Microwave plasma source and plasma processing apparatus

A microwave plasma and plasma technology, applied in the direction of plasma, semiconductor/solid-state device manufacturing, discharge tube, etc., can solve problems such as trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

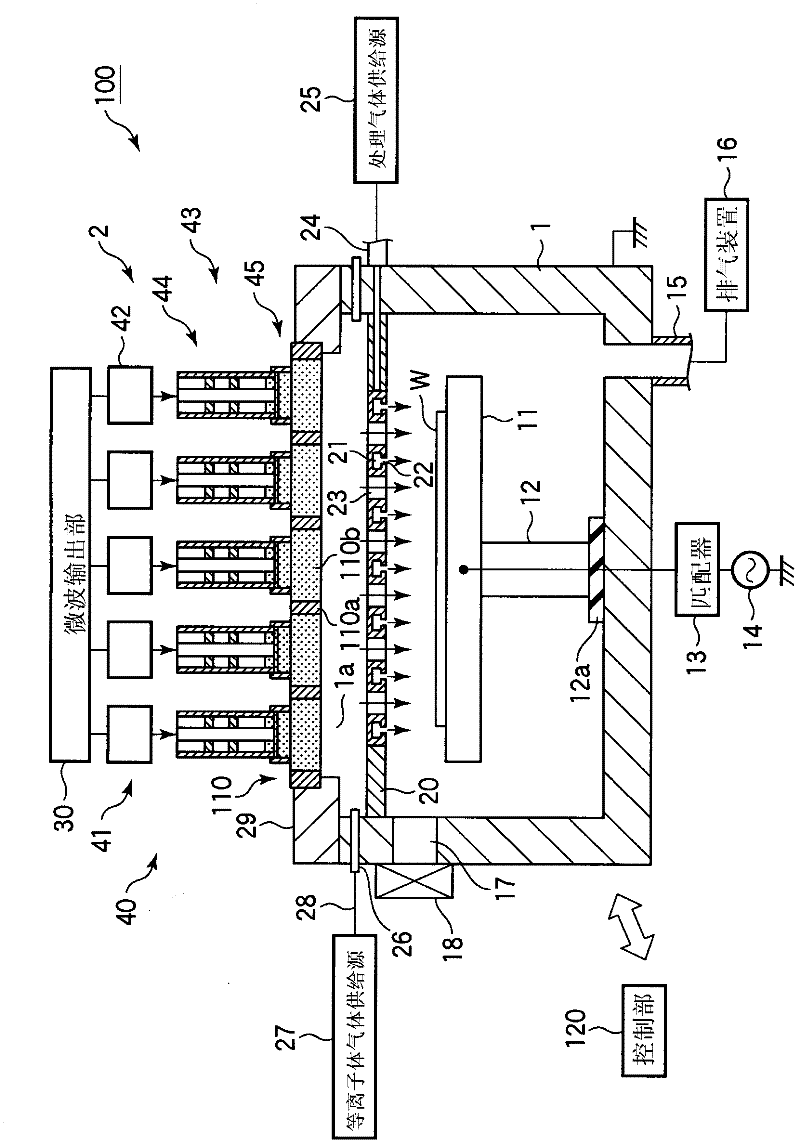

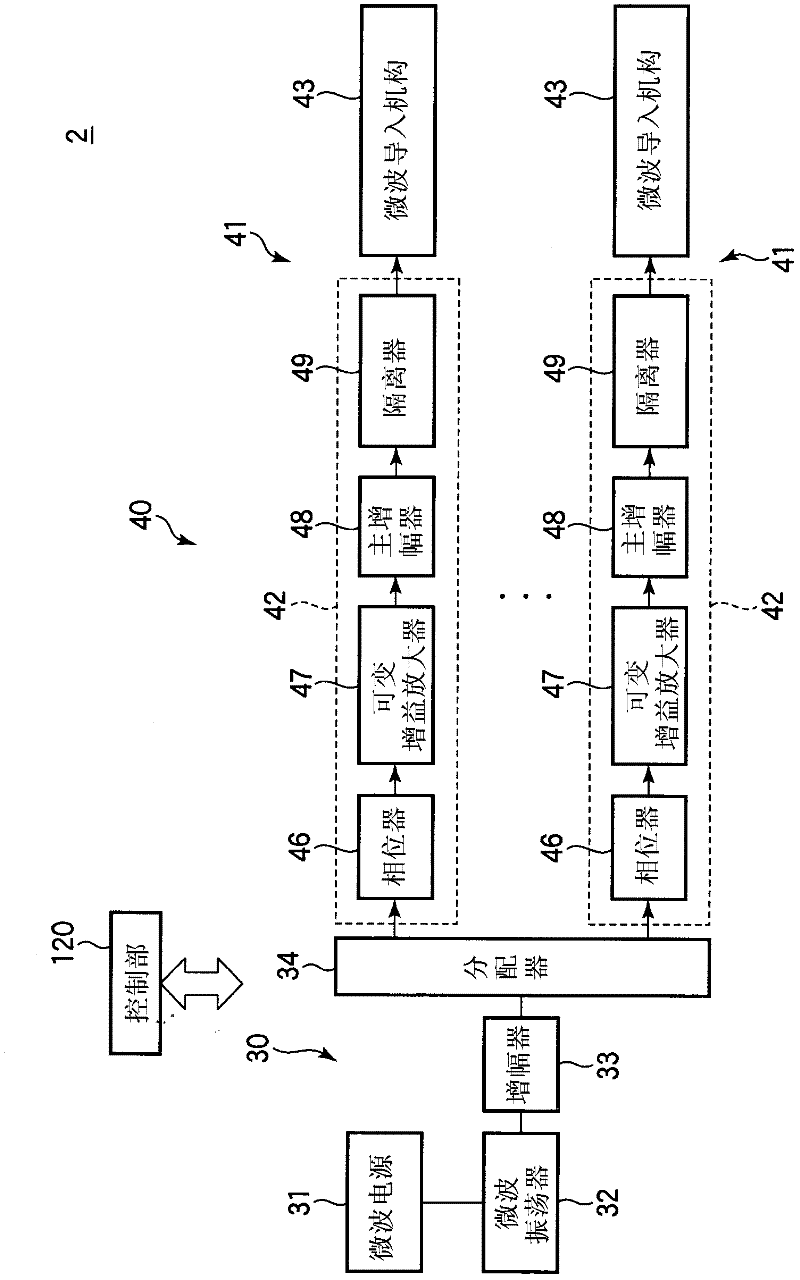

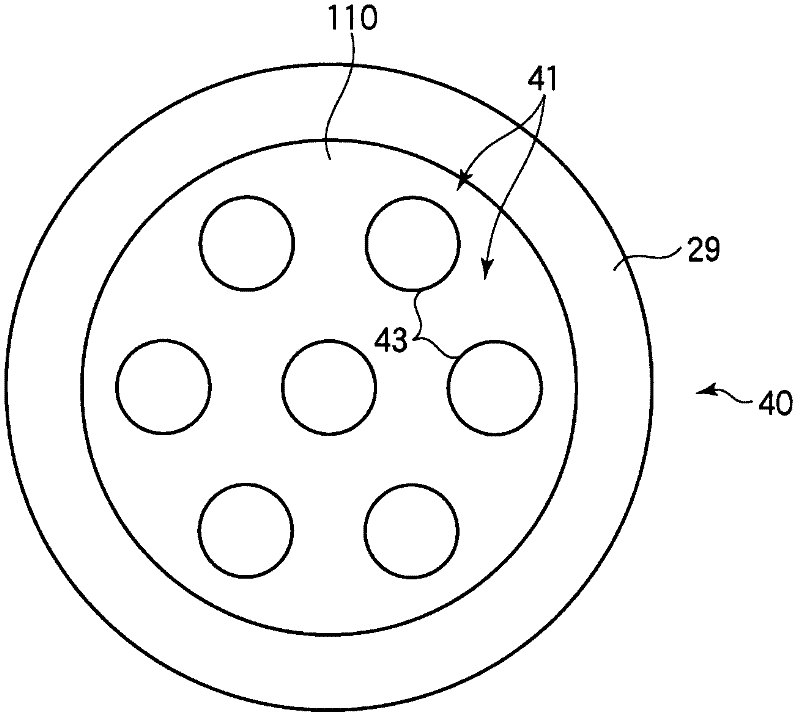

[0059] figure 1 is a cross-sectional view showing a schematic structure of a surface wave plasma processing apparatus having a microwave plasma source according to a first embodiment of the present invention, figure 2 is a structural diagram showing the structure of a microwave plasma source, image 3 It is a plan view schematically showing the microwave supply part of the microwave plasma source, Figure 4 is a diagram showing an example of a circuit configuration of a main amplifier used in an antenna module in a microwave plasma source, Figure 5 A sectional view showing the microwave introducing mechanism used in the antenna module of the microwave plasma source, Image 6 In order to represent the power supply structure of the microwave introduction mechanism, in Figure 5 A cross-sectional view of the AA' line, Figure 7 To represent the iron core and sliding parts in the tuner, in Figure 5 A cross-sectional view of the BB' line.

[0060] The surface wave plasma pro...

no. 2 approach

[0110] Next, a second embodiment of the present invention will be described.

[0111] In this embodiment, the basic structure of the microwave plasma source and the plasma processing device is the same as that of the first embodiment, and the structure of the top plate is different.

[0112] Figure 12 It is a plan view schematically showing the microwave supply part and the top plate of the plasma source in this embodiment, Figure 13 for in Figure 12 Cross-sectional view of line CC'. As shown in these figures, in this embodiment, a circular top plate 110 is formed, and a dielectric member 110b made of a dielectric such as quartz is embedded in a portion where a plurality of microwave introduction mechanisms 43 for radiating microwaves into the chamber 1 are arranged. It has a hexagonal shape, and between adjacent dielectric members 110b, one side of the hexagonal shape is provided close to each other so as to face each other. Therefore, in the metal frame 110a supportin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com