Vapor generator and vapor deposition apparatus

A technology for generating devices and steam, which is applied in lighting devices, vacuum evaporation coatings, devices for coating liquids on surfaces, etc., can solve problems such as deterioration of organic film quality and deterioration of organic evaporation materials, and achieve good film quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

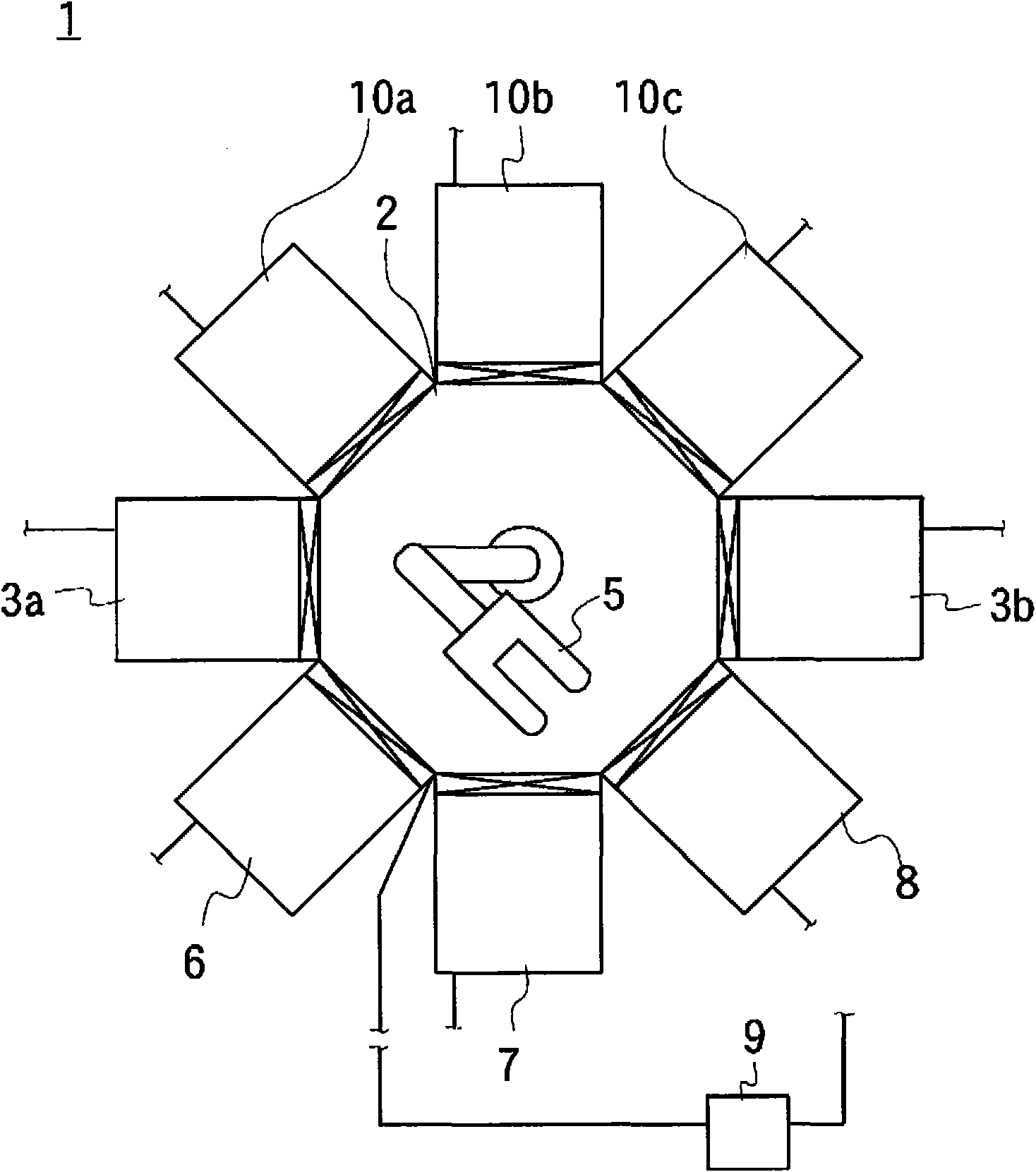

[0032] figure 1 Symbol 1 in represents an example of the manufacturing apparatus of the present invention for manufacturing an organic electroluminescence element. The manufacturing apparatus 1 has a transfer chamber 2 , one or more vapor deposition apparatuses 10 a to 10 c , a sputtering chamber 7 , loading and unloading chambers 3 a and 3 b , and processing chambers 6 and 8 . The respective vapor deposition devices 10a to 10c, the sputtering chamber 7, the loading and unloading chambers 3a and 3b, and the processing chambers 6 and 8 are connected to the transfer chamber 2, respectively.

[0033] A vacuum exhaust system 9 is connected to the transfer chamber 2 , the vapor deposition devices 10 a to 10 c , the sputtering chamber 7 , the loading and unloading chambers 3 a and 3 b , and the processing chambers 6 and 8 . The vacuum exhaust system 9 creates a vacuum atmosphere inside the transfer chamber 2, the vapor deposition apparatuses 10a to 10c, the processing chambers 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com