Substrate elevation pin and substrate processing device

A technology of lift pins and substrates, which is applied in transportation and packaging, electrical components, semiconductor/solid-state device manufacturing, etc. It can solve the quality problems of substrate processing products, increase the temperature difference between lift pins 3 and substrates 2, and reduce quality problems. The effect of qualified products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

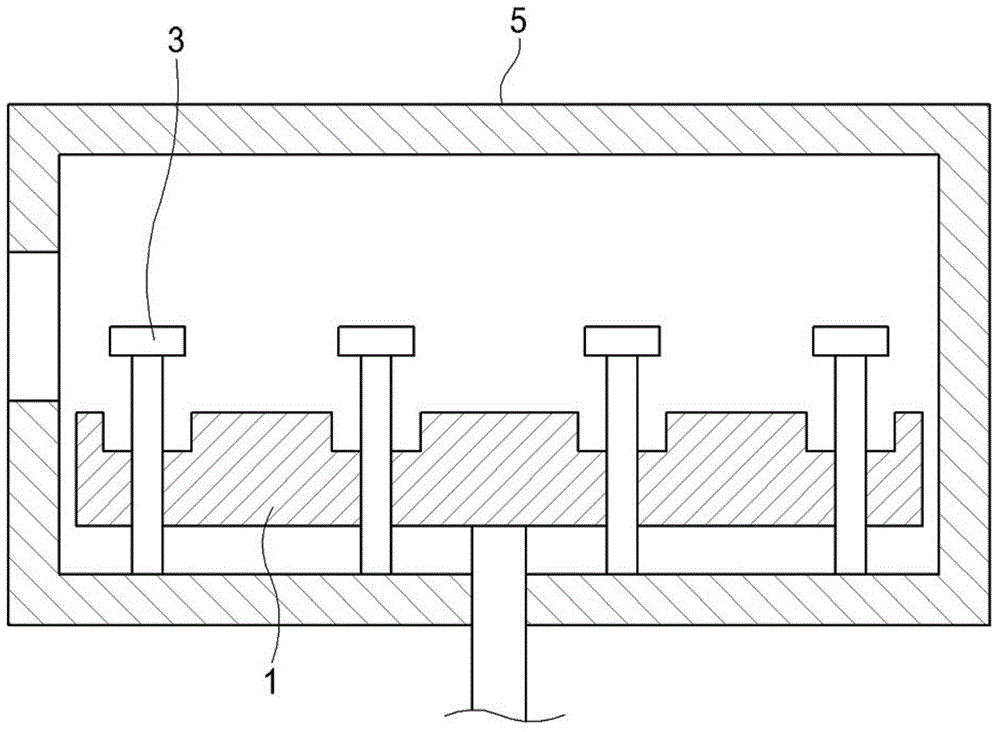

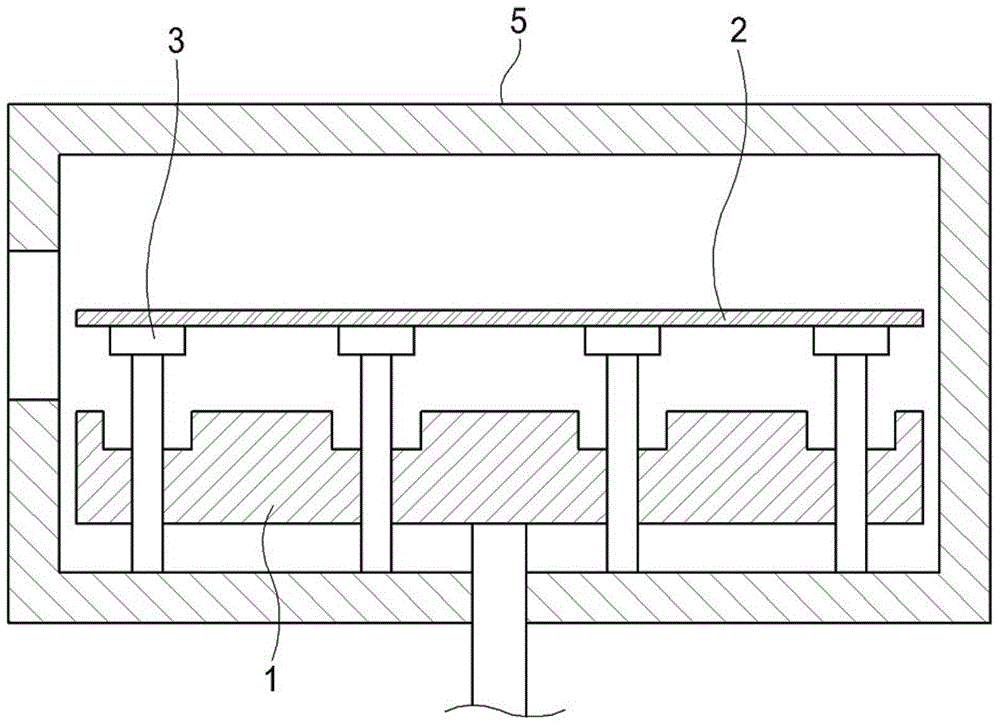

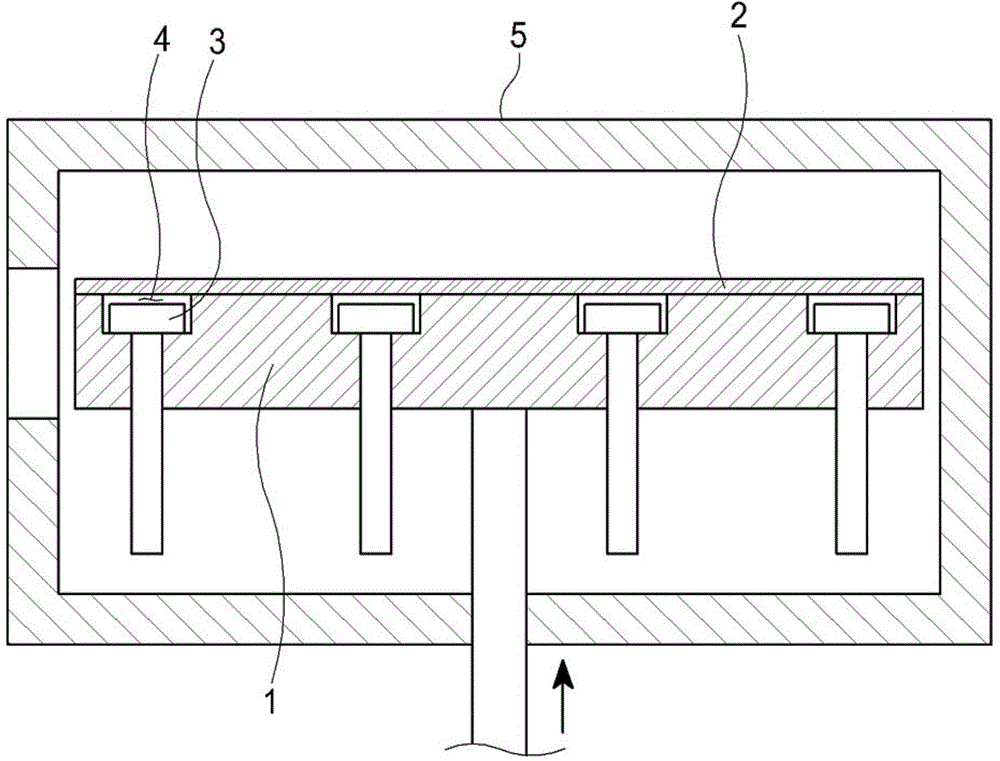

[0043] The substrate lift pin of the present invention is inserted into the vertical through-hole 1b, and the bottom surface of the support groove 1a formed on the upper surface of the substrate holder 1 is narrower, so that it moves up and down relative to the substrate holder 1 as it moves up and down. Place and remove the base plate 2 on the upper part. Different from the traditional lifting pin, the substrate lifting pin of the present invention supports the substrate 2 at its upper part. After the substrate 2 is placed on the upper part of the substrate support 1, it can also be elastically supported so that the upper surface of the lifting pin is in contact with the lower part of the substrate 2. Face close.

[0044] In particular, the substrate lift pin includes a main body portion 10 , a pin portion 20 , and an elastic portion 30 . The main body part 10 is inserted into the through-hole 1b, and when the board|substrate holder 1 ascends, it is hooked by the support gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com