Helical resonator type plasma processing apparatus

A spiral resonator and plasma technology, applied in the direction of plasma, semiconductor/solid-state device manufacturing, discharge tube, etc., to achieve the effect of improving density uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will now be described more fully hereinafter with reference to the accompanying drawings, in which preferred embodiments of the invention are shown by way of example. The same reference numerals identify the same elements throughout the drawings.

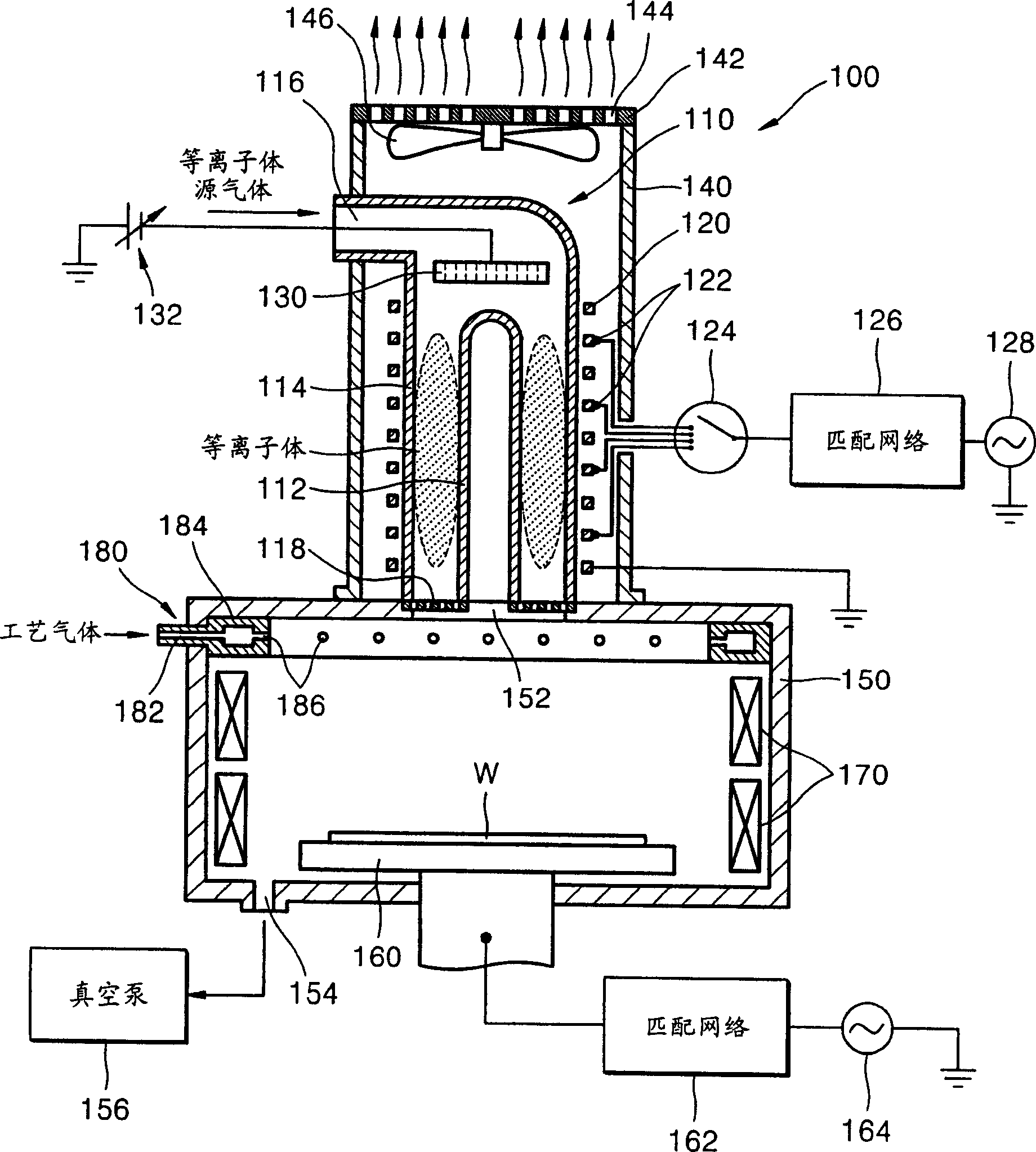

[0041] image 3 is a vertical cross-sectional view of a spiral resonator plasma processing apparatus according to a preferred embodiment of the present invention, Figure 4 yes image 3 A partially cut-away perspective view of the dielectric tube, control electrode, helical coil, and plasma distributor is shown.

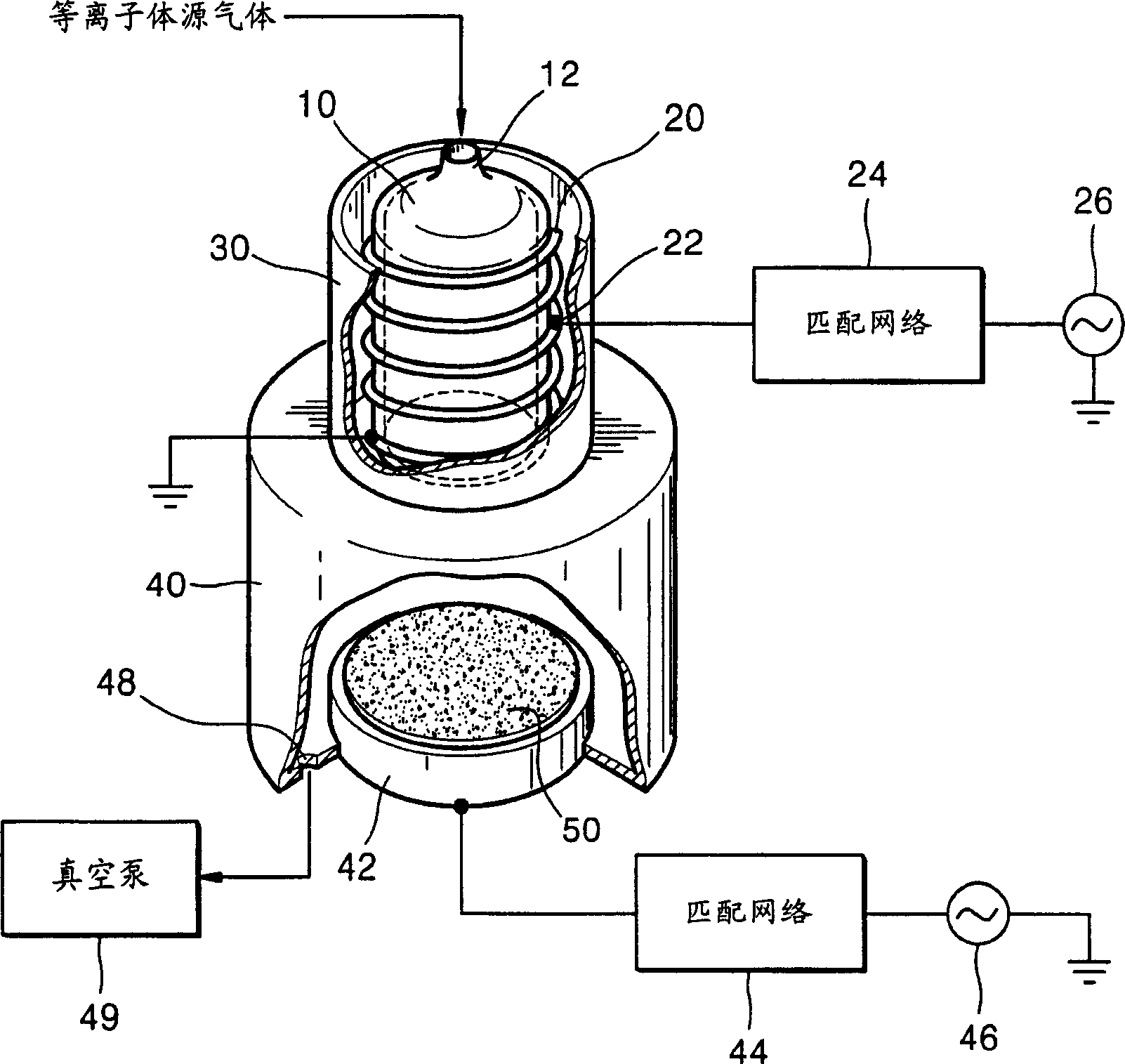

[0042] refer to image 3 and 4 , the spiral resonator plasma processing apparatus according to the present invention is a semiconductor processing apparatus for performing fine processing by means of plasma generated by a spiral resonator 100, such as etching a substrate surface, or depositing a predetermined material on a substrate layer. The substrate loaded in the processing chamber 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com