Method for depositing insulating film on recessed portion having high aspect ratio

一种绝缘膜、凹陷部的技术,应用在电气元件、半导体/固态器件制造、电路等方向,能够解决半导体元件实现微细结构困难、绝缘特性等膜质量下降、绝缘膜困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

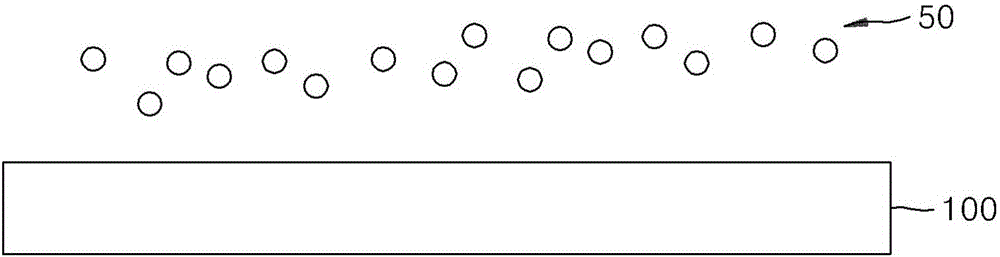

[0034] Below, refer to the attached Figure 1 to Figure 12 Preferred embodiments of the present invention are described in more detail. The embodiments of the present invention can be modified in various ways, and the scope of the present invention should not be construed as being limited to the embodiments described below. This embodiment is provided to explain the present invention in more detail to those skilled in the art to which the present invention belongs. Therefore, the shape of each element appearing in the drawings may be exaggerated in order to emphasize clearer illustration.

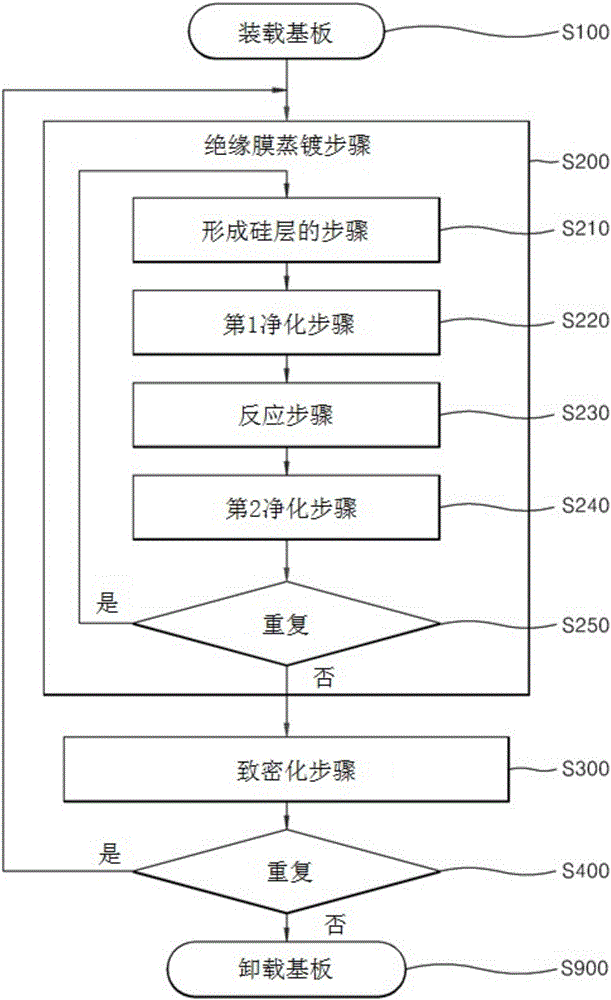

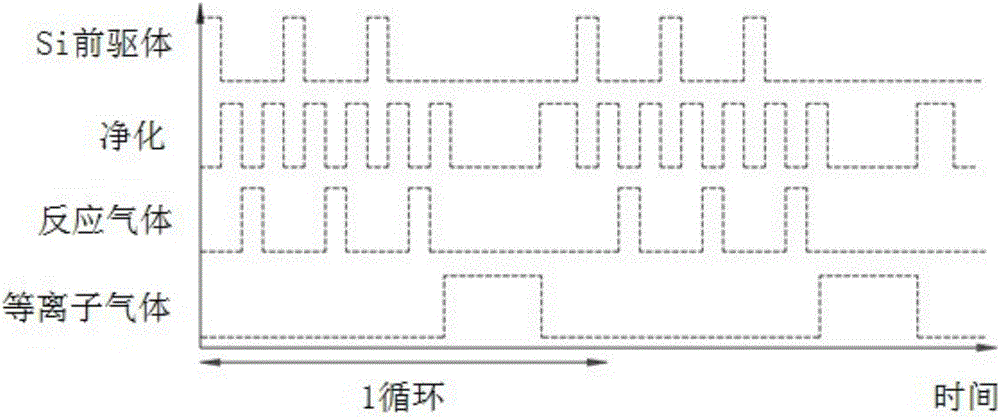

[0035] figure 1 is a flowchart showing an insulating film vapor deposition method according to an embodiment of the present invention. like figure 1 As shown, a substrate is loaded inside a cavity of a semiconductor manufacturing apparatus (S100). An insulating film is deposited on the substrate placed inside the chamber (S200). To deposit the insulating film, step S210 of forming a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com