Plasma processing apparatus and plasma processing method

A plasma and processing device technology, applied in the field of plasma processing, can solve the problems of loss, high RF power, and the reduction of plasma generation efficiency, and achieve the effects of reducing power loss, simplifying the matching device, and improving the generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

[0141] (Other Embodiments or Modifications)

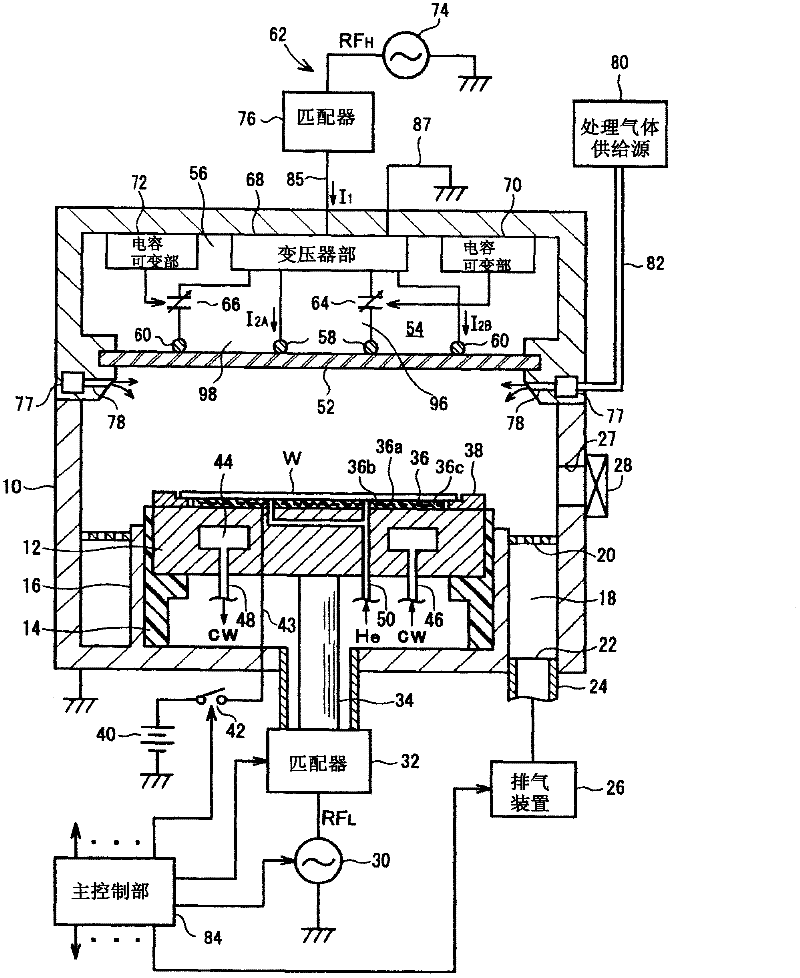

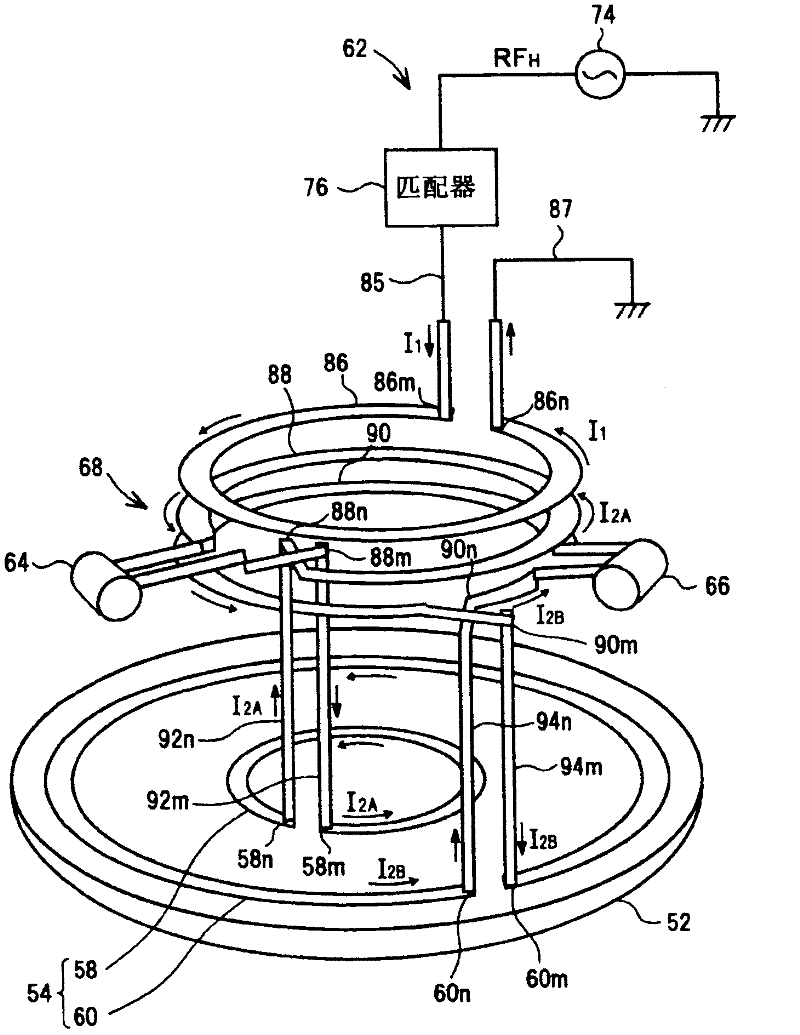

[0142] The inductively coupled plasma processing apparatus of the above-mentioned embodiment ( figure 1 , figure 2 ) The transformer unit 68 is installed in the antenna chamber 56 . However, it is also possible to install the transformer unit 68 outside the antenna housing 56 . In addition, the arrangement posture and direction of the primary coil 86 and / or the secondary coils 88 and 90 can also be selected arbitrarily.

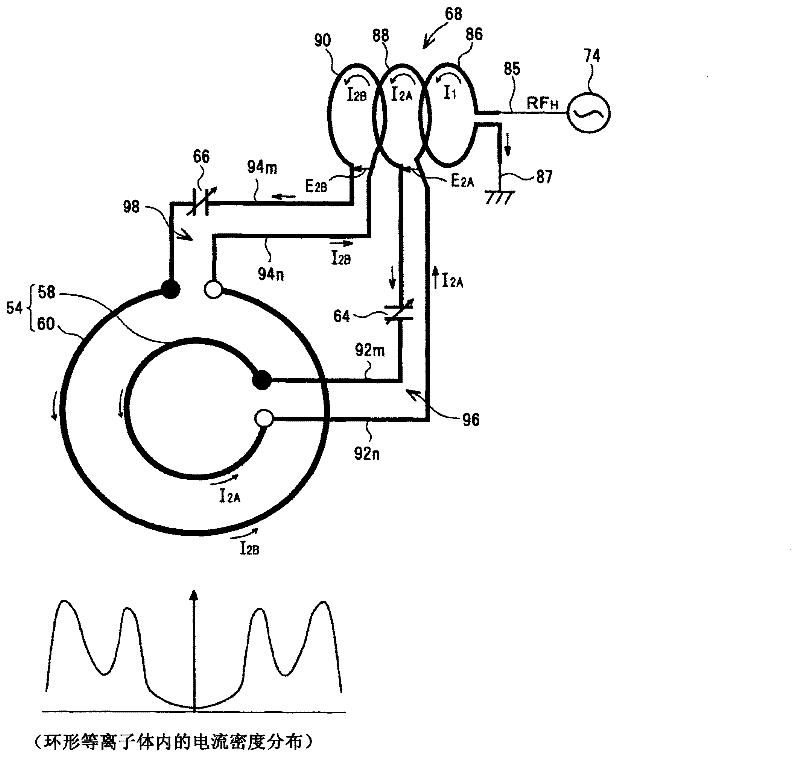

[0143] In the inductively coupled plasma processing apparatus of the above embodiment, capacitors 64 ( 100 ), 66 ( 102 ) are provided in all secondary circuits 96 , 98 formed between coaxial antenna group 54 and transformer unit 68 . However, for example, the primary coil 86 of the transformer unit 68 and the secondary coils 88, 90 each have multiple turns, and a tap changer switch can be attached to the secondary coils 88, 90 (adjustment of the secondary current I by tap changer). 2A , I 2B structure), whil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com