Inductance coupling plasma processing device and plasma processing method

A technology of plasma and inductive coupling, applied in the direction of plasma, circuit, discharge tube, etc., can solve the problems of increased power cost, device cost, and power loss, etc., and achieve the effect of increased cost and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

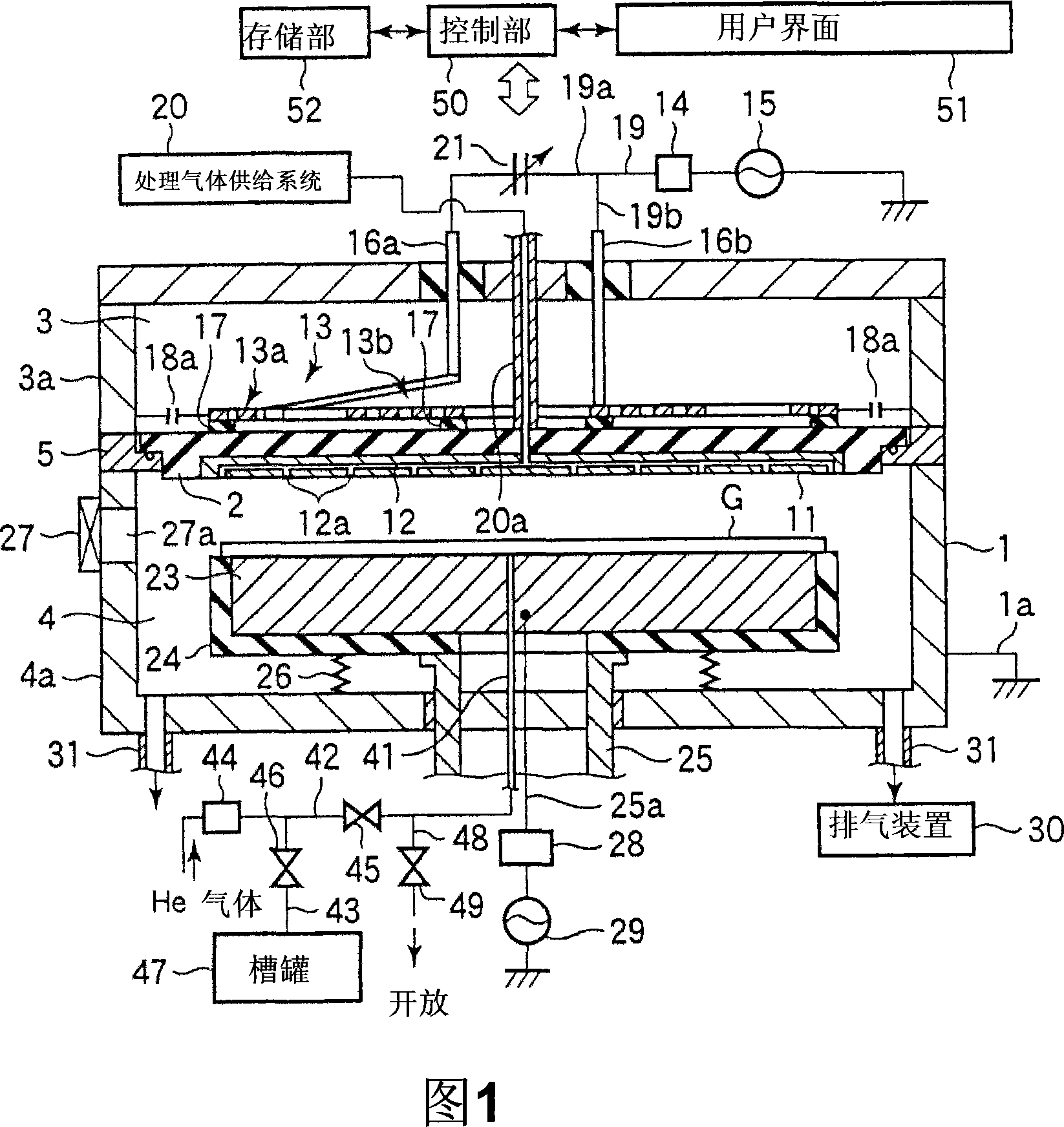

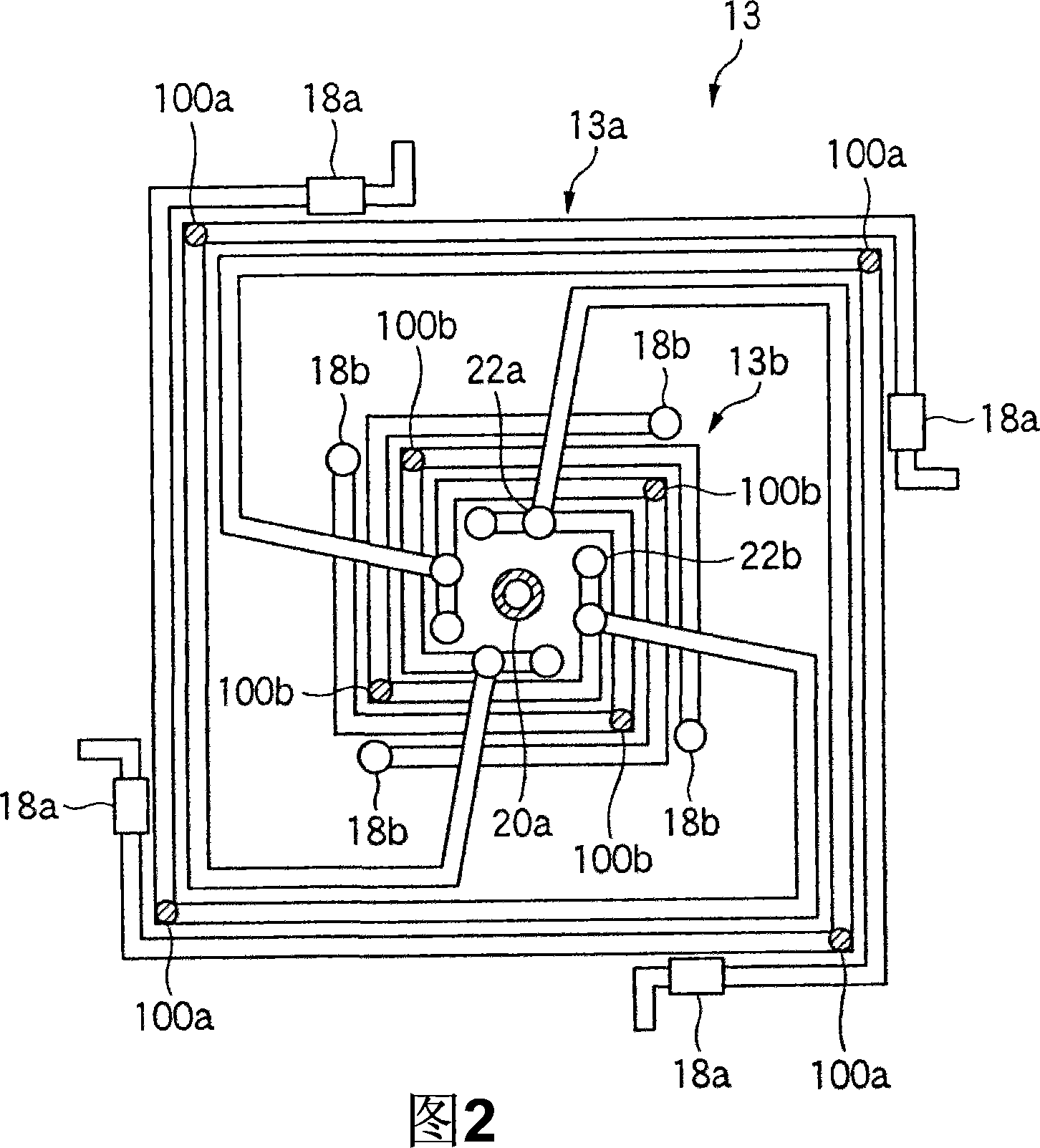

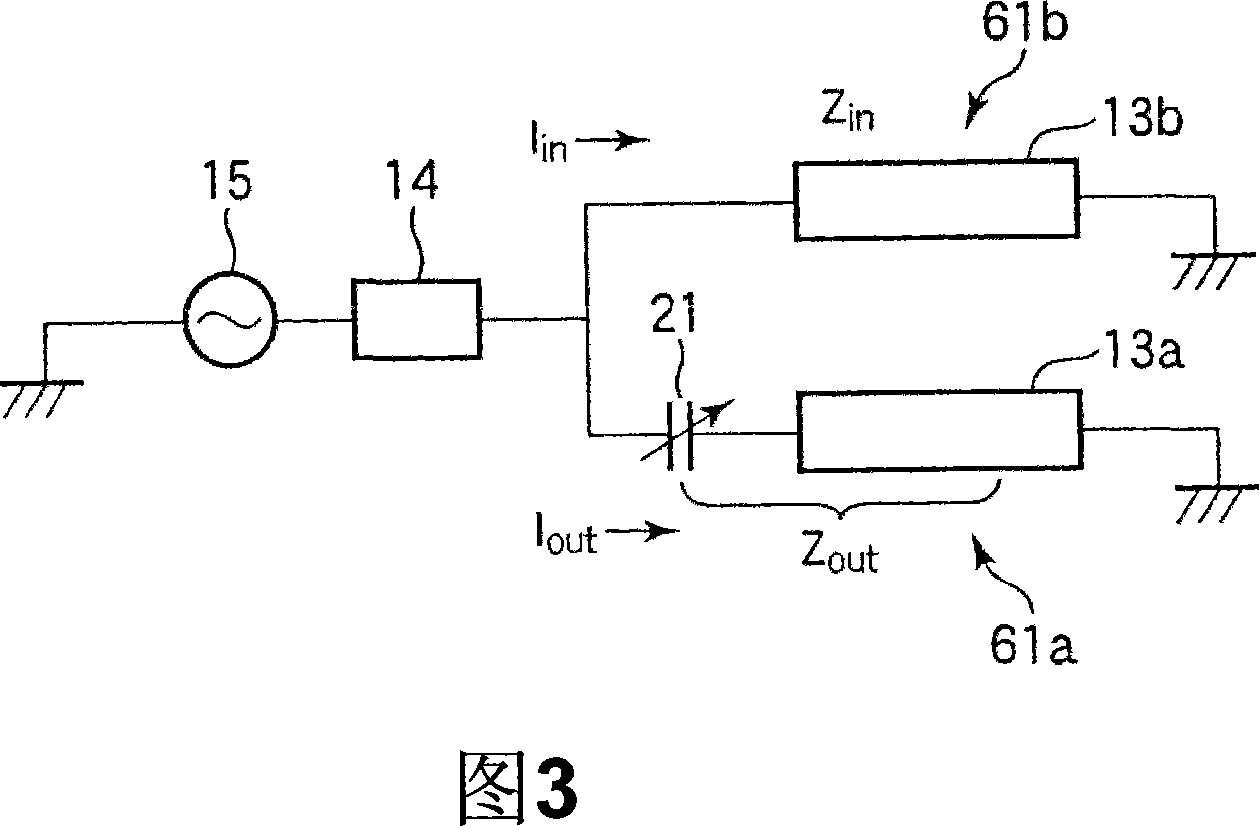

[0052] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. 1 is a cross-sectional view showing an inductively coupled plasma processing apparatus according to an embodiment of the present invention, and FIG. 2 is a plan view showing a high-frequency antenna used in the inductively coupled plasma processing apparatus. This apparatus can be used for, for example, etching of metal films, ITO films, oxide films, etc., and ashing of resist films when forming thin film transistors on a glass substrate for FPD. Here, the FPD includes, for example, a liquid crystal display (LCD), a light emitting diode (LED) display, an electroluminescence (Electro Luminescence: EL) display, a fluorescent display tube (Vacuum Fluorescent Display: VFD), a plasma display panel (PDP), and the like. .

[0053] This plasma processing apparatus has an airtight main body container 1 in the shape of a square cylinder made of a conductive material, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com