Plasma processing apparatus and plasma processing method

A plasma and processing device technology, applied in the field of plasma processing, can solve problems such as insufficient plasma density uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

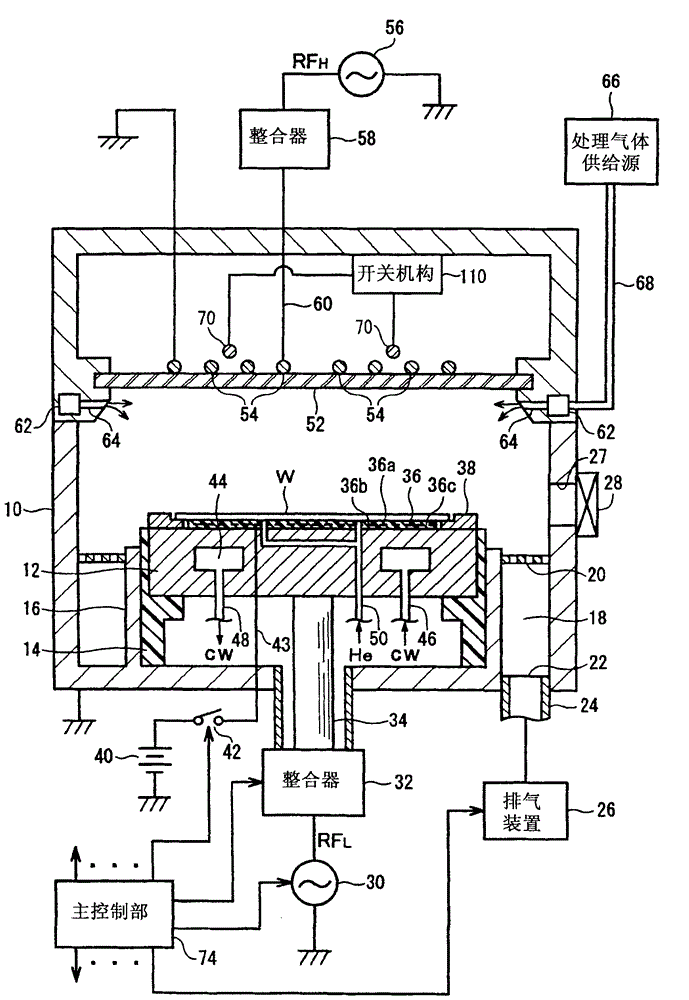

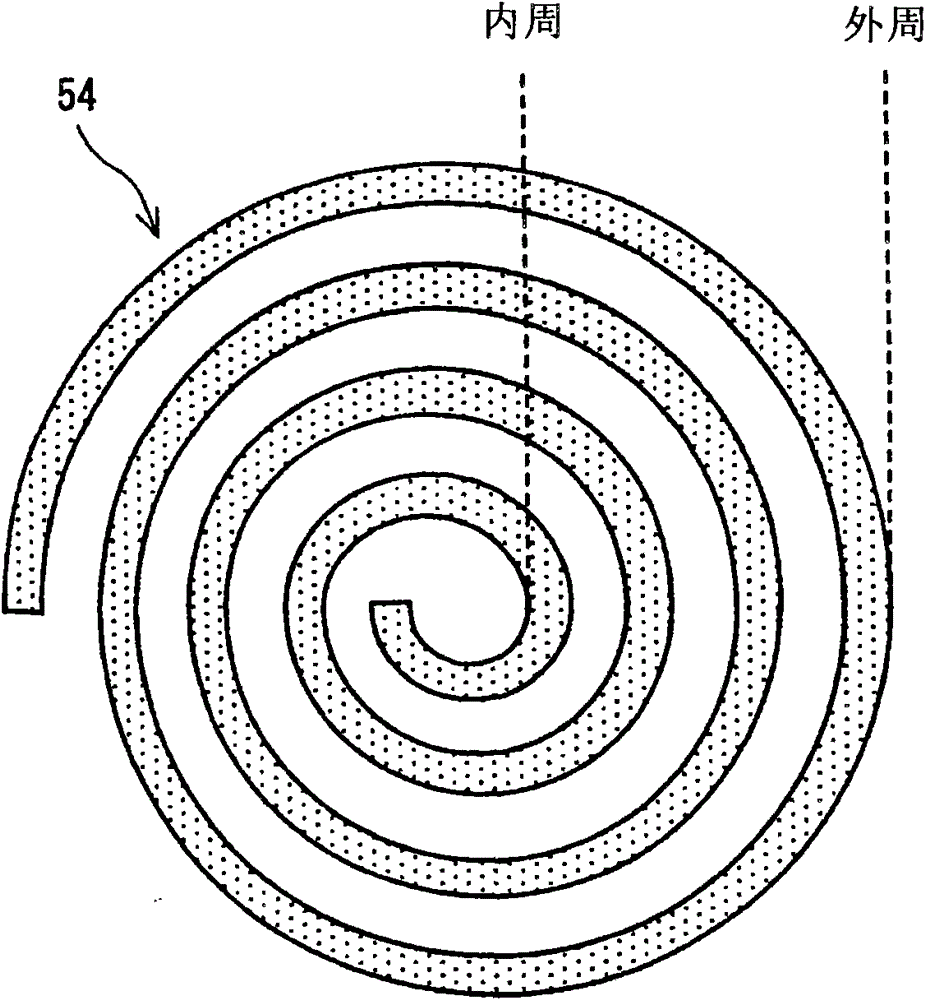

[0077] exist Figure 1 to Figure 10 The first embodiment of the present invention is described in .

[0078] figure 1 The configuration of the inductively coupled plasma processing apparatus according to the first embodiment of the present invention is shown. This inductively coupled plasma processing apparatus is configured as a plasma etching apparatus using a planar coil-shaped RF antenna, and includes a cylindrical vacuum chamber (processing container) 10 made of metal such as aluminum or stainless steel. Chamber 10 is securely grounded.

[0079] First, the structure of each part not related to plasma generation in this inductively coupled plasma etching apparatus will be described.

[0080] In the lower center of the chamber 10, a disc-shaped susceptor 12 on which a substrate to be processed, for example, a semiconductor wafer W is placed, is horizontally arranged as a substrate holding table also serving as a high-frequency electrode. The base 12 is made of aluminum,...

no. 2 approach

[0130] Next, refer to Figure 11-1 4. Describe the second embodiment of the present invention.

[0131] exist Figure 11 The middle shows the configuration of the inductively coupled plasma processing apparatus in the second embodiment. In the figure, there is a device similar to the above-mentioned first embodiment ( figure 1 ) parts of the same structure or function are given the same symbols.

[0132] The second embodiment is characterized by including a variable resistance mechanism 120 instead of the switch mechanism 110 as compared to the first embodiment described above.

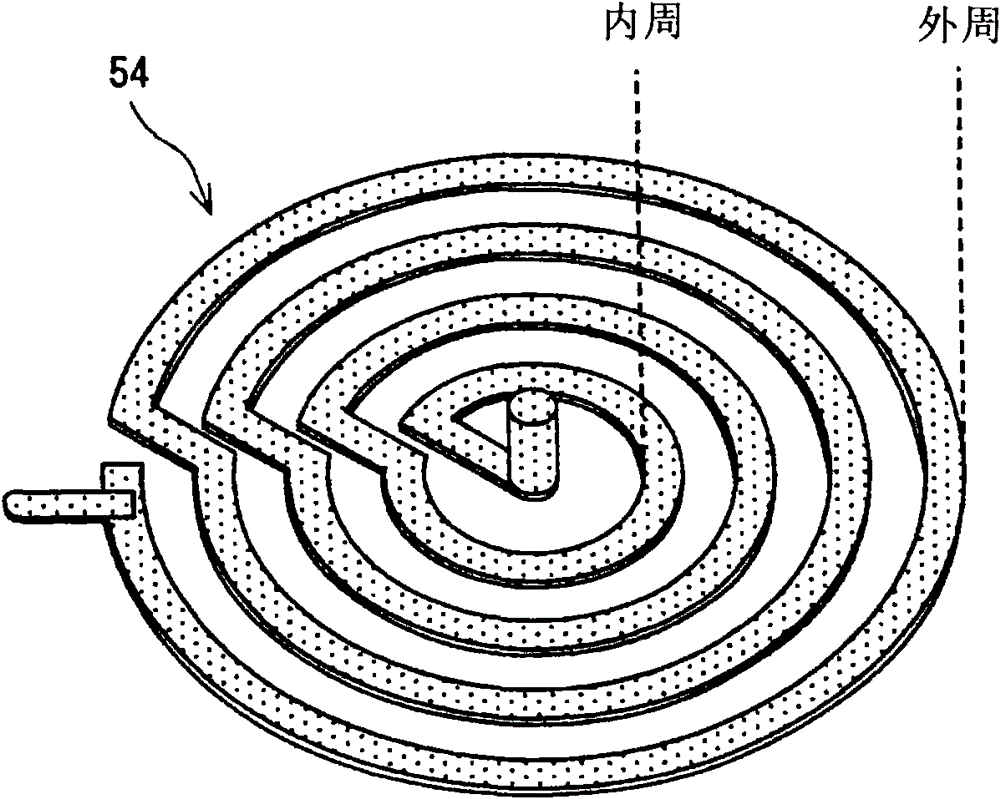

[0133] More specifically, the correction coil 70 is composed of an annular single-turn coil or a multi-turn coil that is open with a moderate gap g at both ends, and is coaxially arranged with respect to the RF antenna 54 so that the coil conductor is positioned at the RF antenna 54 in the radial direction. Between the inner circumference and the outer circumference of the coil 54 (preferably in t...

no. 3 approach

[0157] As another embodiment, it can also be configured such that the switch mechanism 110 in the above-mentioned first embodiment is replaced by Figure 18 The switch mechanism 150 is shown. The switch mechanism 150 has a switch 152 connected to both open ends of the correction coil 70 via a conductor, and a switch control circuit 154 that switches the ON / OFF state of the switch 152 based on an instruction from the main control unit 74 .

[0158] In this switch mechanism 150 , when the switch 152 is switched to the OFF state, no induced current flows through the correction coil 70 , so it is equivalent to a case where there is no correction coil 70 . When the switch 152 is switched to the closed (ON) state, the correction coil 70 is equivalent to a coil with both ends closed, and when the RF antenna 54 flows high-frequency RF H When a current is applied, an induced current flows through the correction coil 70 .

[0159] Such as Figure 19 As shown, it is also possible to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com