Substrate Processing Apparatus for Mechanically Controlling Plasma Density

A substrate processing device and plasma technology, which are applied to circuits, discharge tubes, electrical components, etc., can solve the problems of inability to effectively control the plasma P density, inability to effectively control the plasma density, faster replacement cycle, etc., and achieve effective control. Effects of plasma density distribution, minimization of operation interruption time, and increased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

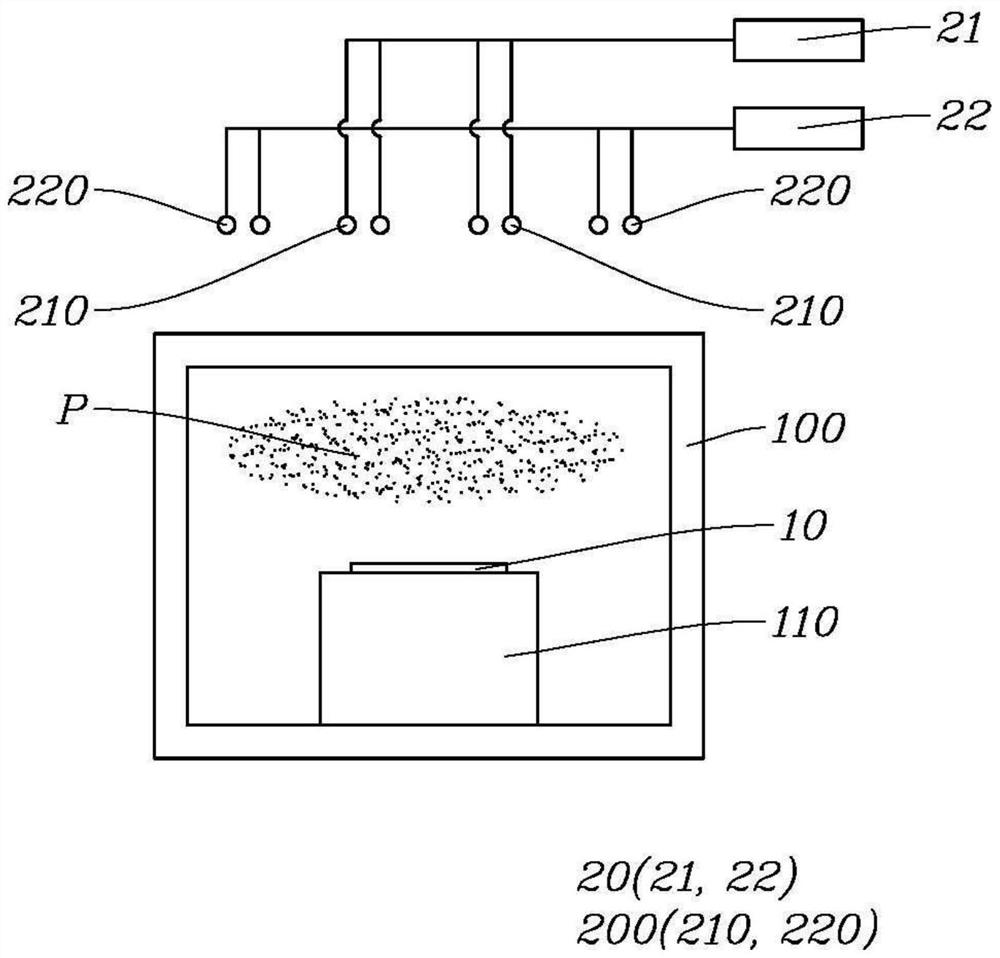

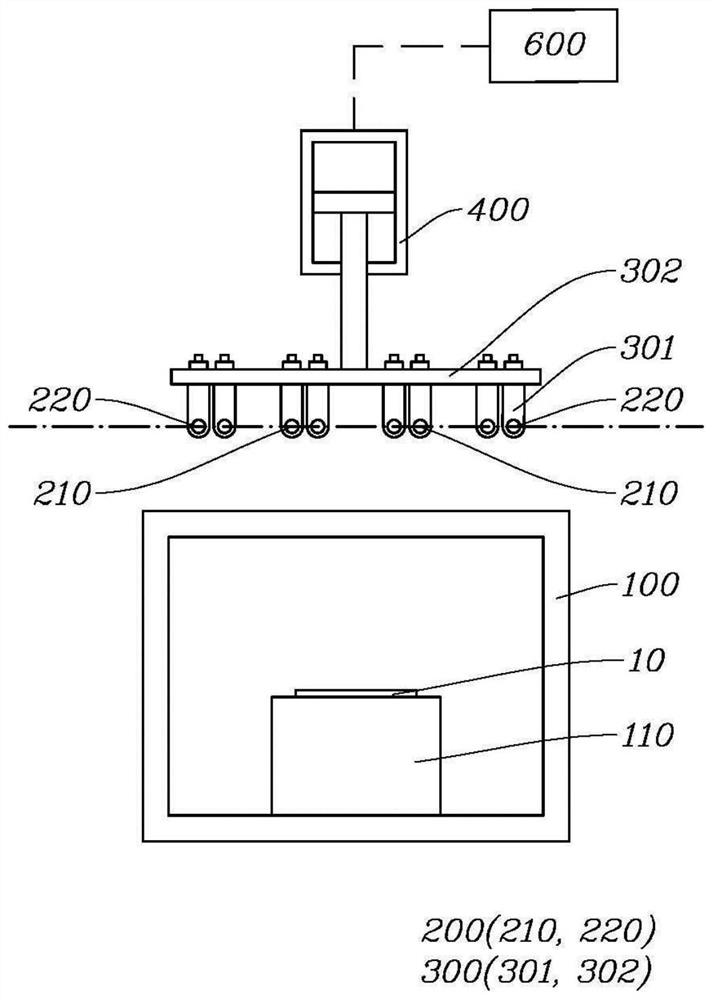

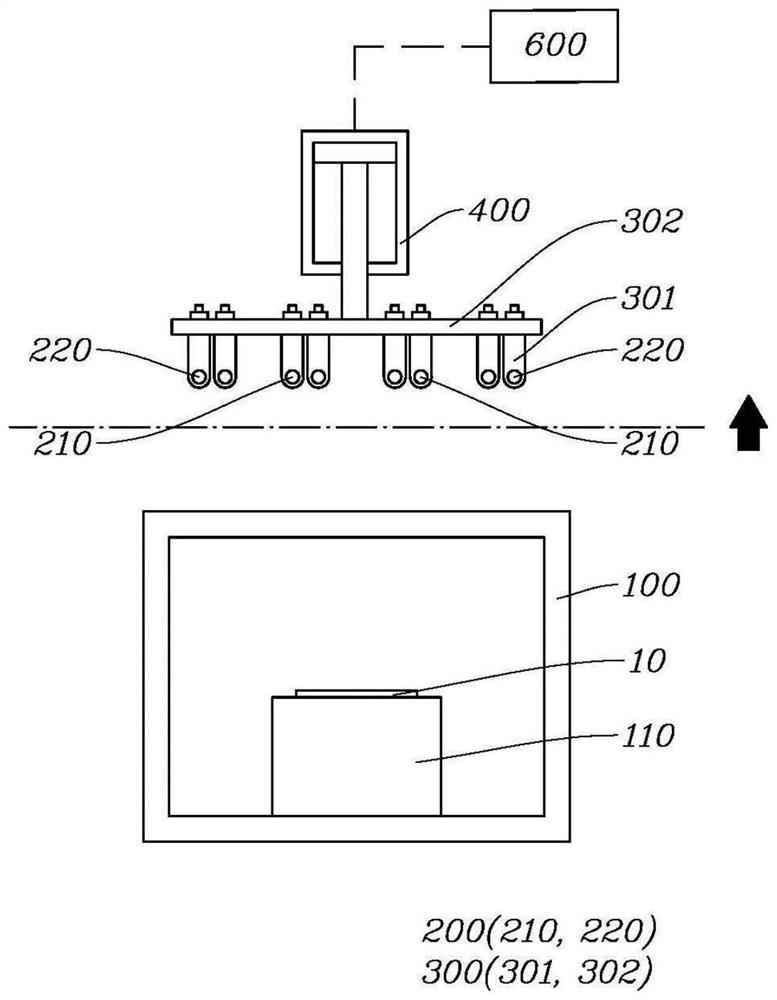

[0083] Such as Figure 2 to Figure 29 As shown, the substrate processing apparatus for mechanically controlling plasma density of the present invention includes a chamber 100 , a chuck 110 and an antenna coil 200 .

[0084] The substrate 10 is processed with plasma inside the chamber 100 .

[0085] At this time, the substrate 10 may be a wafer or a tray on which the wafer is mounted.

[0086] In addition, the substrate processing apparatus may be an apparatus that performs one or more of etching, vapor deposition, and ashing using plasma.

[0087] The substrate 10 is disposed on the chuck 110 and is disposed inside the cavity 100 .

[0088] The chuck 110 may be disposed at the upper or lower portion inside the cavity 100 according to the structure of the cavity 100 .

[0089] The antenna coil 200 is disposed outside the cavity 100 at a position corresponding to the chuck 110 via the substrate 10 .

[0090] The antenna coil 200 radiates high-frequency waves to the process g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com