Self-assemblable container for generic use and manufacturing method thereof

一种自组装、容器的技术,应用在容器制造机械、刚性/半刚性容器的制造、容器等方向,能够解决降低垂直压缩的能力、结构变弱、负载不稳定等问题,达到大扭矩强度、大抗力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0113] The above-mentioned problems are at least partially solved by the self-assembled universal container of the invention, preferably exclusively made of ecologically renewable biodegradable materials, as described in this application document.

[0114] Since the structural elements of the container are obtained by laser cutting methods, the peripheral surfaces of the elements are perfectly sealed and cauterized, thus avoiding the penetration of moisture through the rim into the interior of the container.

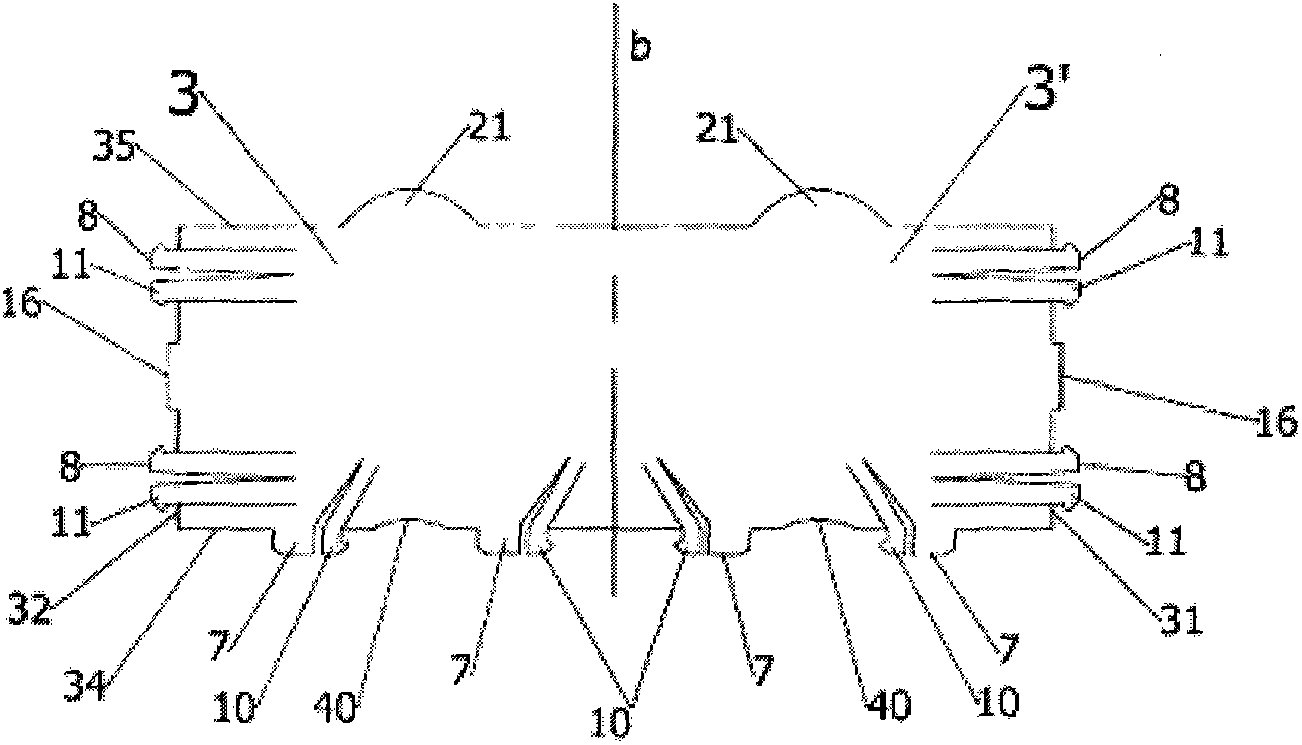

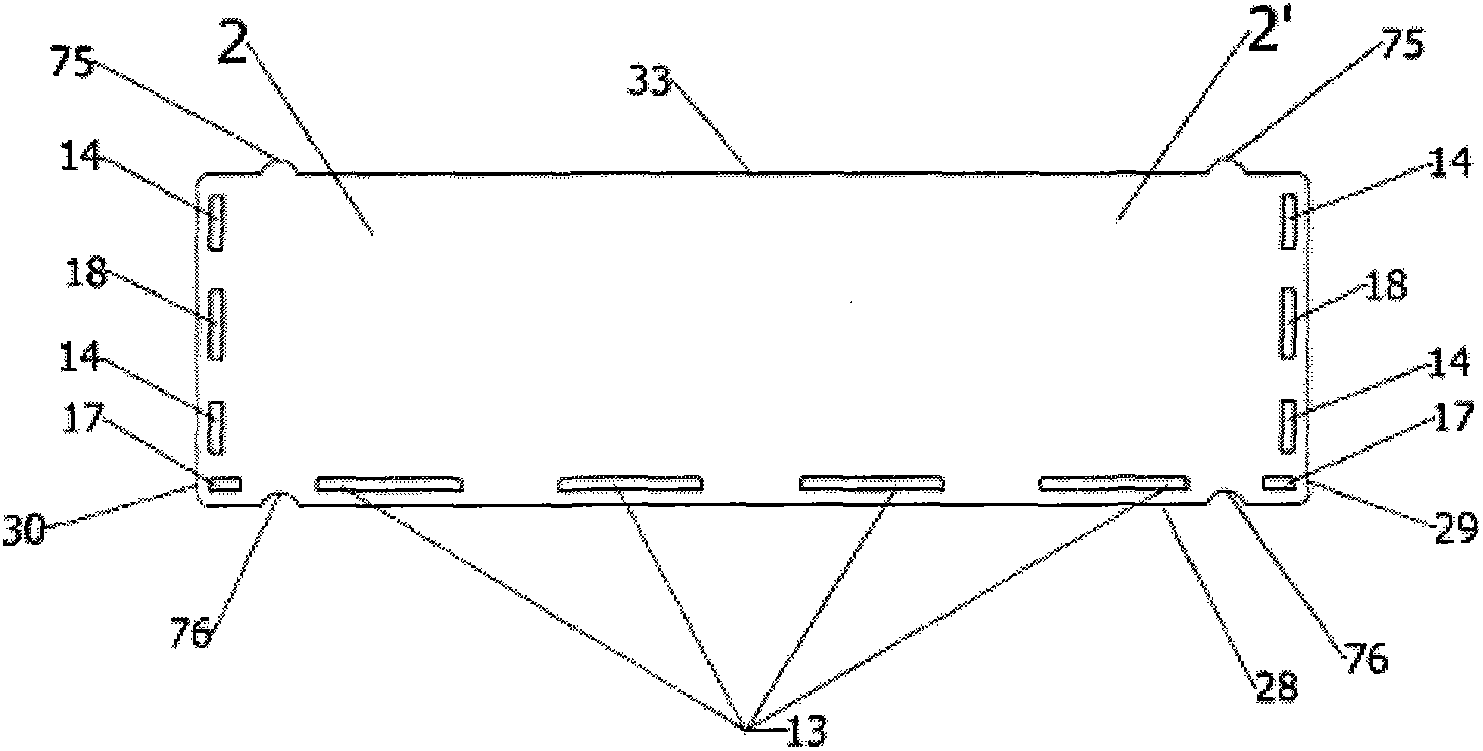

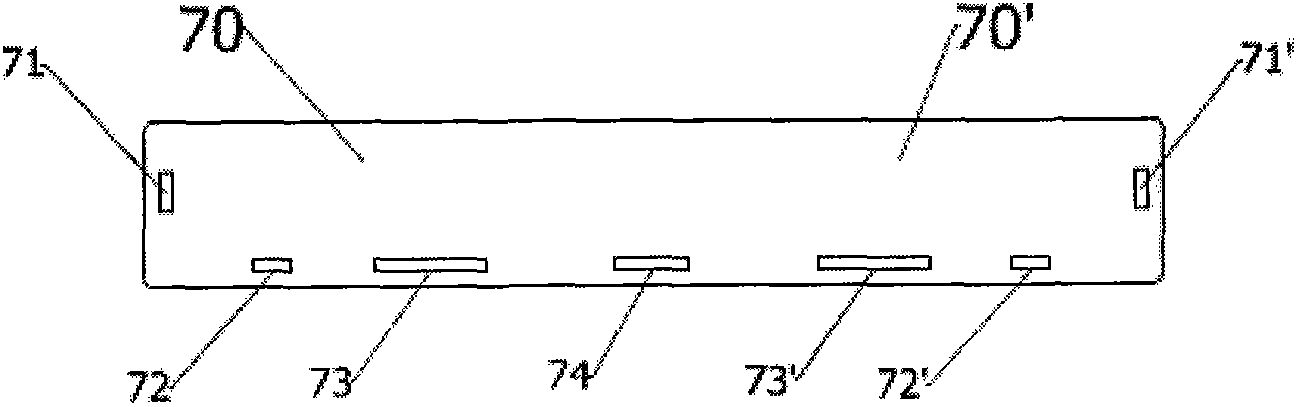

[0115] Such as Figures 1.4 to 1.6 As shown, the main independent structural elements used to construct the vessel are the bottom panel (1), two long or longitudinal side panels (2) (2') and two short or transverse side panels (3) (3' ), as will be mentioned below, in some preferred embodiments, a possible cover plate (4), a possible lateral anti-collapse support (5a) (5b) with a geometric shape, and / or two Transverse slats (70)(70'), already mentioned above, the instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com