Anode construction for top light emitting organic display and manufacturing process thereof

A technology of anode structure and manufacturing process, applied in the field of anode structure and manufacturing process of top-emitting organic display, can solve the problems of high resistance, low luminous efficiency, increased heat generation and power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

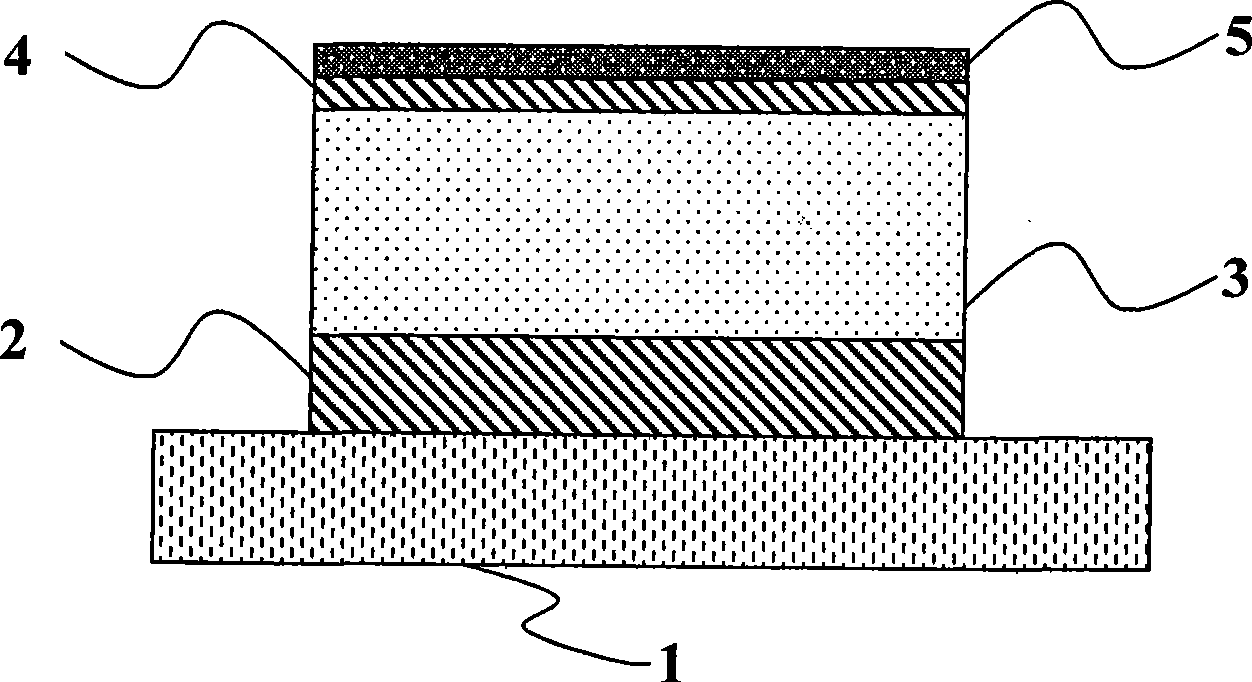

[0020] Example 1: An anode structure of a top-emission organic display uses silicon as a substrate to form a silicon substrate layer 1, uses chromium, aluminum and molybdenum materials to form a film-coated electrode body, and forms a high-purity chromium film layer 2 on the silicon substrate layer 1 A four-layer film anode structure of a high-purity aluminum film layer 3 , a high-purity chromium film layer 4 and a high-purity molybdenum film layer 5 .

[0021] If implemented by electron beam evaporation, it will include the following processes:

[0022] 1. Before coating, preheat the silicon substrate layer 1, the preheating temperature is 85°C, and the vacuum degree of the evaporation chamber is 10 -5 Pa;

[0023] 2. For metal coating, the order of evaporation is high-purity chromium, high-purity aluminum, high-purity chromium, and high-purity molybdenum. The steps of evaporation are as follows:

[0024] A, silicon substrate layer 1 is preheated;

[0025] B, vapor-deposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com