Solar control film and double layer composite solar control film

A technology of sunlight control and double-layer composite, applied in the field of double-layer composite sunlight control film, can solve the problems of easy fading and short service life of dyed film, and achieve the advantages of reducing frequency and time, saving environmental protection, and reducing the intensity of reflected light. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

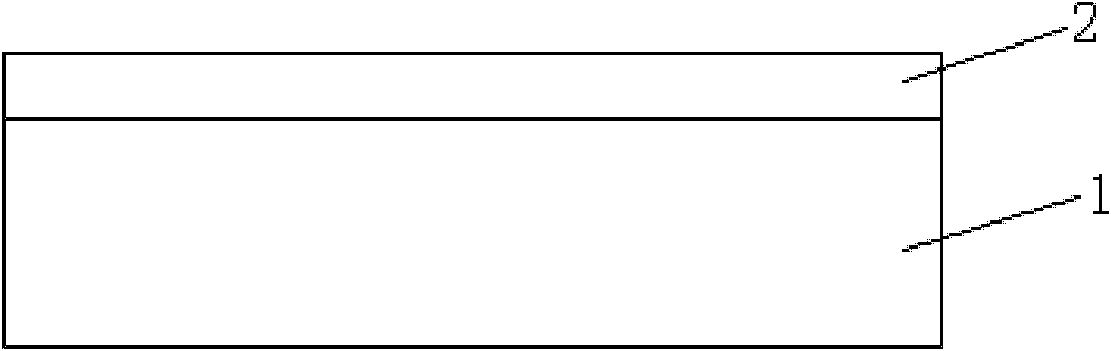

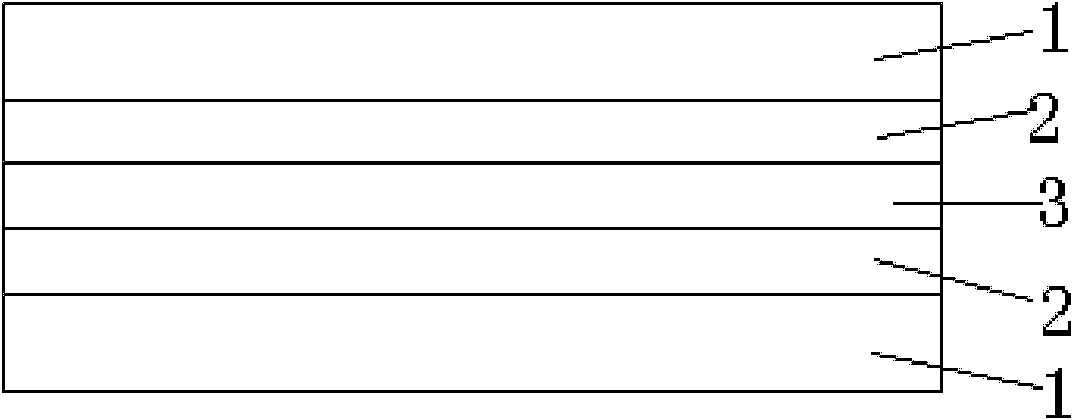

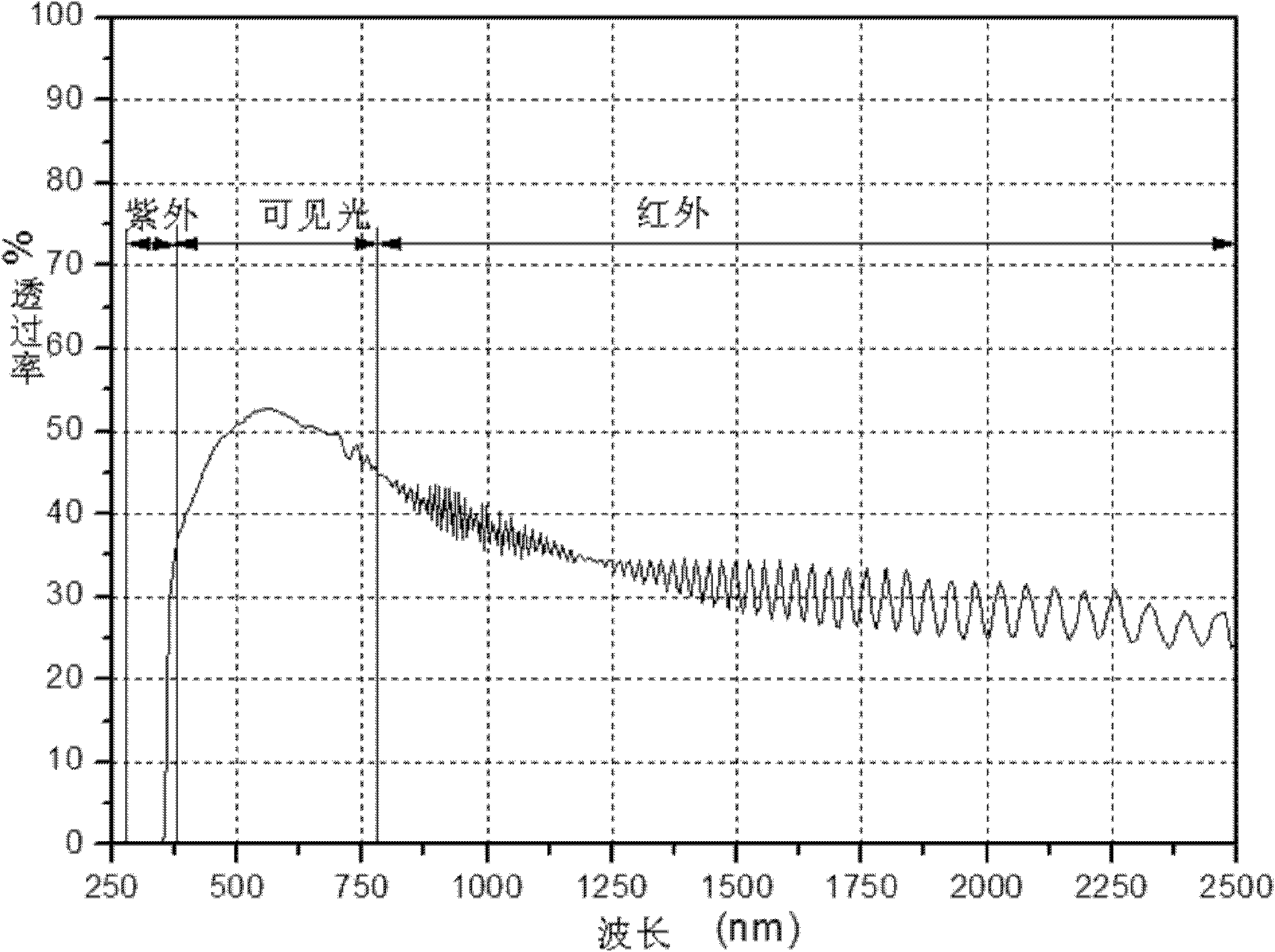

[0019] The solar control thin film of the invention is a titanium nitride film plated on a base material PET by adopting an intermediate frequency reaction magnetron sputtering twin target method magnetron sputtering. The thickness of the substrate PET is 23 μm-50 μm. The thickness of the titanium nitride film is 5nm-30nm. The base material PET is polyethylene terephthalate, English name: polyethylene terephthalate. The solar light transmittance of the substrate PET is ≥86%, and the heat-resistant temperature is >150°C.

[0020] The preferred thickness of the present invention is: the thickness of substrate PET is 23 μ m, the thickness of titanium nitride film is 5 nm;

[0021] The thickness of the substrate PET is 36 μm, and the thickness of the titanium nitride film is 20 nm;

[0022] The thickness of the substrate PET is 50 μm, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Heat resistance temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com