Method for producing filming decorative glass using vacuum filming machine

A technology for decorative glass and vacuum coating, applied in the field of coating decorative glass by vacuum coating machine, can solve the problem of inability to produce metallized film, etc., achieve excellent durability and stability, the film layer is hard and firm, and the effect of purifying the air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

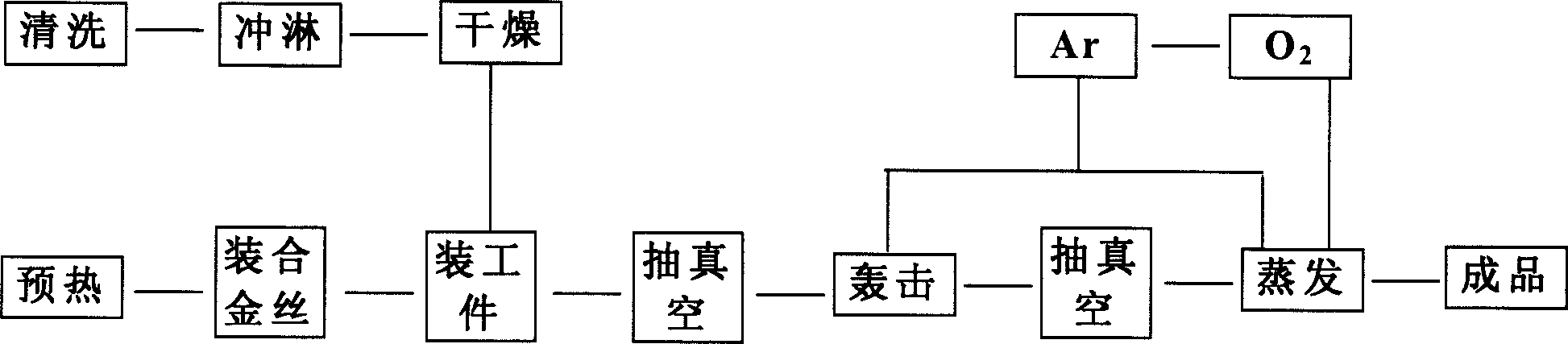

[0023] Example: such as figure 1 As shown, a method for making coated decorative glass with a vacuum coating machine, the manufacturing process steps are as follows:

[0024] (1) Cleaning of workpiece material, loading alloy wire and workpiece:

[0025] Since the combination of the film and the surface of the workpiece mainly depends on the van der Waald force (dispersion force), the cleanliness of the workpiece surface is crucial to the adhesion of the film layer. Any stains (such as finger marks) with a thickness greater than 0.6 nanometers, etc. Will seriously affect the adhesion of the film layer. Therefore, the surface of the workpiece must be strictly cleaned before coating. If the workpiece is fresh glass, it can be scrubbed only with tap water and a nylon brush, and then rinsed with pure water after blowing off the tap water with a fan. Then follow the cold wind and hot wind to blow off and dry. The above process can be handled by a special washing machine.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com