Plasma processing apparatus and plasma processing method

a processing apparatus and plasma technology, applied in the field of plasma processing apparatus and plasma processing method, can solve the problems of unbalanced plasma density distribution, unbalanced plasma distribution, electrode or plasma distribution on the target object, etc., to improve the uniformity of process characteristics, improve performance and the degree of freedom, and improve the effect of plasma density distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

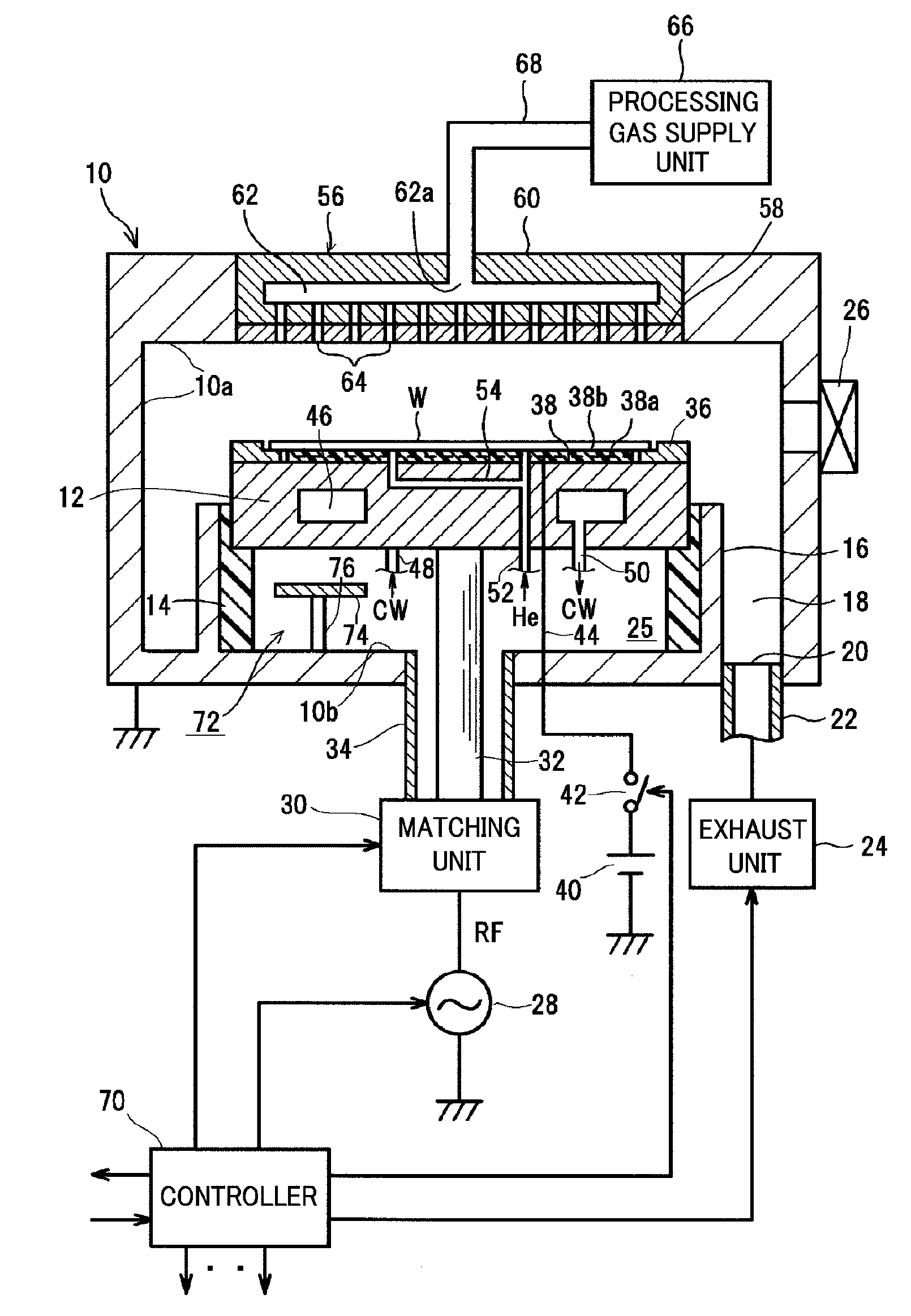

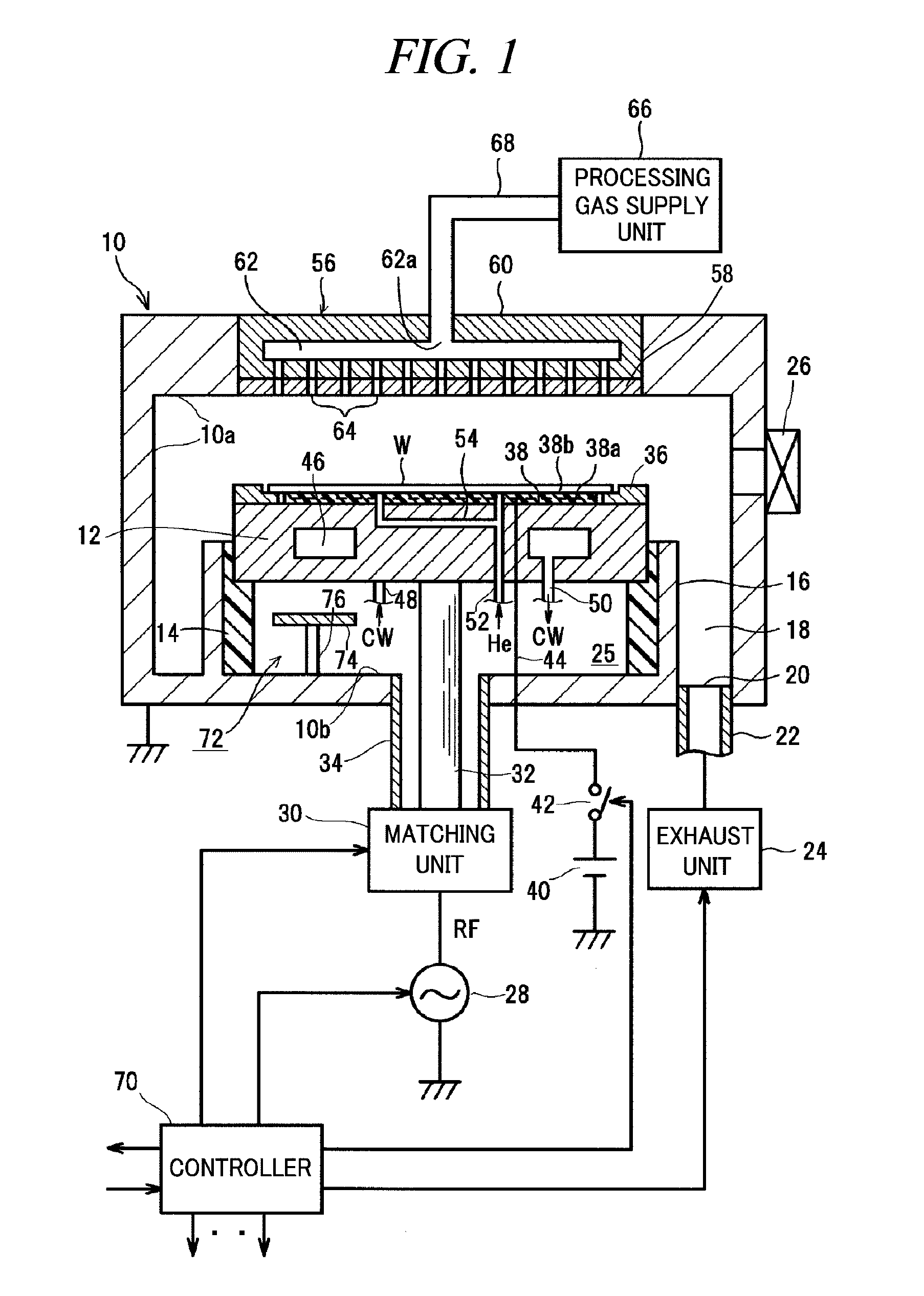

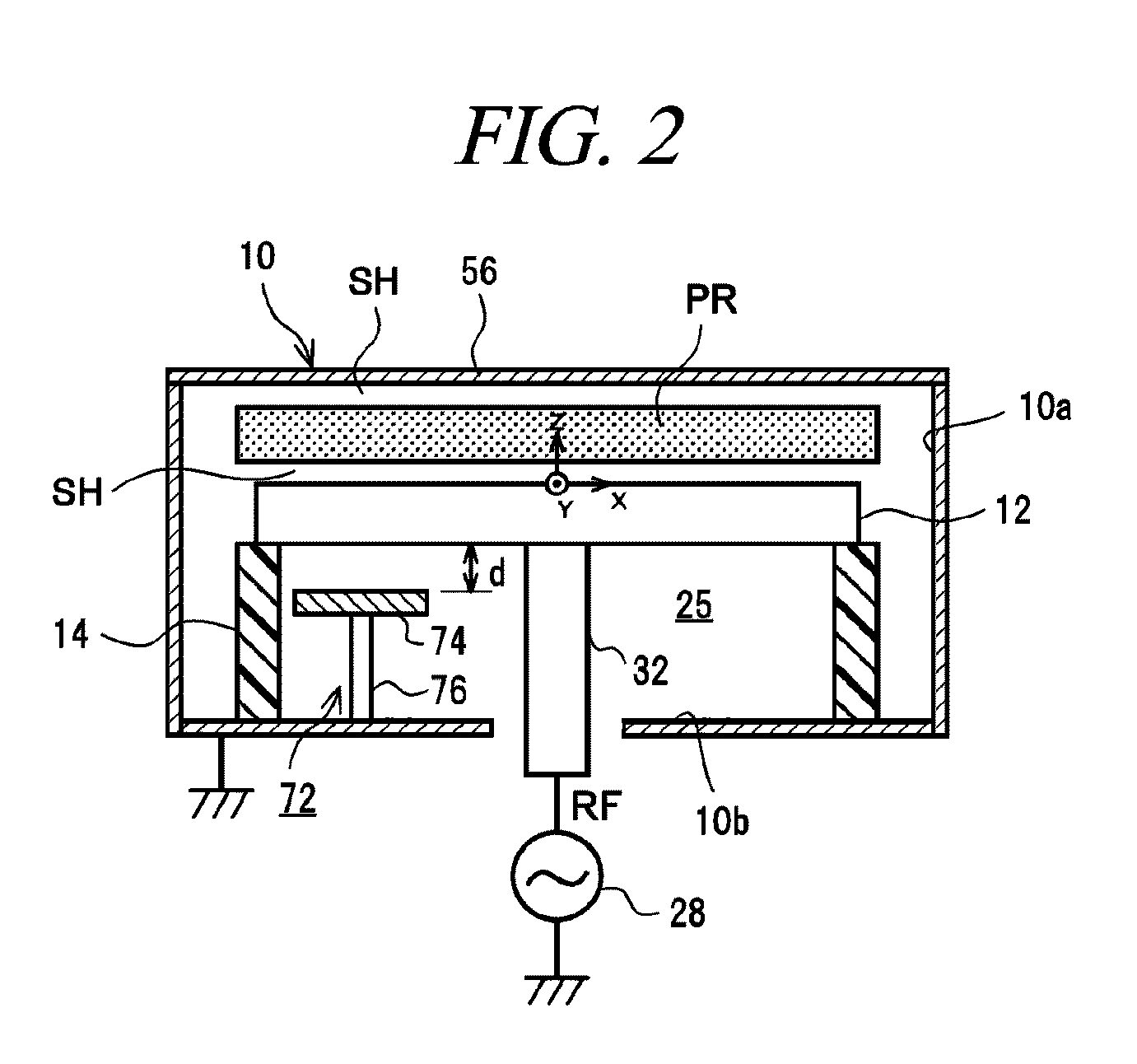

[0086]The plasma density distribution controller 72 in accordance with a first embodiment includes a conductive plate (first conductor) 74 which is placed substantially parallel (horizontally) under the rear surface of the susceptor 12 at a certain position to face the susceptor 12 and a conductive rod (second conductor) 76 which supports the conductive plate 74 upward and is electrically grounded. Both the conductive plate 74 and the conductive rod 76 are made of conductive metal such as copper or aluminum.

[0087]To be more specific, the conductive plate 74 is extended in a circular arc shape along a circumference direction of the power feed rod 32 or along an inner wall of the cylindrical insulating member 14, and is distanced from the rear surface of the susceptor 12 at a certain distance d. The conductive rod 76 is uprightly extended from the conductive plate 74. An upper end (first connecting portion) of the conductive rod 76 is fixed to a certain portion of a bottom surface of ...

second embodiment

[0112]In a second embodiment which is characteristically or developmentally modified from the layout of FIG. 9 in the first embodiment, a plurality of pairs of conductive rods 76(1), 76(2), . . . can be equi-spaced around a circumference (about 360°) in an azimuthal direction.

[0113]For example, in case of a three-pair type as illustrated in FIG. 10, three conductive rods 76(1), 76(2), and 76(3) are equi-spaced at about 120° around the power feed rod 32. In case of a four-pair type as illustrated in FIG. 11, four conductive rods 76(1), 76(2), 76(3), and 76(4) are equi-spaced at about 90° around the power feed rod 32.

[0114]FIG. 12 shows etching rate distribution obtained by the plasma etching apparatus (second embodiment apparatus) shown in FIG. 1 including the plasma density distribution controller 72 (three-pair type of FIG. 10) in accordance with the second embodiment in the first experimental example (recipe A) as compared to etching rate distribution obtained by the comparative e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com