Method and device for preparing high-frequency soft magnetic thin film

A soft magnetic thin film, radio frequency magnetron sputtering technology, applied in the direction of ion implantation plating, coating, metal material coating process, etc. The method is simple and easy to implement, and the effect of excellent high frequency characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

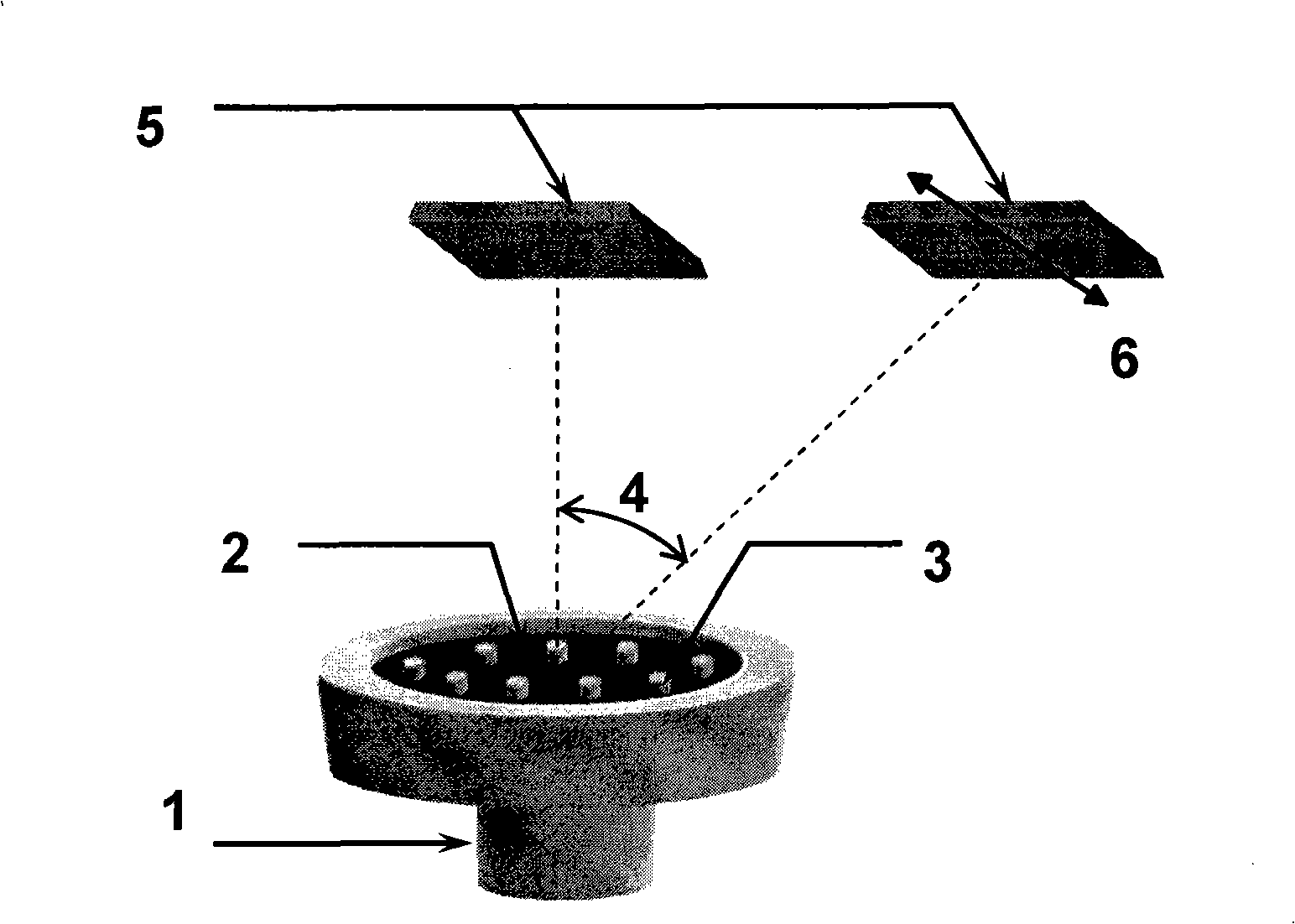

[0019] The equipment used to prepare the thin film in the present invention is the RF sputtering part of the FJL560-1 ultra-high vacuum magnetron and ion beam combined sputtering equipment produced by Shenyang Zhongkeyi in 2003. But the target material that the present invention adopts is a kind of composite target, is exactly the magnetic metal target (composition can be Fe x co 1-x , x=0~0.7) uniformly place a non-magnetic metal sheet, and then use traditional radio frequency magnetron sputtering equipment to deposit a soft magnetic film on the Si or glass surface. Thin film deposition conditions are: background vacuum -5 Pa, sputtering power 50W corresponds to a power density of 1.7W / cm 2 , the substrate is water-cooled, the Ar flow rate is 20SCCM, and the Ar pressure is 0.2Pa. In the thin film preparation process, by changing the angle α between the normal line of the target and the line connecting the center of the target to the center of the substrate, the purpose of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com