Electrochemical micro-additive manufacturing method for dynamic control of confined electric field in bipotential tool electrodes

A tool electrode, bi-potential technology, applied in the direction of additive processing, electroforming, electrolysis process, etc., can solve the problems of microstructure size consistency, surface quality with a certain distance, poor flatness, surface roughness, etc. The effect of processing locality, stable voltage drop, and precise size control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

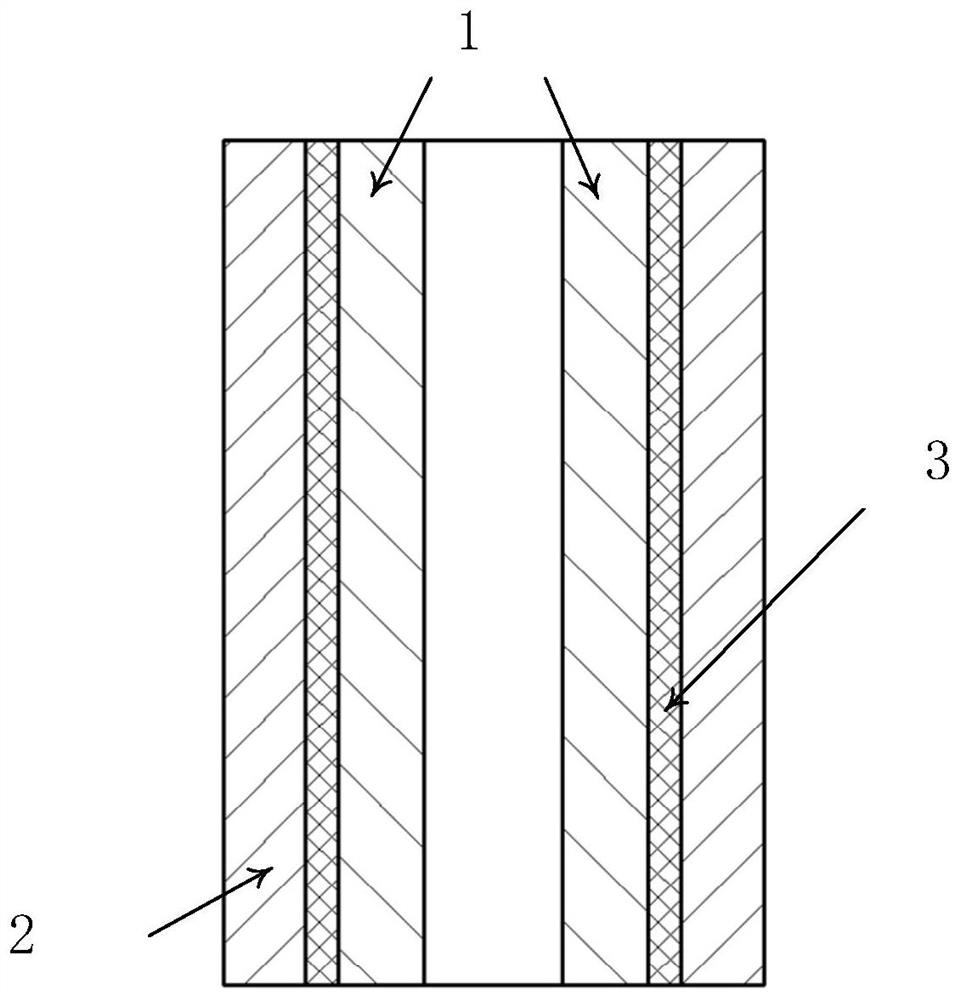

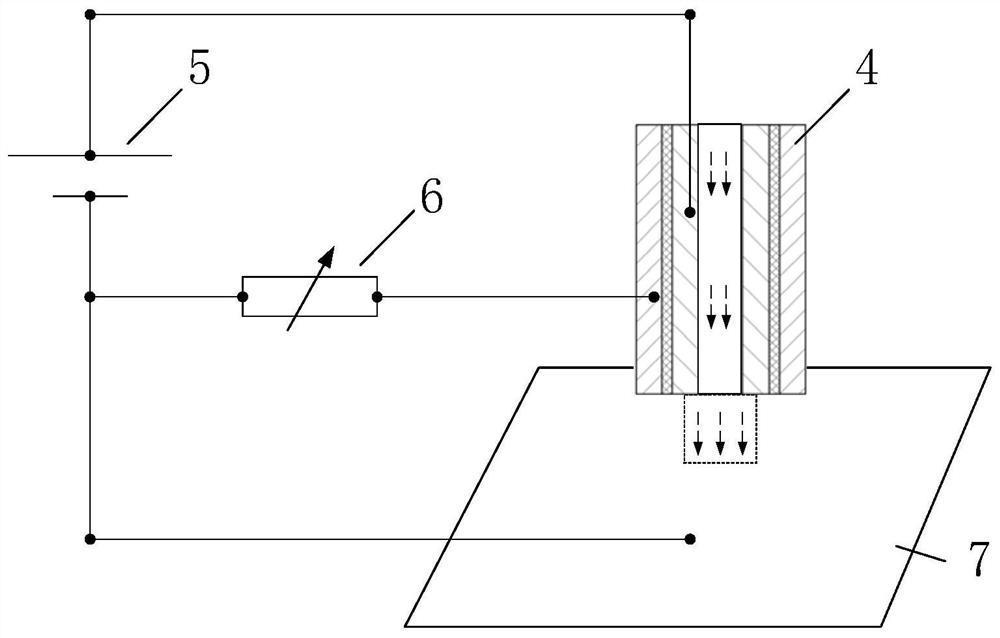

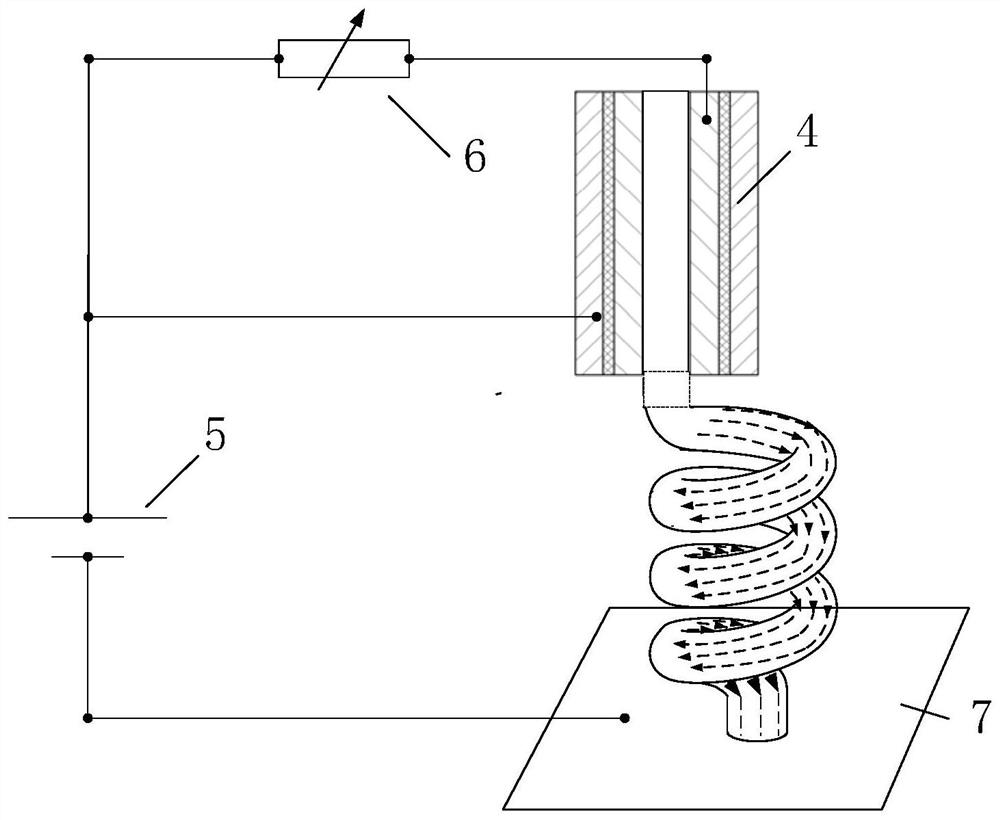

[0019] Such as figure 1 As shown, the bipotential tool electrode 4 is mainly composed of an insoluble anode 1 , an auxiliary electrode 2 and an insulating layer 3 . The following is attached figure 2 and 3 The concrete implementation process of the present invention is described in detail, specifically as follows:

[0020] Step 1, preparing a bipotential tool electrode 4;

[0021] Step 2. In the initial growth stage, the positive pole of the power supply 5 is connected to the anode 1 in the bipotential tool electrode 4, the negative pole of the power supply 5 is connected to the substrate 7, and the electronic load 6 is connected in series with the auxiliary electrode 2 in the bipotential tool electrode 4 to the negative pole of the power supply 5;

[0022] Step 3. Enter the electroforming liquid, set the constant voltage working mode of the electronic load 6 to realize the pressure drop, and make the potential of the auxiliary electrode 2 lower than the potential of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com