Double-layer structure deep-ultraviolet transparent conductive film and preparation method thereof

A transparent conductive film, double-layer structure technology, applied in semiconductor/solid-state device manufacturing, coatings, circuits, etc., can solve the problems of high sheet resistance, expensive equipment, and difficulty in forming large-area films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

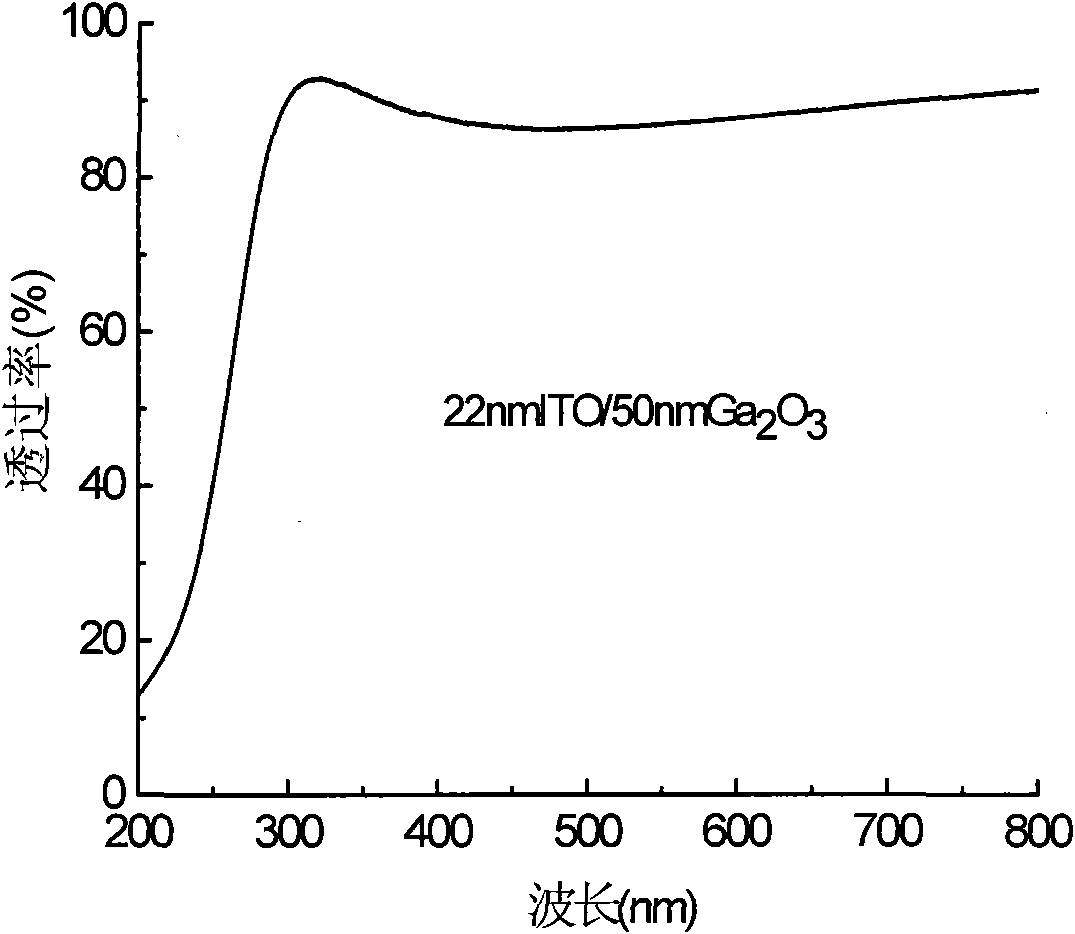

[0019] Example 1: 22nmITO / 50nmGa 2 O 3

[0020] The substrate is made of JGS1 far-ultraviolet optical quartz glass, the substrate is ultrasonically cleaned with acetone, alcohol and deionized water, and dried with a nitrogen gun. Ga with a purity of 99.99wt% 2 O 3 The ceramic target is installed in a radio frequency cathode target tank in the magnetron sputtering chamber, and the SnO 2 / (In 2 O 3 +SnO 2 ) An ITO target material with a ratio of 10 wt% is installed in a DC cathode target tank in the magnetron sputtering chamber. Put the cleaned JGS1 far ultraviolet optical quartz glass into the substrate holder, and insert the substrate holder into the substrate tray in the sputtering chamber. Use mechanical pumps and molecular pumps to vacuum the sputtering chamber, so that the vacuum degree of the sputtering chamber is less than 6.0×10 -4 Pa. Set a temperature controller to adjust the heating current to heat the substrate to stabilize the substrate temperature at 250°C. Adjust ...

Embodiment 2

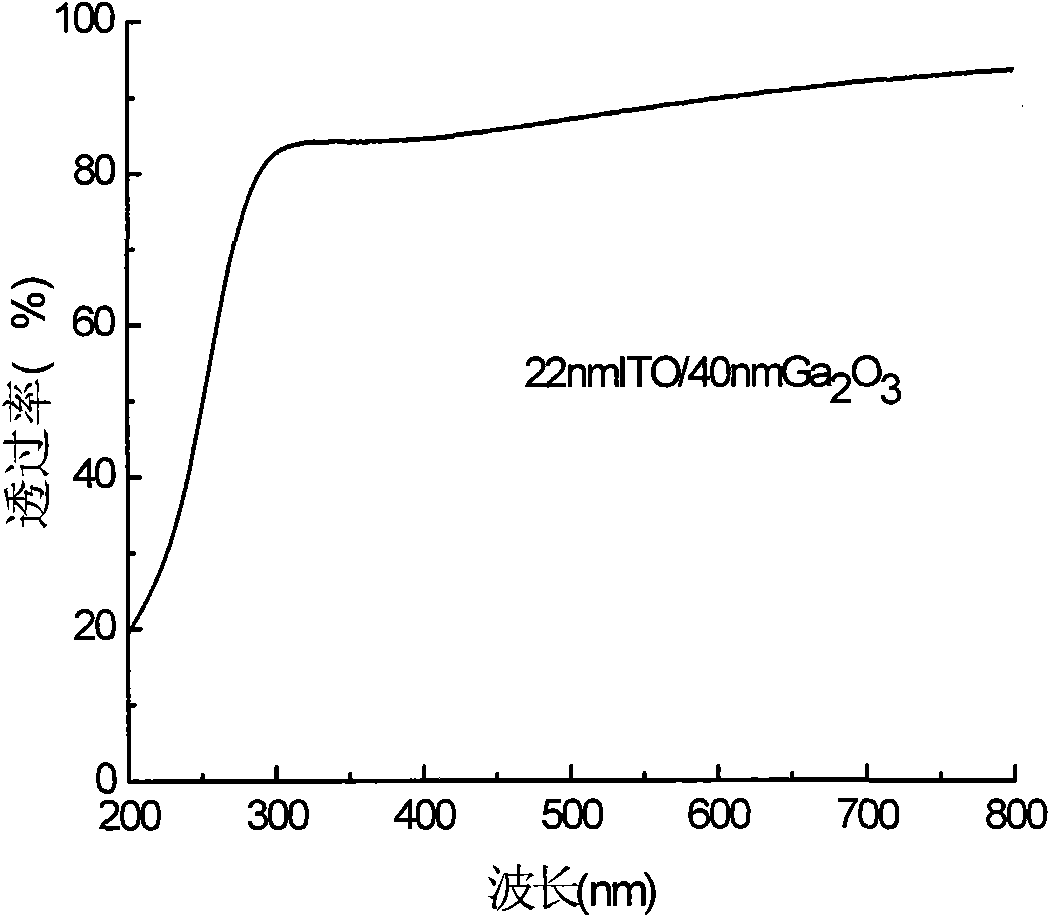

[0021] Example 2: 22nmITO / 40nmGa 2 O 3

[0022] The preparation process is the same as in Example 1, except that the radio frequency sputtering deposition of Ga 2 O 3 The layer thickness is 40nm. Using the above process to finally form a double-layer structure 22nmITO / 40nmGa 2 O 3 Deep ultraviolet transparent conductive film. The prepared double-layer structure 22nmITO / 40nmGa 2 O 3 The transmittance curve of deep ultraviolet transparent conductive film in the range of 200-800nm is as follows figure 2 Shown. The optical transmittance at 280nm (without substrate) is 75.8%, the optical transmittance at 300nm (without substrate) is 82.6%, and the average transmittance (without substrate) in the 300-800nm spectral range is higher than 86%. The sheet resistance is 334Ω, and the sheet resistivity is 2.07×10 -3 Ω.cm.

Embodiment 3

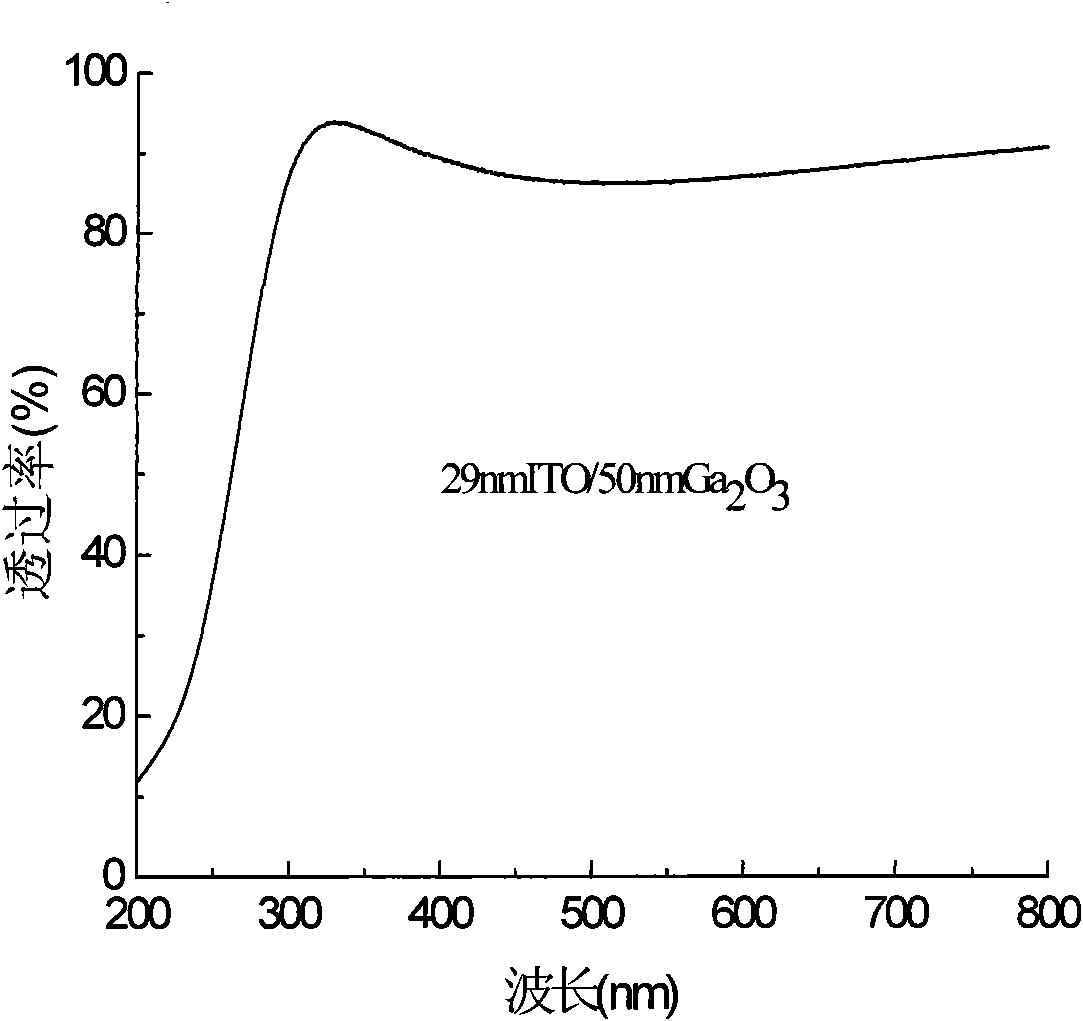

[0023] Example 3: 29nmITO / 50nmGa 2 O 3

[0024] The preparation process is the same as in Example 1, except that the substrate uses JGS2 ultraviolet optical quartz glass, the substrate temperature is 300℃, the sputtering gas argon pressure is 1.0Pa, the RF sputtering power is 60W, the DC sputtering current is 140mA, and the DC sputtering voltage is 360V. , The thickness of the sputter deposited ITO layer is 29nm. Using the above process to finally form a double-layer structure 29nmITO / 50nmGa 2 O 3 Deep ultraviolet transparent conductive film. Prepared 29nmITO / 50nm Ga 2 O 3 The transmittance curve of the double-layer structure deep ultraviolet transparent conductive film in the range of 200-800nm is as follows image 3 Shown. The optical transmittance at 280nm (without substrate) is 70.9%, the optical transmittance at 300nm (without substrate) is 87.5%, and the average transmittance (without substrate) in the 300-800nm spectral range is higher than 88%. The sheet resistance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com