Manufacturing method of back-channel-etching oxide thin-film transistor

An oxide thin film, back channel technology, applied in transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of high process temperature, corrosion, incompatible with flexible substrates, etc., to achieve high film formation rate, The effect of uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

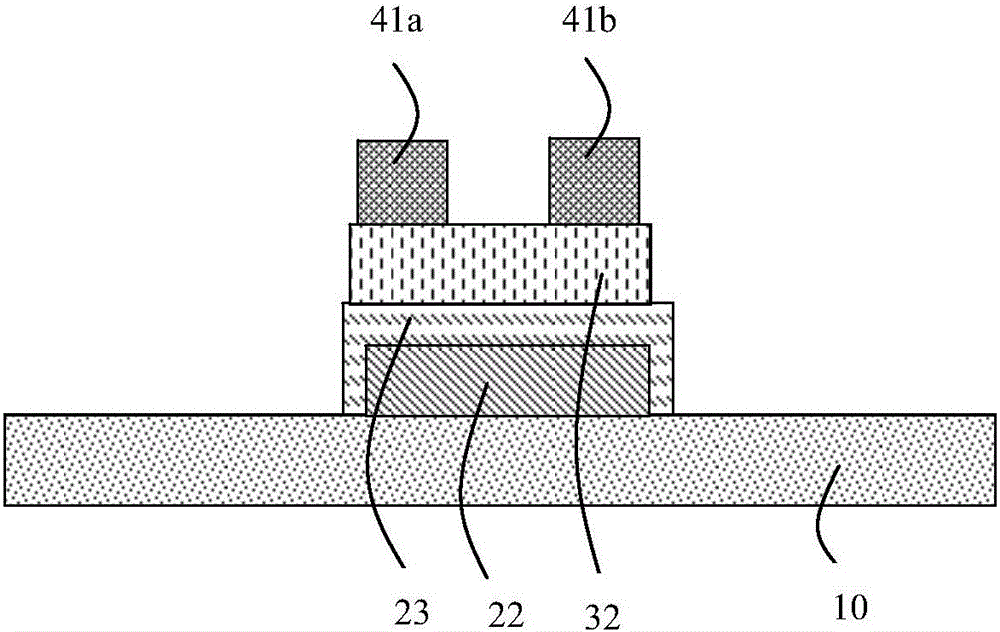

[0041] A method for preparing a back-channel-etched oxide thin film transistor comprises the following preparation steps a, b, c, and d in sequence.

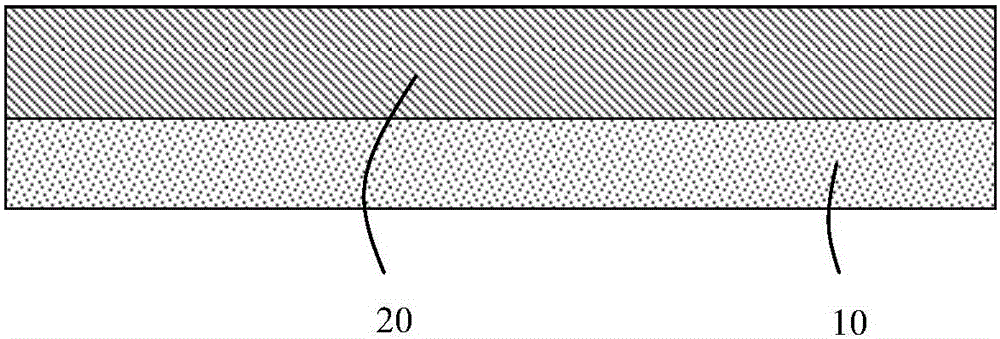

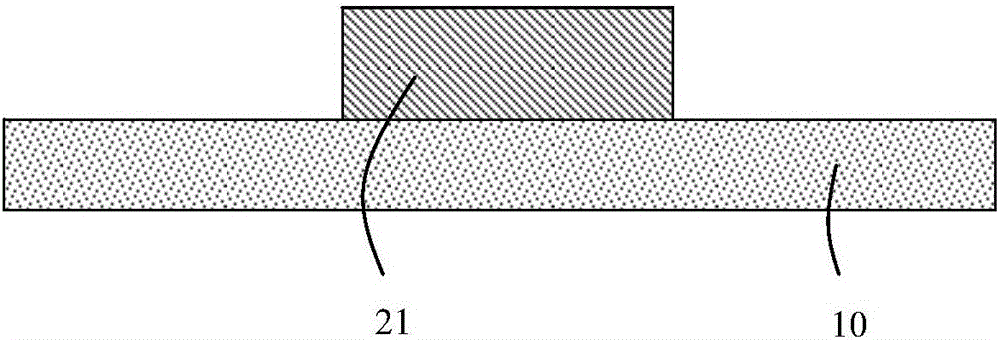

[0042] a. on the substrate 10, adopt the method of DC sputtering to prepare the first film layer 20, such as figure 2 As shown, the thickness is 100 to 1000 nm. Then the prepared first thin film layer 20 is patterned by wet etching method to obtain the first patterned thin film layer 21, the first patterned thin film layer 21 has a gate shape, such as image 3 shown.

[0043] The material of the first film layer 20 is a metal or an alloy that can be anodized to form an insulating oxide, such as aluminum, aluminum alloy, titanium, titanium alloy, tantalum or tantalum alloy, and the like.

[0044] The substrate 10 can be a glass substrate or a flexible substrate. When the substrate is a flexible substrate, it can be thin glass, polyethylene naphthalate (PEN), polyethylene terephthalate (PET), polyimide (PI) or metal foil, etc....

Embodiment 2

[0057] A method for preparing a back-channel-etched oxide thin film transistor comprises the following preparation steps a, b, c, and d in sequence.

[0058] a. on the substrate 10, adopt the method of DC sputtering to prepare the first film layer 20, such as figure 2 As shown, the material is metal tantalum with a thickness of 600nm. Then the prepared first thin film layer 20 is patterned by wet etching method to obtain the first patterned thin film layer 21, the first patterned thin film layer 21 has a gate shape, such as image 3 shown.

[0059] b. adopt the method for direct current sputtering to prepare the second film layer 30, such as Figure 4 As shown, the material is metallic tin with a thickness of 20nm. Then the prepared second thin film layer 30 is patterned by wet etching to obtain a second patterned thin film layer 31, and the second patterned thin film layer 31 has an active layer shape, such as Figure 5 shown.

[0060] c. adopt the method for direct cur...

Embodiment 3

[0069] A method for preparing a back-channel-etched oxide thin film transistor comprises the following preparation steps a, b, c, and d in sequence.

[0070] a. On the flexible PEN substrate 10 containing buffer layer, adopt the method for direct current sputtering to prepare the first film layer 20, as figure 2 As shown, the material is an aluminum neodymium alloy with a thickness of 300nm, and then the prepared first thin film layer 20 is patterned by wet etching to obtain the first patterned thin film layer 21, the first patterned thin film layer 21 have a gate shape such as image 3 shown.

[0071] b. adopt the method for direct current sputtering to prepare the second film layer 30, such as Figure 4 As shown, the material is a tin-zinc alloy with a thickness of 30nm. Then the prepared second thin film layer 30 is patterned by wet etching to obtain a second patterned thin film layer 31, and the second patterned thin film layer 31 has an active layer shape, such as F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com