Process for production of semiconductor light-emitting element substrate

A technology of light-emitting elements and manufacturing methods, applied in semiconductor/solid-state device manufacturing, semiconductor devices, optical elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0105] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. In addition, the components, configurations, etc. described below do not limit the present invention, and it is obvious that various changes can be made in accordance with the gist of the present invention.

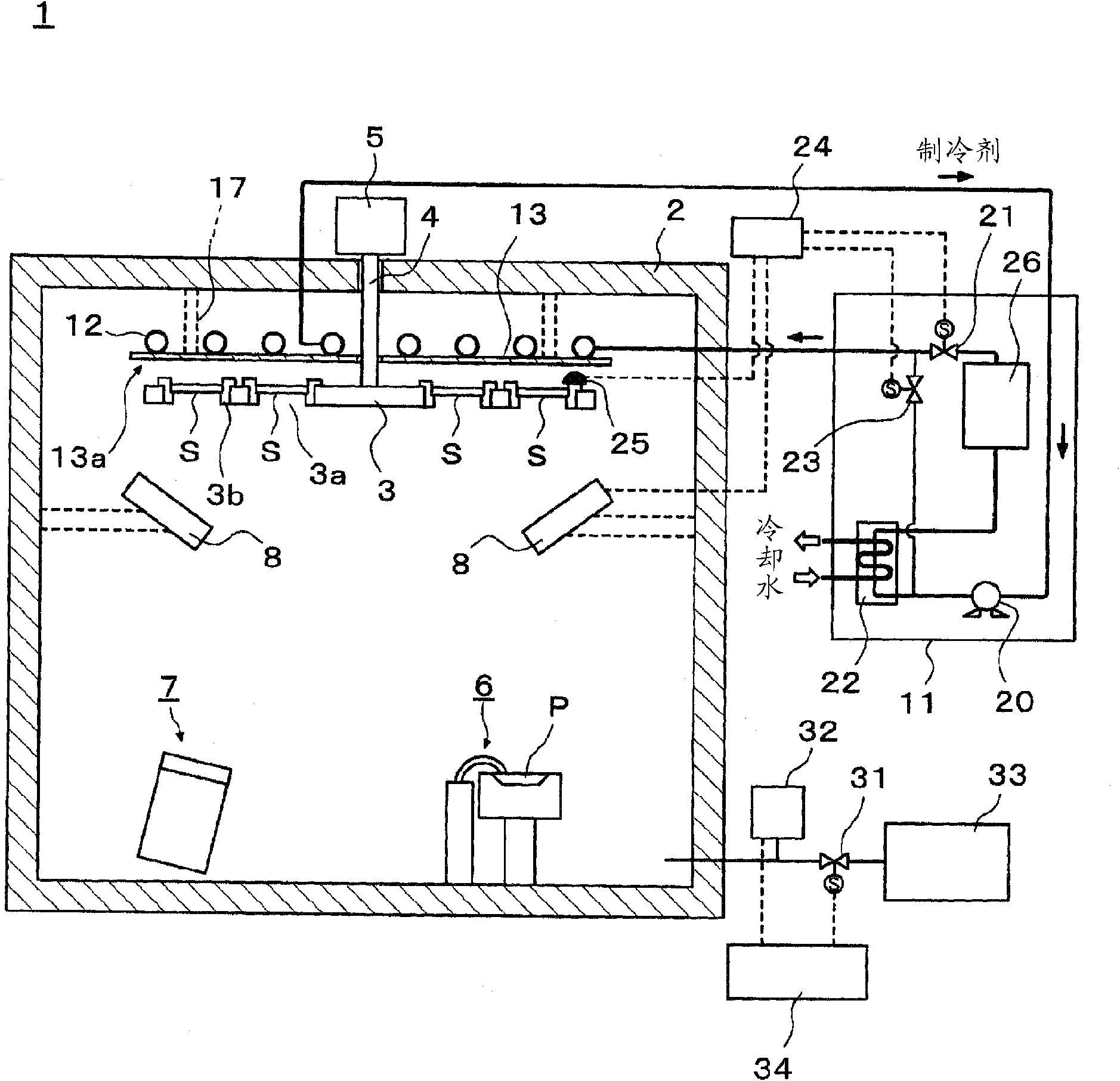

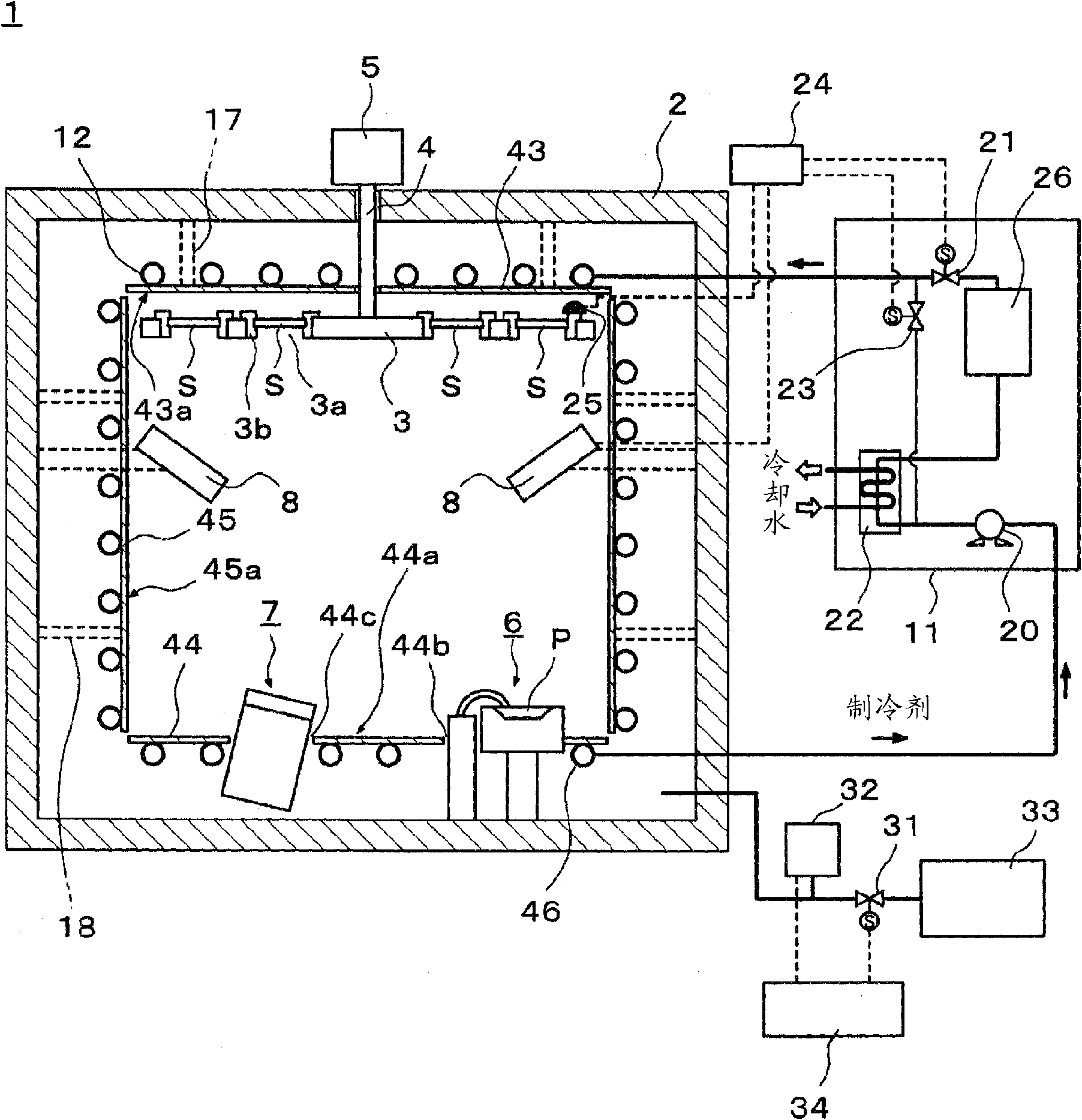

[0106] figure 1 It is an explanatory diagram of an ion-assisted vapor deposition apparatus 1 as a thin film forming apparatus, and a part of the apparatus is shown in cross section.

[0107] As shown in the figure, the ion-assisted vapor deposition apparatus 1 includes as main components: a vacuum chamber 2, a substrate holder 3, a substrate holder rotating shaft 4, a substrate holder rotating motor 5, an evaporation source 6, an ion source 7, a heating unit 8, Refrigerator 11, refrigerant pipe 12 and cooling plate 13.

[0108] The vacuum chamber 2 is a container for film formation inside. The vacuum chamber 2 of the present embodiment is a hollow body having a substan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com