Titanium metal plate painting and manufacturing technology thereof

A manufacturing process and metal plate technology, applied in manufacturing tools, metal processing equipment, decorative arts, etc., can solve the problems of monotonous color, insufficient expressiveness, and long manufacturing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

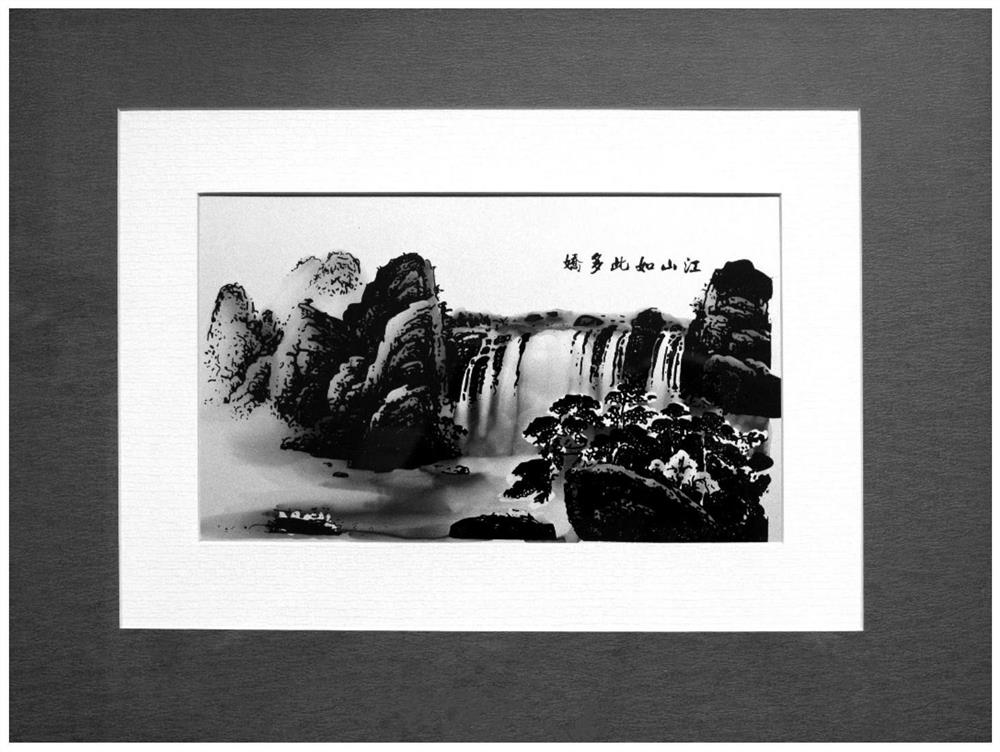

Image

Examples

Embodiment 1

[0019] A titanium metal plate painting manufacturing process, the specific steps:

[0020] 1. Prepare a titanium plate or strip with a thickness of 0.8-1.0mm and no pit defects on the surface;

[0021] 2. Cut the titanium plate or strip into a 300*200mm plate on the shearing machine;

[0022] 3. Mechanically polish the surface of the cut titanium plate first, use nylon fiber polishing wheels with hardness and mesh number of 5P 180 # / 320#, 9P 320# / 400#, 12P 400# / 600#, and use them in turn. The surface polishing machine polishes the surface of the titanium plate, and polishes the four corners of the titanium plate to smooth, the finish reaches 7-8 grade, after Ra=0.8~1.6μm, use water and hydrogen with a volume percentage of 100:1:0.2 Fluoric acid and nitric acid mixed solution, the concentration is 50-100g / L, clean the surface of the titanium plate, the temperature is 15-25 ℃, the pickling time is 10-20min, rinse with clean water and air-dry for later use.

[0023] 4. Make the...

Embodiment 2

[0031] A titanium metal plate painting manufacturing process, the specific steps:

[0032] 1. Prepare a titanium plate or strip with a thickness of 0.8-1.0mm and no pits or defects on the surface;

[0033] 2. Cut the titanium plate or strip into a 1400*400mm plate on the shearing machine;

[0034] 3. Mechanically polish the surface of the cut titanium plate first, use nylon fiber polishing wheels with hardness and mesh number of 5P 180 # / 320#, 9P 320# / 400#, 12P 400# / 600#, and use The plane polishing machine polishes the surface of the titanium plate, and polishes the four corners of the titanium plate smoothly, and the finish reaches 7-8 grades. After Ra=0.8-1.6 μm, water and hydrogen with a volume percentage of 100:1:0.2 are used. Fluoric acid and nitric acid mixed solution, the concentration is 50-100g / L, clean the surface of the titanium plate, the temperature is 15-25 ℃, the pickling time is 10-20min, rinse with clean water and air-dry for later use.

[0035] 4. Make the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com