Plasma processing apparatus

A plasma and processing device technology, applied in the field of plasma processing, can solve the problems of uniformity and reduction of anisotropic etching, and achieve the effect of improving uniformity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings.

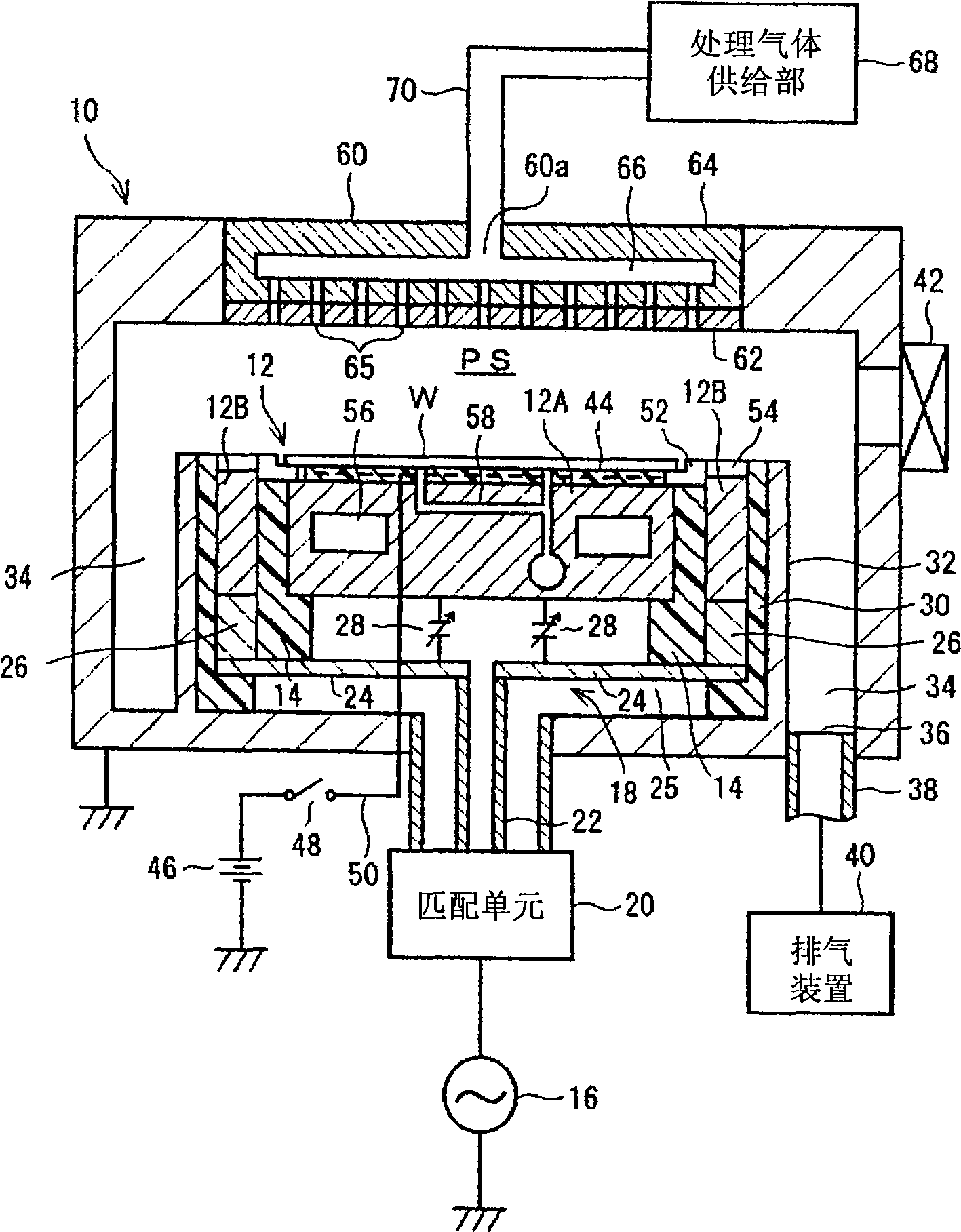

[0059] figure 1 The configuration of a plasma processing apparatus according to an embodiment of the present invention is shown. This plasma processing apparatus is configured as a capacitively coupled plasma etching apparatus of a cathode coupler, and includes, for example, a cylindrical chamber (processing container) 10 made of metal such as aluminum or stainless steel. Chamber 10 is securely grounded.

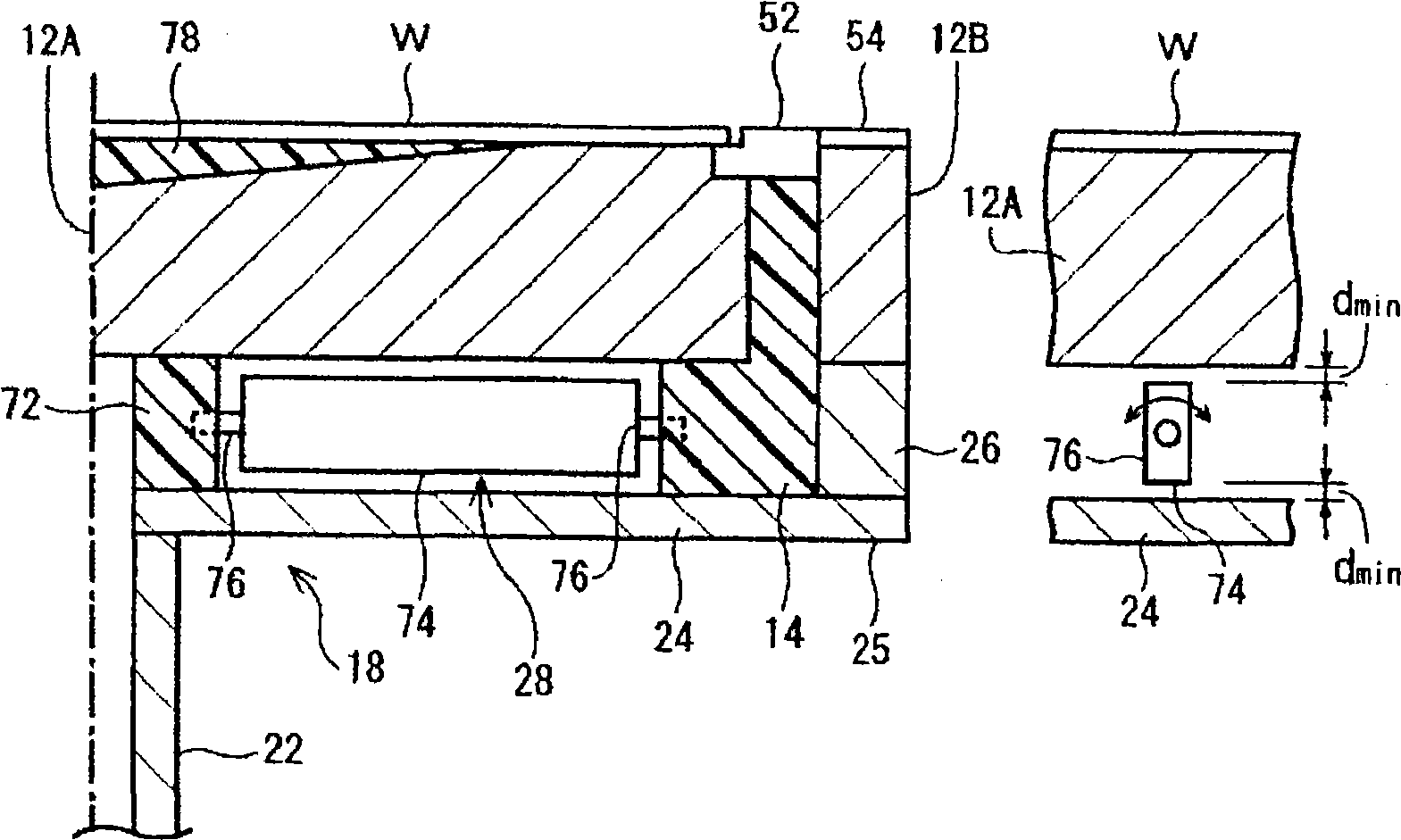

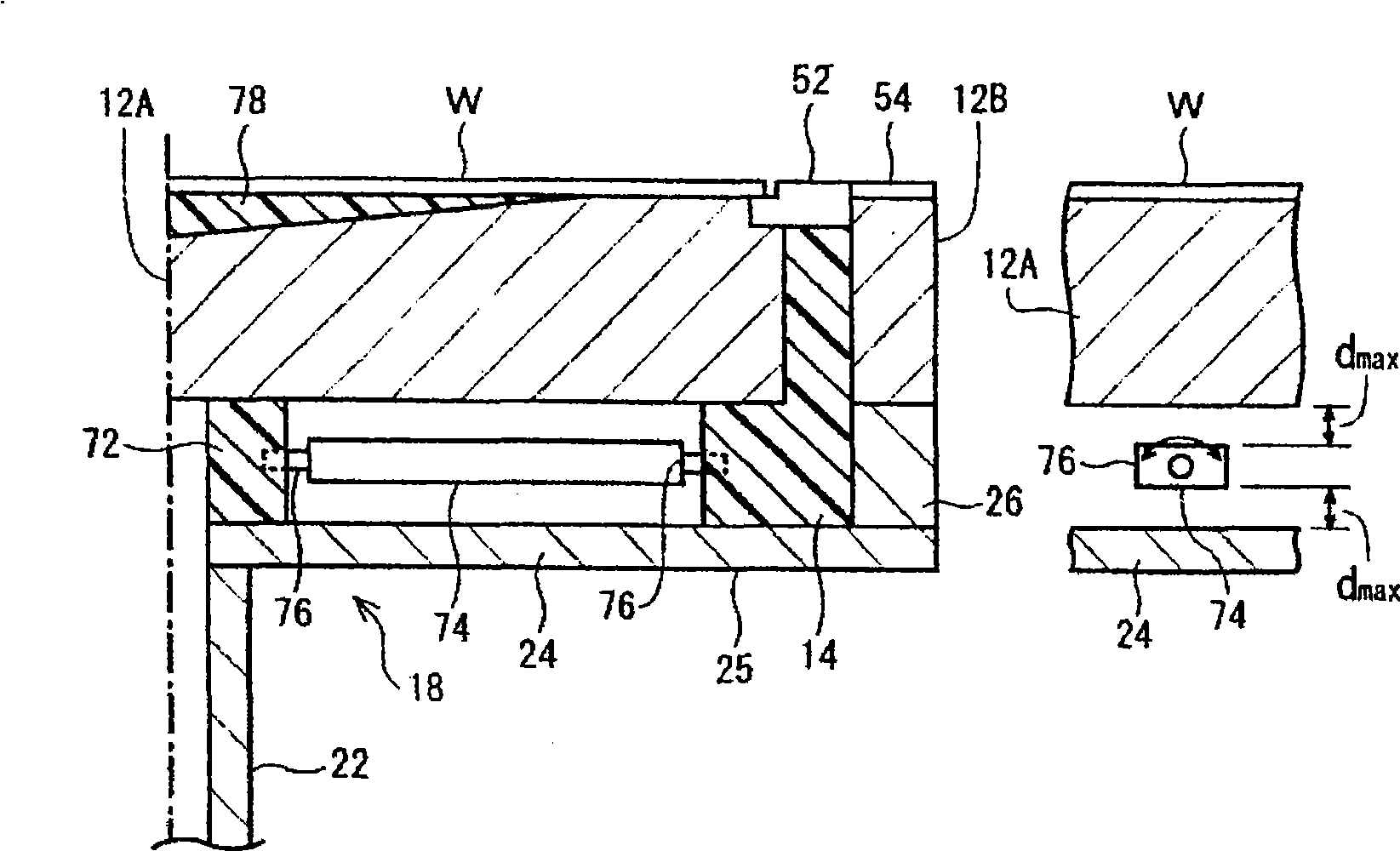

[0060] A susceptor or lower electrode 12 is arranged horizontally in the chamber 10 as a high-frequency electrode. The susceptor 12 is divided into two in the radial direction into a disc-shaped susceptor center electrode (lower center electrode) 12A on which, for example, a semiconductor wafer W is placed as a substrate to be processed, and a ring-shaped susceptor center electrode 12A surrounding the outer periphery of the susceptor center electrode 12A. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com