Double-layer structure deep-ultraviolet transparent conductive film and preparation method thereof

A technology of transparent conductive film and double-layer structure, which is applied in semiconductor/solid-state device manufacturing, coating, circuit, etc., and can solve the problems of difficult large-area film formation, expensive equipment, and high sheet resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

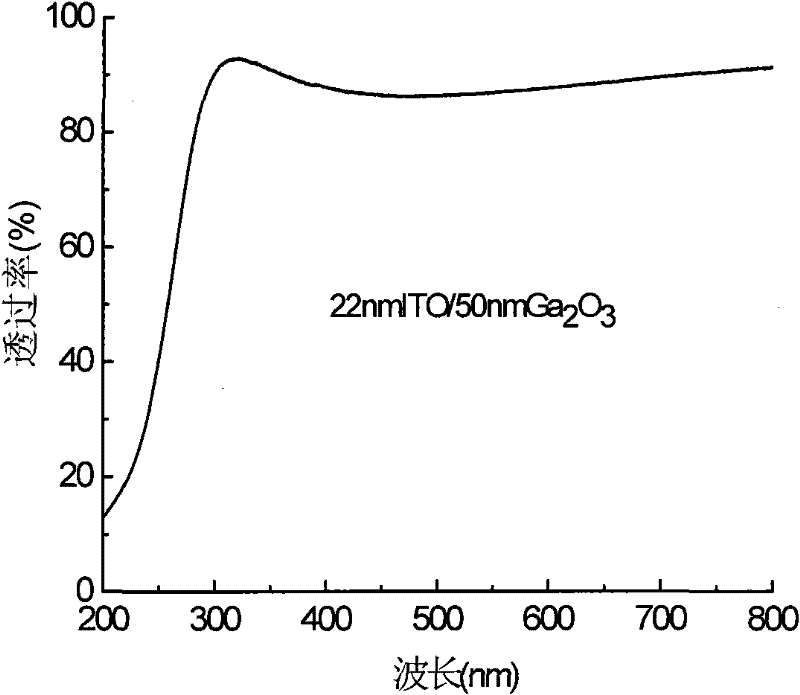

[0019] Example 1: 22nmITO / 50nmGa 2 o 3

[0020] The substrate is made of JGS1 far-ultraviolet optical quartz glass. The substrate is ultrasonically cleaned with acetone, alcohol and deionized water, and dried with a nitrogen gun. The purity of 99.99wt% Ga 2 o 3 The ceramic target is installed in a radio frequency cathode target slot in the magnetron sputtering chamber, and the SnO 2 / (In 2 o 3 +SnO 2 ) ratio of 10wt% ITO target is installed in a DC cathode target slot in the magnetron sputtering chamber. Put the cleaned JGS1 far-ultraviolet optical quartz glass into the substrate holder, and insert the substrate holder into the substrate tray in the sputtering chamber. Use a mechanical pump and a molecular pump to evacuate the sputtering chamber so that the vacuum degree of the sputtering chamber is less than 6.0×10 -4 Pa. Set the temperature controller, adjust the heating current to heat the substrate, and stabilize the substrate temperature at 250°C. Adjust the fl...

Embodiment 2

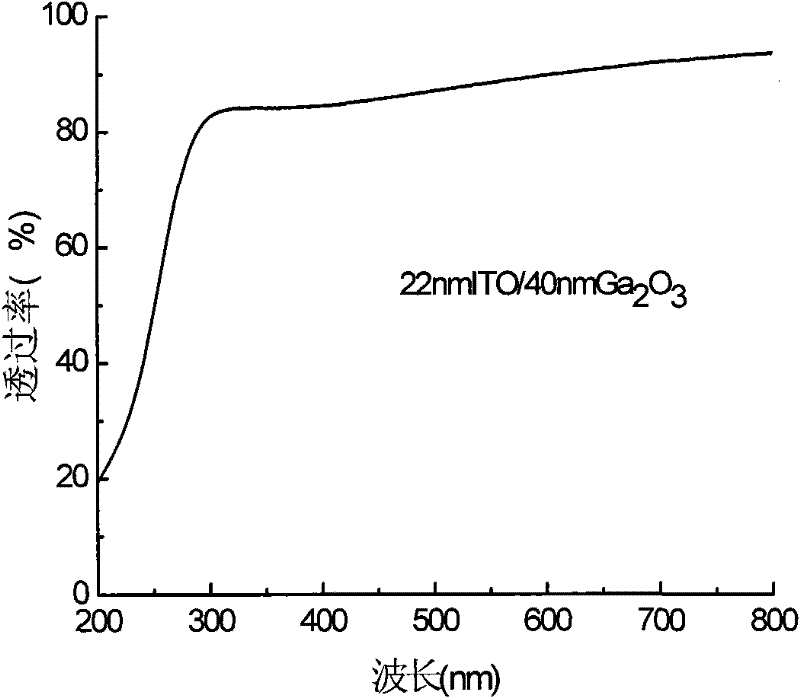

[0021] Example 2: 22nmITO / 40nmGa 2 o 3

[0022] The preparation process is the same as in Example 1, except that the radio frequency sputtering deposits Ga 2 o 3 The layer thickness is 40 nm. Using the above process to finally form a double-layer structure 22nmITO / 40nmGa 2 o 3 Deep UV transparent conductive film. The prepared double-layer structure 22nmITO / 40nmGa 2 o 3 The transmittance curve of the deep ultraviolet transparent conductive film in the range of 200-800nm is as follows figure 2 shown. The optical transmittance (excluding substrate) at 280nm is 75.8%, the optical transmittance at 300nm (excluding substrate) is 82.6%, and the average transmittance (excluding substrate) in the 300-800nm spectral range is higher than 86%. The surface resistance of the film is 334Ω, and the film resistivity is 2.07×10 -3 Ω.cm.

Embodiment 3

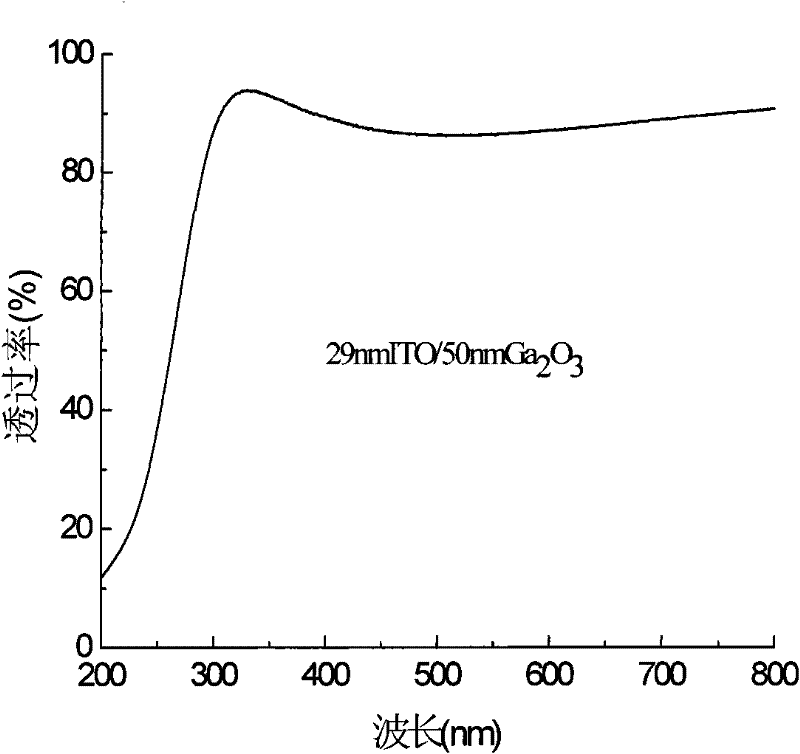

[0023] Example 3: 29nmITO / 50nmGa 2 o 3

[0024] The preparation process is the same as in Example 1, except that the substrate is made of JGS2 ultraviolet optical quartz glass, the substrate temperature is 300°C, the argon pressure of the sputtering gas is 1.0Pa, the RF sputtering power is 60W, the DC sputtering current is 140mA, and the DC sputtering voltage is 360V , sputter-deposited ITO layer thickness 29nm. Using the above process to finally form a double-layer structure 29nmITO / 50nmGa 2 o 3 Deep UV transparent conductive film. The prepared 29nmITO / 50nm Ga 2 o 3 The transmittance curve of the double-layer structure deep ultraviolet transparent conductive film in the range of 200-800nm is as follows image 3 shown. The optical transmittance (excluding substrate) at 280nm is 70.9%, the optical transmittance at 300nm (excluding substrate) is 87.5%, and the average transmittance (excluding substrate) in the 300-800nm spectral range is higher than 88%. The surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com