Electrochemical machining bipolar electrode of revolution body surface boss structure and electrochemical machining method of electrochemical machining bipolar electrode

A bipolar electrode and boss structure technology, applied in the direction of processing electrodes, electric processing equipment, electrochemical processing equipment, etc., can solve problems such as difficulties, complex implementation of composite magnetic field devices, and complex movement forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

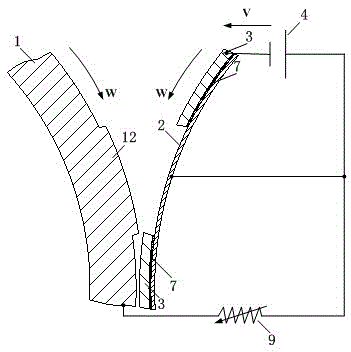

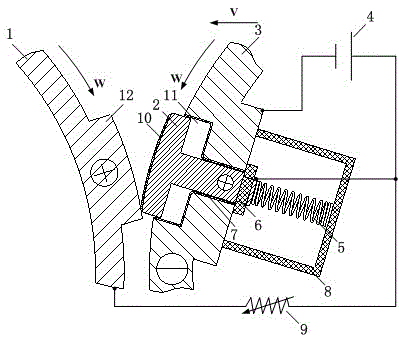

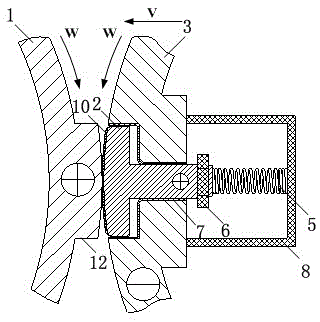

[0028] combine figure 1 , 2 , 3, 4, 5 illustrate the implementation process of the present invention:

[0029] figure 1 Schematic diagram of the dual-electrode structure for electrolytic machining of low bosses with a height of 0-1mm. The auxiliary electrode is fixed on the inner wall of the tool cathode and is insulated by an insulating layer. The anode of the workpiece is connected in series with the electronic load and then connected to the positive pole of the power supply in parallel with the auxiliary electrode, and the cathode of the tool is connected to the negative pole of the power supply. The electronic load is set to a constant voltage mode during operation to ensure a stable positive potential difference between the auxiliary electrode and the anode of the workpiece.

[0030] figure 2 , 3 , 4 are schematic diagrams when the auxiliary electrode is in different positions for electrolytic machining of a high boss with a height of 1-20 mm. When turning into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com