Copper oxide doped tin dioxide base ammonia gas sensitive sensor manufacturing method

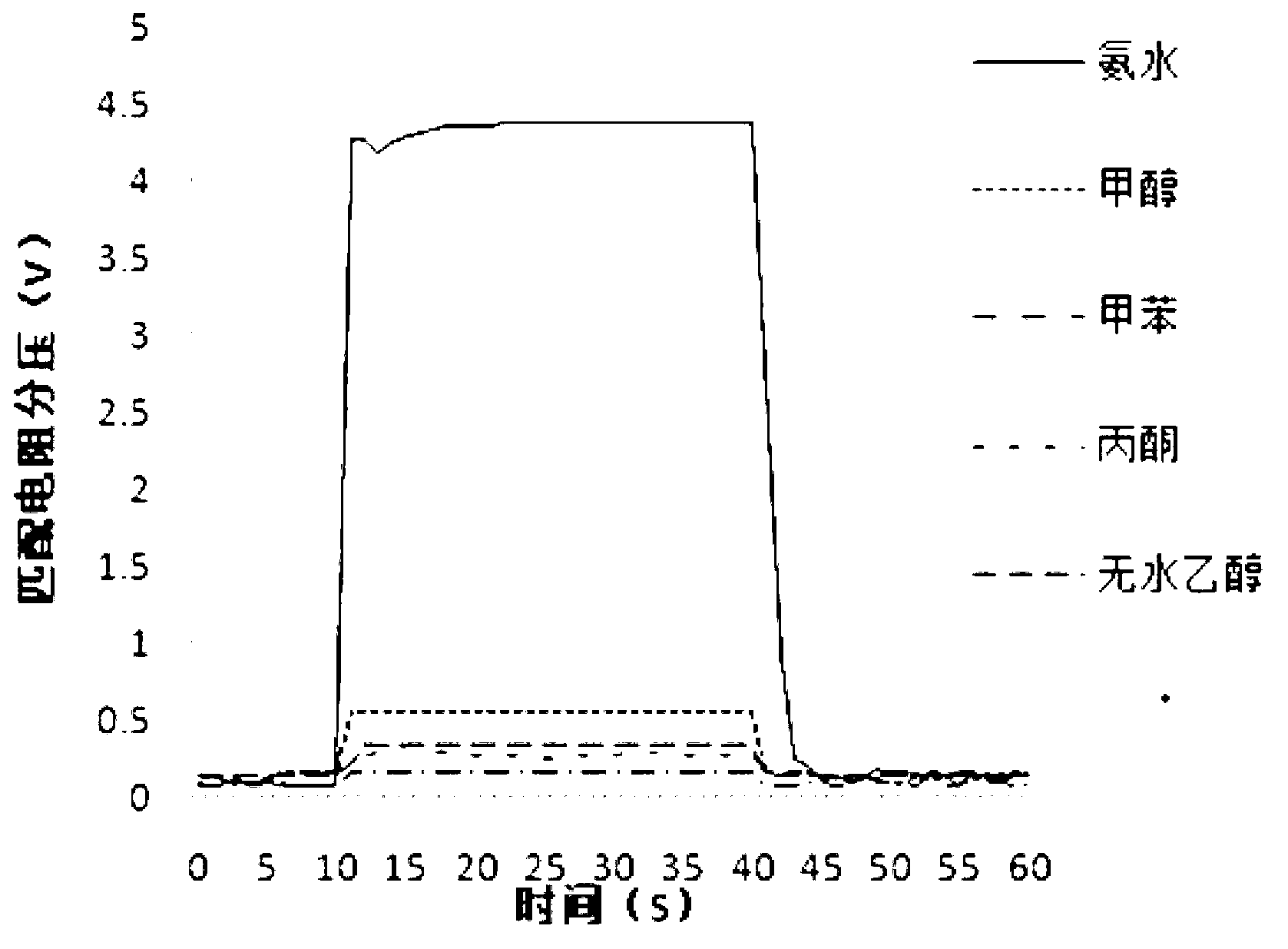

A tin dioxide-based, gas-sensing sensor technology is applied in the field of preparation of ammonia gas-sensing sensing elements, and can solve the problems of low sensitivity, long response-recovery time, etc., and achieve high sensitivity, short response and recovery time, and film-forming quality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of SnO by RF Sputtering 2 Thin film: Al first 2 o 3 The ceramic tubes were cleaned with alcohol and dried before placing them on the sample holder.

[0028] 1. Place the Cu target and the Sn target with a purity of 99.99% on two RF targets respectively. Vacuum the system until the system air pressure is close to 10 -5 Pa.

[0029] 2. After vacuuming, argon and oxygen with an argon-oxygen ratio of 3:1 are introduced into the system.

[0030] 3. Pre-sputter for 10 minutes when starting sputtering. During this process, adjust the power of the Sn target to 80W and the power of the Cu target to 40W. Take out the sample after 45 minutes of sputtering.

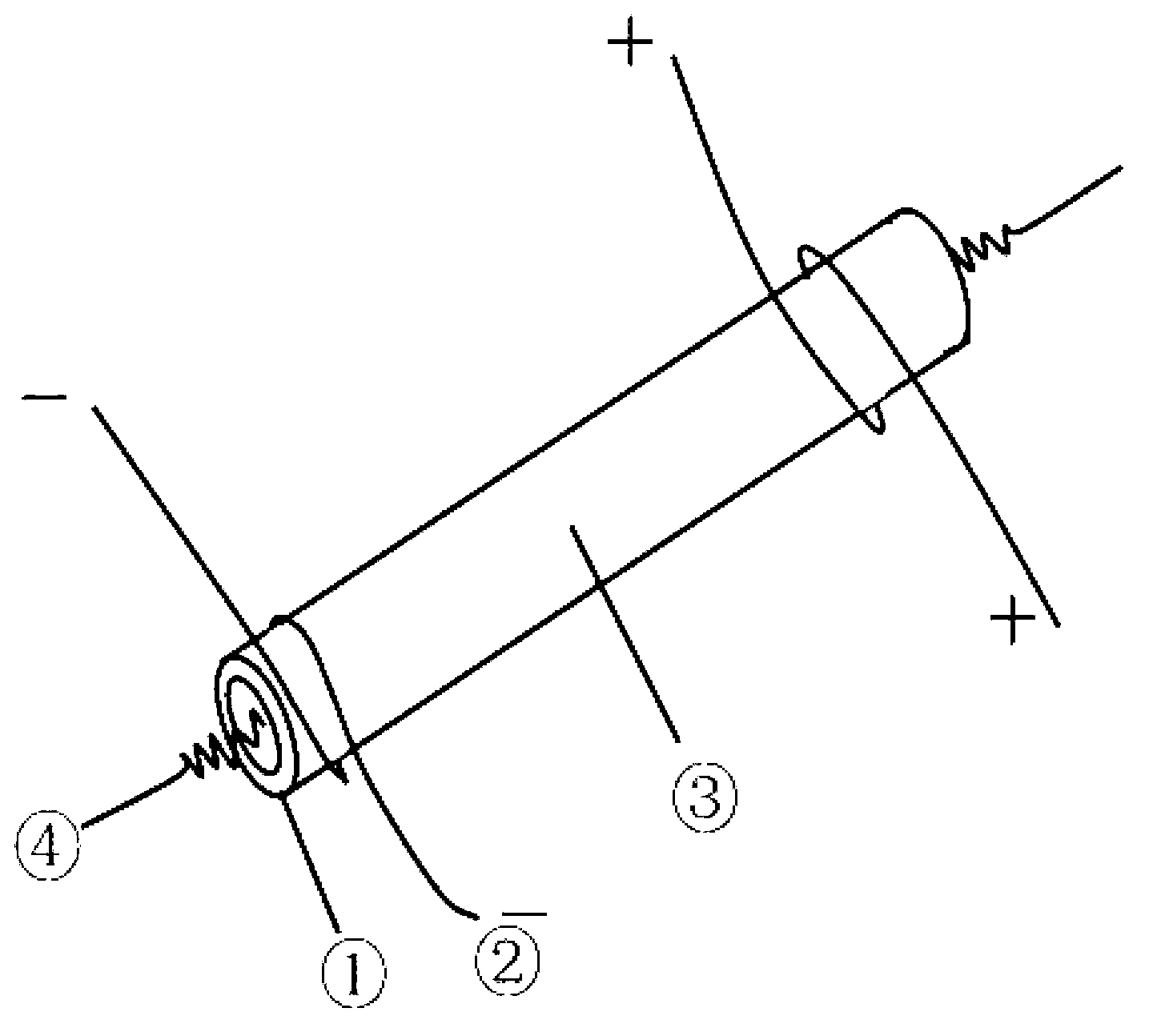

[0031] 4. Sputter with SnO 2 Material Al 2 o 3 The ceramic tubes were annealed at 500 °C for 3 h so that the Al 2 o 3 The SnO required for the surface formation of ceramic tubes 2 film, such as figure 1 As shown, Al 2 o 3 The ceramic tube 1 has a built-in heating wire 4 for heating Al 2 o 3 Ceramic ...

Embodiment 2

[0035] Preparation of SnO by RF Sputtering 2 Thin film: Al first 2 o 3 The ceramic tubes were cleaned with alcohol and dried before placing them on the sample holder.

[0036] 1. Place the Cu target and the Sn target with a purity of 99.99% on two RF targets respectively. Vacuum the system until the system air pressure is close to 10 -5 Pa.

[0037] 2. After vacuuming, argon and oxygen with an argon-oxygen ratio of 4:1 are introduced into the system.

[0038] 3. Pre-sputter for 10 minutes at the start of sputtering. During this process, adjust the power of the Sn target to 60W and the power of the Cu target to 30W. Take out the sample after 45 minutes of sputtering.

[0039] 4. Sputter with SnO 2 Material Al 2 o 3 The ceramic tube was annealed at 300 °C for 2 h to allow the Al 2 o3 The SnO required for the surface formation of ceramic tubes 2 film, such as figure 1 As shown, Al 2 o 3 A heating wire is built into the ceramic tube to heat the Al 2 o 3 Ceramic tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com