Microwave plasma source and plasma processing apparatus

a plasma processing apparatus and plasma technology, applied in the direction of plasma technique, electrical apparatus, electric discharge tubes, etc., can solve the problems of non-uniform plasma density distribution, process complexity, and inability to uniformize the plasma density distribution, so as to improve the in-plane uniformity of electric field intensity and uniform plasma process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

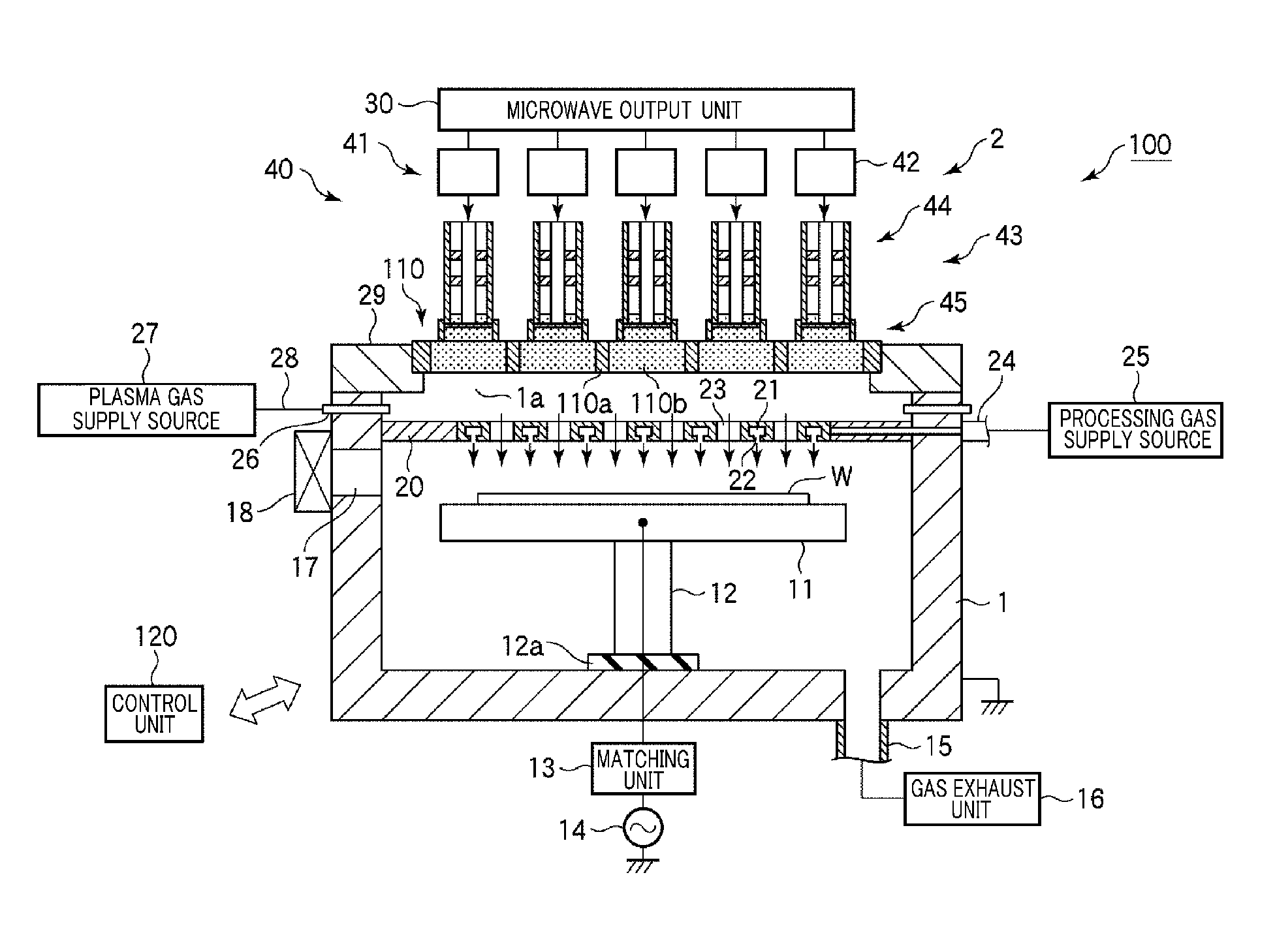

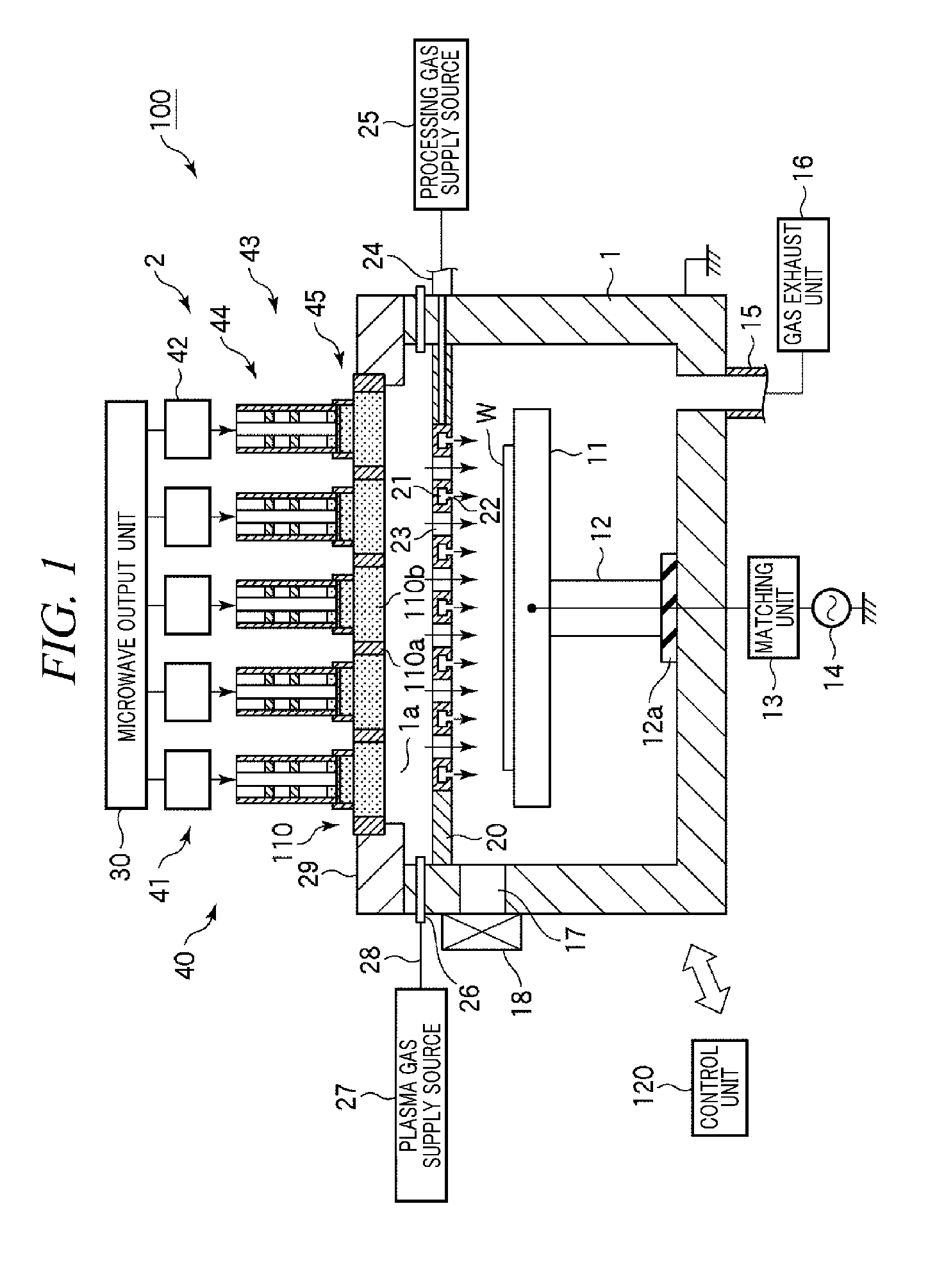

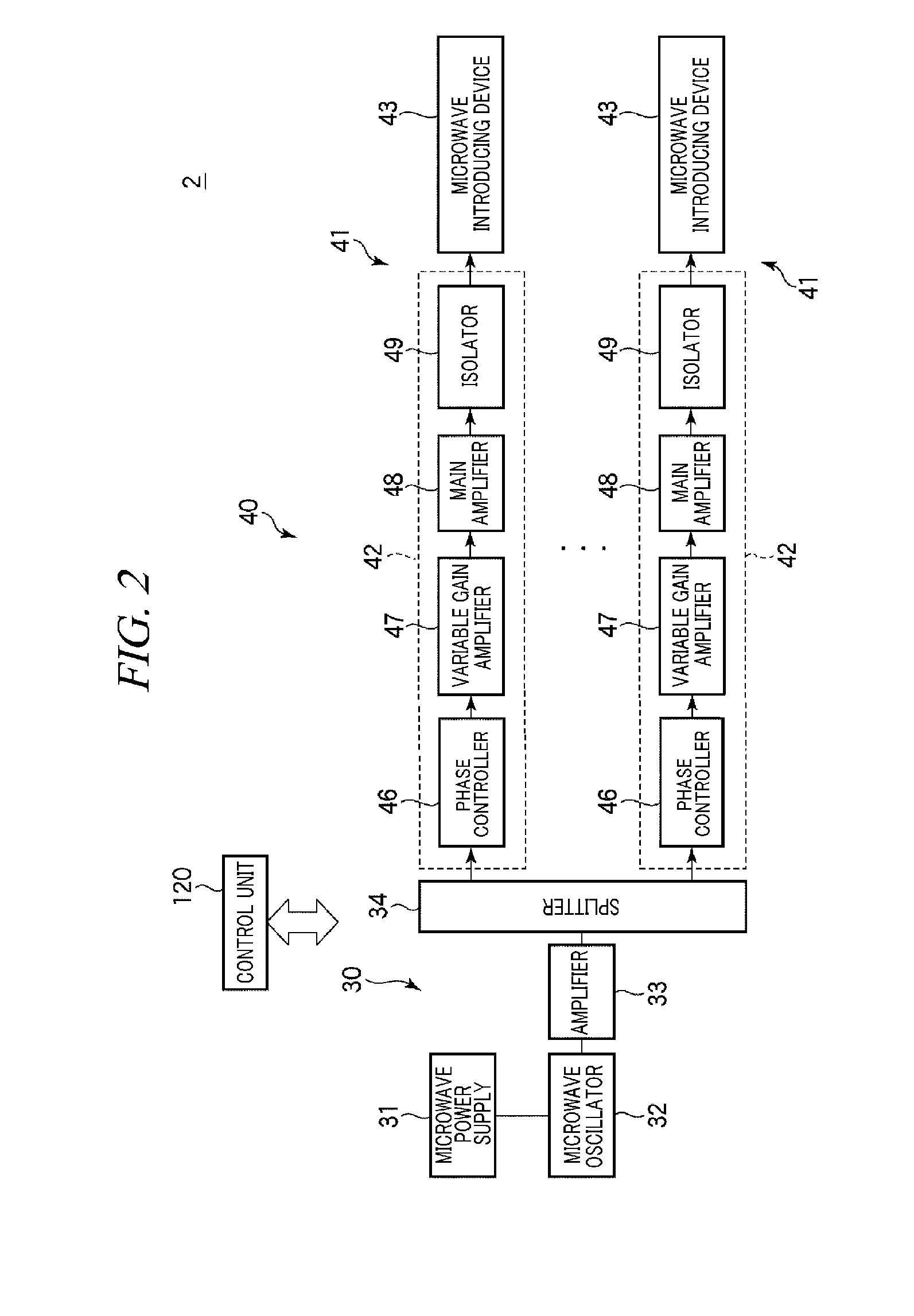

[0035]FIG. 1 is a cross sectional view illustrating a schematic configuration of a surface wave plasma processing apparatus having a microwave plasma source in accordance with a first embodiment of the present disclosure. FIG. 2 is a configuration view of the microwave plasma source. FIG. 3 is a plane view schematically illustrating a microwave supply unit of the microwave plasma source. FIG. 4 shows an example circuit configuration of a main amplifier of an antenna module of the microwave plasma source. FIG. 5 is a cross sectional view illustrating a microwave introducing device of the antenna module of the microwave plasma source. FIG. 6 is a transversal cross sectional view taken along a line AA′ of FIG. 5, and shows a power supply unit of the microwave introducing device. FIG. 7 is a transversal cross sectional view taken along a line BB′ of FIG. 5, and shows a slug and a sliding member of a tuner.

[0036]A surface wave plasma processing apparatus 100 is configured as a plasma etc...

second embodiment

[0084]Now, a second embodiment of the present disclosure will be described.

[0085]Although basic configurations of a microwave plasma source and a plasma processing apparatus in accordance with the second embodiment are the same as those of the first embodiment, a ceiling plate has a different configuration.

[0086]FIG. 12 illustrates a plane view schematically illustrating a ceiling plate and a microwave introducing device of a microwave plasma source in accordance with the second embodiment. FIG. 13 is a cross sectional view taken along a line CC′ of FIG. 12. As shown in FIGS. 12 and 13, a circular ceiling plate 110 in accordance with the second embodiment includes dielectric members 110b fitted to positions where a multiple number of microwave introducing devices 43 for radiating microwaves into the chamber 1 are provided. Each dielectric member 110b is made of a dielectric material such as quartz and has a hexagon shape. Adjacent dielectric members 110b are placed close to each oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com