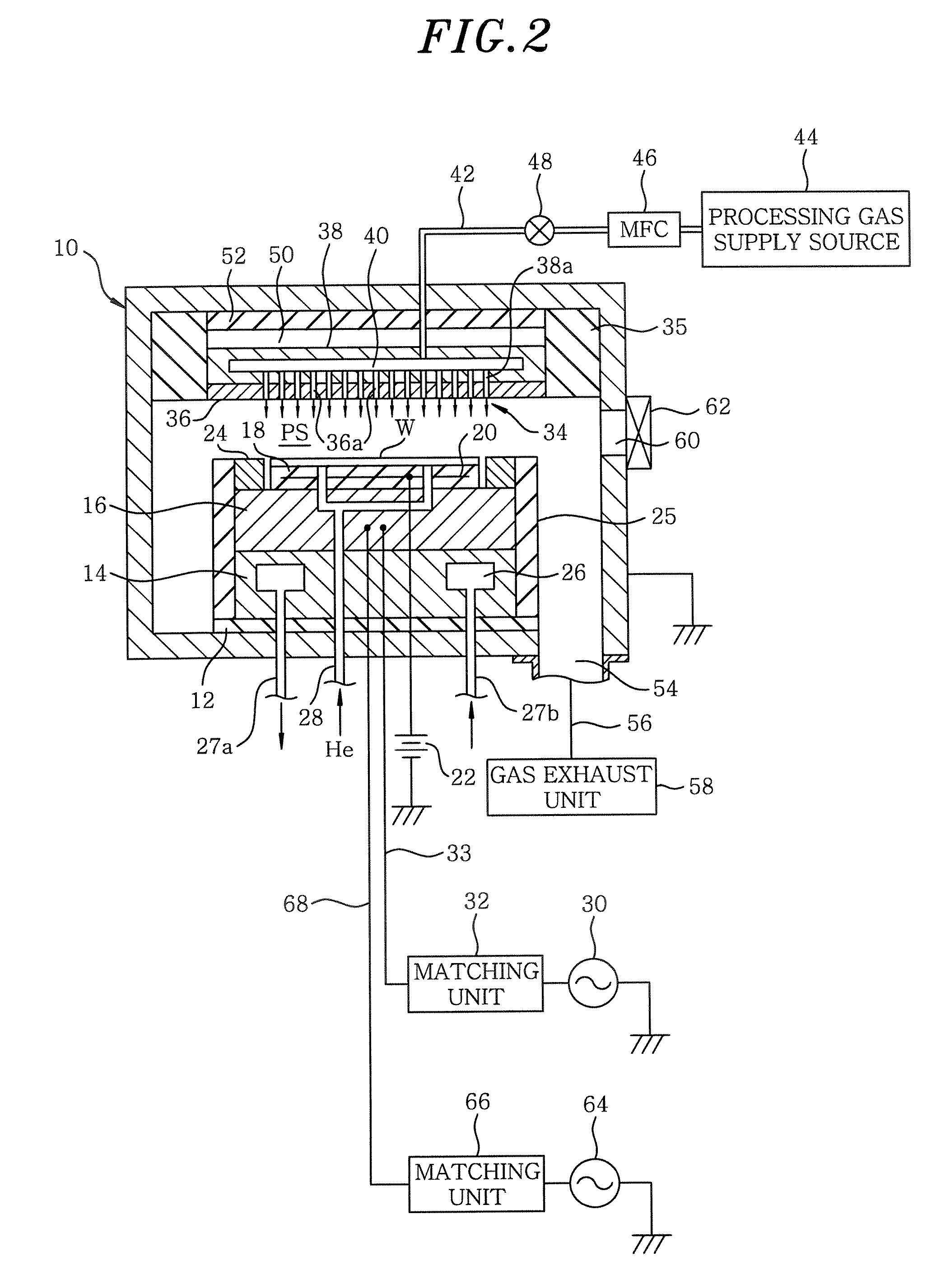

Plasma processing apparatus and plasma processing method

ActiveUS20110094996A1Improving uniformity of plasma processLow densityLiquid surface applicatorsElectric discharge tubesRadio frequencyRf discharge

A plasma processing apparatus includes a processing chamber including a dielectric window; a coil-shaped RF antenna, provided outside the dielectric window; a substrate supporting unit provided in the processing chamber; a processing gas supply unit; an RF power supply unit for supplying an RF power to the RF antenna to generate a plasma of the processing gas by an inductive coupling in the processing chamber, the RF power having an appropriate frequency for RF discharge of the processing gas; a correction coil, provided at a position outside the processing chamber where the correction coil is to be coupled with the RF antenna by an electromagnetic induction, for controlling a plasma density distribution on the substrate in the processing chamber; a switching device provided in a loop of the correction coil; and a switching control unit for on-off controlling the switching device at a desired duty ratio by pulse width modulation.

Owner:TOKYO ELECTRON LTD

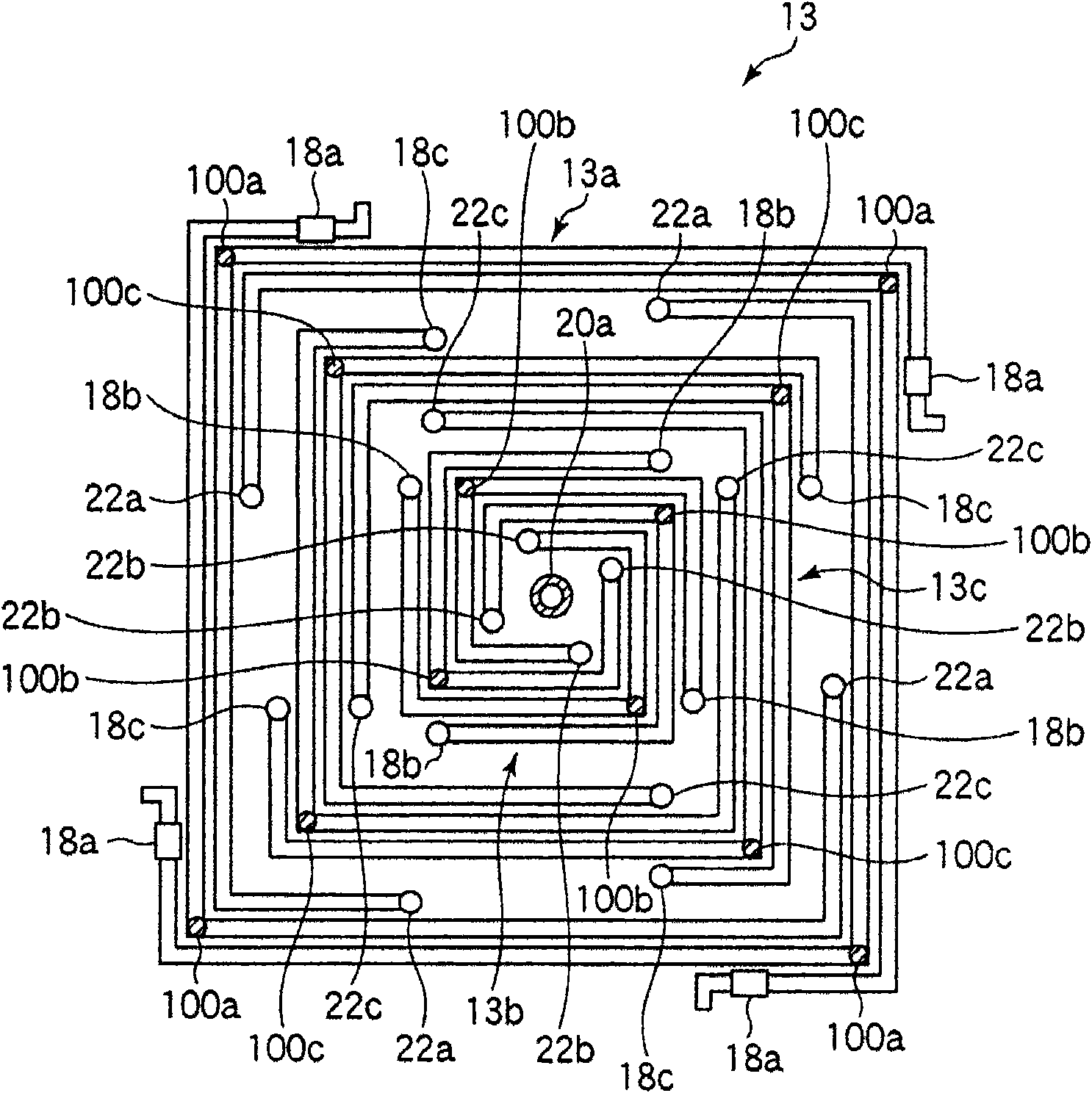

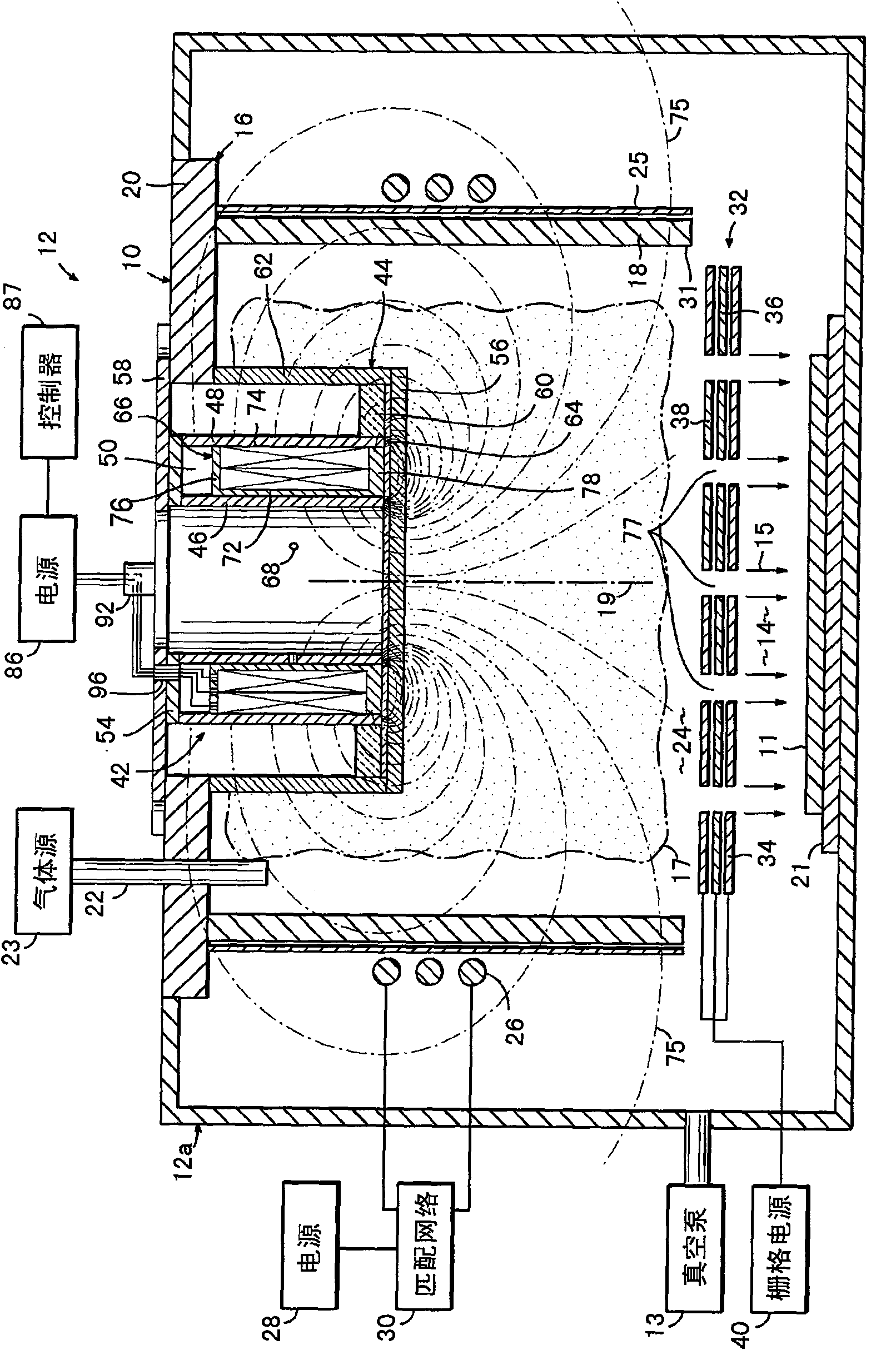

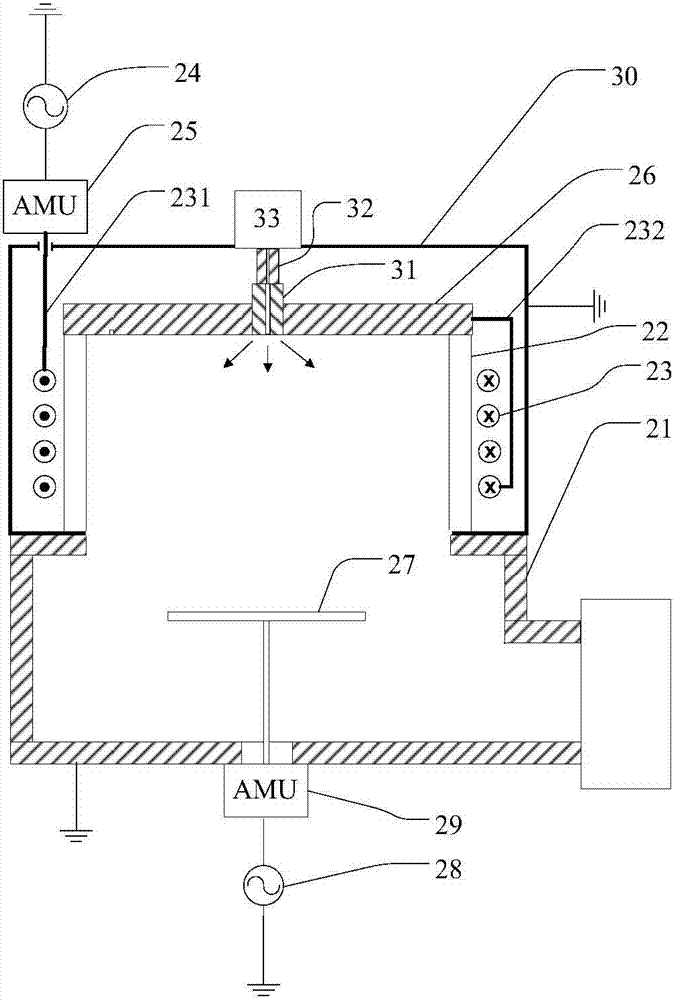

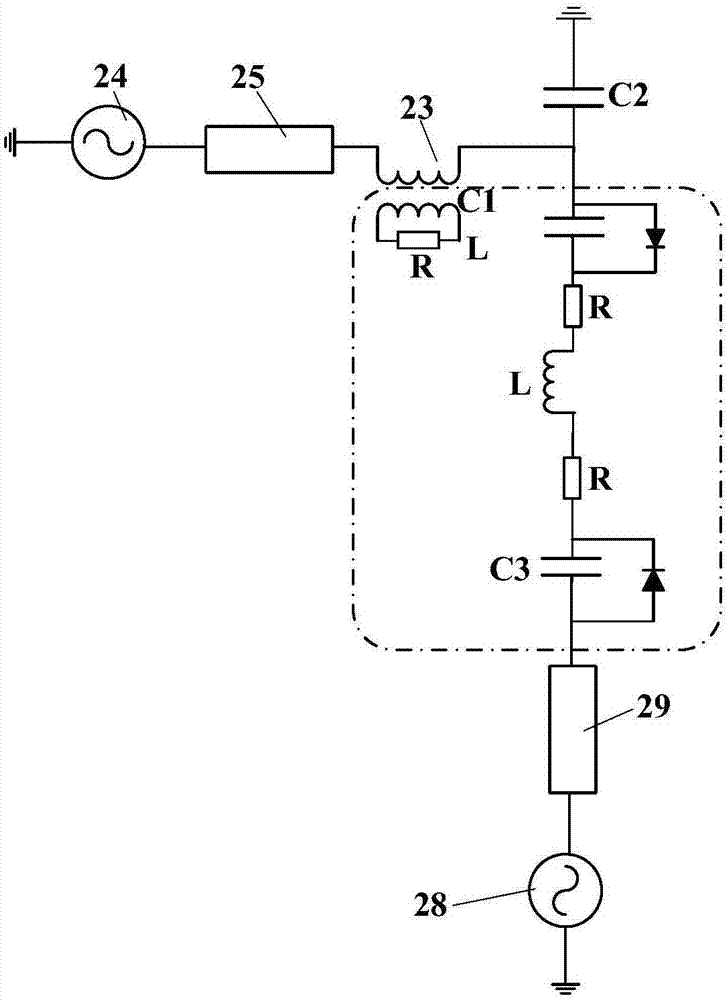

Inductance coupling plasma processing device and plasma processing method

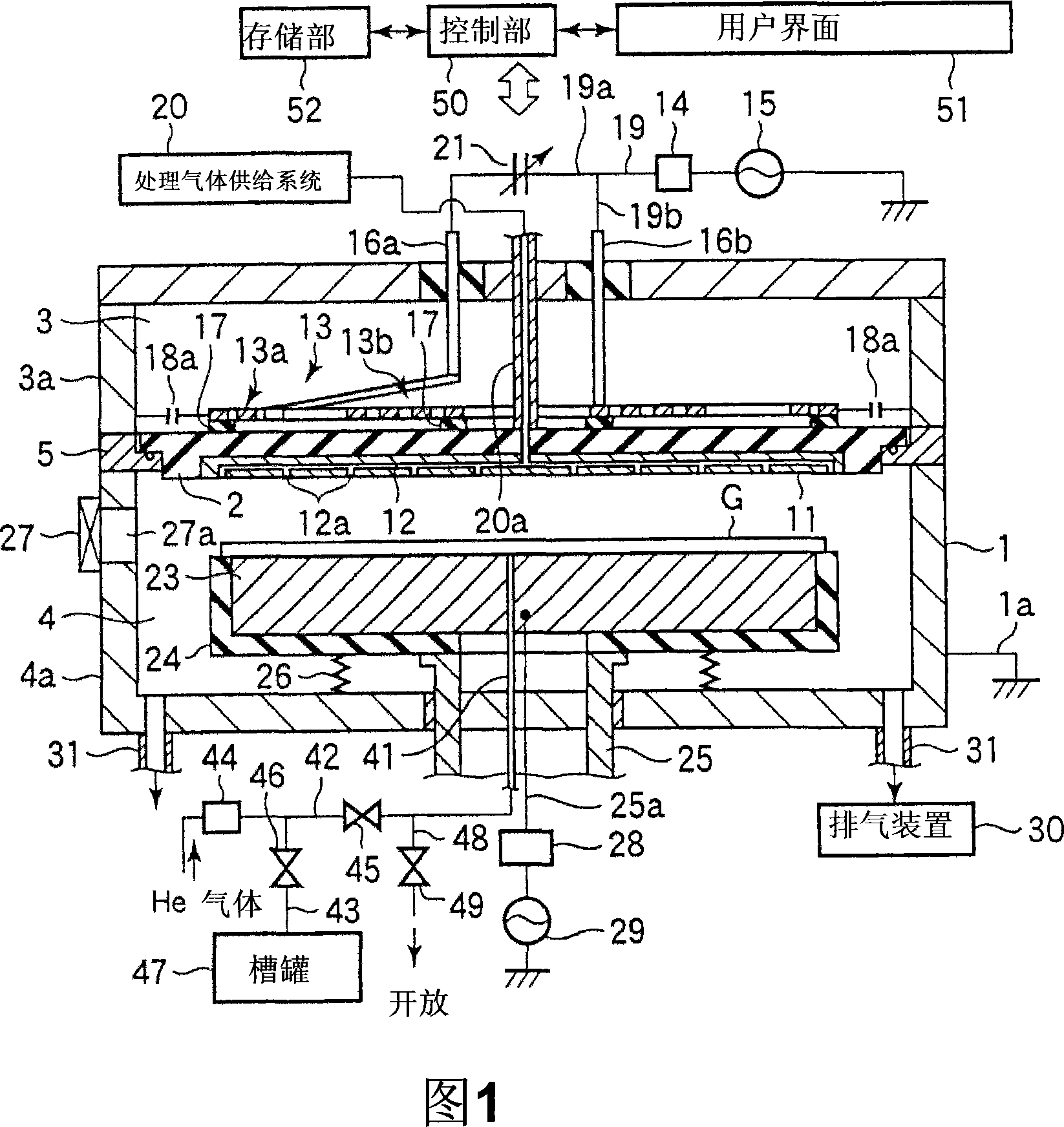

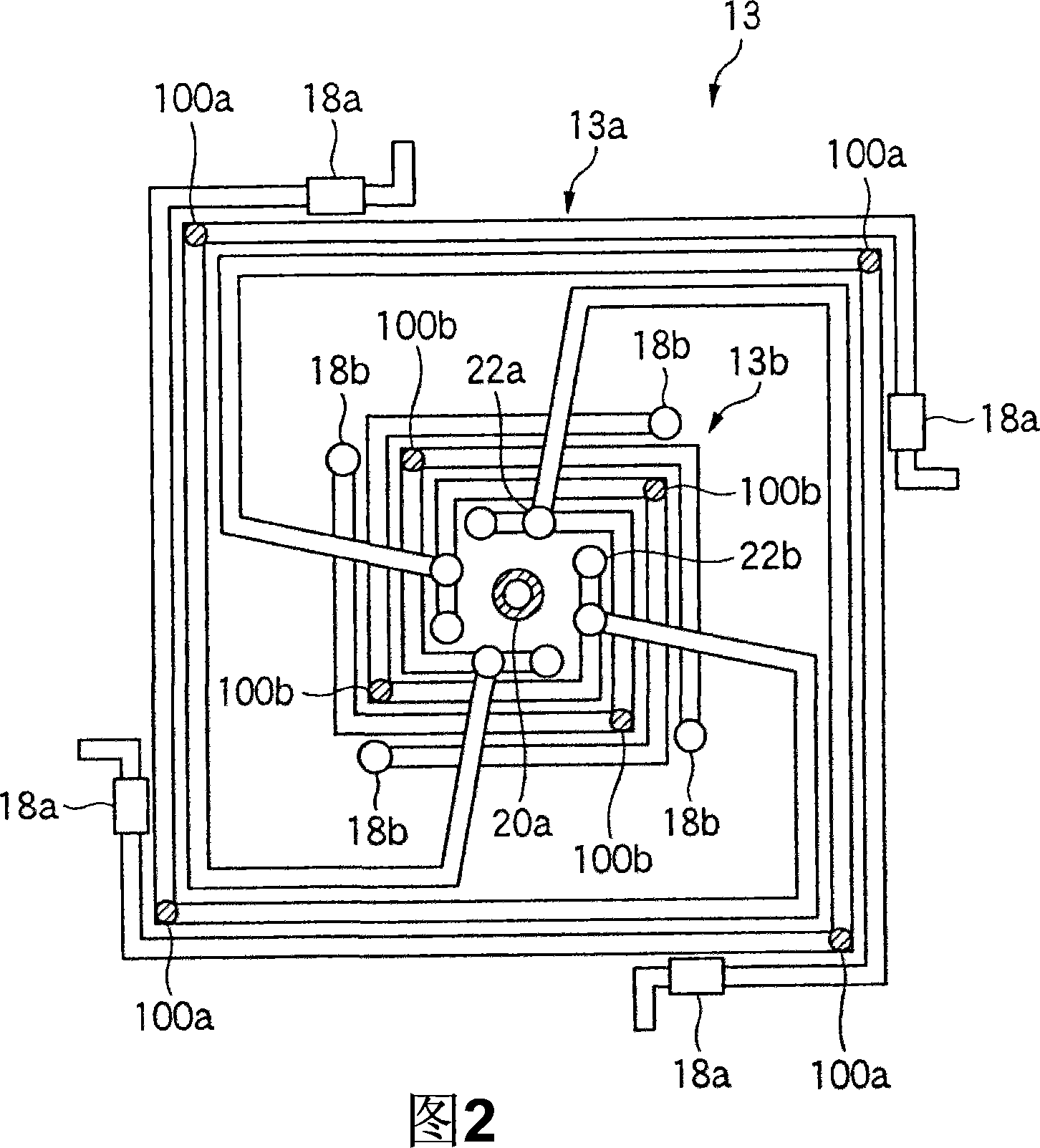

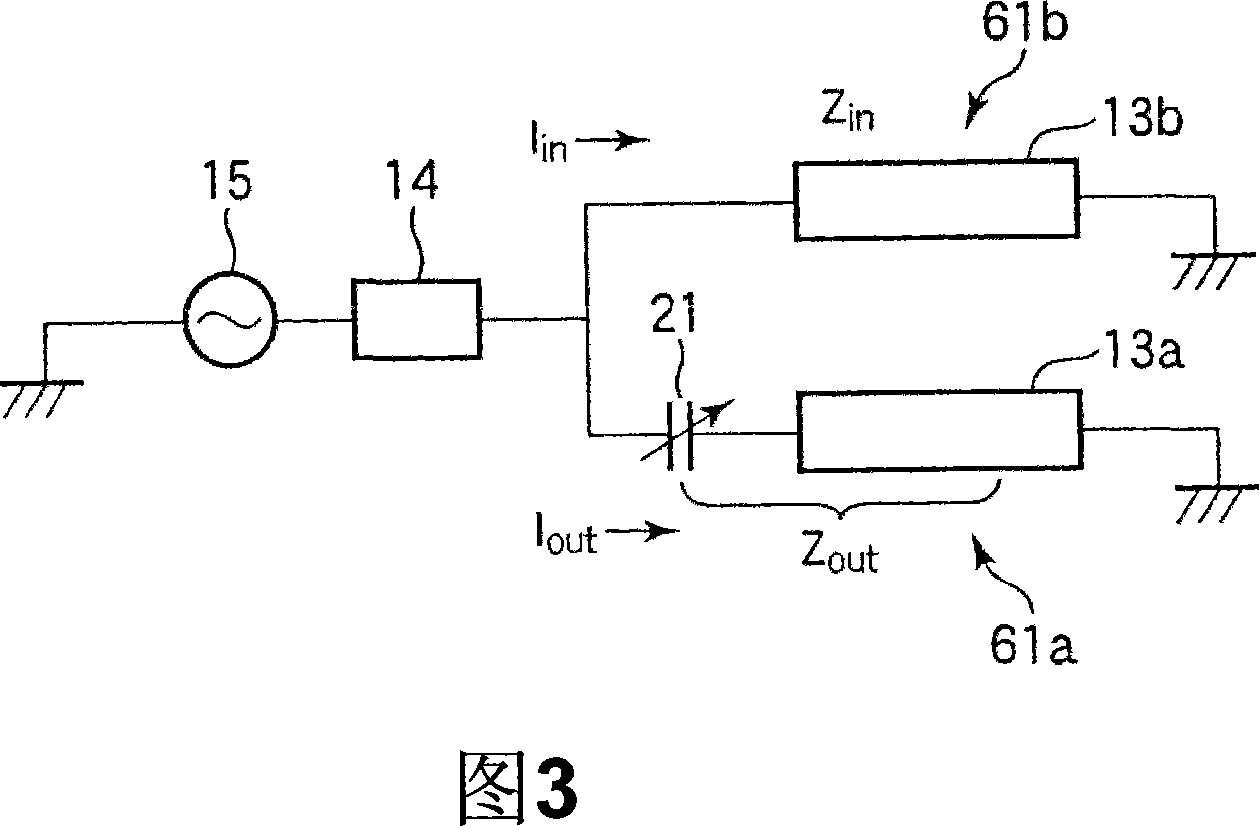

ActiveCN101076220AHigh control precisionMolten spray coatingElectric discharge tubesDielectricEngineering

The invention provides an inductance coupling plasma processing device, which can control plasma density of high precision, without replacing aerial, increasing the device price and electric power cost. A HF antenna (13) is installed by dielectric wall (2) above the processing chamber (4) and the said HF antenna comprises an outside aerial part (13a) forming induction field on the lateral part through applying the electric power of high frequency in the processing chamber (4) and inside aerial part (13b) forming induction field on the medial part and the variable capacitor (21) is connected with one side of the outside aerial part (13a) and the inside aerial part (13b). The current value of the outside aerial part (13a) and the inside aerial part (13b)is controlled through adjusting the capacitivity of the variable capacitor (21) and the plasma density distribution of the inductance coupling plasma formed in the processing chamber (4) is also controlled.

Owner:TOKYO ELECTRON LTD

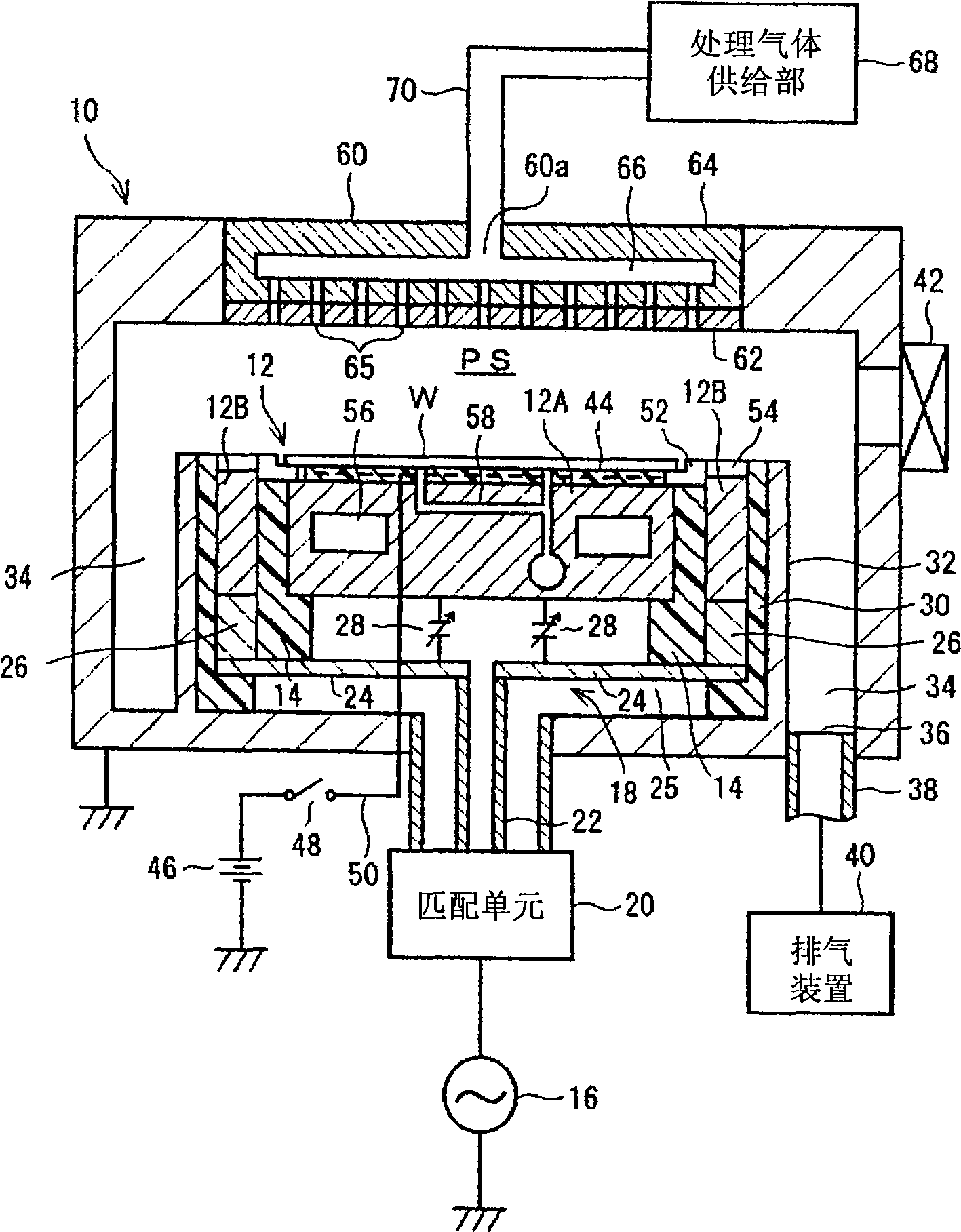

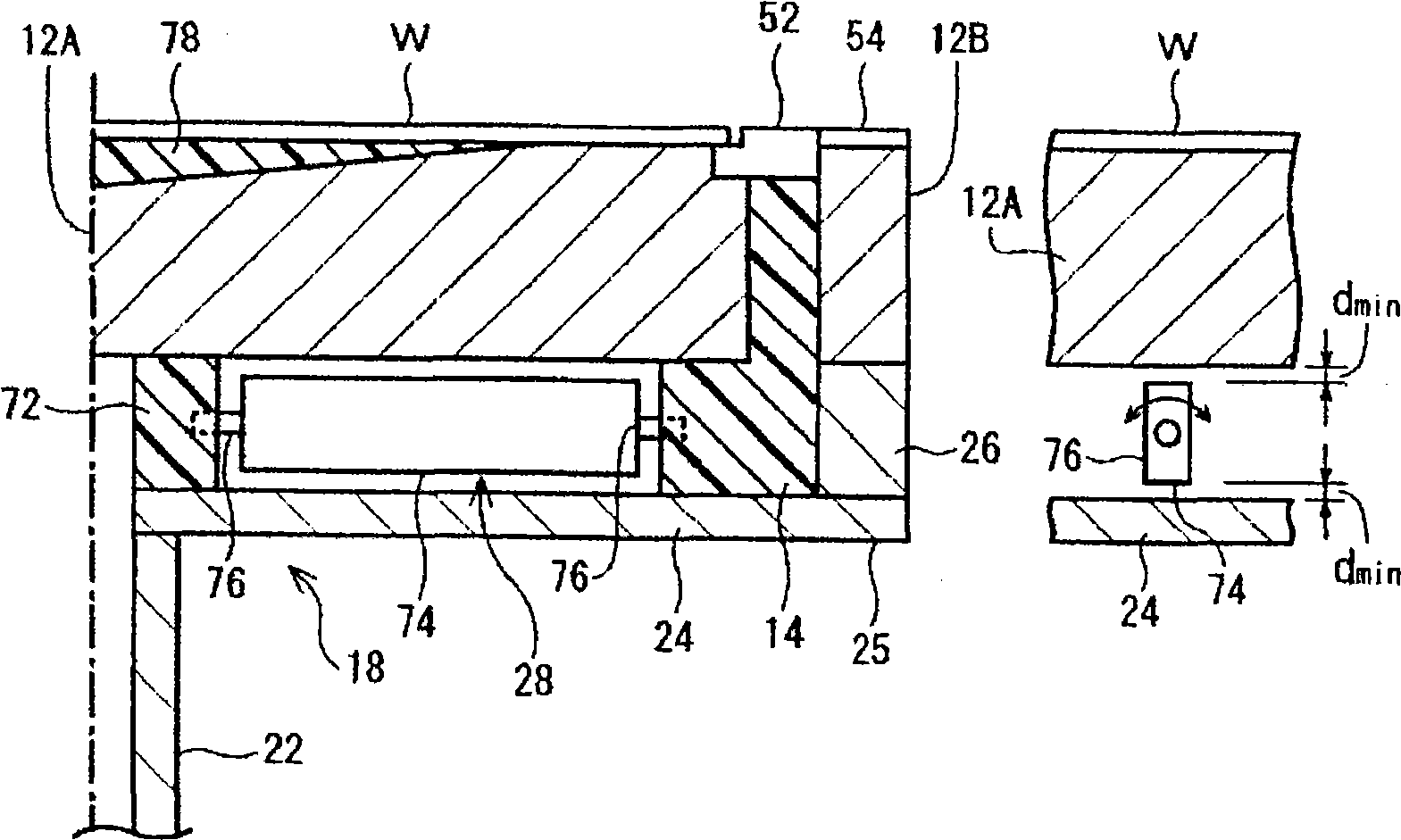

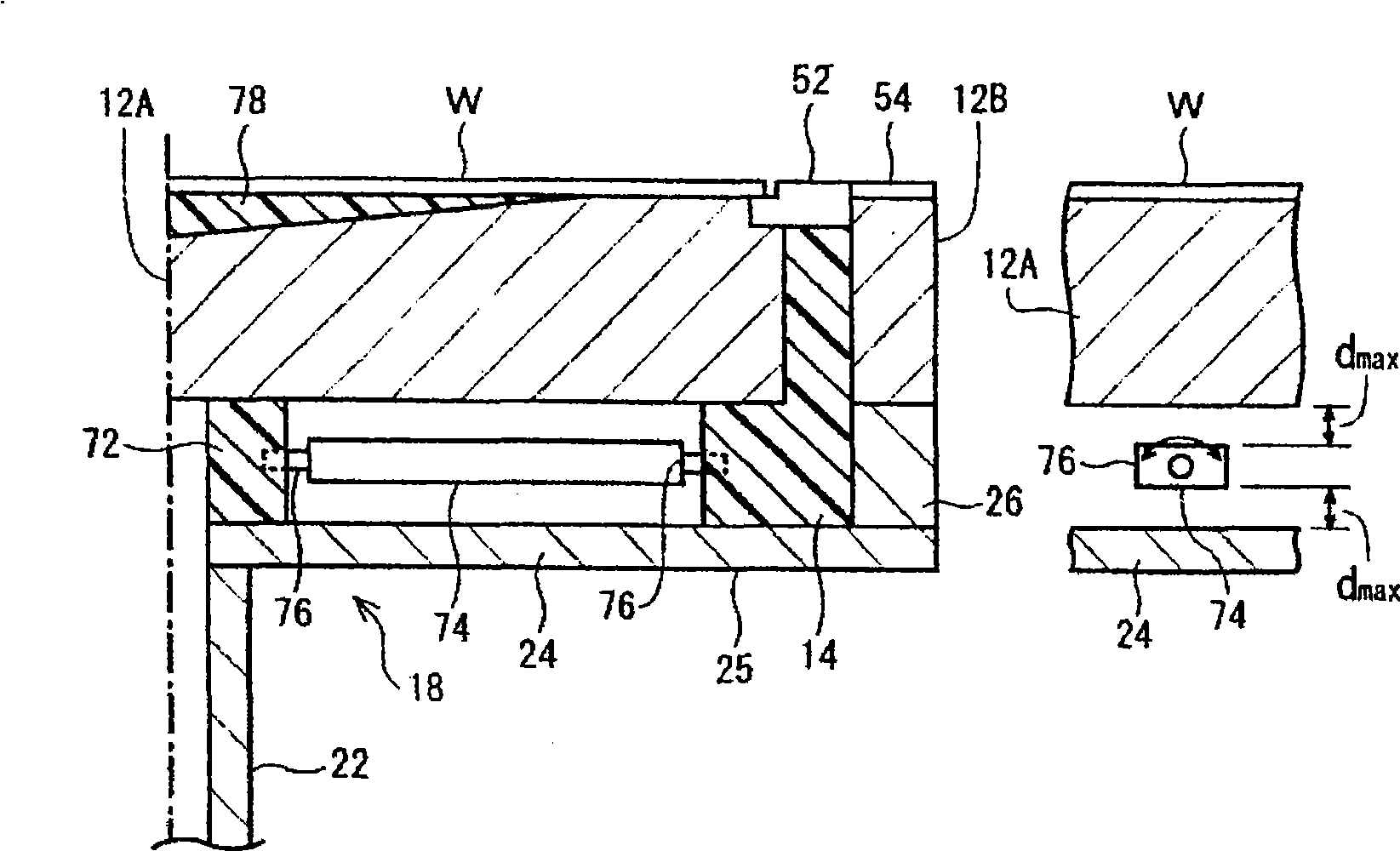

Plasma processing apparatus

ActiveCN101546697AIntensity distribution optimizationControl density distributionElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceSusceptor

The present invention provides a capacitively coupled plasma processing apparatus capable of easily and arbitrarily adjusting the plasma density distribution, and improving uniformity and the manufacturing yield of the plasma processing. The susceptor 12 is radially divided into two: a susceptor center electrode 12A, and an annular susceptor peripheral electrode 12B surrounding. The RF power output from a high frequency power source is preferably supplied to the susceptor perimeter electrode 12B through a lower power feed conductor 18 for high frequency discharge or plasma generation, and simultaneously the RF power is supplied to the susceptor central electrode 12A as well through the variable capacitance coupling unit 28 at a variable distribution ratio.

Owner:TOKYO ELECTRON LTD

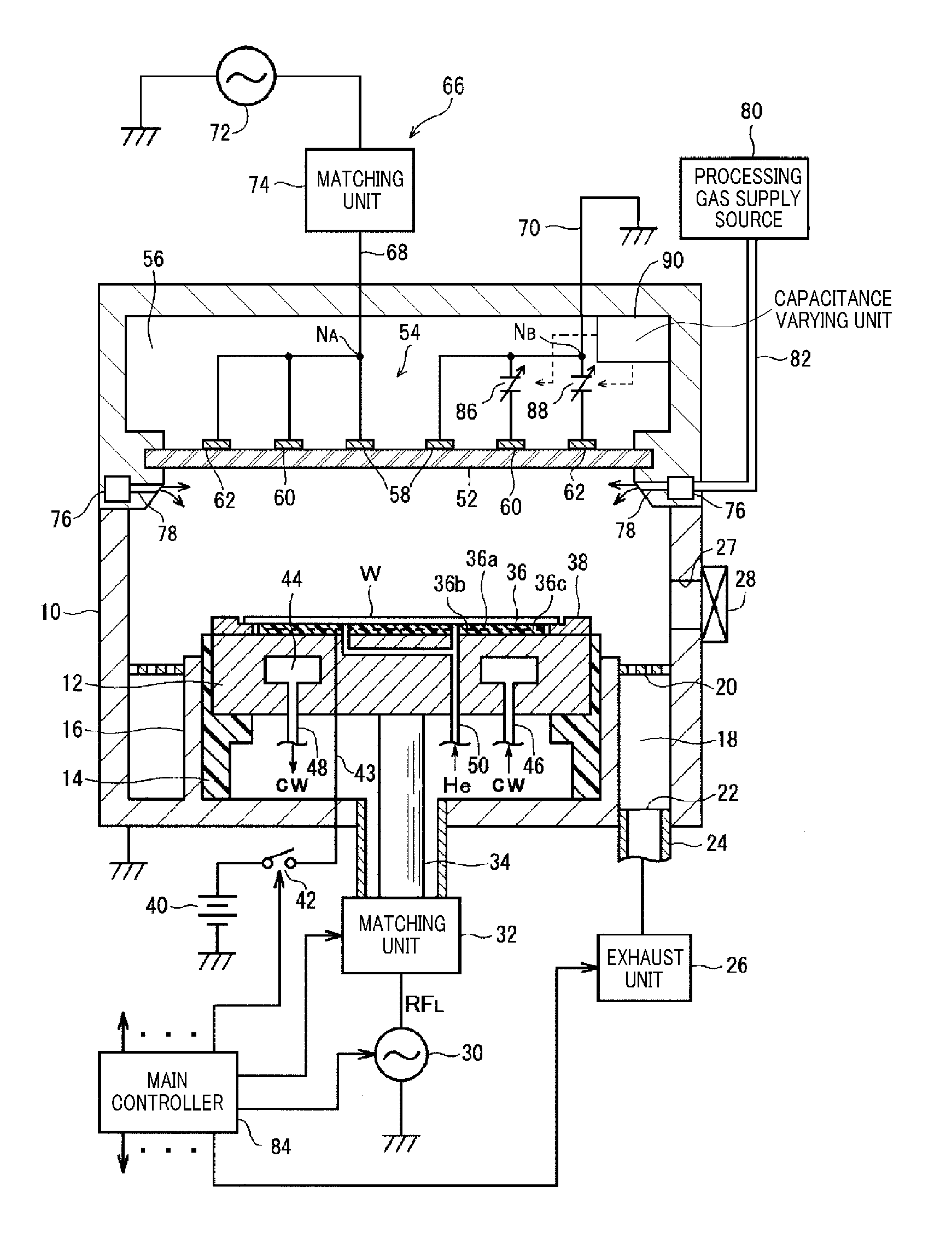

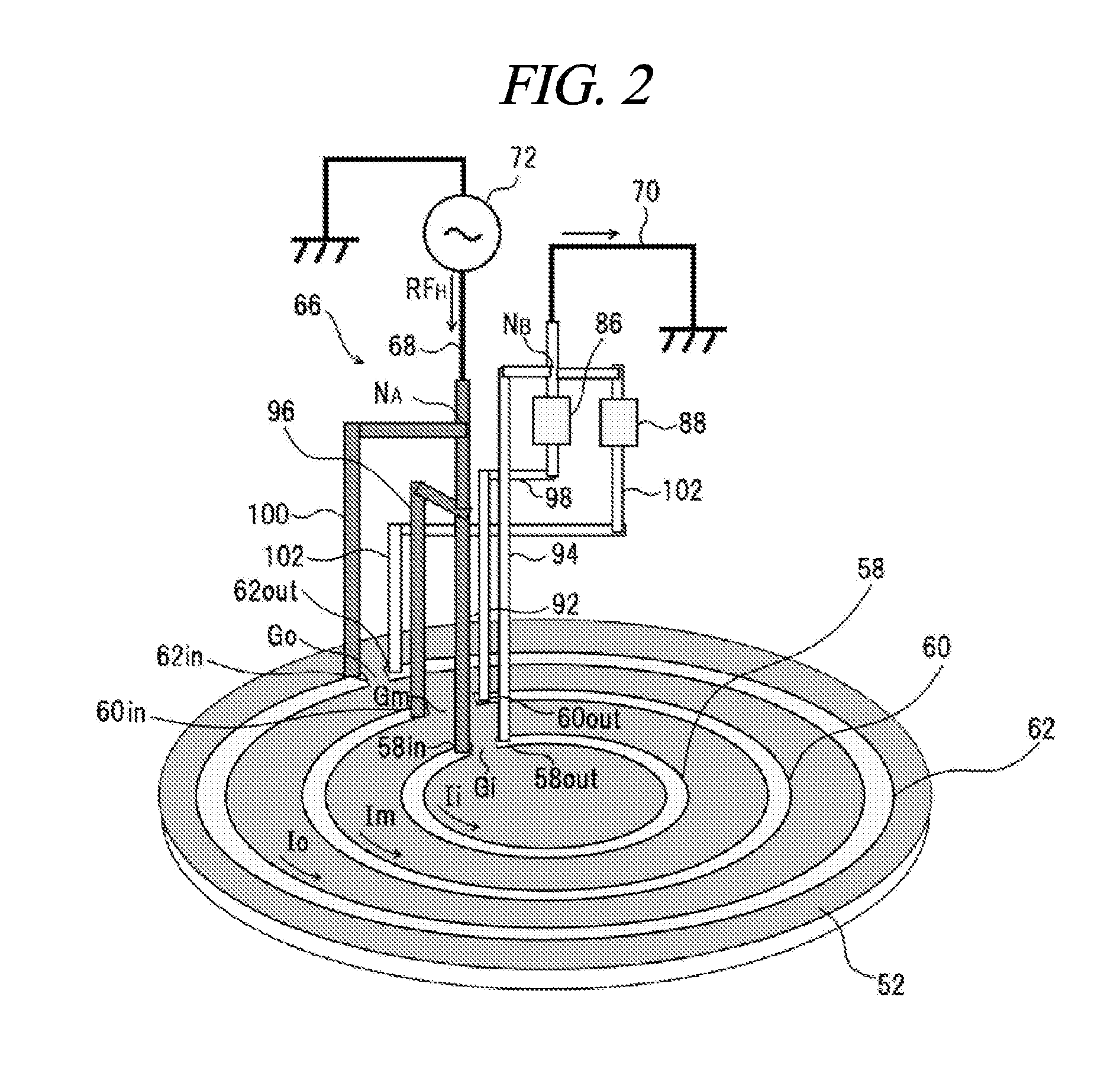

Plasma processing apparatus and plasma processing method

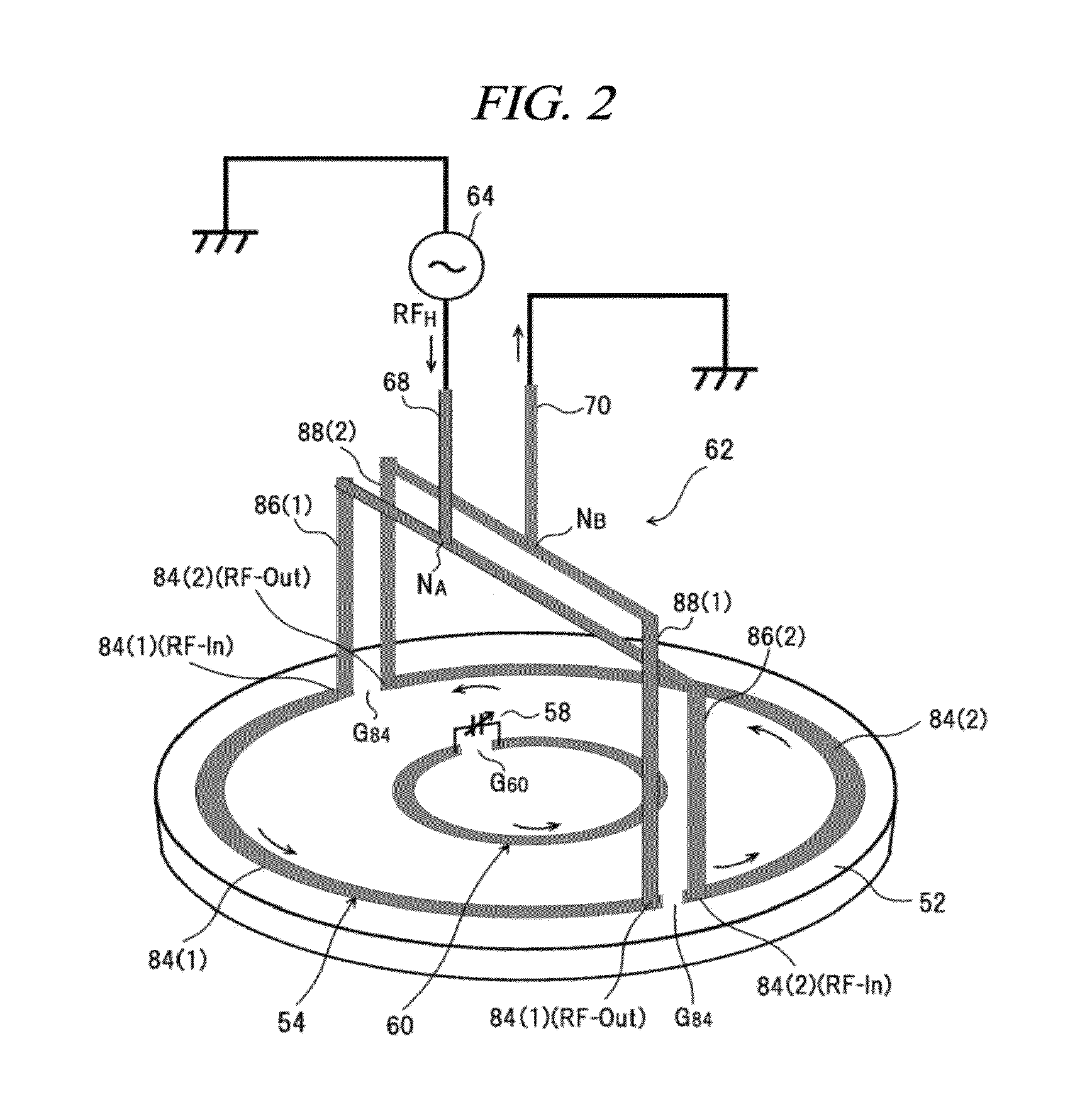

InactiveUS20120248066A1Effectively and easily controllingIncrease freedomLiquid surface applicatorsElectric discharge tubesHigh frequency powerInductively coupled plasma

An inductively coupled plasma process can effectively and properly control plasma density distribution within donut-shaped plasma in a processing chamber is provided. In an inductively coupled plasma processing apparatus, a RF antenna 54 disposed above a dielectric window 52 is segmented in a diametrical direction into an inner coil 58, an intermediate coil 60, and an outer coil 62 in order to generate inductively coupled plasma. Between a first node NA and a second node NB provided in high frequency transmission lines of the high frequency power supply unit 66, a variable intermediate capacitor 86 and a variable outer capacitor 88 are electrically connected in series to the intermediate coil 60 and the outer coil 62, respectively, and no reactance device is connected to the inner coil 58.

Owner:TOKYO ELECTRON LTD

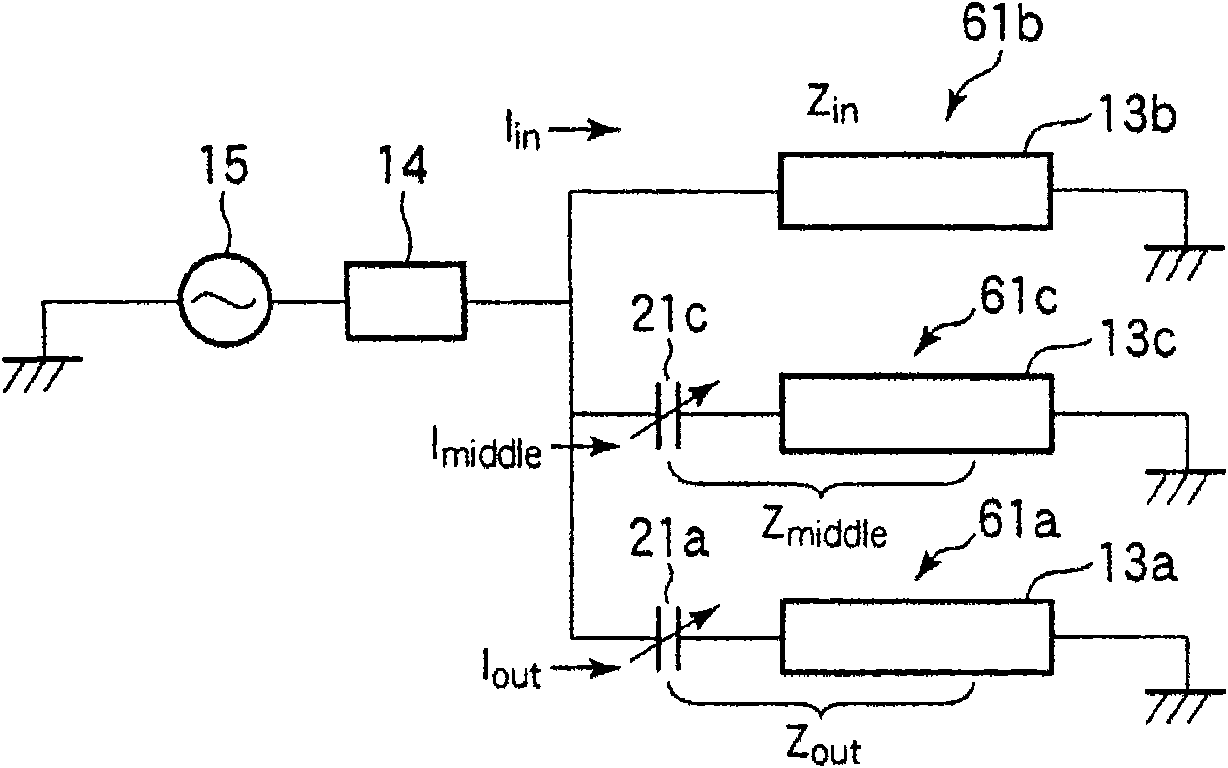

Inductive couple plasma processing device

InactiveCN101583234AElectric discharge tubesSemiconductor/solid-state device manufacturingConductor CoilPlasma processing

The present invention provides an inductive couple plasma processing device capable of obtaining a uniform plasma distribution even to a large substrate. The inductive couple plasma is provided with a high-frequency antenna 13 separated by a dielectric wall 2 in the upper side of a processing chamber 4, and the high-frequency antenna 13 comprises an external side antenna part 13a mainly forming an induced field in the external side part, an internal side antenna part 13b mainly forming an induced field in the internal side part, and a middle antenna part 13c for forming an induced field between the external side part and the internal side part, and variable capacitors 21a, 21c for controlling the plasma density distribution of a inductive couple plasma are respectively connected with the external side antenna part 13a and the middle antenna part 13c. Each antenna part forms a helical multiple-antenna, furthermore, in the configuration area, a winding method is set according to a mode of forming a uniform electric field, and the winding number is set according to a mode of realizing uniformization of the electric field in the configuration area of each antenna.

Owner:TOKYO ELECTRON LTD

Ion sources and methods for generating an ion beam with controllable ion current density distribution

Ion sources and methods for generating an ion bean with a controllable ion current density distribution. The ion source includes a discharge chamber having an optical grid position proximate at a first end and a re-entrant vessel positioned proximate a second end that opposes the first end. A plasma shaper extends from the re-entrant vessel and into the plasma discharge chamber. A position of the plasma shaper is adjustable relative to the grid-based ion optic such that the plasma shaper may operably change a plasma density distribution within the discharge chamber.

Owner:VEECO INSTR

Adjustable electrodes and coils for plasma density distribution control

InactiveUS7829815B2Electric discharge tubesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A adjustable upper coil or electrode for a reaction chamber apparatus useable in semiconductor processing, is constructed so that its shape may be selectively changed or so at least two portions thereof may be selectively driven at different power and / or frequencies. The adjustable upper coil or electrode, therefore, enables the plasma density distribution in the reaction chamber apparatus to be selectively controlled.

Owner:TAIWAN SEMICON MFG CO LTD

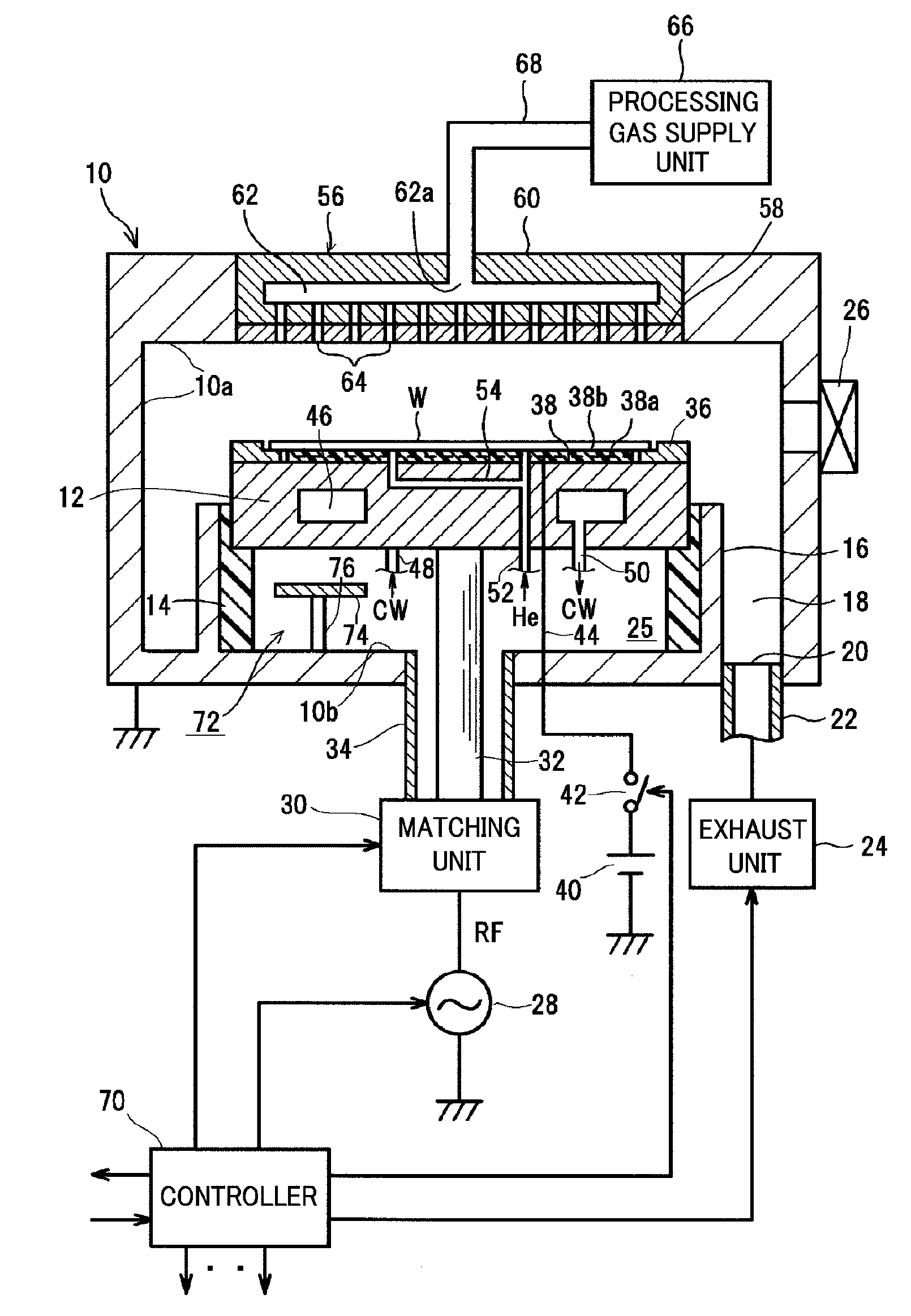

Plasma processing apparatus and plasma processing method

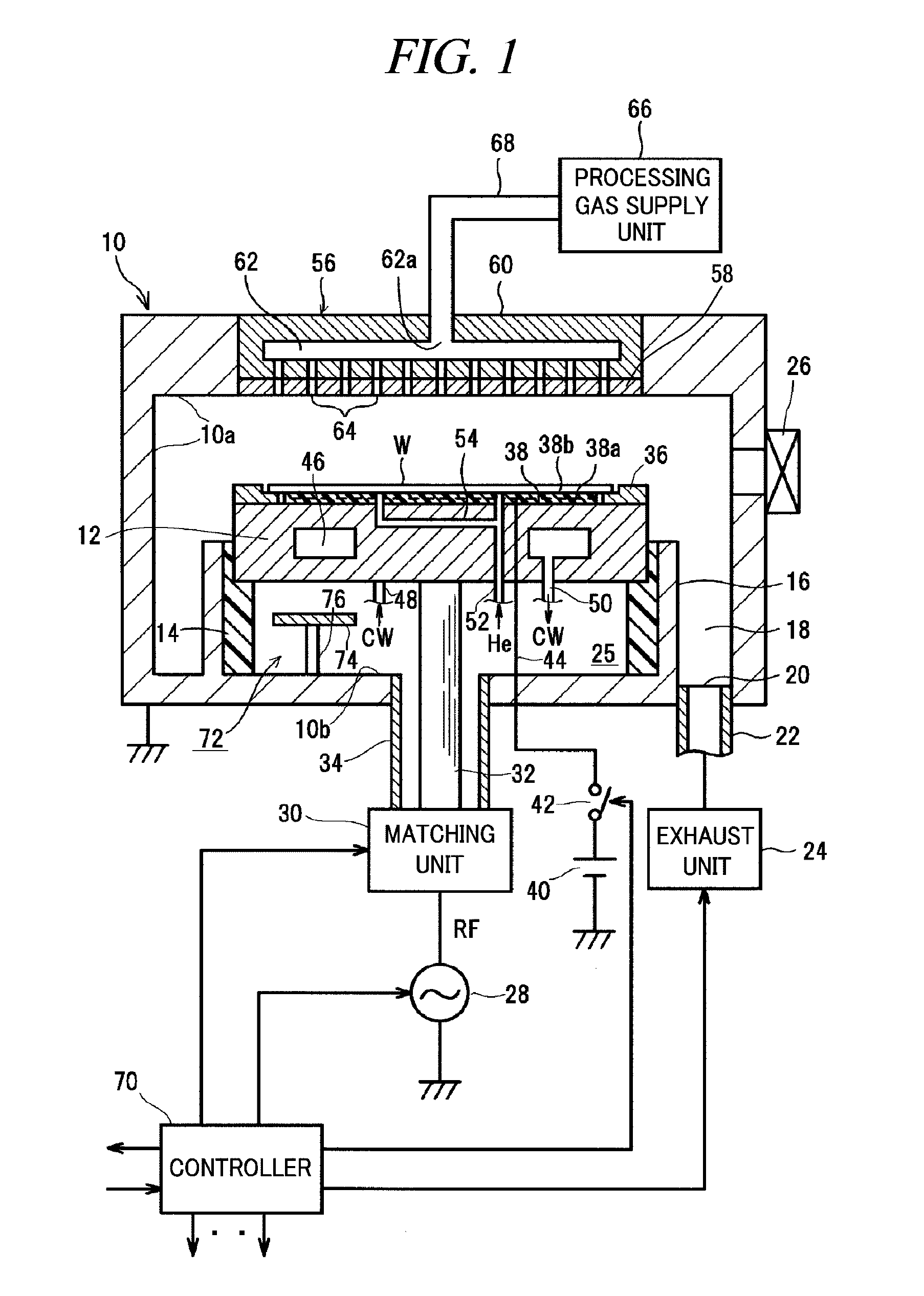

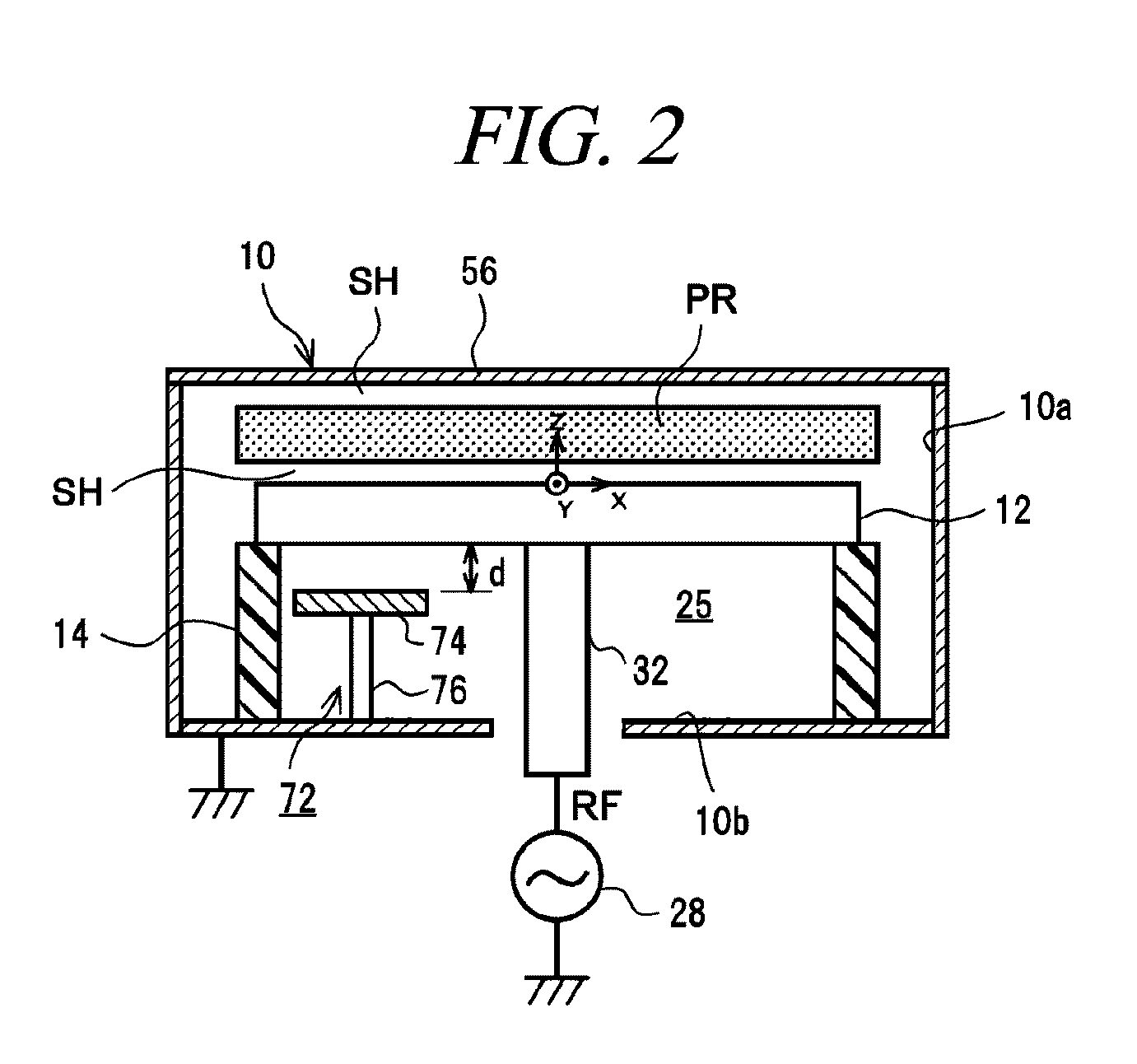

InactiveUS20100243609A1Improve uniformityIncreased degrees of freedomElectric discharge tubesDecorative surface effectsCapacitanceSusceptor

Uniformity of plasma density distribution and process characteristics is improved by greatly improving performance and the degree of freedom for controlling the plasma density distribution. A capacitively coupled plasma processing apparatus includes a plasma density distribution controller, installed in a chamber lower room, for controlling plasma density distribution on a susceptor. The plasma density distribution controller includes a conductive plate (first conductor) which is placed under a rear surface of the susceptor at a certain position to face the susceptor and a conductive rod (second conductor) which supports the conductive plate upward and is electrically grounded. An upper end (first connecting portion) of the conductive rod is fixed to a certain portion of a bottom surface of the conductive plate, and a lower end (second connecting portion) of the conductive rod is fixed to or is in contact with a bottom wall of a chamber.

Owner:TOKYO ELECTRON LTD

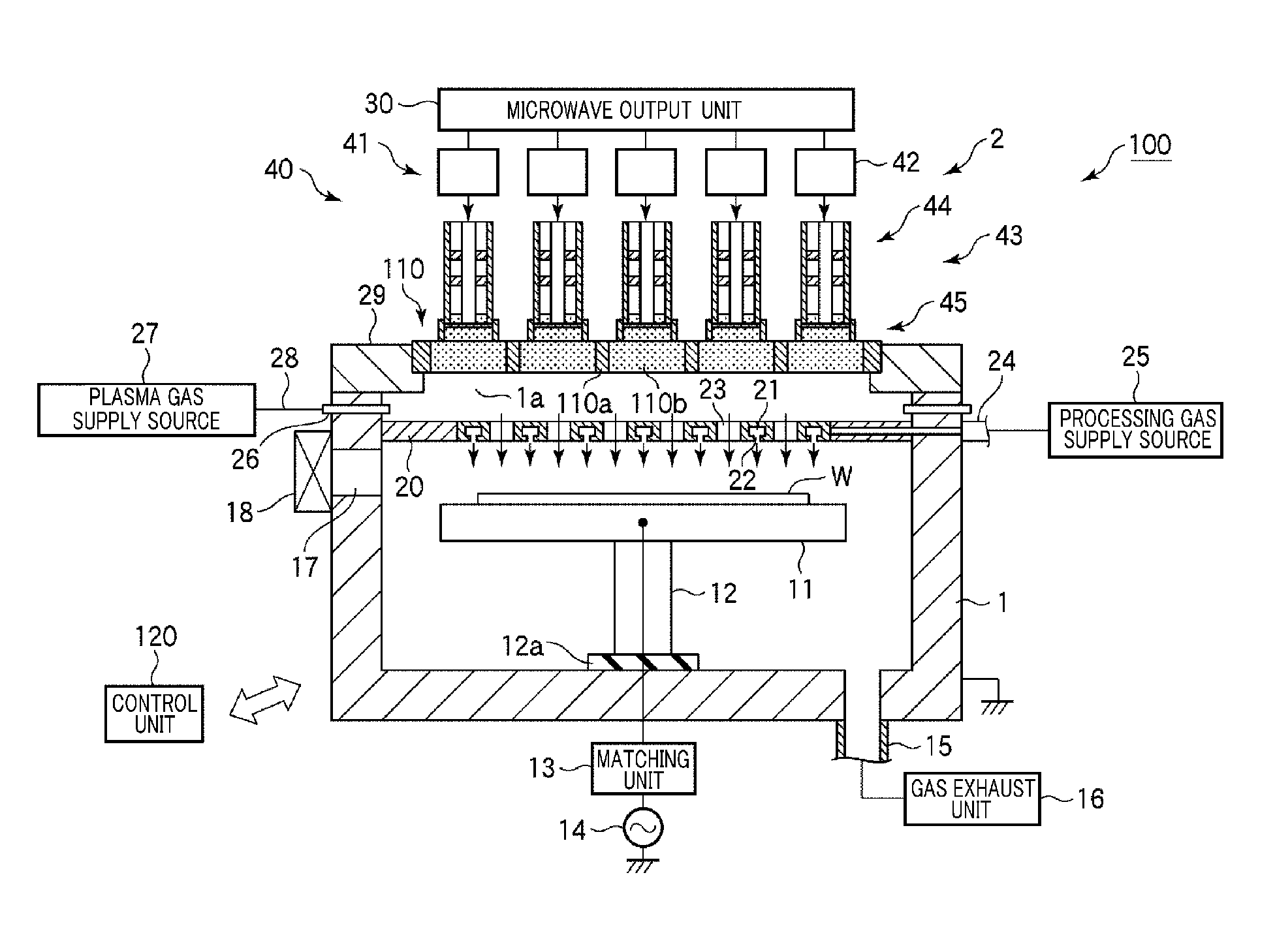

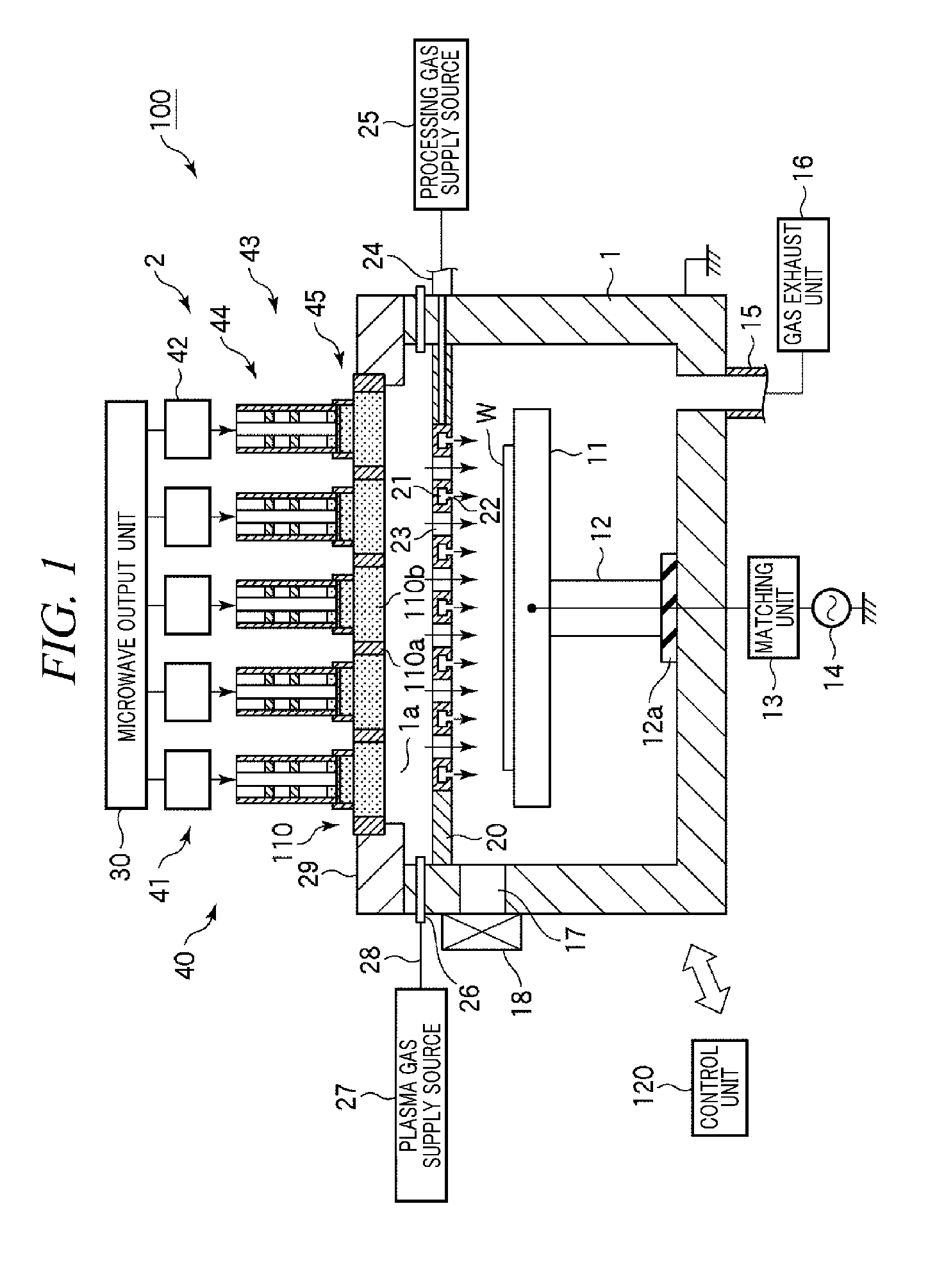

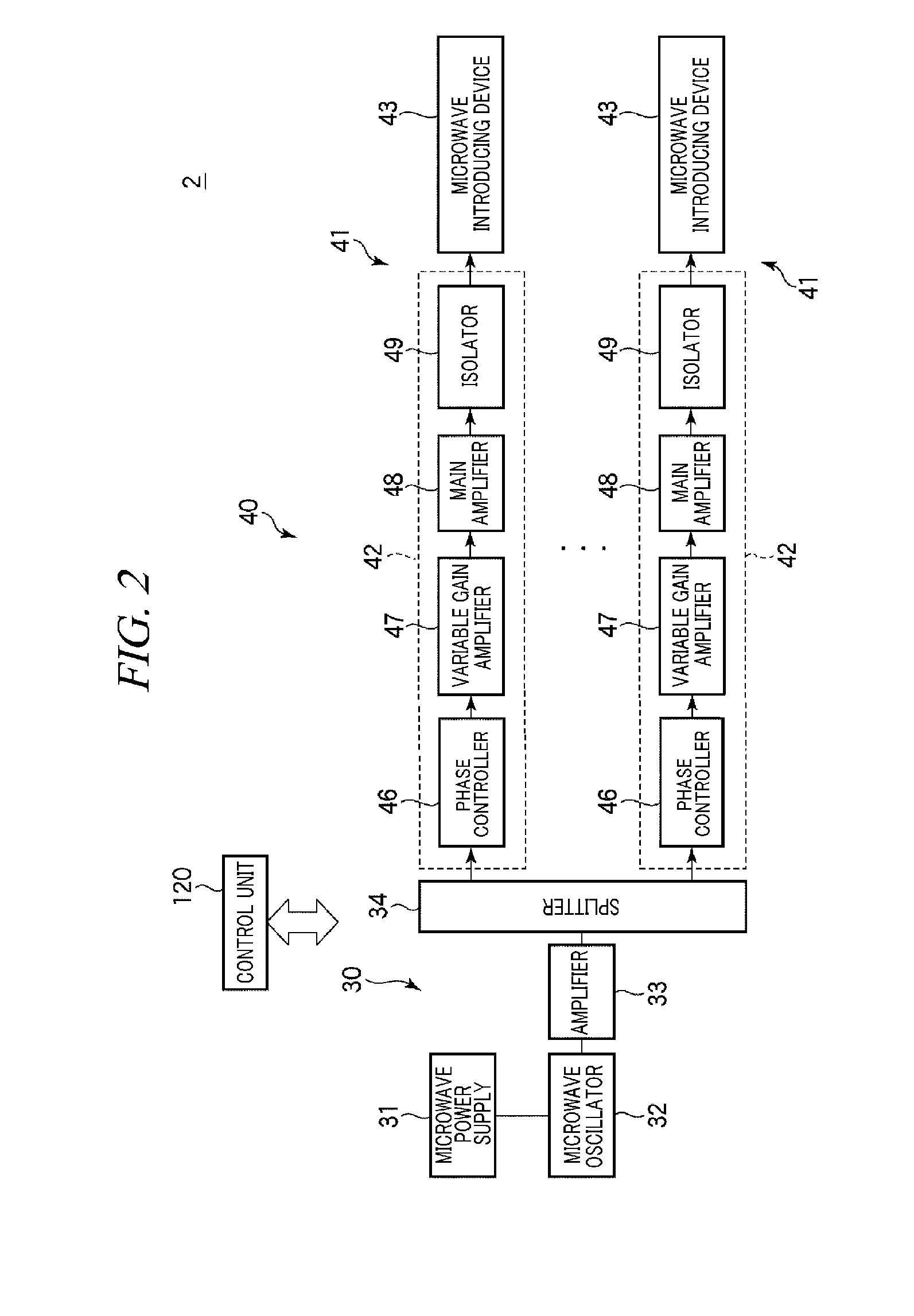

Microwave plasma source and plasma processing apparatus

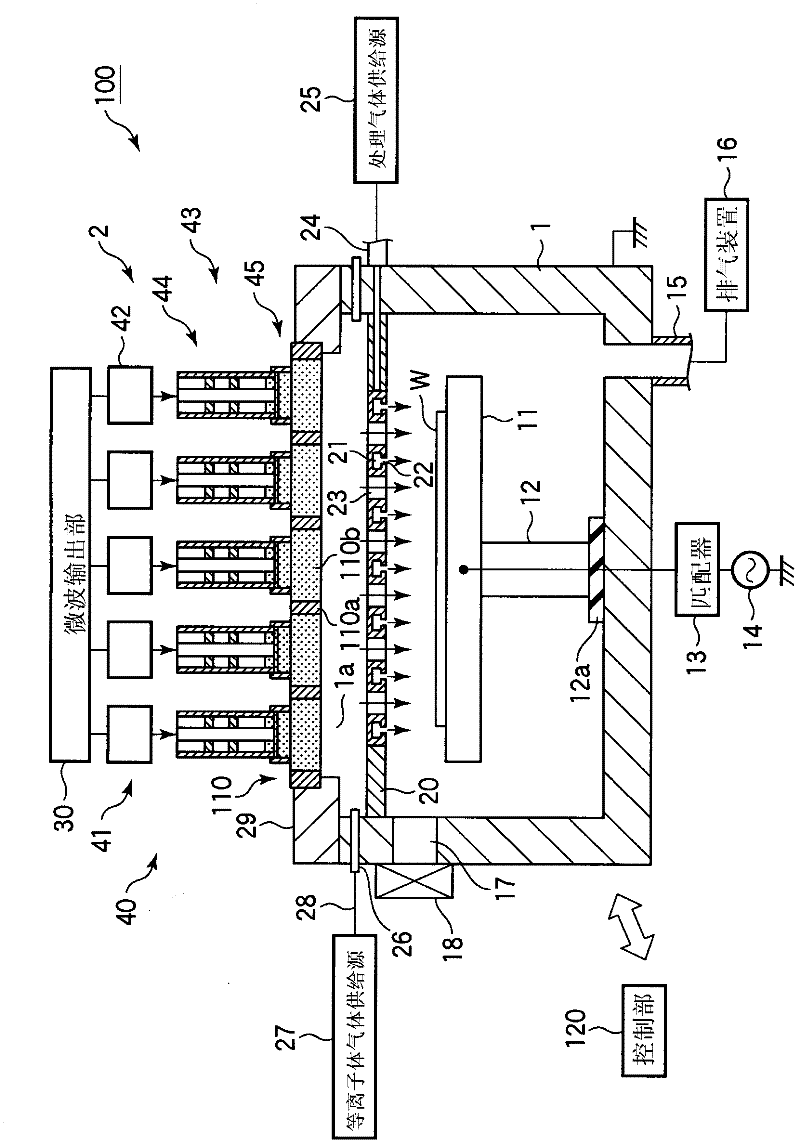

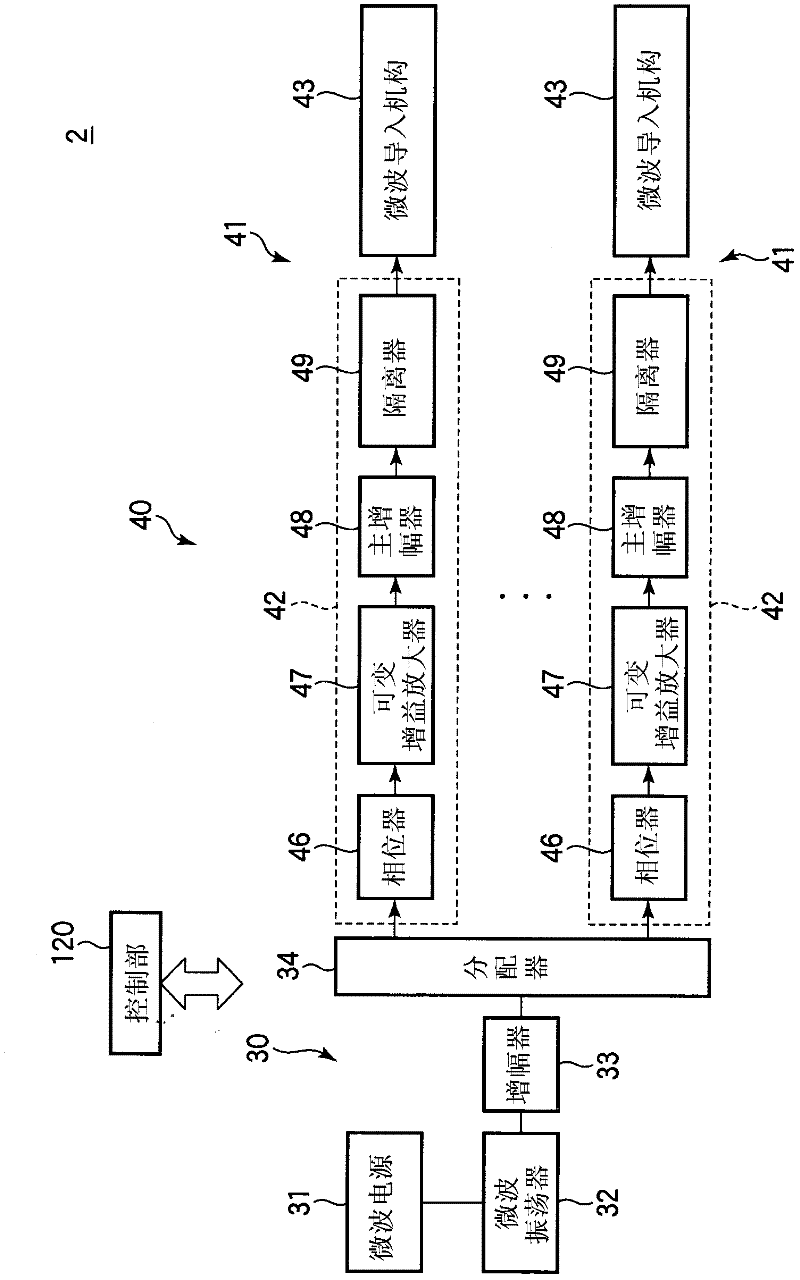

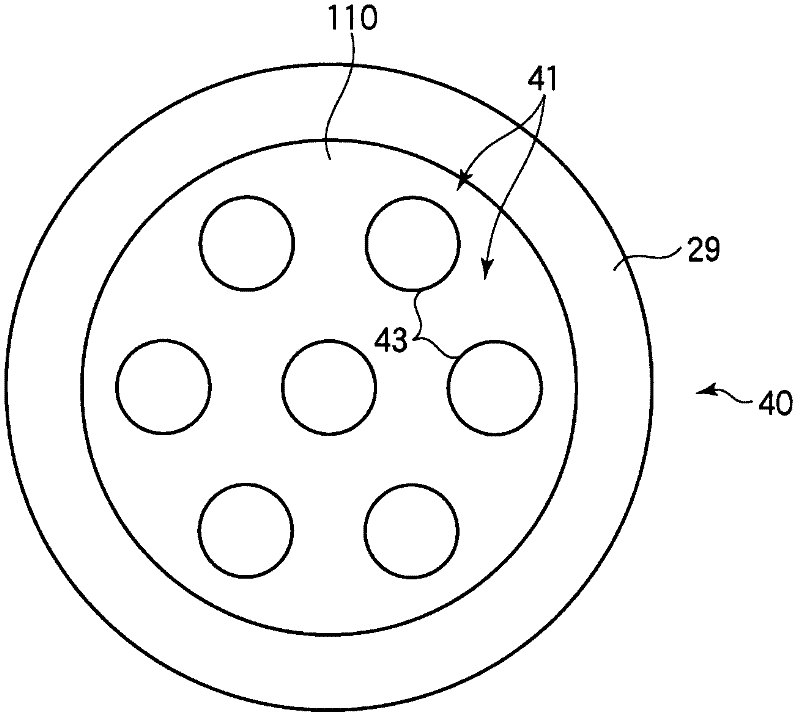

InactiveUS20120090782A1Improve in-plane uniformityUniform plasma treatmentElectric discharge tubesSemiconductor/solid-state device manufacturingMicrowave ovenPlasma processing

There are provided a microwave plasma source and a plasma processing apparatus capable of improving uniformity of a plasma density distribution within a processing chamber by controlling positions of nodes and antinodes of a standing wave of microwave within the processing chamber not to be fixed. The microwave plasma source 2 includes a microwave supply unit 40. The microwave supply unit 40 includes multiple microwave introducing devices 43 each introducing microwave into the processing chamber; and multiple phase controllers 46 for adjusting phases of the microwaves inputted to the microwave introducing devices 43. Here, the phases of the microwaves inputted to the microwave introducing devices 43 are adjusted by fixing an input phase of the microwave inputted to one of two adjacent microwave introducing devices 43 while varying an input phase of the microwave inputted to the other microwave introducing device 43 according to a periodic waveform.

Owner:TOKYO ELECTRON LTD

Helical resonator type plasma processing apparatus

InactiveCN1614746AImprove density uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingDouble tubeHelical coil

The invention discloses a spiral resonator plasma processing equipment. The plasma processing apparatus includes: a processing chamber having a substrate holder supporting a substrate to be processed; a dielectric tube disposed on the processing chamber so as to communicate with an interior space of the processing chamber; a helical coil wound around the outer tube of the dielectric tube; and an RF power supply that supplies RF power to the helical coil. The dielectric tube is in the form of a double tube, including an inner tube and an outer tube. A plasma source gas inlet is arranged in the outer tube to supply the plasma source gas into the space between the inner tube and the outer tube. A control electrode is arranged in the dielectric tube to control the plasma potential. This plasma processing apparatus provides a uniform plasma density distribution along the radial direction of the wafer and facilitates control of the plasma potential within the processing chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

Plasma processing apparatus and plasma processing method

ActiveUS20110094995A1Improving uniformity of plasma processLow densityElectric discharge tubesDecorative surface effectsEngineeringRadio frequency

A plasma processing apparatus includes: a processing chamber including a dielectric window; a coil-shaped RF antenna, provided outside the dielectric window; a substrate supporting unit, provided in the chamber, for mounting thereon a target substrate; a processing gas supply unit for supplying a processing gas to the chamber; and an RF power supply unit for supplying an RF power to the RF antenna to generate a plasma of the processing gas by an inductive coupling in the chamber. The apparatus further includes a correction coil, provided at a position outside the chamber where the correction coil is to be coupled with the RF antenna by an electromagnetic induction, for controlling a plasma density distribution in the chamber; and an antenna-coil distance control unit for controlling a distance between the RF antenna and the correction coil while supporting the correction coil substantially in parallel with the RF antenna.

Owner:TOKYO ELECTRON LTD

Ion sources and methods of operating an electromagnet of an ion source

ActiveCN101681781AVacuum evaporation coatingSputtering coatingVolumetric Mass DensityPlasma density distribution

Ion sources and methods of operating an electromagnet of an ion source for generating an ion beam with a controllable ion current density distribution. The ion source (10) includes a discharge chamber (16) and an electromagnet (42; 42a-d) adapted to generate a magnetic field (75) for changing a plasma density distribution inside the discharge chamber (16). The methods may include generating plasma (17) in the discharge space (24), generating and shaping a magnetic field (75) in the discharge space (24) by applying a current to an electromagnet (42; 42a-d) that is effective to define the plasma density distribution, extracting an ion beam (15) from the plasma (17), measuring a distribution profile for the ion beam density, and comparing the actual distribution profile with a desired distribution profile for the ion beam density. Based upon the comparison, the current applied to the electromagnet (42; 42a-d) may be adjusted to modify magnetic field (75) the magnetic field in the discharge space and, thereby, alter the plasma density distribution.

Owner:VEECO INSTR

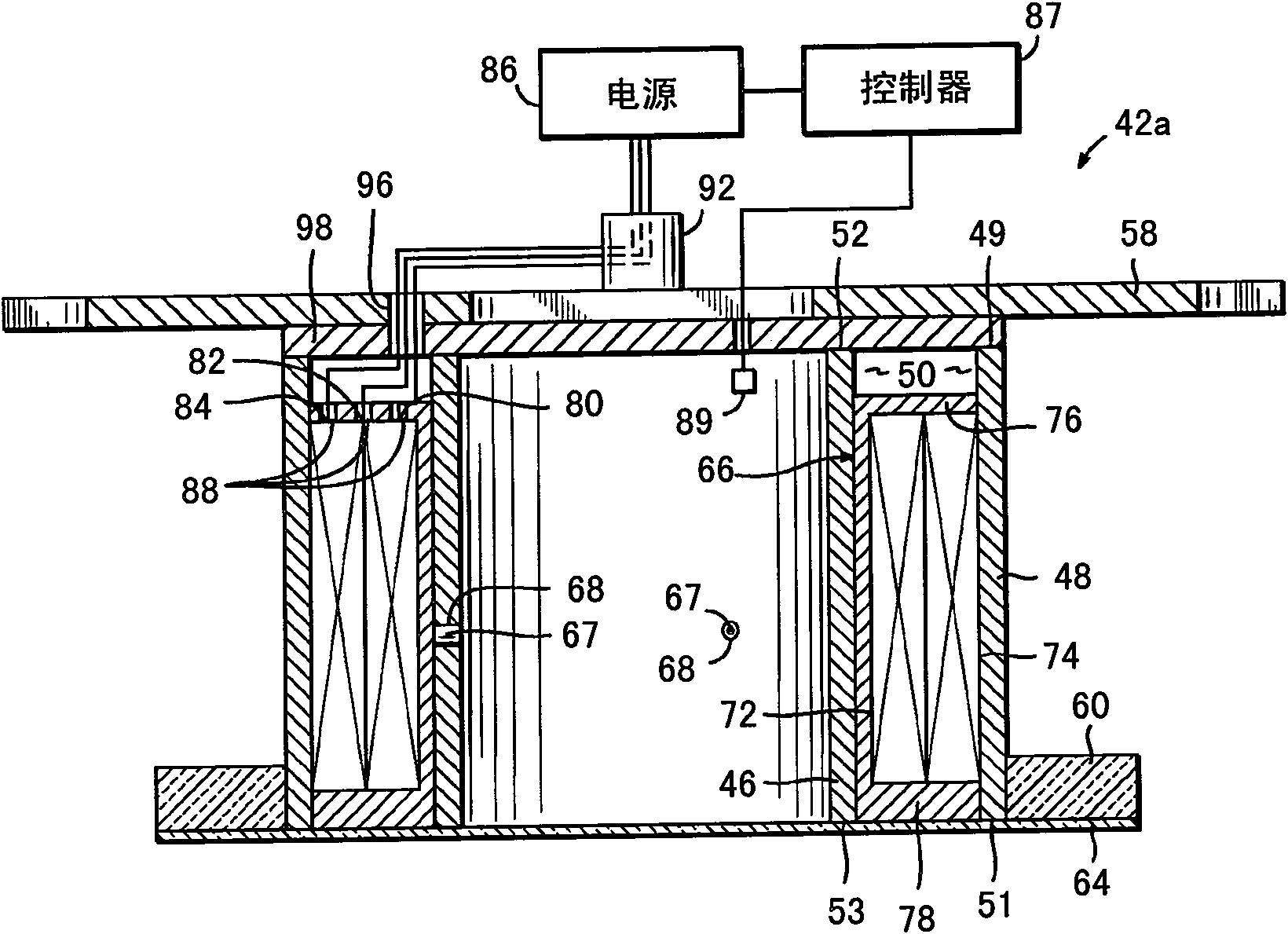

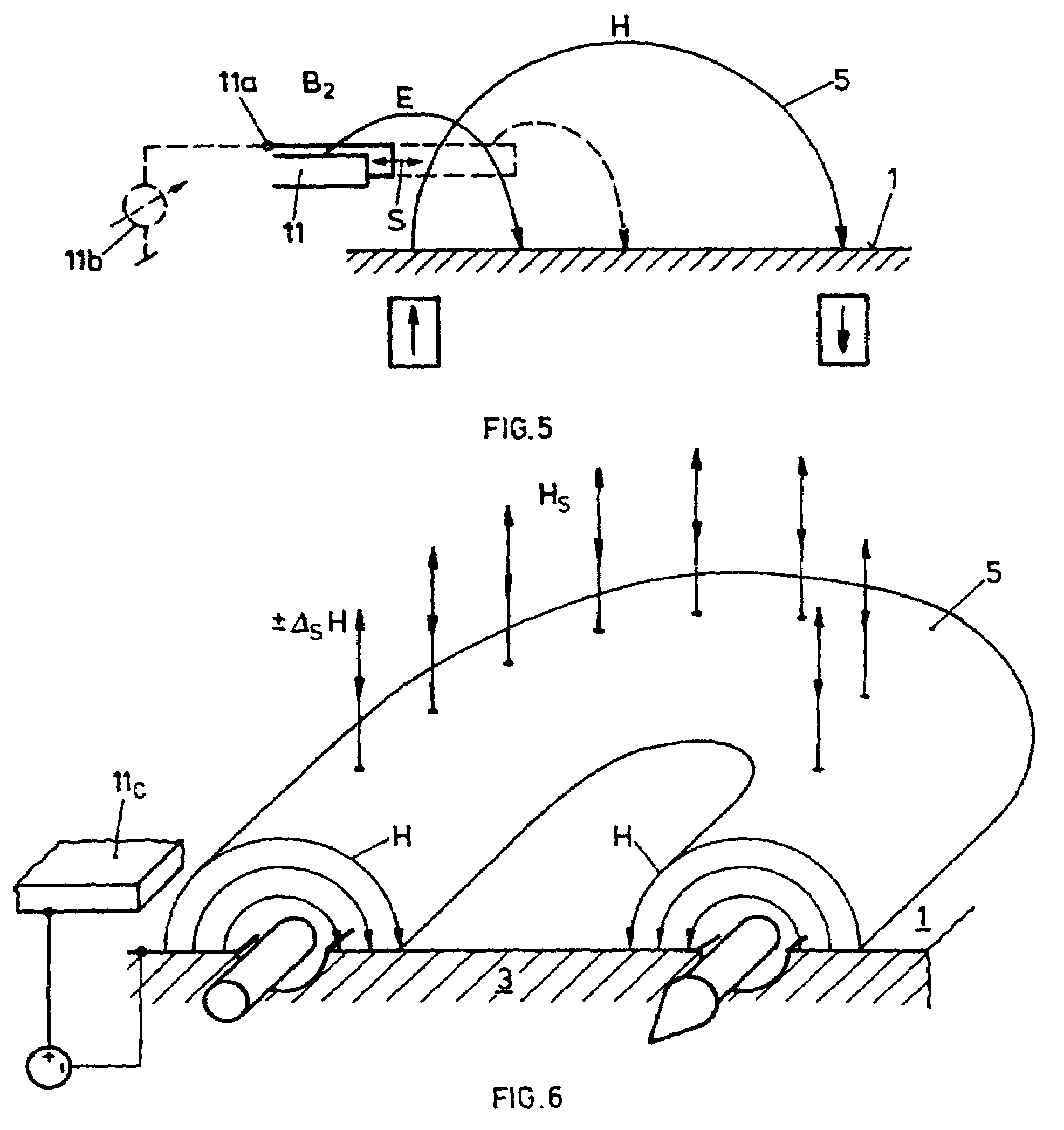

Method for controlling plasma density or the distribution thereof

Method for manufacturing magnetron sputter-coated workpieces includes placing a substrate adjacent a magnetron source having a target cathode, generating above the target cathode, at least one plasma loop by an electron trap established by generating a magnetic field which forms, in top view on the target cathode, a magnet field loop and, viewed in cross-section on the target cathode, a tunnel-shaped arc field and, an electric field which crosses the magnetic field of the magnet field loop. Plasma density distribution above the target cathode is controlled by interacting a control anode with the electron trap in a control segment area of the plasma loop. Magnetron sputter-coating the substrate by the magnetron sputter-source then takes place.

Owner:OERLIKON ADVANCED TECH +1

Ion sources and methods for generating an ion beam with controllable ion current density distribution

ActiveUS8835869B2Stability-of-path spectrometersBeam/ray focussing/reflecting arrangementsGratingIon beam

Ion sources and methods for generating an ion bean with a controllable ion current density distribution. The ion source includes a discharge chamber having an optical grid position proximate at a first end and a re-entrant vessel positioned proximate a second end that opposes the first end. A plasma shaper extends from the re-entrant vessel and into the plasma discharge chamber. A position of the plasma shaper is adjustable relative to the grid-based ion optic such that the plasma shaper may operably change a plasma density distribution within the discharge chamber.

Owner:VEECO INSTR

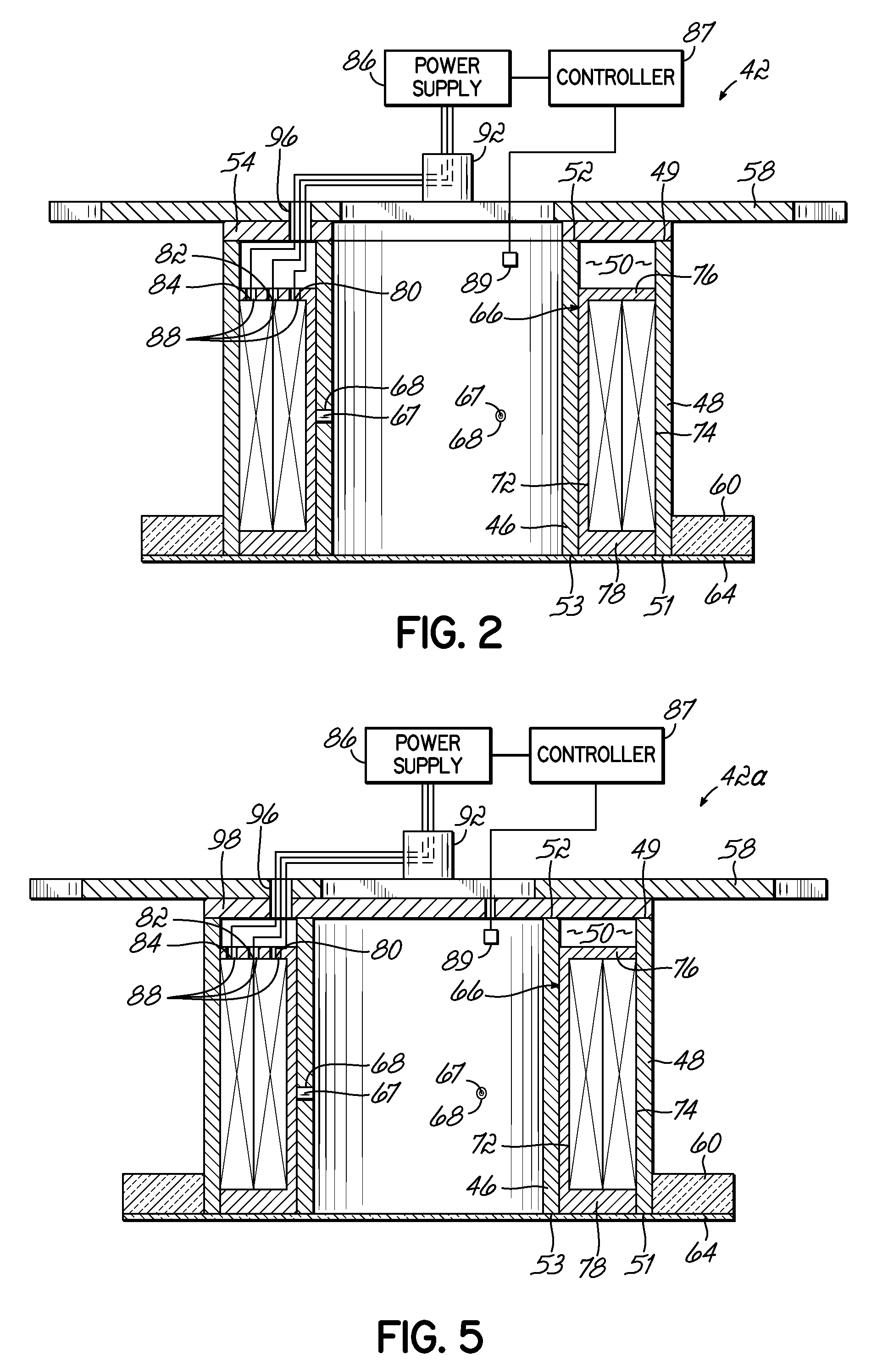

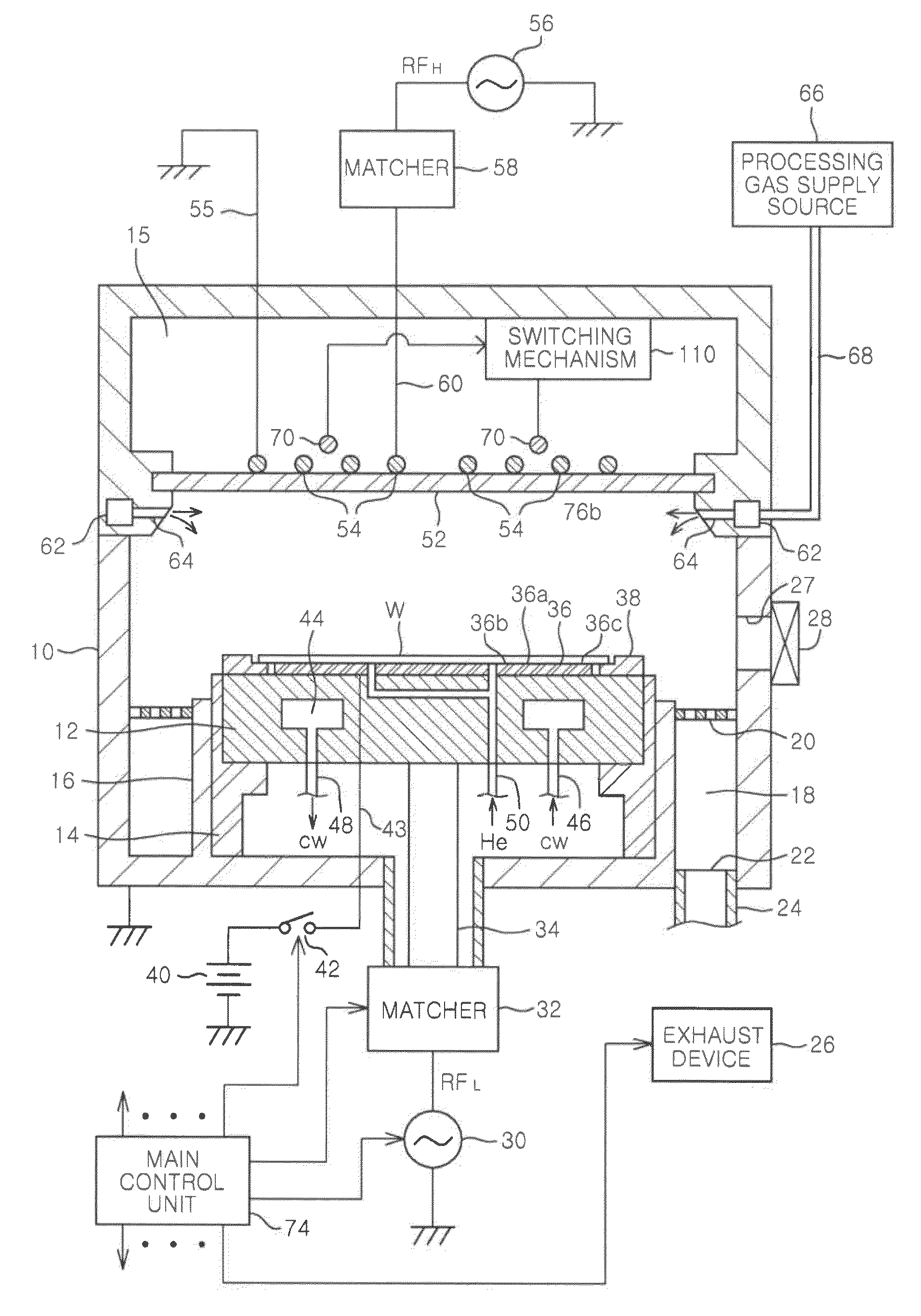

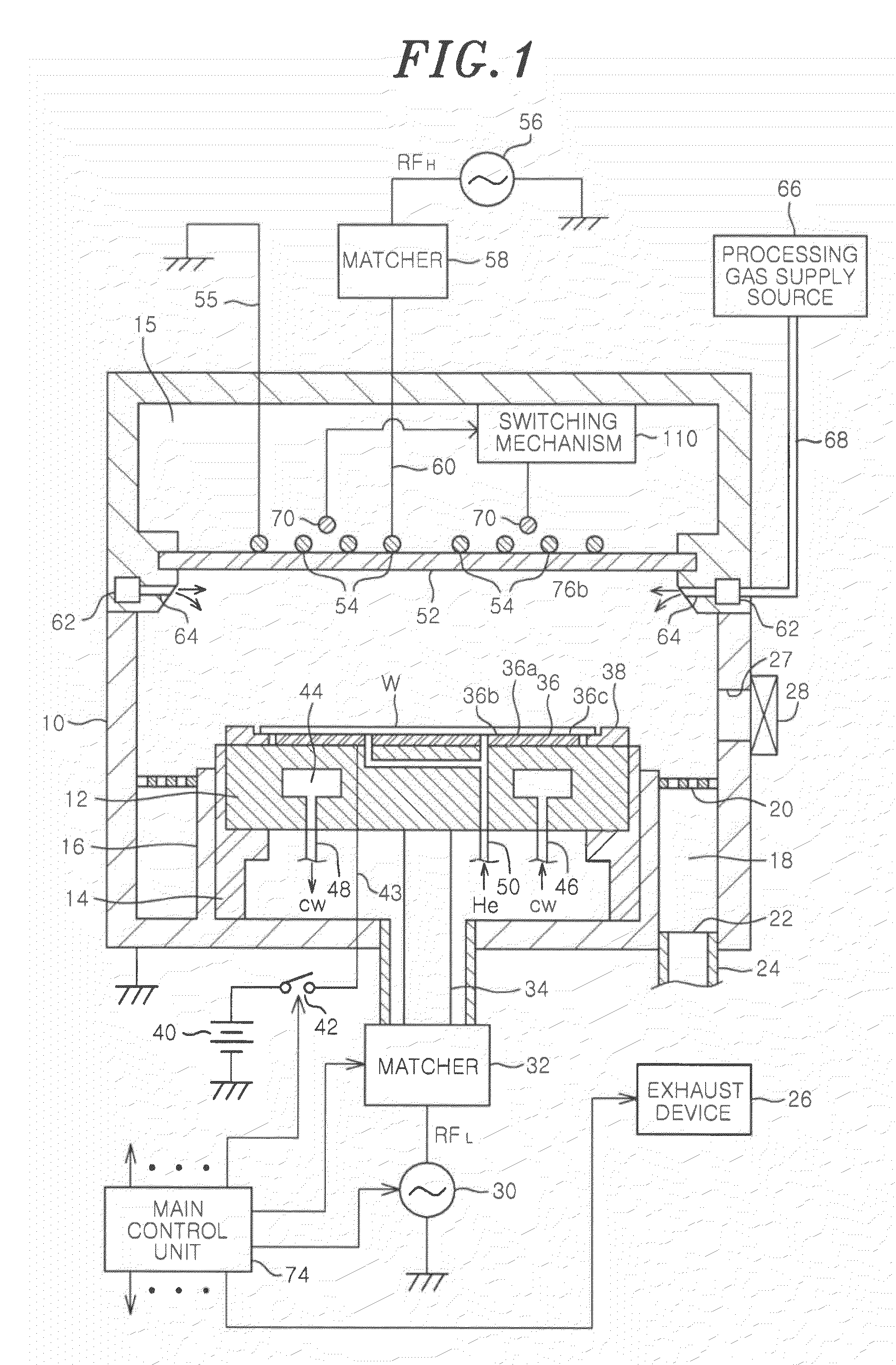

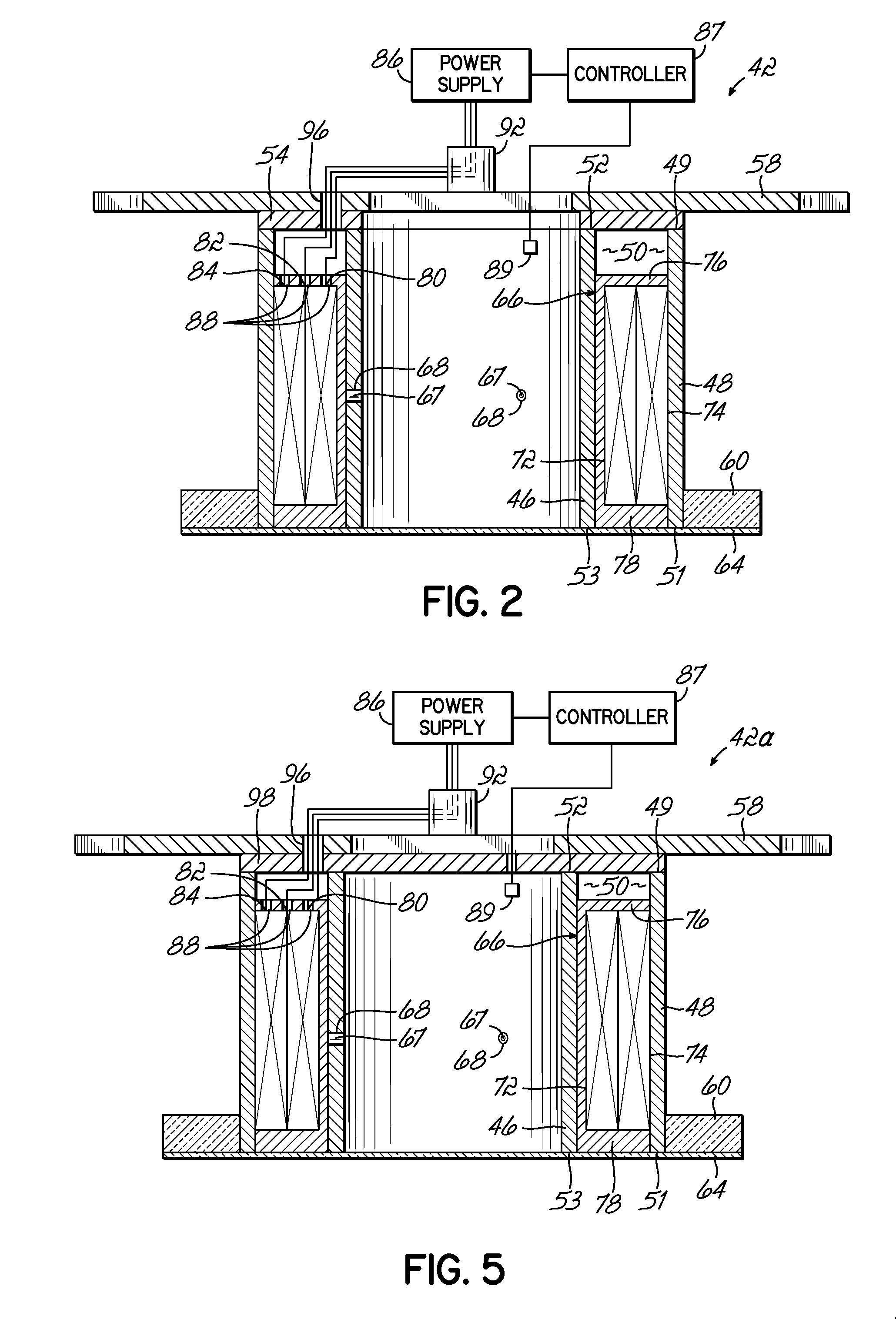

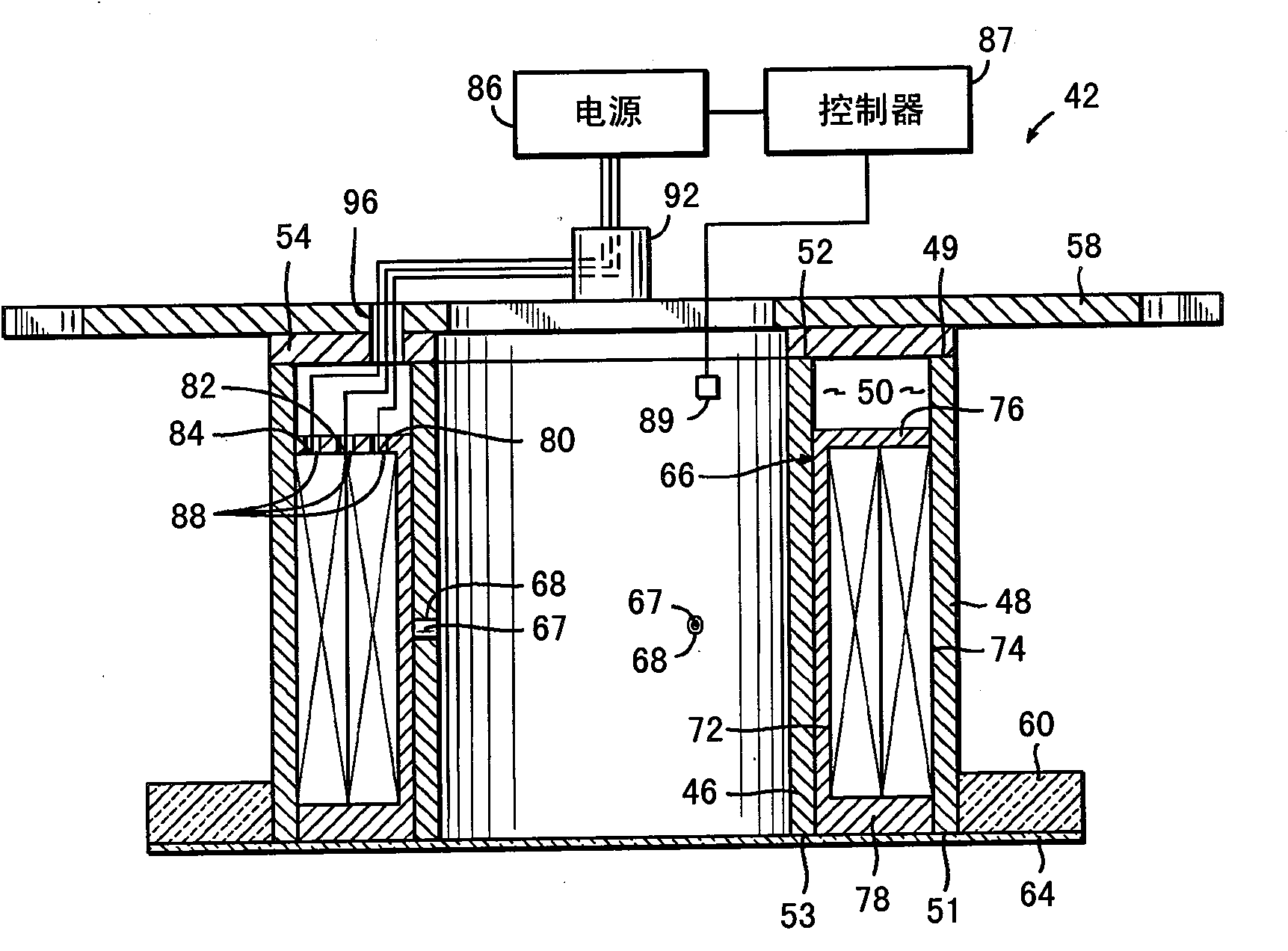

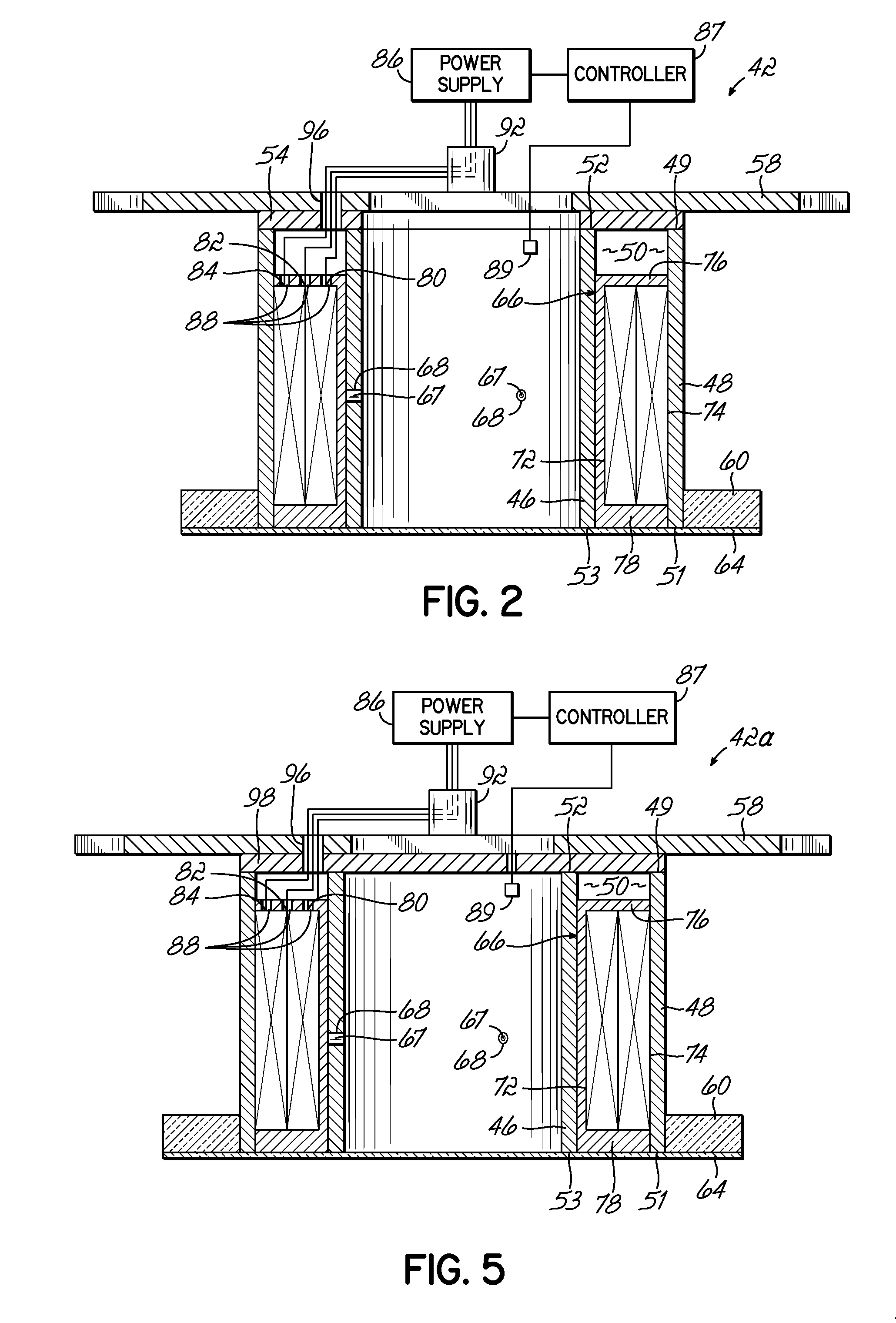

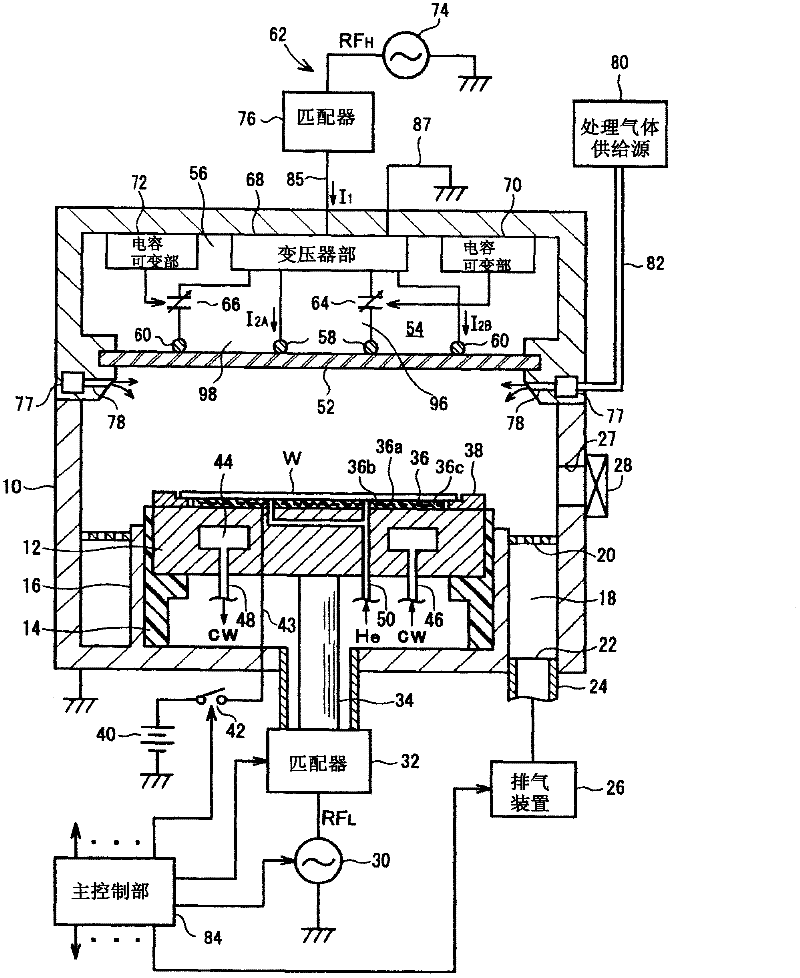

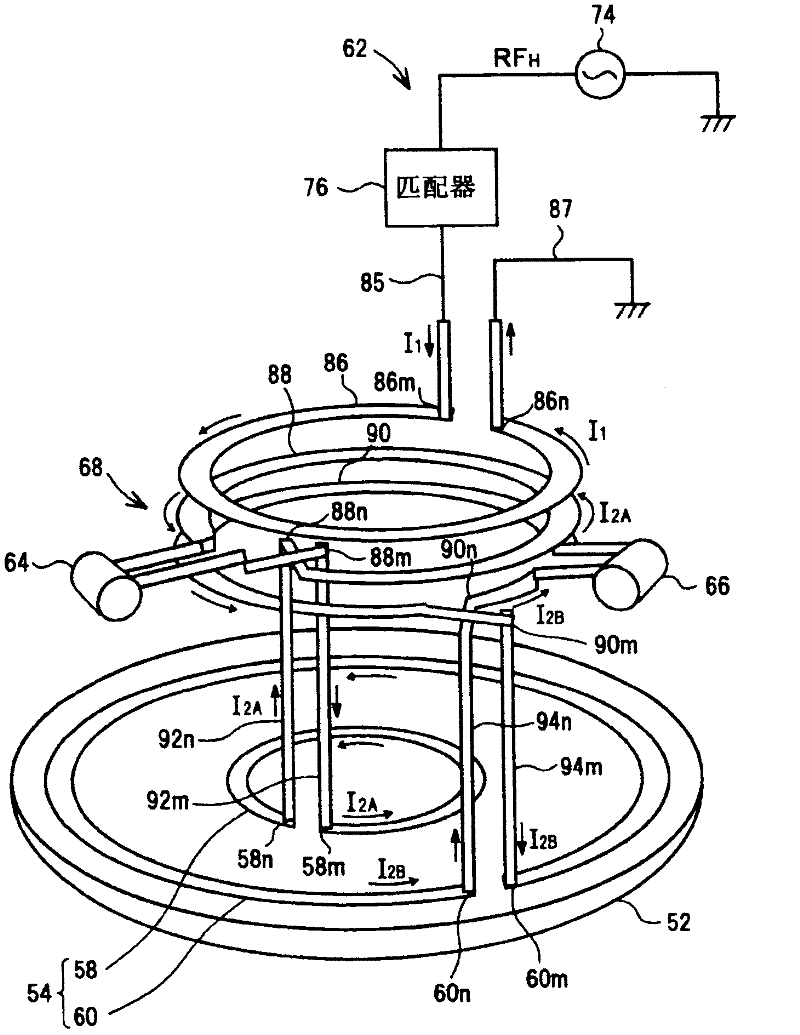

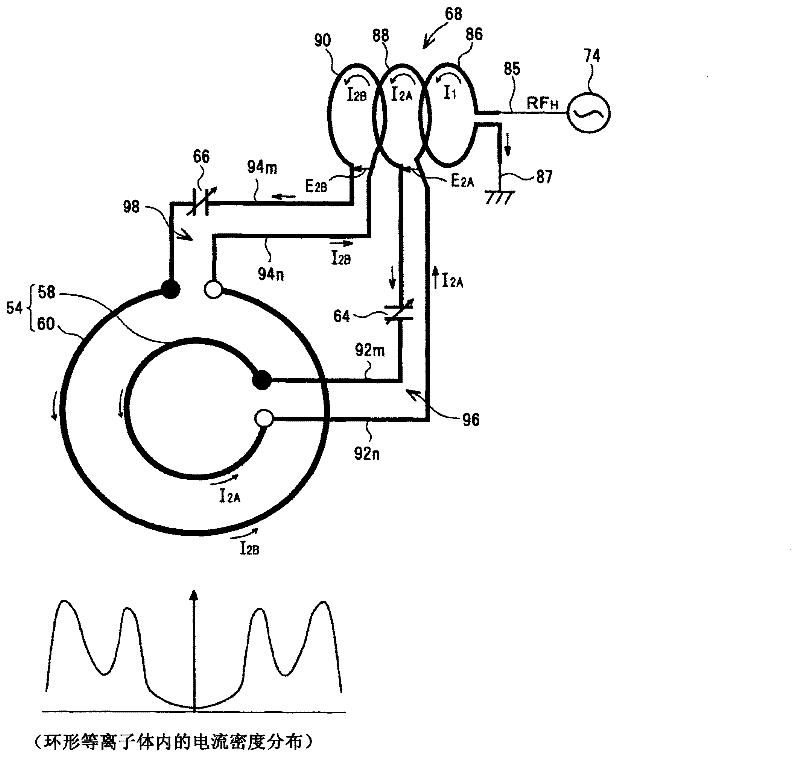

Plasma processing apparatus and plasma processing method

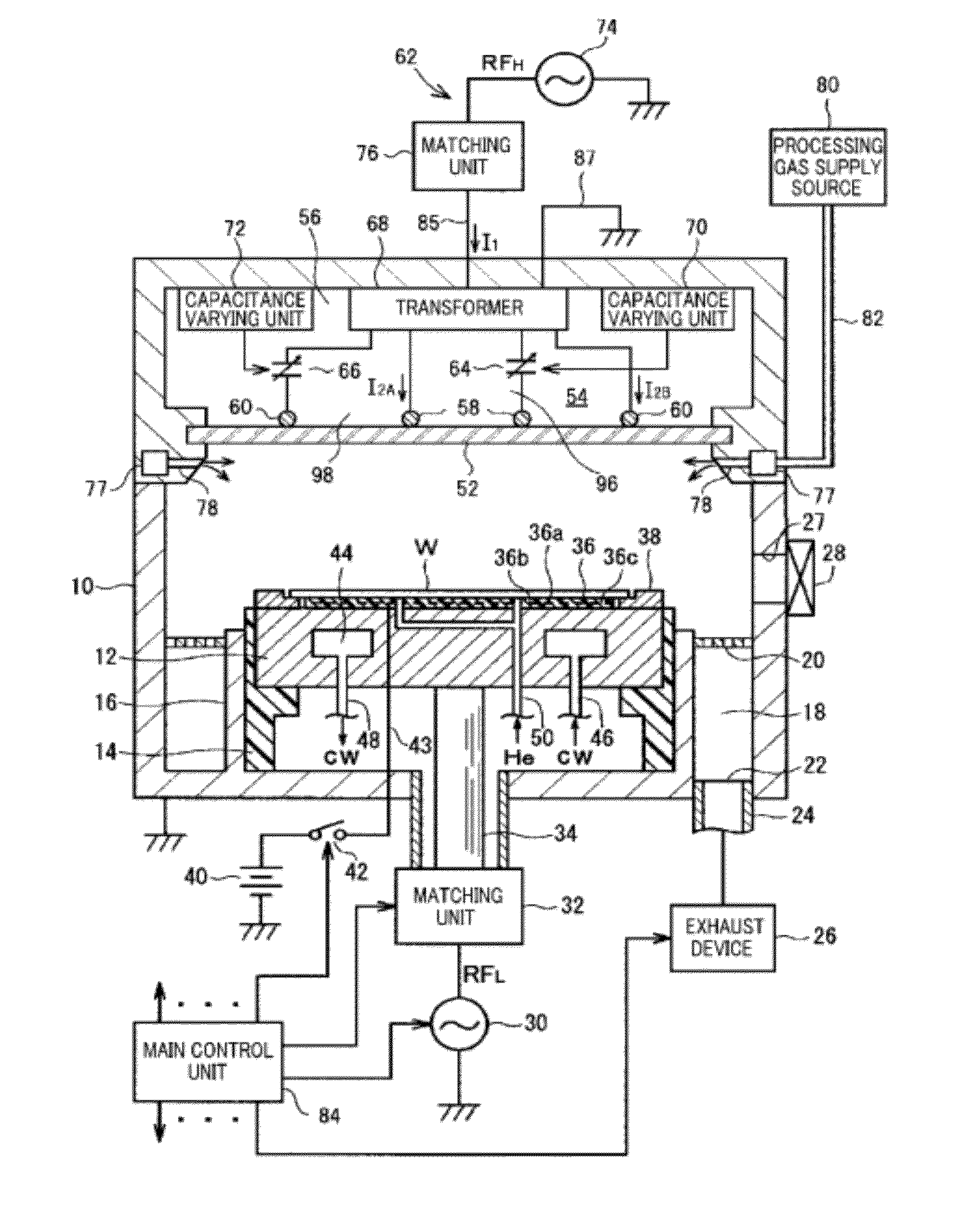

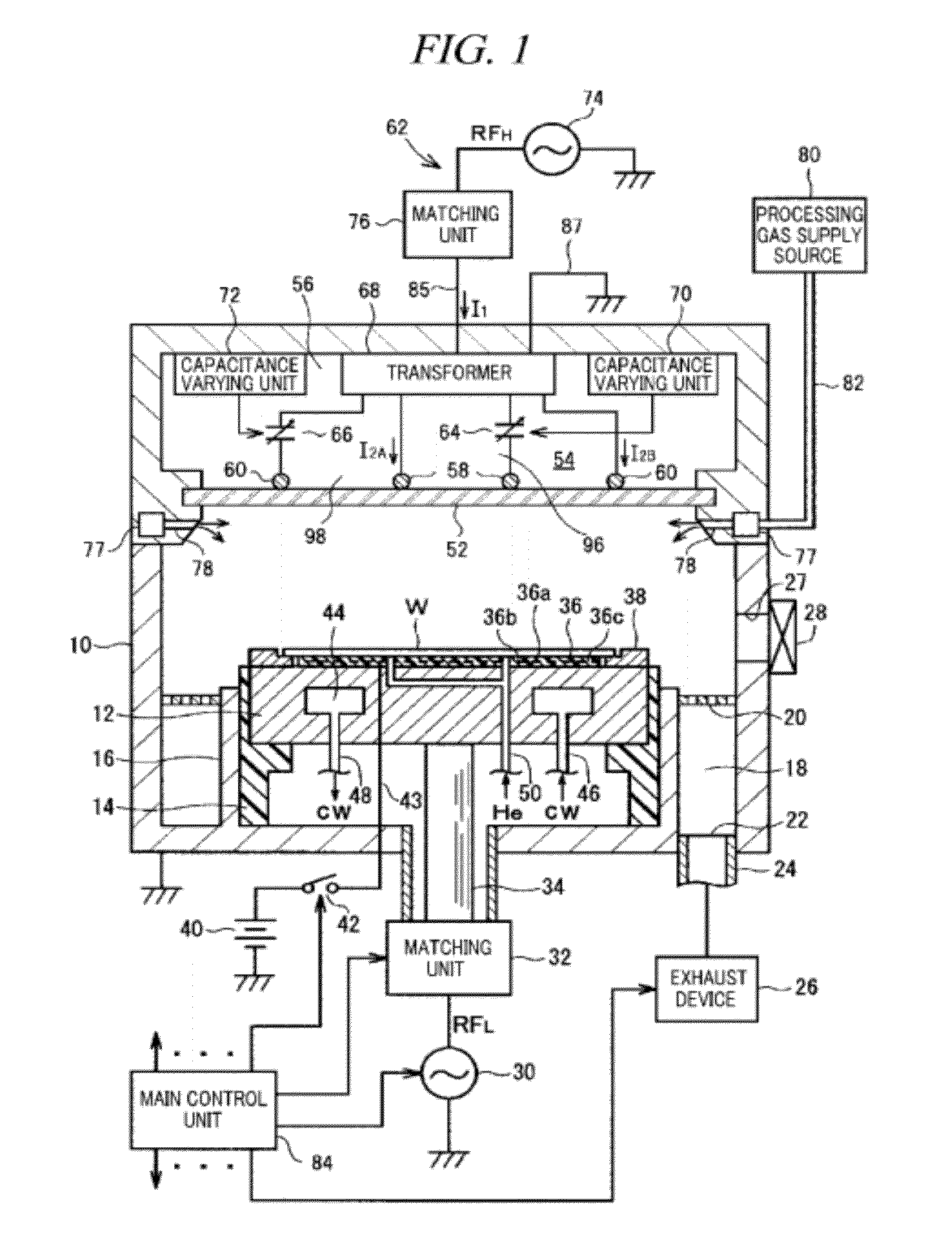

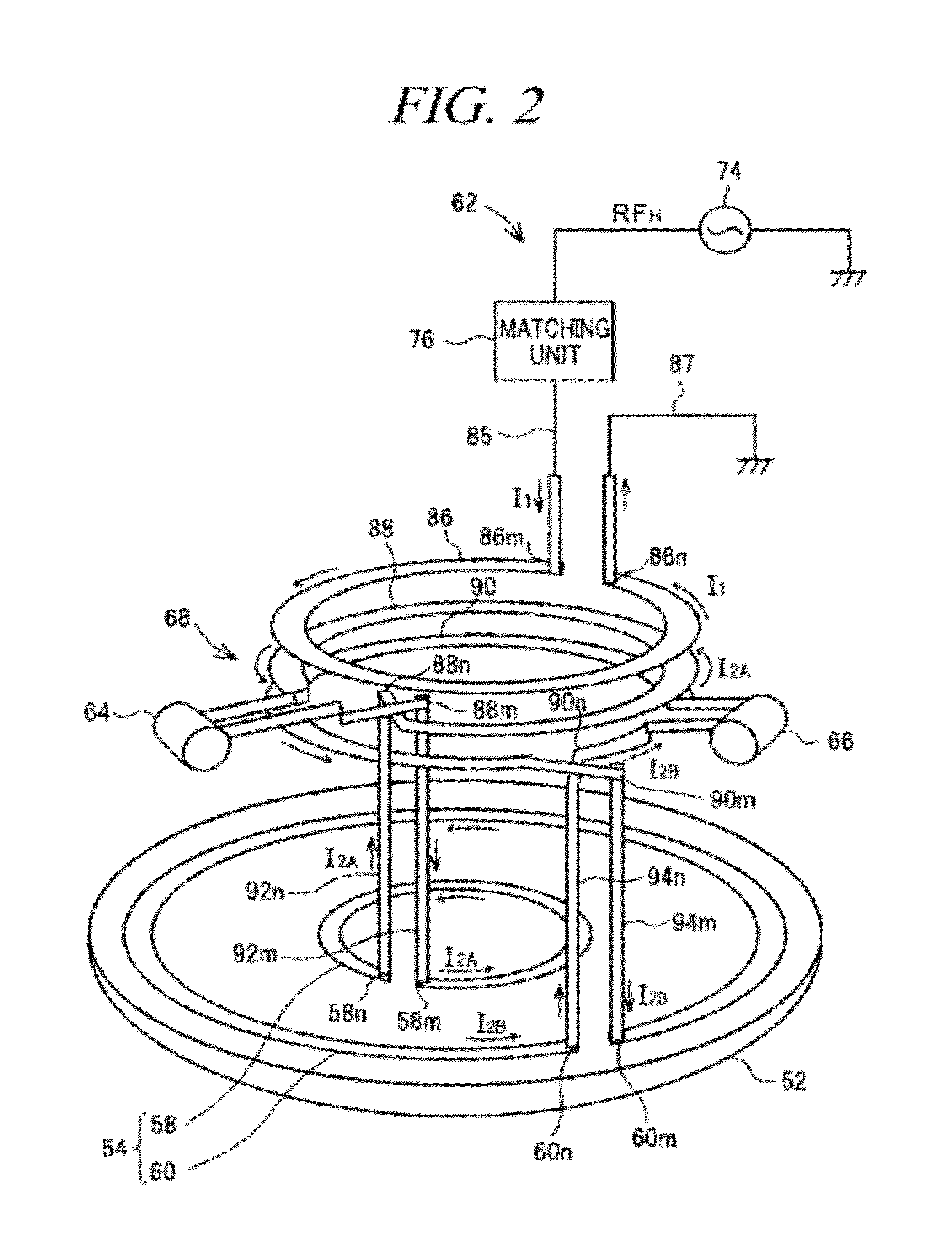

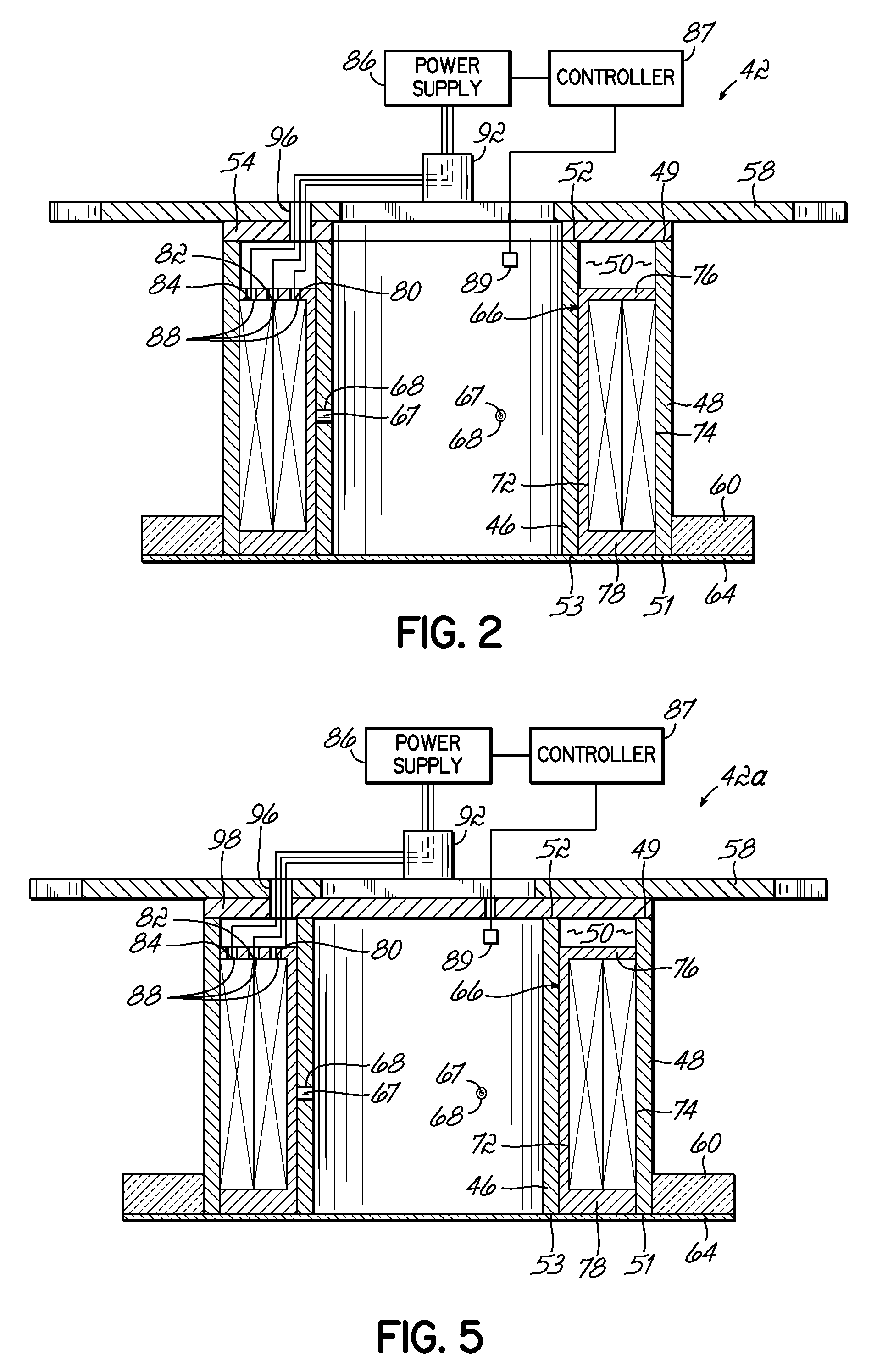

ActiveCN102420090AImprove production efficiencyReduce power lossElectric discharge tubesPlasma techniqueCapacitanceHigh frequency power

There is provided an inductively coupled plasma processing apparatus capable of reducing a RF power loss within a high frequency power supply unit (particularly, a matching unit) and capable of enhancing a plasma generation efficiency. In this inductively coupled plasma processing apparatus, a multiple number of closed-loop secondary circuits 96, 98 independent from each other are formed between a coaxial antenna group 54 and a transformer 68. Further, by varying electrostatic capacitances of variable capacitors 64 and 66, secondary currents I2A and I2B flowing through an inner antenna 58 and an outer antenna 60, respectively, of the coaxial antenna group 54 are independently controlled. Accordingly, it is possible to readily control a plasma density distribution on a semiconductor wafer W in a diametrical direction.

Owner:TOKYO ELECTRON LTD

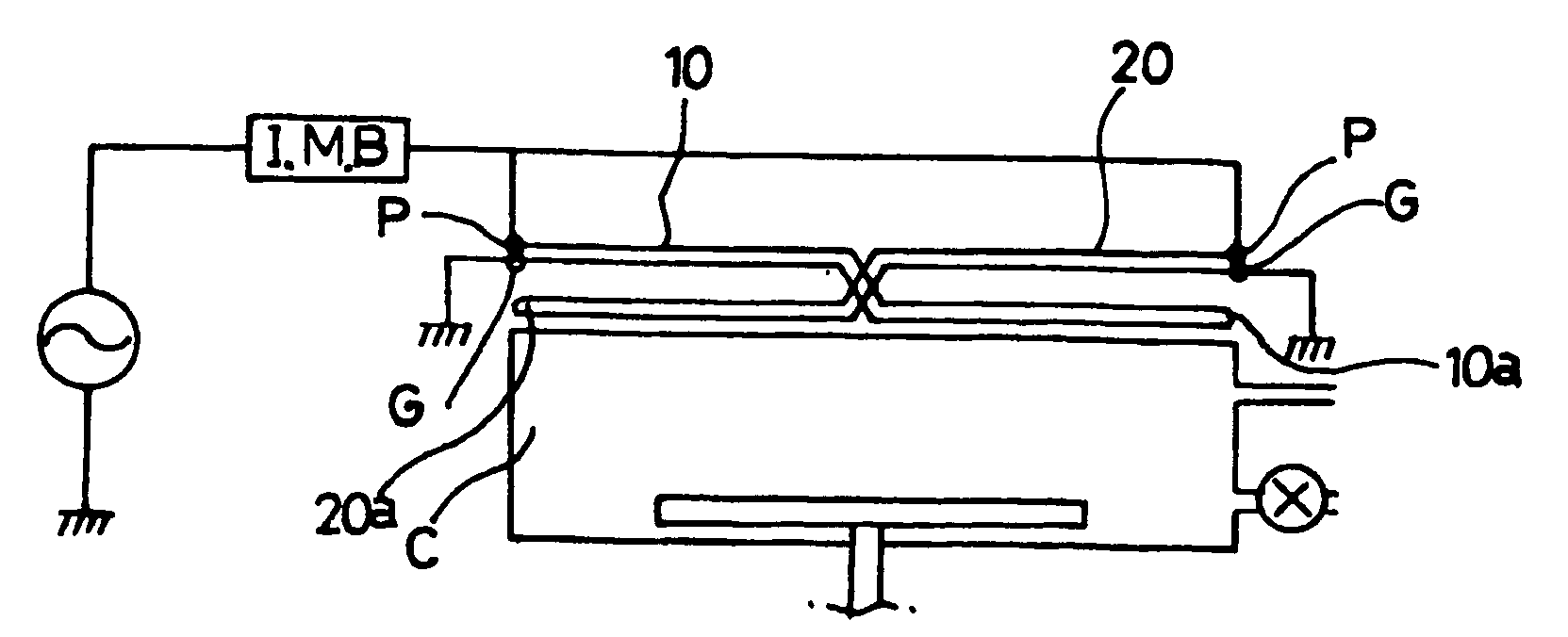

Antenna structure for inductively coupled plasma generator

InactiveUS7079085B2Simple structureAvoid it happening againResonant long antennasAntenna arraysDisplay deviceEngineering

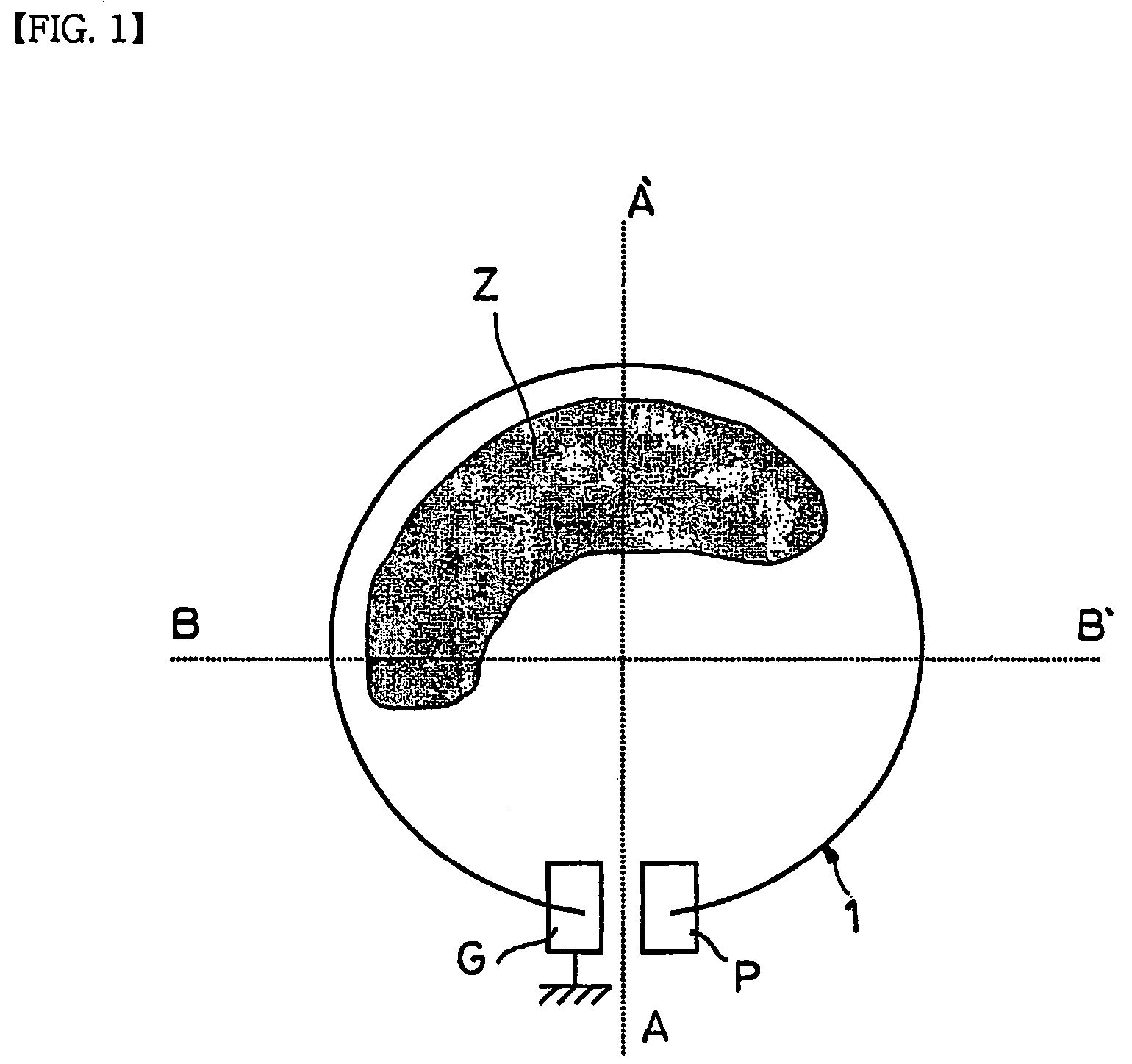

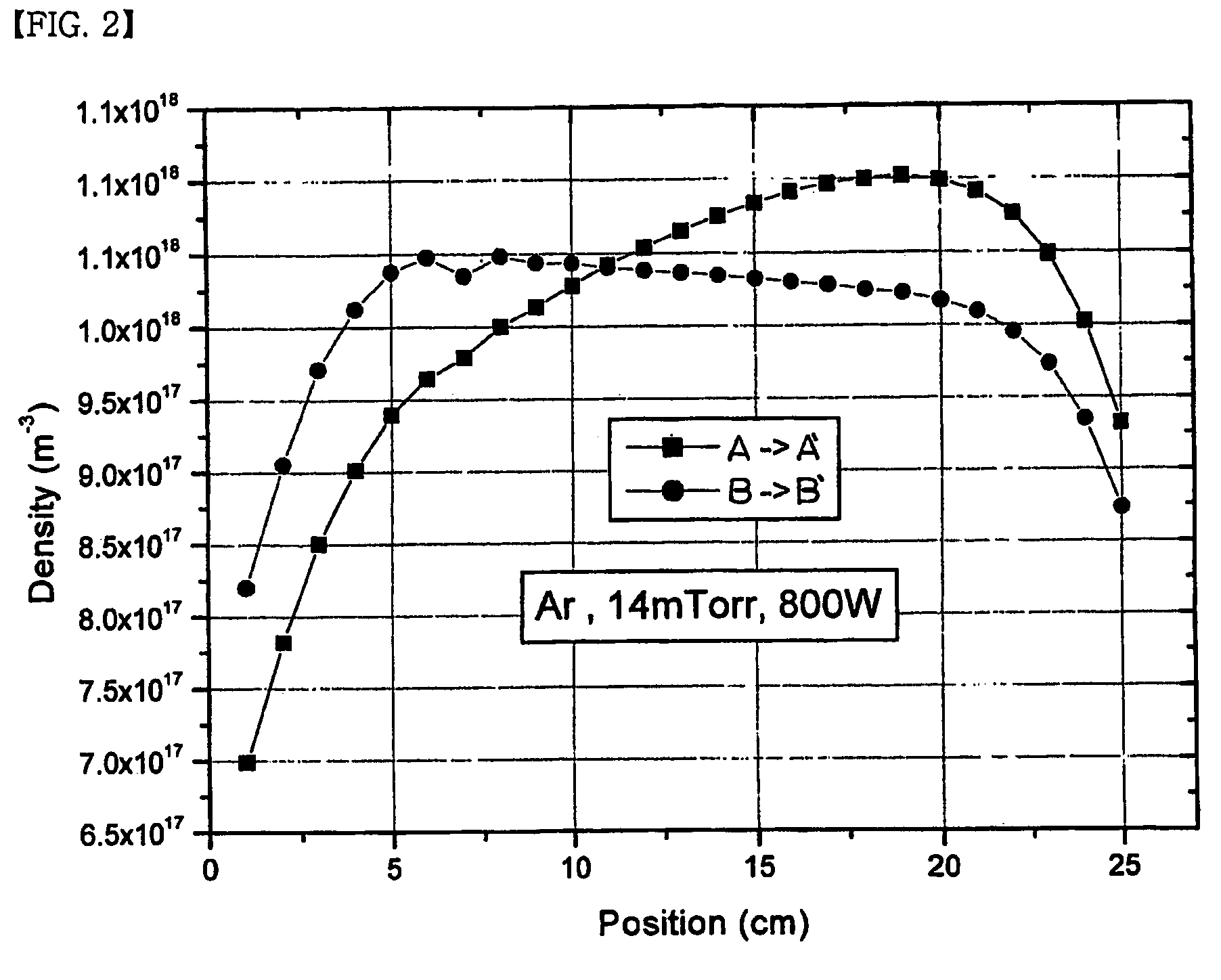

An antenna structure for an inductively coupled plasma generator suitable for processing large-diameter wafers or large, flat-panel display devices by making a plasma density distribution uniform and symmetrical with respect to a rotating direction inside a circular or rectangular chamber in which a wafer is processed. In the antenna structure having a powered end to which RF power is applied and a ground end connected to the ground, at least two loop antenna elements are disposed electrically in parallel with each other, the powered ends and ground ends of the respective antennas are disposed symmetrically with respect to the center of the antennas, and the antennas crossing each other such that the powered ends and ground ends thereof are disposed at a part far from a chamber and central parts thereof are disposed at a part close to the chamber.

Owner:PLASMART CO LTD

Plasma processing apparatus

ActiveUS9293299B2Easy to controlEliminate the effects ofElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceHigh frequency power

Owner:TOKYO ELECTRON LTD

Plasma processing apparatus and plasma processing method

ActiveUS20120074100A1Reduce total powerImprove power generation efficiencyElectric discharge tubesDecorative surface effectsCapacitanceHigh frequency power

There is provided an inductively coupled plasma processing apparatus capable of reducing a RF power loss within a high frequency power supply unit (particularly, a matching unit) and capable of enhancing a plasma generation efficiency. In this inductively coupled plasma processing apparatus, a multiple number of closed-loop secondary circuits 96, 98 independent from each other are formed between a coaxial antenna group 54 and a transformer 68. Further, by varying electrostatic capacitances of variable capacitors 64 and 66, secondary currents I2A and I2B flowing through an inner antenna 58 and an outer antenna 60, respectively, of the coaxial antenna group 54 are independently controlled. Accordingly, it is possible to readily control a plasma density distribution on a semiconductor wafer W in a diametrical direction.

Owner:TOKYO ELECTRON LTD

Methods of operating an electromagnet of an ion source

ActiveUS8158016B2Vacuum gauge using ionisation effectsDecorative surface effectsIon beamPlasma density distribution

Owner:VEECO INSTR

Plasma processing apparatus and plasma processing method

ActiveUS20070227664A1Reduces plasma densityIncrease electrode densityElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceElectricity

A plasma processing apparatus includes a processing vessel capable of being vacuum evacuated; a first electrode disposed in the processing vessel in a state electrically floating via an insulating member or a space; a second electrode, arranged in the processing vessel to face and be in parallel to the first electrode with a specific interval, supporting a substrate to be processed; a processing gas supply unit for supplying a desired processing gas into a processing space surrounded by the first electrode, the second electrode and a sidewall of the processing vessel; and a first radio frequency power supply unit for applying a first radio frequency power to the second electrode to generate a plasma of the processing gas in the processing space. An electrostatic capacitance between the first electrode and the processing vessel is set such that a desired plasma density distribution is obtained for the generated plasma.

Owner:TOKYO ELECTRON LTD

Plasma processing device, plasma processing method and method of manufacturing element including substrate to be processed

ActiveUS8475672B2Easy to adjustUniform densityCellsElectric discharge tubesElectrical polarityEngineering

The present invention provides a plasma processing device and a plasma processing method that can easily adjust plasma density distribution while making the plasma density uniform, and a method of manufacturing an element including a substrate to be processed. In an embodiment of the present invention, the inside of a vacuum vessel (1) is divided by a grid (4) having communication holes into a plasma generation chamber (2) and a plasma processing chamber (5). On the upper wall (26) of the plasma generation chamber (2), magnetic coils (12) are arranged such that magnetic field lines within the vacuum vessel (1) point from the center of the vacuum vessel (1) to a side wall (27), and, outside the side wall (27) of the plasma generation chamber (2), ring-shaped permanent magnets (13) are arranged such that a polarity pointing to the inside of the vacuum vessel (1) is a north pole and a polarity pointing to the outside of the vacuum vessel (1) is a south pole.

Owner:CANON ANELVA CORP

Microwave plasma source and plasma processing apparatus

InactiveCN102458032AAveraging of electric field strengthIntensity averagingElectric discharge tubesSemiconductor/solid-state device manufacturingMicrowavePlasma processing

There are provided a microwave plasma source and a plasma processing apparatus capable of improving uniformity of a plasma density distribution within a processing chamber by controlling positions of nodes and antinodes of a standing wave of microwave within the processing chamber not to be fixed. The microwave plasma source 2 includes a microwave supply unit 40. The microwave supply unit 40 includes multiple microwave introducing devices 43 each introducing microwave into the processing chamber; and multiple phase controllers 46 for adjusting phases of the microwaves inputted to the microwave introducing devices 43. Here, the phases of the microwaves inputted to the microwave introducing devices 43 are adjusted by fixing an input phase of the microwave inputted to one of two adjacent microwave introducing devices 43 while varying an input phase of the microwave inputted to the other microwave introducing device 43 according to a periodic waveform.

Owner:TOKYO ELECTRON LTD

Reaction cavity and semiconductor processing device

ActiveCN107369604AReduce phase differenceUniform density distributionElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The present invention provides a reaction cavity and a semiconductor processing device. The reaction cavity comprises a top electrode device and a bottom electrode device, and the bottom electrode device is arranged in the reaction cavity and configured to bear a wafer. The top electrode device comprises a medium cylinder, a coil, a top power source and a top electrode module, and the medium cylinder is arranged at the top of the reaction cavity; the coil is around and arranged at the periphery of the medium cylinder; the top electrode device comprises a top electrode plate, and the top electrode plate is arranged at the top of the medium cylinder; and the top power source is configured to load excitation power to the top electrode plate and the coil at the same time. The reaction cavity can reduce the voltage difference between the output end and the input end of the coil and can weaken the influence generated by a nonuniform electric field so as to improve the plasma density distribution uniformity.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

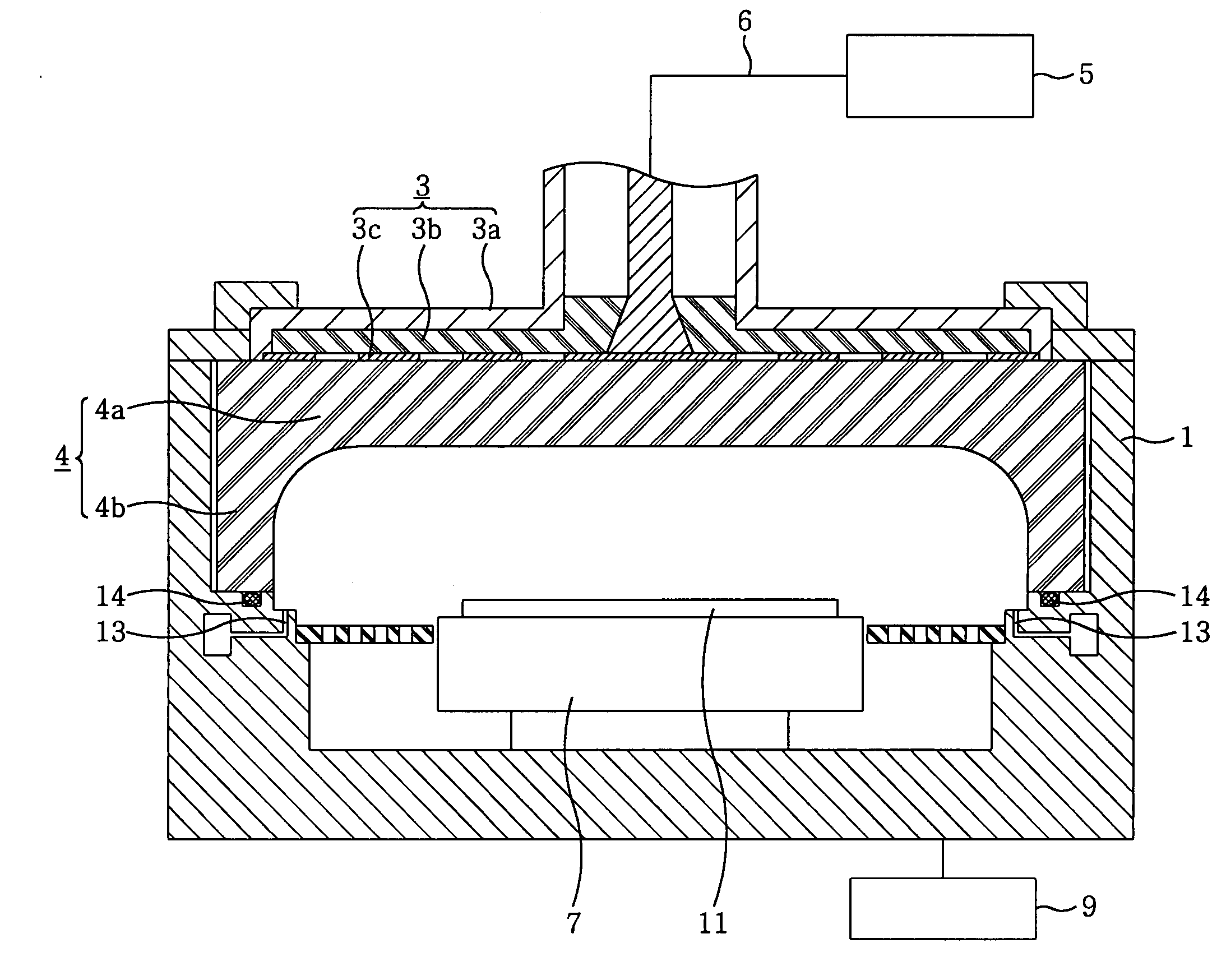

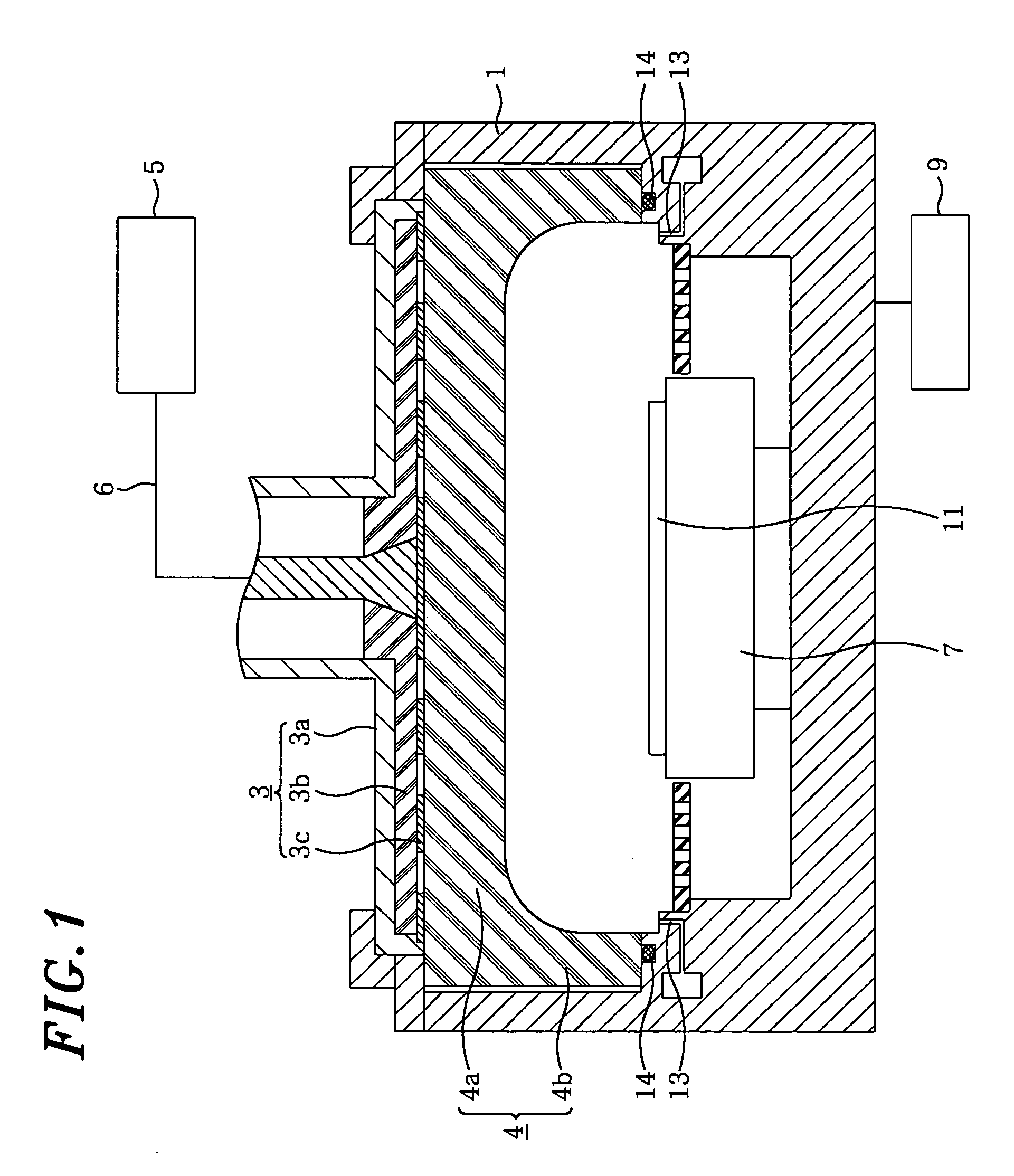

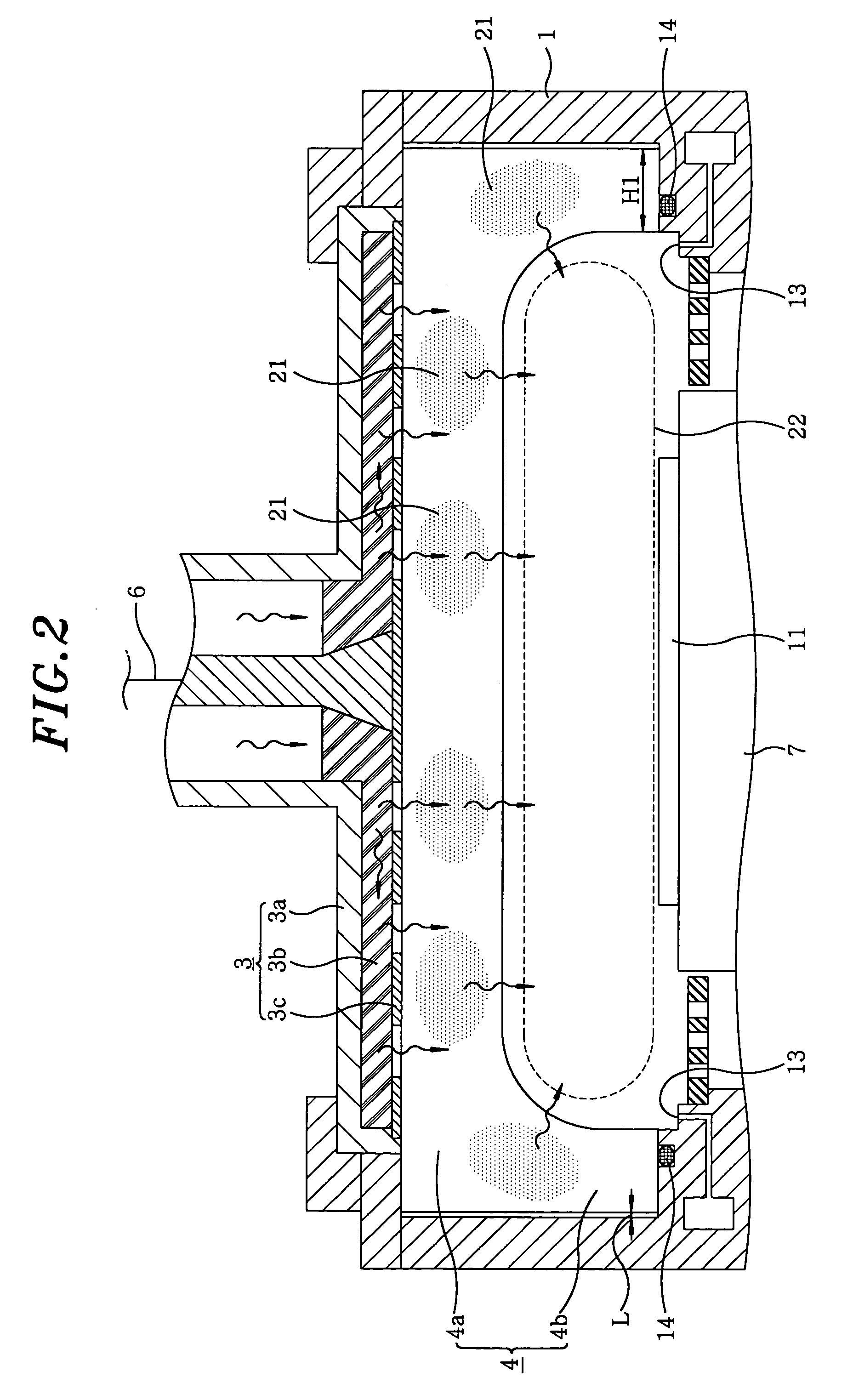

Plasma processing device

InactiveUS20060005769A1Increase plasma densityImprove uniformityLiquid surface applicatorsElectric discharge tubesMicrowaveHigh frequency power

A plasma processing device comprising a chamber (1), a high-frequency power supply and an antenna unit (3). The antenna unit (3) comprises a slot plate (3c) , a slow wave plate (3b) and an antenna cover (3a) . A top plate unit (4) having a flat plate (4a) and sidewalls (4b) is disposed at the upper portion of the chamber (1). The flat plate (4a) contacts the slot plate (3c) disposed to face a housed substrate (11). The sidewalls (4b) are formed so as to extend toward a substrate-disposed side from the periphery of the flat plate (4a) . The outer periphery surfaces of sidewalls (4b) contact the chamber (1). The thickness of the sidewalls (4b) is set to be at least λg / 4, where λg is the wavelength of a microwave based on the permittivity of the top plate (4). Accordingly, a plasma density can be further increased and a uniformity in plasma density distribution can be improved.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com