High abrasion-proof and anti static antibacterial coating

An antibacterial coating and antistatic technology, applied in conductive coatings, antifouling/underwater coatings, coatings, etc., can solve problems such as four-legged ZnO whiskers that are not involved, and achieve excellent anti-corrosion properties and mechanical properties, preparation technology Unique, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

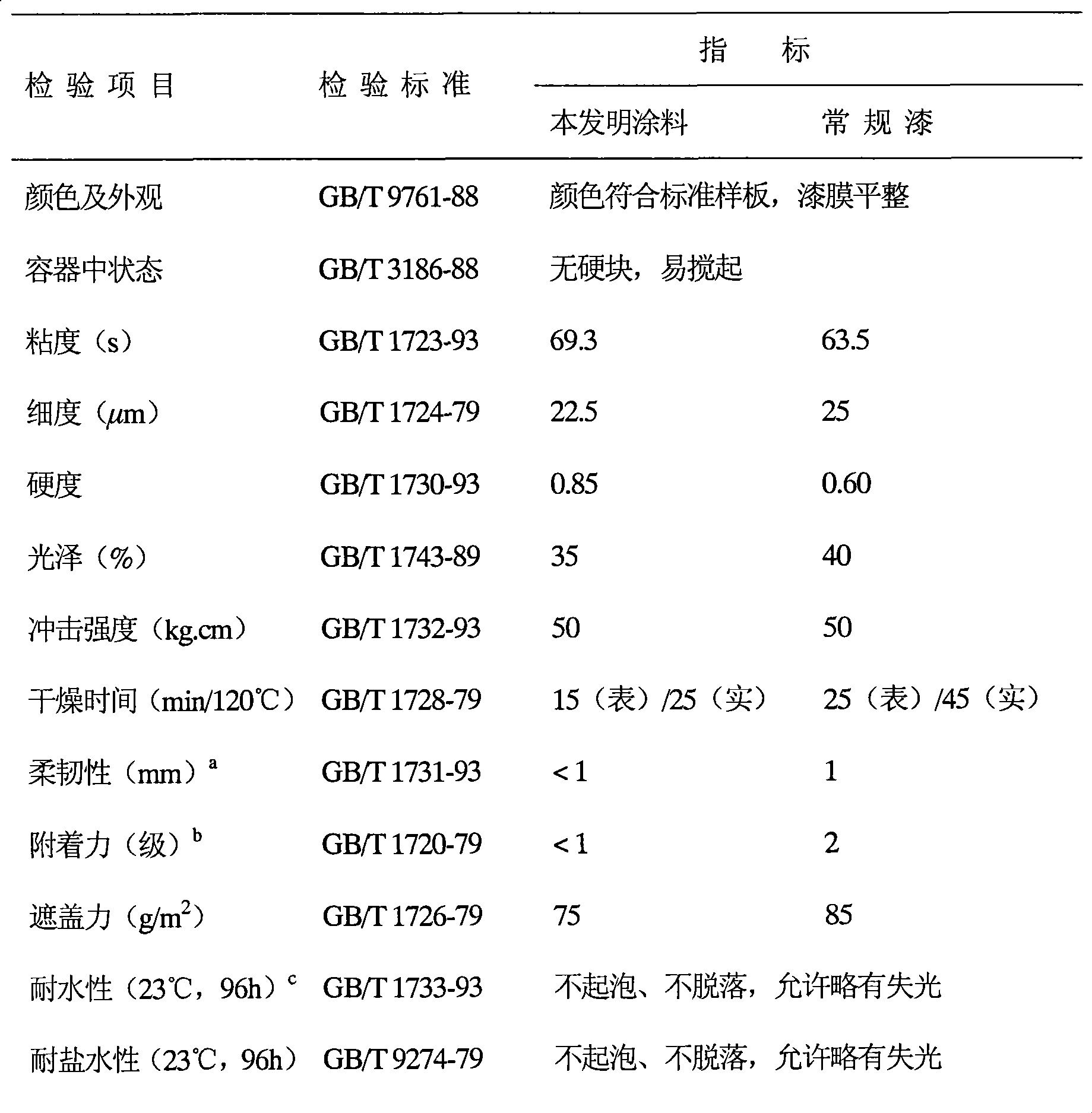

Embodiment 1

[0027] A T-ZnO whisker quick-drying modified alkyd resin enamel was prepared. Pour 5‰ (weight fraction) of T-ZnO whiskers prepared by chemical method into 2 times the weight of petroleum ether, stir for 5 minutes, disperse in an ultrasonic instrument for 10 minutes, and distill the petroleum ether in a distillation bottle. After dissolving 1% silane coupling agent KH-550 of the weight of T-ZnO whiskers with petroleum ether that is 1 times the volume of T-ZnO whiskers, pour the dispersed T-ZnO whiskers into it after simple stirring, and then ultrasonically Coupling treatment in the instrument for 10 minutes to obtain T-ZnO whisker paste. According to the dosage ratio of the modified alkyd resin paint formula, 60 parts of modified alkyd resin (base material), T-ZnO whisker paste, pre-mixed, ground, filtered coloring and body pigment (21 parts) , additives (6 parts) and solvent No. 200 mineral spirits (12 parts) are mixed together in a mixing tank, and then ground by a three-rol...

Embodiment 2

[0038] A T-ZnO whisker iron red alkyd primer was prepared. Pour 5% (weight fraction) of T-ZnO whiskers prepared by chemical method into ethanol whose weight is twice the amount, stir for 5 minutes, disperse in an ultrasonic instrument for 10 minutes, and distill the ethanol out in a distillation bottle. After dissolving 1% titanate 402# coupling agent of the T-ZnO whisker weight with acetone that is 1 times the volume of the T-ZnO whisker, pour the dispersed T-ZnO whisker into it and stir briefly, and then ultrasonically Coupling treatment in the instrument for 10 minutes to obtain T-ZnO whisker paste. According to the dosage ratio of the modified alkyd resin paint formula, 40 parts of modified alkyd resin (base material), T-ZnO whisker paste, pre-mixed, ground, filtered iron red pigment (20 parts) and The extender pigment (21 parts), the additive (6 parts) and the solvent (12 parts) are mixed together in a mixing tank, and then ground by a three-roll mill until the fineness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com