Inductive couple plasma processing device

A plasma and processing device technology, applied in the field of plasma processing devices, can solve the problems of insufficient diffusion effect, deterioration of plasma distribution, uneven distribution of plasma, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

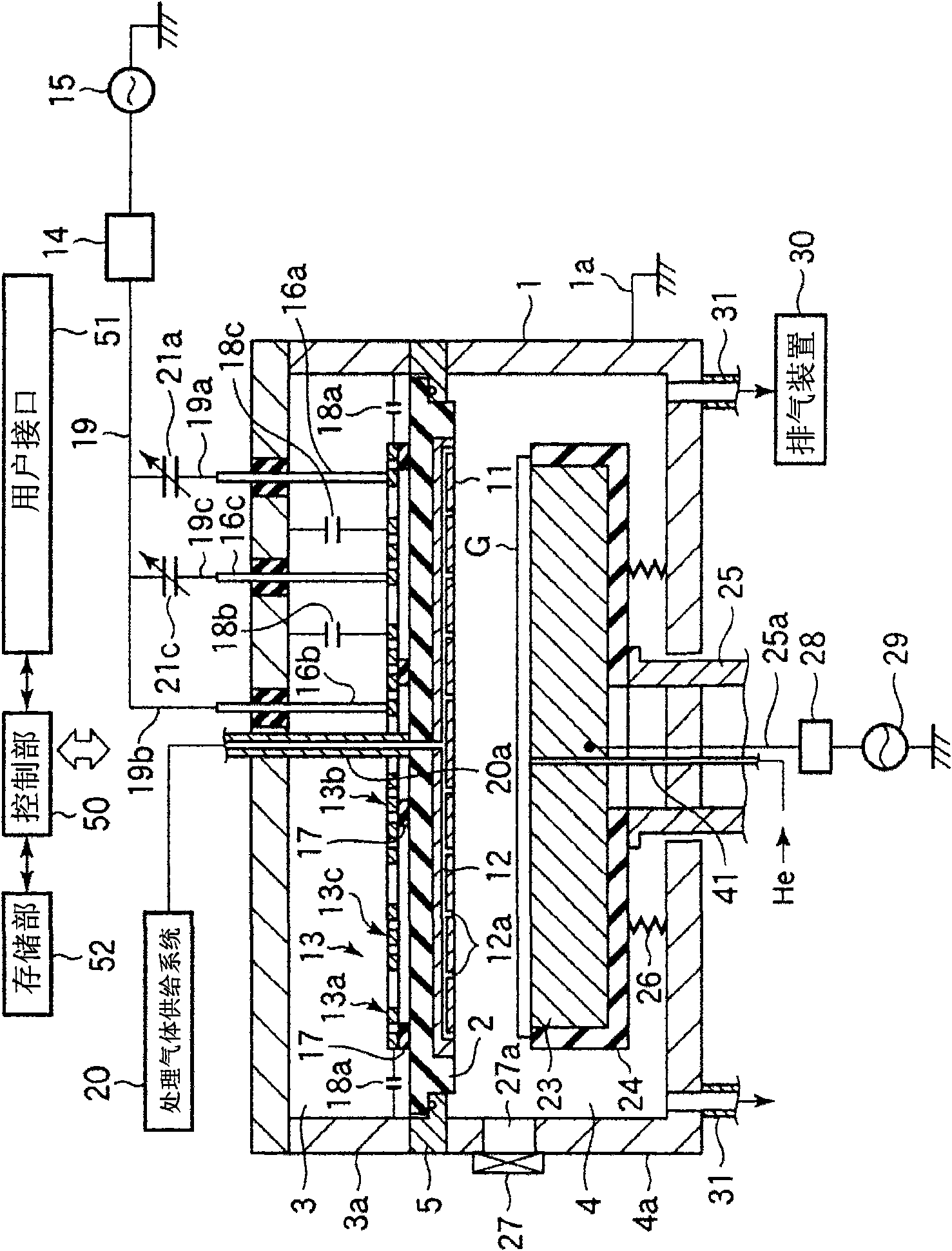

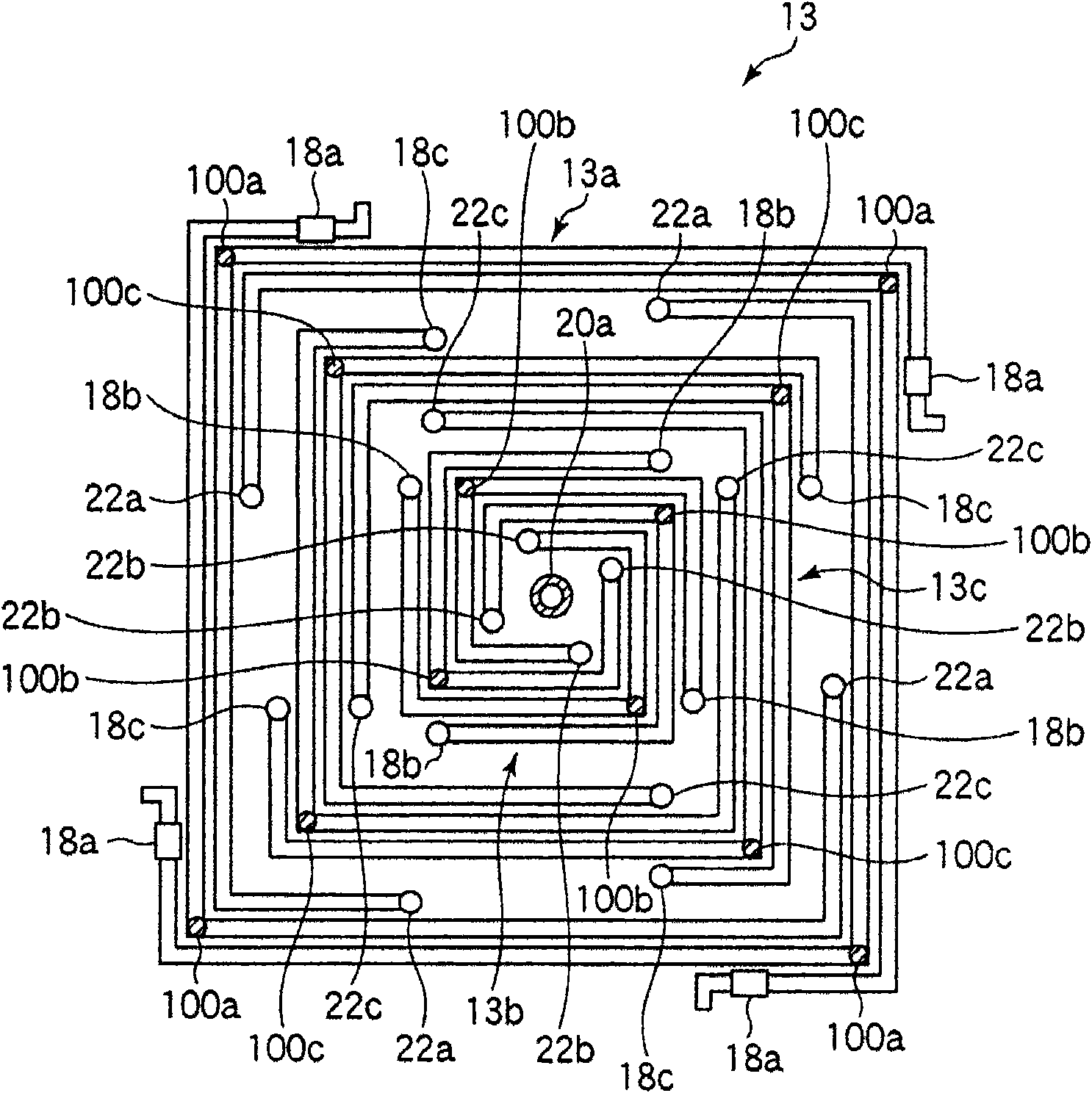

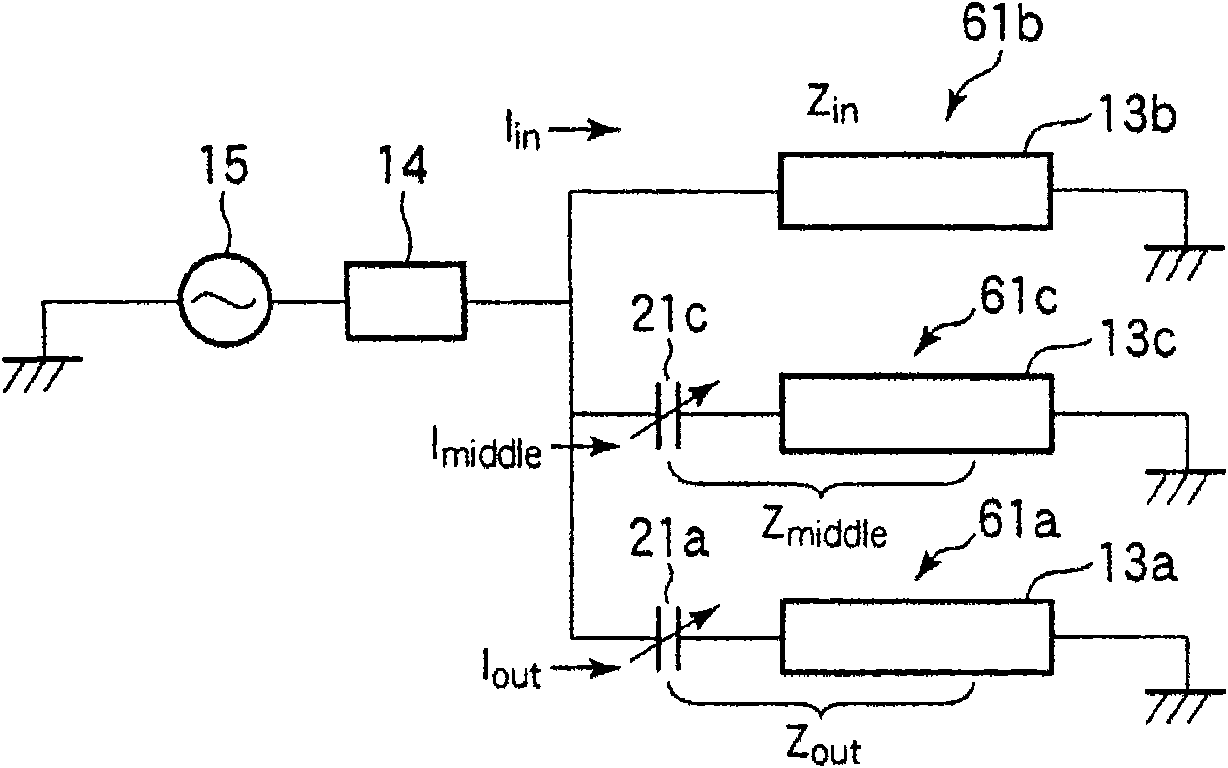

[0043] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a sectional view showing an inductively coupled plasma processing apparatus according to an embodiment of the present invention. figure 2 It is a plan view showing the radio-frequency antenna used in this inductively coupled plasma processing apparatus. This apparatus is used, for example, for etching a metal film, an ITO film, an oxide film, etc., or for ashing a resist film when forming a thin film transistor on a glass substrate for FPD. Here, examples of the FPD include a liquid crystal display (LCD), an electroluminescence (EL) display, a plasma display panel (PDP), and the like.

[0044] This plasma processing apparatus has an airtight main body container 1 in the shape of an angular tube made of a conductive material such as aluminum whose inner wall surface is anodized. The main body container 1 is detachably assembled and grounded through a grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com