Method for sputtering and depositing tin indium oxide transparent electroconductive film on flexible substrate at room temperature

A transparent conductive film, indium tin oxide technology, applied in sputtering plating, ion implantation plating, metal material coating process and other directions, can solve the problems of substrate degeneration, demanding process parameters, indium tin oxide doping , to reduce the requirements of process parameters, facilitate industrial production, and achieve the effect of excellent photoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

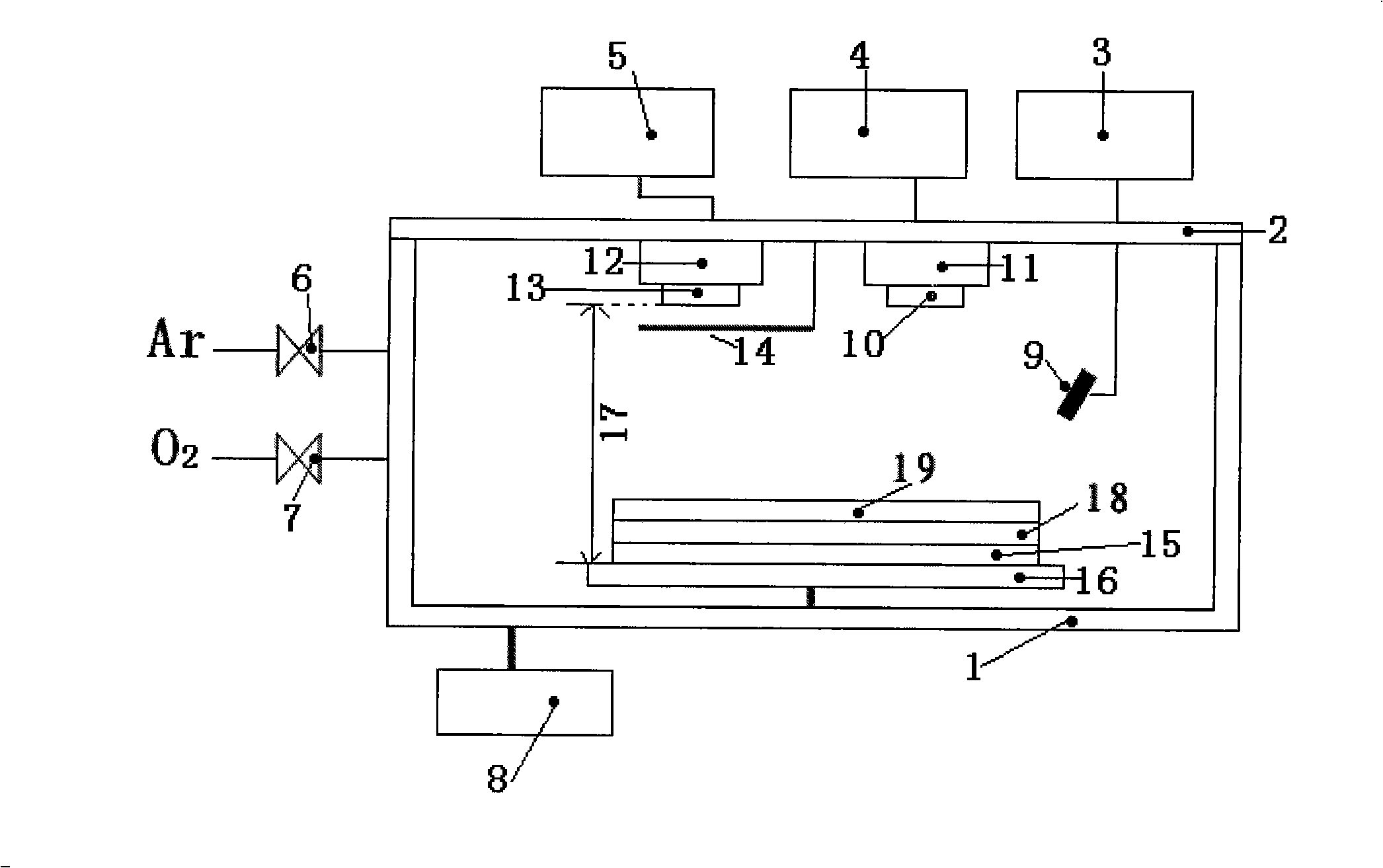

Embodiment 1

[0040] The polyimide substrate with an area of 10cm × 10cm was placed in the electronic cleaning agent for scrubbing, ultrasonically cleaned with deionized water for several times, and then ultrasonically cleaned with absolute ethanol; then dried, and placed in the radio frequency magnetron sputtering equipment. The vacuum bell 1 is evacuated; argon and oxygen are dynamically introduced, and the flow is adjusted so that the ratio of argon to oxygen is maintained at (6.0~7.5):0.2, and the total working pressure is 5×10 -1 Pa; turn on the UV lamp 9 with a working wavelength of 365nm in the vacuum bell 1 for online UV irradiation; use RF magnetron sputtering, when the RF power is 300W, pre-coat the thickness of the film on the polyimide substrate is a 10nm silicon dioxide film 18; an indium tin oxide ceramic target with a composition ratio of 90:10 (wt%) is used as the target material, and the indium tin oxide film is deposited by DC magnetron sputtering. The DC sputtering powe...

Embodiment 2

[0042] Put the polyethylene terephthalate substrate with an area of 10cm×10cm into the electronic cleaning agent and scrub it, then ultrasonically clean it with deionized water several times, and then ultrasonically clean it with absolute ethanol; then dry it and place it in a radio frequency magnetron sputter The vacuum bell 1 of the injection equipment is evacuated; argon and oxygen are dynamically introduced, and the flow rate is adjusted so that the ratio of argon to oxygen is maintained at (6.0~7.5):0.2, and the total working pressure is 5×10 -1 Pa; turn on an ultraviolet lamp 9 with a working wavelength of 365 nm; use radio frequency magnetron sputtering, when the radio frequency power is 300 W, pre-coat a silicon dioxide film 18 with a thickness of 10 nm on the polyimide substrate; use The indium tin oxide ceramic target with the composition ratio of 80:20 (wt%) was used as the target material, and the indium tin oxide film was deposited by radio frequency magnetron sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com